Sign up for the newsletter

Digital editions.

Total quality management: three case studies from around the world

With organisations to run and big orders to fill, it’s easy to see how some ceos inadvertently sacrifice quality for quantity. by integrating a system of total quality management it’s possible to have both.

Top 5 ways to manage the board during turbulent times Top 5 ways to create a family-friendly work culture Top 5 tips for a successful joint venture Top 5 ways managers can support ethnic minority workers Top 5 ways to encourage gender diversity in the workplace Top 5 ways CEOs can create an ethical company culture Top 5 tips for going into business with your spouse Top 5 ways to promote a healthy workforce Top 5 ways to survive a recession Top 5 tips for avoiding the ‘conference vortex’ Top 5 ways to maximise new parents’ work-life balance with technology Top 5 ways to build psychological safety in the workplace Top 5 ways to prepare your workforce for the AI revolution Top 5 ways to tackle innovation stress in the workplace Top 5 tips for recruiting Millennials

There are few boardrooms in the world whose inhabitants don’t salivate at the thought of engaging in a little aggressive expansion. After all, there’s little room in a contemporary, fast-paced business environment for any firm whose leaders don’t subscribe to ambitions of bigger factories, healthier accounts and stronger turnarounds. Yet too often such tales of excess go hand-in-hand with complaints of a severe drop in quality.

Food and entertainment markets are riddled with cautionary tales, but service sectors such as health and education aren’t immune to the disappointing by-products of unsustainable growth either. As always, the first steps in avoiding a catastrophic forsaking of quality begins with good management.

There are plenty of methods and models geared at managing the quality of a particular company’s goods or services. Yet very few of those models take into consideration the widely held belief that any company is only as strong as its weakest link. With that in mind, management consultant William Deming developed an entirely new set of methods with which to address quality.

Deming, whose managerial work revolutionised the titanic Japanese manufacturing industry, perceived quality management to be more of a philosophy than anything else. Top-to-bottom improvement, he reckoned, required uninterrupted participation of all key employees and stakeholders. Thus, the total quality management (TQM) approach was born.

All in Similar to the Six Sigma improvement process, TQM ensures long-term success by enforcing all-encompassing internal guidelines and process standards to reduce errors. By way of serious, in-depth auditing – as well as some well-orchestrated soul-searching – TQM ensures firms meet stakeholder needs and expectations efficiently and effectively, without forsaking ethical values.

By opting to reframe the way employees think about the company’s goals and processes, TQM allows CEOs to make sure certain things are done right from day one. According to Teresa Whitacre, of international consulting firm ASQ , proper quality management also boosts a company’s profitability.

“Total quality management allows the company to look at their management system as a whole entity — not just an output of the quality department,” she says. “Total quality means the organisation looks at all inputs, human resources, engineering, production, service, distribution, sales, finance, all functions, and their impact on the quality of all products or services of the organisation. TQM can improve a company’s processes and bottom line.”

Embracing the entire process sees companies strive to improve in several core areas, including: customer focus, total employee involvement, process-centred thinking, systematic approaches, good communication and leadership and integrated systems. Yet Whitacre is quick to point out that companies stand to gain very little from TQM unless they’re willing to go all-in.

“Companies need to consider the inputs of each department and determine which inputs relate to its governance system. Then, the company needs to look at the same inputs and determine if those inputs are yielding the desired results,” she says. “For example, ISO 9001 requires management reviews occur at least annually. Aside from minimum standard requirements, the company is free to review what they feel is best for them. While implementing TQM, they can add to their management review the most critical metrics for their business, such as customer complaints, returns, cost of products, and more.”

The customer knows best: AtlantiCare TQM isn’t an easy management strategy to introduce into a business; in fact, many attempts tend to fall flat. More often than not, it’s because firms maintain natural barriers to full involvement. Middle managers, for example, tend to complain their authority is being challenged when boots on the ground are encouraged to speak up in the early stages of TQM. Yet in a culture of constant quality enhancement, the views of any given workforce are invaluable.

AtlantiCare in numbers

5,000 Employees

$280m Profits before quality improvement strategy was implemented

$650m Profits after quality improvement strategy

One firm that’s proven the merit of TQM is New Jersey-based healthcare provider AtlantiCare . Managing 5,000 employees at 25 locations, AtlantiCare is a serious business that’s boasted a respectable turnaround for nearly two decades. Yet in order to increase that margin further still, managers wanted to implement improvements across the board. Because patient satisfaction is the single-most important aspect of the healthcare industry, engaging in a renewed campaign of TQM proved a natural fit. The firm chose to adopt a ‘plan-do-check-act’ cycle, revealing gaps in staff communication – which subsequently meant longer patient waiting times and more complaints. To tackle this, managers explored a sideways method of internal communications. Instead of information trickling down from top-to-bottom, all of the company’s employees were given freedom to provide vital feedback at each and every level.

AtlantiCare decided to ensure all new employees understood this quality culture from the onset. At orientation, staff now receive a crash course in the company’s performance excellence framework – a management system that organises the firm’s processes into five key areas: quality, customer service, people and workplace, growth and financial performance. As employees rise through the ranks, this emphasis on improvement follows, so managers can operate within the company’s tight-loose-tight process management style.

After creating benchmark goals for employees to achieve at all levels – including better engagement at the point of delivery, increasing clinical communication and identifying and prioritising service opportunities – AtlantiCare was able to thrive. The number of repeat customers at the firm tripled, and its market share hit a six-year high. Profits unsurprisingly followed. The firm’s revenues shot up from $280m to $650m after implementing the quality improvement strategies, and the number of patients being serviced dwarfed state numbers.

Hitting the right notes: Santa Cruz Guitar Co For companies further removed from the long-term satisfaction of customers, it’s easier to let quality control slide. Yet there are plenty of ways in which growing manufacturers can pursue both quality and sales volumes simultaneously. Artisan instrument makers the Santa Cruz Guitar Co (SCGC) prove a salient example. Although the California-based company is still a small-scale manufacturing operation, SCGC has grown in recent years from a basement operation to a serious business.

SCGC in numbers

14 Craftsmen employed by SCGC

800 Custom guitars produced each year

Owner Dan Roberts now employs 14 expert craftsmen, who create over 800 custom guitars each year. In order to ensure the continued quality of his instruments, Roberts has created an environment that improves with each sale. To keep things efficient (as TQM must), the shop floor is divided into six workstations in which guitars are partially assembled and then moved to the next station. Each bench is manned by a senior craftsman, and no guitar leaves that builder’s station until he is 100 percent happy with its quality. This product quality is akin to a traditional assembly line; however, unlike a traditional, top-to-bottom factory, Roberts is intimately involved in all phases of instrument construction.

Utilising this doting method of quality management, it’s difficult to see how customers wouldn’t be satisfied with the artists’ work. Yet even if there were issues, Roberts and other senior management also spend much of their days personally answering web queries about the instruments. According to the managers, customers tend to be pleasantly surprised to find the company’s senior leaders are the ones answering their technical questions and concerns. While Roberts has no intentions of taking his manufacturing company to industrial heights, the quality of his instruments and high levels of customer satisfaction speak for themselves; the company currently boasts one lengthy backlog of orders.

A quality education: Ramaiah Institute of Management Studies Although it may appear easier to find success with TQM at a boutique-sized endeavour, the philosophy’s principles hold true in virtually every sector. Educational institutions, for example, have utilised quality management in much the same way – albeit to tackle decidedly different problems.

The global financial crisis hit higher education harder than many might have expected, and nowhere have the odds stacked higher than in India. The nation plays home to one of the world’s fastest-growing markets for business education. Yet over recent years, the relevance of business education in India has come into question. A report by one recruiter recently asserted just one in four Indian MBAs were adequately prepared for the business world.

RIMS in numbers

9% Increase in test scores post total quality management strategy

22% Increase in number of recruiters hiring from the school

20,000 Increase in the salary offered to graduates

50,000 Rise in placement revenue

At the Ramaiah Institute of Management Studies (RIMS) in Bangalore, recruiters and accreditation bodies specifically called into question the quality of students’ educations. Although the relatively small school has always struggled to compete with India’s renowned Xavier Labour Research Institute, the faculty finally began to notice clear hindrances in the success of graduates. The RIMS board decided it was time for a serious reassessment of quality management.

The school nominated Chief Academic Advisor Dr Krishnamurthy to head a volunteer team that would audit, analyse and implement process changes that would improve quality throughout (all in a particularly academic fashion). The team was tasked with looking at three key dimensions: assurance of learning, research and productivity, and quality of placements. Each member underwent extensive training to learn about action plans, quality auditing skills and continuous improvement tools – such as the ‘plan-do-study-act’ cycle.

Once faculty members were trained, the team’s first task was to identify the school’s key stakeholders, processes and their importance at the institute. Unsurprisingly, the most vital processes were identified as student intake, research, knowledge dissemination, outcomes evaluation and recruiter acceptance. From there, Krishnamurthy’s team used a fishbone diagram to help identify potential root causes of the issues plaguing these vital processes. To illustrate just how bad things were at the school, the team selected control groups and administered domain-based knowledge tests.

The deficits were disappointing. A RIMS students’ knowledge base was rated at just 36 percent, while students at Harvard rated 95 percent. Likewise, students’ critical thinking abilities rated nine percent, versus 93 percent at MIT. Worse yet, the mean salaries of graduating students averaged $36,000, versus $150,000 for students from Kellogg. Krishnamurthy’s team had their work cut out.

To tackle these issues, Krishnamurthy created an employability team, developed strategic architecture and designed pilot studies to improve the school’s curriculum and make it more competitive. In order to do so, he needed absolutely every employee and student on board – and there was some resistance at the onset. Yet the educator asserted it didn’t actually take long to convince the school’s stakeholders the changes were extremely beneficial.

“Once students started seeing the results, buy-in became complete and unconditional,” he says. Acceptance was also achieved by maintaining clearer levels of communication with stakeholders. The school actually started to provide shareholders with detailed plans and projections. Then, it proceeded with a variety of new methods, such as incorporating case studies into the curriculum, which increased general test scores by almost 10 percent. Administrators also introduced a mandate saying students must be certified in English by the British Council – increasing scores from 42 percent to 51 percent.

By improving those test scores, the perceived quality of RIMS skyrocketed. The number of top 100 businesses recruiting from the school shot up by 22 percent, while the average salary offers graduates were receiving increased by $20,000. Placement revenue rose by an impressive $50,000, and RIMS has since skyrocketed up domestic and international education tables.

No matter the business, total quality management can and will work. Yet this philosophical take on quality control will only impact firms that are in it for the long haul. Every employee must be in tune with the company’s ideologies and desires to improve, and customer satisfaction must reign supreme.

Contributors

- Industry Outlook

Implementation of Total Quality Management (TQM): Toyota Case Study

Introduction, implementation of tqm in toyota, tqm practices in toyota, benefits of tqm in toyota, examples of tqm in toyota, toyota quality management, toyota tqm implementation challenges.

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business.

It requires that quality management standards be applied in all branches and at all levels of the organization. The characteristic of Toyota Corporation going through the total quality process is unambiguous and clear.

Toyota has limited interdepartmental barriers, excellent customer and supplier relations, spares time to be spent on training, and the recognition that quality is realized through offering excellent products as well as the quality of the entire firm, including personnel, finance, sales, and other functions.

The top management at Toyota Corporation has the responsibility for quality rather than the employees, and it is their role to provide commitment, support, and leadership to the human and technical processes (Kanji & Asher, 1996).

Whereas the TQM initiative is to succeed, the management has to foster the participation of Toyota Corporation workers in quality improvement and create a quality culture by altering attitudes and perceptions towards quality.

This research report assesses the implementation of TQM and how Toyota manages quality in all organization management systems while focusing on manufacturing quality. The report evaluates the organization management elements required when implementing TQM, identifies, and investigates the challenges facing Quality Managers or Executives in implementing Quality Management Systems.

In order to implement TQM, Toyota corporations focused on the following phases:

- The company extended the management responsibility past the instantaneous services and products

- Toyota examined how consumers applied the products generated, and this enabled the company to develop and improve its commodities

- Toyota focused on the insubstantial impacts on the procedures as well as how such effects could be minimized through optimization

- Toyota focused on the kaizen (incessant process development) in order to ensure that all procedures are measurable, repeatable, and visible.

The commitment from business executives is one of the key TQM implementation principles that make an organization successful. In fact, the organizational commitment present in the senior organizational staff ranges from top to lower administration. These occur through self-driven motives, motivation, and employee empowerment. Total Quality Management becomes achievable at Toyota by setting up the mission and vision statements, objectives, and organizational goals.

In addition, the TQM is achievable via the course of active participation in organizational follow-up actions. These actions denote the entire activities needed and involved during the implementation of the set-out ideologies of the organization. From Toyota Corporation’s report, TQM has been successful through the commitment of executive management and the organizational workforce (Toyota Motor Corporation, 2012).

Through inventory and half the bottlenecks at half cost and time, the adopters of TMS (Toyota Management System) are authorized to manufacture twice above the normal production. To manage the quality in all organizational management systems, the Toyota Production System incorporates different modernisms like strategy or Hoshin Kanri use, overall value supervision, and just-in-time assembly.

The amalgamation of these innovations enables Toyota to have a strong competitive advantage despite the fact that Toyota never originated from all of them. The 1914 Henry Ford invention relied on the just-in-time production model. The Ford system of production, from a grand perspective, warrants massive production, thus quality (Toyota Motor Corporation, 2012).

Kanji and Asher (1996) claim that to manage the minute set of production necessitated by the splintered and small post-war marketplaces, the JIT system focuses on the motion and elimination of waste materials. This reduces crave for work-in-process inventory by wrapping up the long production lines. Toyota Corp wraps the production lines into slashed change-over times, a multi-trained workforce that runs manifold machines, and new-fangled cells into a U shape.

When supplementing the just-in-cells, the system of kanban is employed by the Toyota Corporation to connect the cells that are unable to integrate physically. Equally, the system helps Toyota integrate with other external companies, consumers, and suppliers.

The TQM and the creativity of Toyota proprietors both support the quality at the source. The rectification and discovery of the production problems require the executives to be committed. At the forefront of Toyota operations, the managers integrate a number of forms of operational quality checks to ensure quality management at all levels.

The uninterrupted tests help the Toyota workforce engaging in the assembly course to scrutinize the value of apparatus, implements, and resources utilized in fabrication. The checks help in the scrutiny of the previously performed tasks by other workers. However, the corporation’s own test enables the workers to revise their personal advances in the assembly course.

The Toyota process owners set up the mistake-proofing (Poka-yoke) procedures and devices to capture the awareness of management and involuntarily correct and surface the augmenting problems. This is essential for the critical production circumstances and steps that prove impractical and tricky for Toyota employees to inspect.

Nevertheless, the policy deployment system decentralizes the process of decision-making at Toyota. This context of implementing Total Quality Management originates from Hoshin Kanri’s management by objective (MBO).

This aspect becomes more advantageous to Toyota when dealing with quality management. The system initially puts into practice the coordinated approach and provides a clear structure for the suppliers, producers, and consumers through inter-organizational cost administration. Moreover, Toyota executives can solve the concurrent delivery, cost, and quality bottlenecks, thus replacing and increasing the relatively slow accounting management mechanisms.

Customer focus that leads to the desired customer satisfaction at Toyota Company is one of the major success factors in TQM implementation. For every business to grow, it should have understanding, reliable, and trustworthy customers. The principle of customer satisfaction and focus has been the most presently well-thought-out aspect of Toyota’s manufacturing quality.

The TQM may characteristically involve total business focus towards meeting and exceeding customers’ expectations and requirements by considering their personal interests. The mission of improving and achieving customer satisfaction ought to stream from customer focus.

Thus, when focusing on manufacturing quality, this aspect enhances TQM implementation. The first priorities at Toyota are community satisfaction, employees, owners, consumers, and mission. The diverse consumer-related features from liberty. The concern to care is eminent in Toyota Corporation during manufacturing.

Toyota has three basic perspectives of TQM that are customer-oriented. These are based on its manufacturing process traced back to the 1950s. The strategies towards achieving quality manufacturing, planning, and having a culture towards quality accomplishment are paramount for TQM implementation to remain successful. To enhance and maintain quality through strategic planning schemes, all managers and employers must remain effectively driven.

This involves training workers on principles concerning quality culture and achievement. Scheduling and planning are analytical applications at Toyota Company that purposes in assessing customer demand, material availability, and plant capacity during manufacturing.

The Toyota Corporation has considerable approaches that rank it among the successful and renowned implementers of TQM. From the inherent and designed structure of Toyota, it becomes feasible to comprehend why quality manufacturing is gradually becoming effective. The inspection department is responsible for taking corrective measures, salvaging, and sorting the desired manufactured product or service quality.

The Toyota Corporation also has a quality control system that is involved in determining quality policies, reviewing statistics, and establishing quality manuals or presentation data. Furthermore, quality assurance is one of the integral principles in quality implementation that is practically present at Toyota. The quality assurance and quality inspectors throughout the Toyota Company structure also manage research and development concerning the quality of manufactured products and services.

The Toyota production and operations management system is similarly dubbed as the managerial system. In fact, in this corporation, operational management is also referred to as the production process, production management, or operations (Chary, 2009). These simply incorporate the actual production and delivery of products.

The managerial system involves product design and the associated product process, planning and implementing production, as well as acquiring and organizing resources. With this broad scope, the production and operation managers have a fundamental role to play in the company’s ability to reach the TQM implementation goals and objectives.

The Toyota Corporation operations managers are required to be conversant and familiar with the TQM implementation concepts and issues that surround this functional area. Toyota’s operation management system is focused on fulfilling the requirements of the customers.

The corporation realizes this by offering loyal and express commodities at logical fees and assisting dealers in progressing commodities proffered. As Slack et al. (2009) observed, the basic performance objectives, which pertain to all the Toyota’s operations, include quality, speed, flexibility, dependability, and cost. Toyota Company has been successful in meeting these objectives through its production and operation functions.

Over several decades, Toyota’s operational processes and management systems were streamlined, resulting in the popularly known Toyota Production System. Although the system had been extensively researched, many companies, such as Nissan, experienced difficulties in replicating TPS.

The TPS was conceived when the company realized that producing massive quantities from limited product lines and ensuring large components to achieve maximum economies of scale led to flaws. Its major objectives were to reduce cost, eliminate waste, and respond to the changing needs of the customers. The initial feature of this system was set-up time reduction, and this forms the basis of TQM implementation.

At Toyota Corporation, quality is considered as acting responsibly through the provision of blunder-gratis products that please the target clientele. Toyota vehicles are among the leading brands in customer satisfaction. Due to good quality, its success has kept growing, and in 2012, the company was the best worldwide. Moreover, Toyota has been keen on producing quality vehicles via the utilization of various technologies that improve the performance of the vehicles.

While implementing TQM, Toyota perceives speed as a key element. In this case, speed objective means doing things fast in order to reduce the time spent between ordering and availing the product to the customer.

The TPS method during processing concentrates on reducing intricacy via the use of minute and uncomplicated machinery that is elastic and full-bodied. The company’s human resources and managers are fond of reorganizing streams and designs to promote minimalism. This enhances the speed of production.

Another objective during TQM implementation is dependability. This means timely working to ensure that customers get their products within the promised time. Toyota has included a just-in-time production system comprised of multi-skilled employees who work in teams. The kanban control allows the workers to deliver goods and services as promised. Advancing value and effectiveness appears to be the distress for administrators, mechanical specialists, and other Toyota human resources.

During TQM implementation, Toyota responds to the demands by changing its products and the way of doing business. Chary (2009) argues that while implementing TQM, organizations must learn to like change and develop responsive and flexible organizations to deal with the changing business environment.

Within Toyota plants, this incorporates the ability to adopt the manufacturing resources to develop new models. The company is able to attain an elevated degree of suppleness, manufacturing fairly tiny bunches of products devoid of losses in excellence or output.

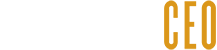

The organizational hierarchy and job descriptions also determine the successful implementation of the TQM. Toyota is amongst the few companies whose organizational structure and task allocation have proved viable in TQM implementation. The company has three levels of management. See the diagram below.

Management hierarchy

Despite the hierarchy and task specification, employees are able to make independent decisions and take corrective measures when necessary to ensure quality during production. Team working is highly encouraged at Toyota Corporation, and this plays a significant role during TQM implementation. All stakeholders are incorporated in quality control initiatives to ensure client demands are satisfied.

However, all employees are required to carry out their assigned tasks, and the management closely supervises the ways of interactions between workers. The management ensures that the manufacturing lines are well-built and all employees are motivated to learn how to improve the production processes.

Toyota is among the few manufacturers in the complete automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilized scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed Toyotaism, is a kind of job association emphasizing ‘lean-assembly.’ The technique merges just-in-time production, dilemma-answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients’ needs instantly, devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the company’s production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with a lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, financial and human resources have become the pillar stones.

The approach of TQM impels marketplace competence from all kinds of organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of an appropriate milieu for accomplishing organizational objectives.

In the case of Toyota, which originated and perfected the philosophy of TQM, the Executives, and Quality Managers met some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus creating reliability problems. Besides, secretive culture and dysfunctional organizational structure cause barriers in communication between the top management, thus, in turn, augmenting public outrage.

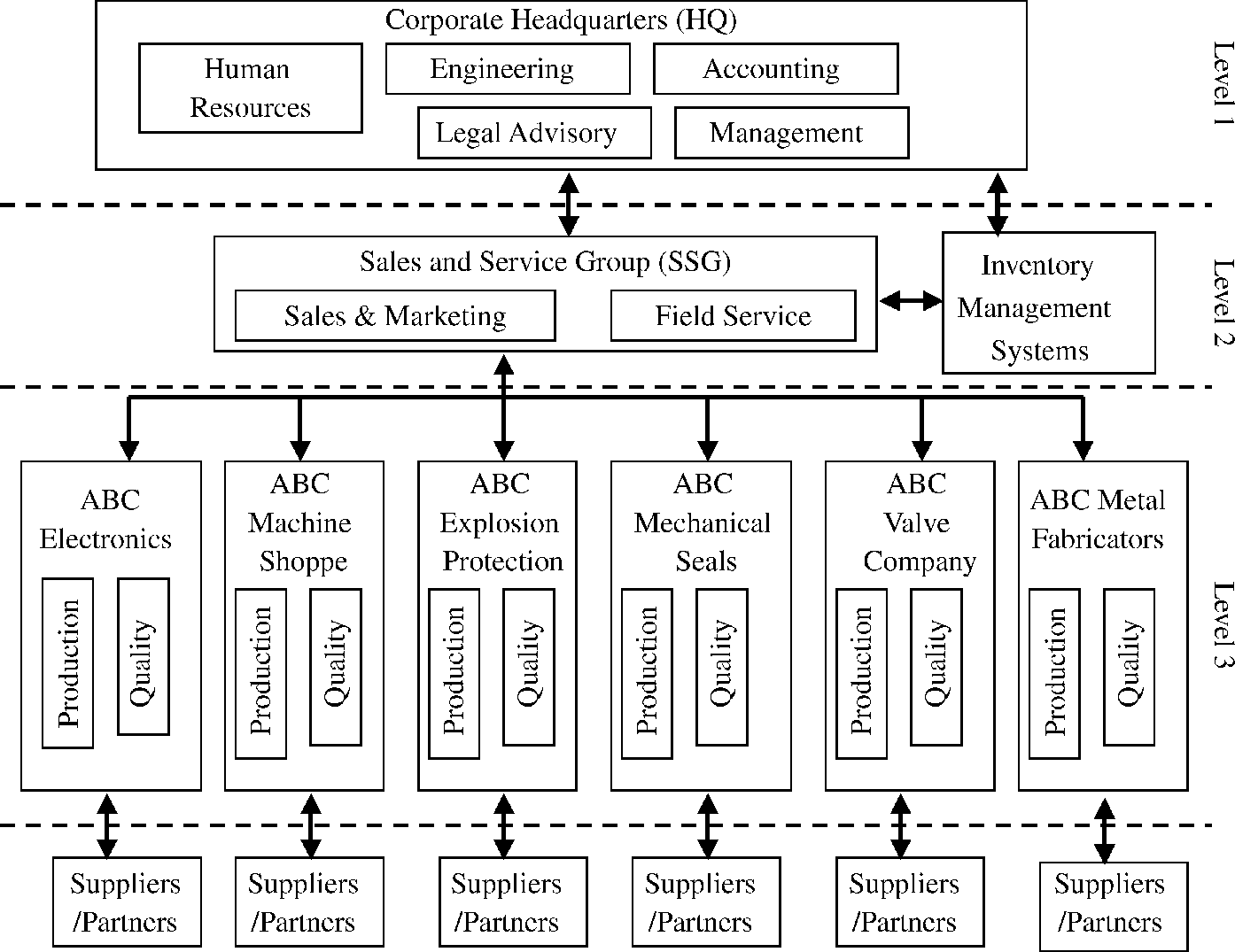

The top executives may fail to provide and scale up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, a lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible, as elaborated in Figure 2 below.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes, helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Chary, D. 2009, Production and operations management , Tata McGraw-Hill Education Press, Mumbai.

Huczynski, A. & Buchanan, D. 2007, Organizational behavior; an introductory text, Prentice Hall, New York, NY.

Kanji, G. K. & Asher, M. 1996, 100 methods for total quality management , SAGE Thousands Oak, CA.

Slack, N. et al. 2009, Operations and process management: principles and practice for strategic management, Prentice Hall, New York, NY.

Toyota Motor Corporation 2012, Annual report 2012. Web.

- First World Hotel: Just-in-Time Manufacturing Model

- Motorola Company's Just-in-Time Implementation

- Lean Manufacturing: Processes

- Barriers and Facilitators of Workplace Learning

- The Science of Behavior in Business

- Standards, models, and quality: Management

- Managerial and Professional Development: Crowe Horwath CPA limited

- Managerial and Professional Development: Deloitte & Touché Company

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, June 12). Implementation of Total Quality Management (TQM): Toyota Case Study. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/

"Implementation of Total Quality Management (TQM): Toyota Case Study." IvyPanda , 12 June 2019, ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda . (2019) 'Implementation of Total Quality Management (TQM): Toyota Case Study'. 12 June.

IvyPanda . 2019. "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

1. IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Bibliography

IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Risk Manag Healthc Policy

Total quality management in the health-care context: integrating the literature and directing future research

Majdi m alzoubi.

1 Department of Community Health, Faculty of Medicine and Health Sciences, University Putra Malaysia, UPM Serdang, Selangor Darul Ehsan, 43400, Malaysia

ZM Al-Hamdan

2 Department of Nursing Management, Faculty of Nursing, Jordan University of Science and Technology, Irbid, Jordan

Synergistic integration of predictors and elements that determine the success of total quality management (TQM) implementations in hospitals has been the bane of theoretical development in the TQM research area. Thus, this paper aims to offer a systematic literature review to provide a foundation on which research on TQM can be built and to identify the predictors of successful TQM in the health-care context.

Materials and methods

A systematic literature survey was adopted in this paper, involving the review of 25 relevant researched articles found in the databases Science Direct, EBSCO, MEDLINE, CINAHL and PubMed.

The systematic literature survey reveals five variables to be core predictors of TQM, signifying how important these variables are in the successful implementation of TQM in the health-care context. Also, it is revealed that the identified core predictors have positive effects on an improved health-care system. However, the systematic survey of the literature reveals a dearth of studies on TQM in the health-care context.

As TQM has become an important management approach for advancing effectiveness in the health-care sector, this kind of research is of value to researchers and managers. Stakeholders in the health sectors should introduce and implement TQM in hospitals and clinics. Nevertheless, this study has limitations, including that the databases and search engines adopted for the literature search are not exhaustive.

Introduction

Given the snowballing global economic competition and other external pressures, organizations have been compelled to pursue enduring quality and quality management which will, in turn, enhance their competitive advantage. Quality as a concept has metamorphosed over the years, and it involves objective quality bordering on the characteristics and quality of goods and services that meet implicit and explicit customer demands. It also includes subjective quality which denotes the capability to produce goods and services in the best, effective and efficient manner. 1

Looking at the health-care context, quality has always been aimed at since the time of Florence Nightingale. 2 Given that quality assurance is a requisite for economic survival, 3 and that it is an ethical, legal and social rights matter, 4 the health sector has been worried about it for more than a decade .2 Quality assurance is significant as it concerns customer satisfaction and the reduction of risks connected with health care to a minimum. 5 In the present time, health care has become a developing profession with an approach to care quality via the appraisal and regulation of structure, process and care result components. 6

Given the ever-increasing competitive and dynamic environment in which hospitals operate, and the need to augment hospitals’ performance and health-care quality, researchers 2 , 7 – 9 have conducted considerable research on enhancement of health-care quality. Moreover, given that nurse performance is crucial to the overall performance of the hospital and effective health-care system, there has been a research focus on nurse performance. 7 Nurses represent a large percentage of the health workers in any hospital. Nurses would play a significant role in the implementation of any intervention programs introduced by any hospital.

Moreover, research 8 – 11 has shown that the health-care system is facing a myriad of challenges which include high care cost, swiftly increasing dependence on technology, economic pressure on health organizations, reduction in health-care quality, 8 , 10 fulfillment of patients’ needs, 9 augmented numbers of patients who are suffering from multiple illnesses, increased demand for high-quality care, increased health-care costs and cost-containment pressures (Organization for Economic Cooperation and Development [OECD] 2007). 11 Some studies have indicated that an active way of surmounting health-care challenges is through an intervention program that will border on quality management (eg, total quality management [TQM]). 12

TQM is a system implemented by the management of an organization to achieve the satisfaction of customers/patients .13 The importance of TQM as a strategy to improve organizational performance has grown in this era of globalization. 14 Numerous research has revealed the role of TQM in the enrichment of system quality and enhancement of both employee and organizational performance. TQM is known for continuous quality improvement, quality management and total quality control. 10 TQM is held to be an innovative approach to the management of organizations. In the medical sector, TQM integrates quality orientation in all processes and procedures in health-care delivery .15 It is now being widely adopted in the medical sector of many countries. The research by Vituri and Évora 2 indicates that the literature on TQM in health sectors reveals that TQM has been fully adopted in some health institutions.

The implementation of TQM, upon which the success of TQM hinges, is intricate and complex; it depends on a good combination of certain predictors (ie, critical success factors [CSF]), and its benefits are difficult to accomplish .16 Different means of integrating predictors of TQM, although inconsistent, have emerged in the literature. 17 Some predictors have been considered crucial to TQM success, 18 and thus the exceptional predictors which can be adopted by organizations, irrespective of their industry, type, size or location. 19 These predictors are regarded as the determinants of firm performance via effective implementation of TQM.

Nevertheless, synergistic integration of predictors and elements, otherwise known as CSFs and which determine the success of TQM implementation, has been the bane of theoretical development in the TQM research area. Some of these predictors have been reported, by extant studies, 20 to have a positive impact on performance.

Likewise, substantive problems exist and can hamper theoretical development in the research area. The literature lacks foundation and structure on which the research on TQM in the health-care context is based, and connections between studies on TQM in the health-care context can hardly be drawn. The current state of extant research on TQM in the health-care context indicates that there is a need for more research in the area. 21 New knowledge development regarding identification of fitting predictors for successful TQM that enhance effectiveness in the health-care sector should be developed and where further research needs to be done should be identified.

Considering the extant works on a systematic literature review on predictors of TQM, two English written studies 14 , 22 are discernible, but Hietschold et al 14 focused on CSFs of TQM in general contexts while Aquilani et al 22 focused on the identification of TQM research, implementation of TQM research and impact-of-TQM-on-performance research in general contexts. Besides these two studies, no studies have focused on the systematic literature survey of predictors/elements of TQM in the health-care context.

Therefore, undertaking a systematic literature review in this aspect of research is germane, and this paper is poised to do as such. This paper conducts a systematic literature survey to provide a foundation stone on which research on TQM in the health-care context can be built, to evaluate the current state of evidence for TQM in the health-care context, to reveal inadequacies in the literature and to point to where further research needs to be done.

This research is guided by the following research question: what are the predictors of successful TQM in the health-care context between the period of 2005 and 2016? Like the two previous studies on a systematic literature review of TQM, this paper adopts and applies the three core steps of planning, execution and reporting that constitute a systematic literature survey. 23

This research seeks to obtain the most important predictors of successful TQM in the health-care context. This includes the review of published peer-reviewed works in English-language journals, which were published between 2005 and 2016. The literature was sourced from Science Direct, EBSCO, MEDLINE (Medical Literature Analysis and Retrieval System Online), CINAHL (Cumulative Index of Nursing and Allied Health Literature) and PubMed (US National Library of Medicine).

As part of the process of systematic literature analysis in this paper, a structured search of the academic literature was conducted to find published articles that identified TQM, total quality management, implementation, CSFs, health care and nursing. The keywords used in the search are TQM, total quality management, implementation, critical success factors, health care and nursing.

As presented in Figure 1 , a search of Science Direct, MEDLINE, EBSCO, CINAHL and PubMed yielded 2133, 6341, 1867, 7 and 474 articles, respectively. Then, repeated citations, dissertations and case studies were deleted. Via reading of the title and abstract, the remaining articles were narrowed down by relevance. Only peer-reviewed academic and practice articles that focus on total quality management, implementation, CSFs health care and nursing were selected. This exercise yielded a total of 475 articles which were published between 2005 and 2016.

Consort flow chart of systematic review method.

Abbreviation: TQM, total quality management.

Furthermore, inclusion and exclusion criteria were applied to narrow down the yielded articles. The inclusion criteria involved articles which were written in English language and published between 2005 and 2016, articles that dwell on implementation and critical factors clearly, articles from any geographical location which examined TQM, TQM principles, TQM tools and methods in the context of the health-care sector, and TQM studies that used a quantitative research approach and quasi-experimental research design. The exclusion criteria involved articles which are written in non-English language and published before 2005 or after 2016, studies in which the population and sample were not health-care workers practicing inside hospitals, gray literature or works that are not published in a peer-reviewed journal, dissertations/theses, proceedings, published abstracts, studies with qualitative research methods, and commentary articles written to convey opinion or stimulate research or discussion, with no research component. By employing these inclusion and exclusion criteria, 20 articles were generated. Moreover, to guarantee all-inclusiveness and to widen the scope of the review, a forward and backward search of citations in articles was conducted. This was recognized via the database searches, and 25 articles were finally selected. Thereafter, the 25 generated articles were fully perused.

Likewise, for exhaustive research, the approach adopted in this paper also involved the identification and measurement of predictors (CSFs) of TQM. This was done by identifying the most common or important predictors in the selected 25 works that analyze the existing models and/or scales in other contexts, industries or countries. It also includes recognition of the papers that investigate the influence of TQM implementation and/or the impact of predictors of TQM on performance. Additionally, for a proper review of the selected works, adequate plotting of the development of the line of reasoning, integrating and synthesizing the studies, authors, study design, study population, variables, measures of variables and findings of each selected article were identified and noted down. Figure 1 represents the consort flow chart of the systematic review method.

Findings and discussion

Altogether, 25 researched articles were eventually reviewed. All of the selected 25 articles are based on empirical evidence, although a possible limitation of this systematic review strategy might be the exclusion of qualitative studies in the research. Based on Table 1 , five predictors were identified. These are presented in Table 2 .

Matrix of the reviewed literature

Abbreviations: HR, human resources; TQM, total quality management.

TQM predictors in the reviewed studies

The researched literature on predictors of successful TQM implementation was found to be from various countries but in the same health sector. While some predictors adopted by a few of the researched studies were identified, the most frequent and core predictors were identified and considered. As depicted in Table 2 , education and training, continuous quality improvement, patient focus/satisfaction, top management commitment and teamwork appear to be the core predictors (CSFs) in this review. This finding validates how important these variables are in the successful implementation of TQM in the health-care context.

It is noteworthy that the core predictors (ie, education and training, continuous quality improvement, patient focus/satisfaction, top management commitment and teamwork) identified in this study were among the variables found to be central and frequently used CSFs in the previous systematic-review-based studies. 14 , 21 This validates and confirms the findings of the previous studies.

Moreover, it is found that the most adopted research method in TQM in the health-care context is cross-sectional research; 56% of the reviewed researched articles 41 – 46 used a cross-sectional research design, but 32% of the studies employed a quasi-experimental research approach. This indicates that there is still a need for more research on TQM in the health-care context which will adopt a quasi-experimental research approach, because quasi-experimental research design can be very useful in recognizing general trends from the results, and reduces the difficulty and ethical worries that may be connected with the pre-selection and random assignment of test subjects. On the geographical location aspect, the result of this analysis showed that 28% of the reviewed studies were conducted in Iran while 20% of the reviewed studies were conducted in Jordan; 12% and 8% of the reviewed studies were conducted in Saudi Arabia and Pakistan, respectively. The other studies, 4% each, came from India, Namibia, Turkey, the United States, France and Mauritius.

With regards to the influence of predictors on performance in the researched studies, it is found that all of the selected articles 47 , 48 , 49 , 50 ,. 51 that examined the effects of the core predictors (continuous quality improvement, education and training, patient focus/satisfaction, top management commitment and teamwork) of TQM indicate a positive effect of TQM in the health-care sector.

More so, the findings of this review signify that predictors of TQM implementation will result in higher levels of nurse performance .51 In addition, the literature and empirical evidence have shown that TQM in an organizational process always results in better performance of the organization. TQM focuses on patient satisfaction, organization problem identification, building and promotion of open decision-making among employees. It embraces a holistic strategy that gives room for every worker to share responsibility for the quality of the work done. It makes use of analytical mechanisms, such as flow and statistical charts and checksheets, to gather information about activities in an organization. 52 In the medical sector, TQM aims at embedding orientation of quality in all processes and procedures in the delivery of health services .15

Nevertheless, this literature survey is not an exhaustive review of the literature on TQM as it solely focused on the effect of TQM. Future research should widen the scope of this paper by including studies conducted in other contexts (eg, education, manufacturing, etc) and studies that use different research methods (eg, longitudinal research method, randomized control trial method). While TQM predictors have increased in number to reach a total of 59 TQM practices, 21 TQM predictors in the context of health care are few but growing. Investigating the nature of TQM predictors and the methods used in examining them indicates that researchers may have been keen in searching for new predictors instead of trying to cluster them and identify those that are critical for successful TQM implementation. In addition, research on TQM predictors in the health-care sector is scanty, as noted previously.

Practically, given the identified core TQM predictors in this study, it is evident that hospitals’ management should consider entrenchment of continuous quality improvement, education and training, patient focus/satisfaction top management commitment and teamwork in the implementation of TQM, which will consequently enhance hospital performance. Given that TQM predictors are many and some of them have been considered core in several specific contexts, industries, dimensions, etc, it is held that stakeholders in different sectors/industries should begin to identify the most vital TQM practices that suit their situations, goals, strategies and expected performances.

Conclusion and recommendations

As TQM has become an important management approach for advancing performance, this kind of research is of value to researchers and managers. Nevertheless, this study has limitations, including that the databases and search engines adopted for the literature search are not exhaustive. Although a good number of keywords are used, there can be other likely keywords that can be included.

This work has contributed to the enrichment of the relevant literature and made theoretical and methodological contributions. It has provided a foundation on which research on TQM can be built via review of the work done between 2005 and 2016, plotting the development of the line of reasoning, and integration and synthesis of studies from TQM in the health-care context. It has also contributed by evaluating the current state of evidence regarding TQM, indicating inadequacies in the literature and pointing to where further research needs to be done. Thus, it contributes to the present body of knowledge as well as the research on TQM in the health-care context.

This work has also established that the most adopted research method in health-care-based TQM is cross-sectional research, followed by quasi-experimental research, and the researched studies were mostly conducted in Asia. The findings of the researched literature indicate a positive effect of TQM in the health-care context, indicating that TQM implementation, which contains the identified core predictors, will result in higher levels of performance. Furthermore, TQM implementation can help health-care professionals to gain more qualified behaviors with total commitment to work toward handling the patients, which in the long run will augment their performance.

The findings of the reviewed studies indicate how it would be useful for stakeholders in the health sectors to introduce and implement TQM in the hospitals and clinics, as this would enhance the performance of the health workers and consequently improve organizational performance. Given the limitations of this work, it is sufficed to suggest that future research should widen the scope of this paper by including studies conducted in other contexts and studies that use different research methods, and it should also develop a comprehensive TQM taxonomy to explain how and why TQM practices coalesce within systems that facilitate higher performance.

The authors report no conflicts of interest in this work.

- Search Menu

- Sign in through your institution

- Virtual Issues

- Advance Articles

- Supplements

- Highly Cited Articles

- Podcast Episodes

- Author Guidelines

- Submission Site

- Review Guidelines

- Open Access

- Self-Archiving Policy

- Reasons to Publish with Military Medicine

- About AMSUS

- About Military Medicine

- Become a Reviewer

- Editorial Board

- Advertising and Corporate Services

- Journals Career Network

- Journals on Oxford Academic

- Books on Oxford Academic

Article Contents

- < Previous

Case Study: The Implementation of Total Quality Management at the Charleston VA Medical Center's Dental Service

The views expressed in this article are those of the author and do not reflect the official policy or position of the U.S. Air Force, Department of Defense, or the Department of Veterans Affairs.

- Article contents

- Figures & tables

- Supplementary Data

Barry L. Matthews, Case Study: The Implementation of Total Quality Management at the Charleston VA Medical Center's Dental Service, Military Medicine , Volume 157, Issue 1, January 1992, Pages 21–24, https://doi.org/10.1093/milmed/157.1.21

- Permissions Icon Permissions

Total Quality Management (TQM) is an evolving management philosophy which has recently been introduced to the health care industry. TQM requires the use of a continuous process improvement methodology for delivered services. It was implemented at Charleston VAMC's Dental Service as a study to determine its effectiveness at the grassroots level. A modified Quality Circle was established within the clinical service under the guidance of Dr. Edward Deming's 14 principles. Top management support was not present. Many lessons were learned as process improvements were made. The overall success was limited due to the inability to address interdepartment process problems.

Email alerts

Citing articles via, looking for your next opportunity.

- Recommend to Your Librarian

Affiliations

- Online ISSN 1930-613X

- Print ISSN 0026-4075

- Copyright © 2024 The Society of Federal Health Professionals

- About Oxford Academic

- Publish journals with us

- University press partners

- What we publish

- New features

- Open access

- Institutional account management

- Rights and permissions

- Get help with access

- Accessibility

- Advertising

- Media enquiries

- Oxford University Press

- Oxford Languages

- University of Oxford

Oxford University Press is a department of the University of Oxford. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide

- Copyright © 2024 Oxford University Press

- Cookie settings

- Cookie policy

- Privacy policy

- Legal notice

This Feature Is Available To Subscribers Only

Sign In or Create an Account

This PDF is available to Subscribers Only

For full access to this pdf, sign in to an existing account, or purchase an annual subscription.

A Total Quality Program 3M Case Studies

Cite this chapter.

- Robert E. Richards 3

Part of the book series: Sagamore Army Materials Research Conference Proceedings ((PHAE,volume 26))

Historically, 3M has worked to maintain a quality image in its world-wide markets. Changing competition, raw materials evolutions, and the economic pressures of the late 1970s brought new recognition to the significance of quality as a key competitive factor. The new quality emphasis required a reworking of not only the techniques and priorities of quality management, but also a revitalizing of the quality commitment of senior management, and the development of a process for building organizational quality continuously.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Unable to display preview. Download preview PDF.

P. B. Crosby, Quality is Free, McGraw-Hill Book Company, ISBN 0-07-014512-1.

Google Scholar

Quality Training Program - QTP-1, 3M Company Education and Training, (1980).

Douglas N. Anderson, The Quality Evolution, 3M Company Publication.

Download references

Author information

Authors and affiliations.

New Products Department, 3M Company, USA

Robert E. Richards

You can also search for this author in PubMed Google Scholar

Editor information

Editors and affiliations.

Army Materials and Mechanics Research Center, Watertown, Massachusetts, USA

James W. McCauley

Syracuse University, Syracuse, New York, USA

Volker Weiss

Rights and permissions

Reprints and permissions

Copyright information

© 1986 Plenum Press, New York

About this chapter

Richards, R.E. (1986). A Total Quality Program 3M Case Studies. In: McCauley, J.W., Weiss, V. (eds) Materials Characterization for Systems Performance and Reliability. Sagamore Army Materials Research Conference Proceedings, vol 26. Springer, Boston, MA. https://doi.org/10.1007/978-1-4613-2119-4_25

Download citation

DOI : https://doi.org/10.1007/978-1-4613-2119-4_25

Publisher Name : Springer, Boston, MA

Print ISBN : 978-1-4612-9253-1

Online ISBN : 978-1-4613-2119-4

eBook Packages : Springer Book Archive

Quality management

- Business management

- Process management

- Project management

Creating a Culture of Quality

- Ashwin Srinivasan

- Bryan Kurey

- From the April 2014 Issue

Manage Your Human Sigma

- John H. Fleming

- Curt Coffman

- James K. Harter

- From the July–August 2005 Issue

Creating a Culture of Continuous Improvement

- Aravind Chandrasekaran

- John S. Toussaint

- May 24, 2019

The Contradictions That Drive Toyota's Success

- Hirotaka Takeuchi

- Norihiko Shimizu

- From the June 2008 Issue

Teaching Smart People How to Learn

- Chris Argyris

- From the May–June 1991 Issue

Will Disruptive Innovations Cure Health Care? (HBR OnPoint Enhanced Edition)

- Clayton M. Christensen

- Richard Bohmer

- John Kenagy

- June 01, 2004

Inside the Mind of the Chinese Consumer

- William McEwen

- Xiaoguang Fang

- Chuanping Zhang

- Richard Burkholder

- From the March 2006 Issue

Quality Circles After the Fad

- Edward E. Lawler III

- Susan A. Mohrman

- From the January 1985 Issue

Strategies for Learning from Failure

- Amy C. Edmondson

- From the April 2011 Issue

The Case for Capitation

- Brent C. James

- Gregory P. Poulsen

- From the July–August 2016 Issue

Learning to Lead at Toyota

- Steven J. Spear

- From the May 2004 Issue

Get Ahead by Betting Wrong

- J.P. Eggers

- From the July–August 2014 Issue

Beyond Toyota: How to Root Out Waste and Pursue Perfection

- James P. Womack

- Daniel T. Jones

- From the September–October 1996 Issue

Will Disruptive Innovations Cure Health Care?

- September 01, 2000

How U.S. Health Care Got Safer by Focusing on the Patient Experience

- Thomas H Lee MD

- Thomas H. Lee

- May 31, 2017

Relentless Idealism for Tough Times

- Alice Waters

- From the June 2009 Issue

Six Sigma Pricing

- Manmohan S. Sodhi

- Navdeep S. Sodhi

- From the May 2005 Issue

Creative Benchmarking

- Dawn Iacobucci

- Christie Nordhielm

- From the November–December 2000 Issue

Crafting the Luxury Experience

- Robert Chavez

- December 04, 2011

Benchmarking Your Staff

- Michael Goold

- David J. Collis

- From the September 2005 Issue

AT&T's Transmission Systems Business Unit (A)

- Rogelio Oliva

- James Quinn

- Elizabeth Keating

- June 15, 2004

Health-Tech Strategy at KG Hospital Part A: Identification and Prioritization of Key Focus Areas

- Vijaya Sunder M

- Meghna Raman

- January 09, 2022

Analyze the Process

- Harvard Business Publishing

- May 15, 2016

COLIN Co.: New Product Development

- Zhenhua Zhang

- December 05, 2017

Caterpillar in Europe: Inventory Reorder Policies

- Michael T. Pich

- Ludo Van Der Heyden

- March 14, 2002

AT&T's Transmission Systems Business Unit (B)

- June 21, 2004

Eliminating Avoidable Blindness Outreach Activities at Aravind Eye Care System

- Kamalini Ramdas

- March 01, 2018

Lean at Wipro Technologies

- Bradley R. Staats

- David M. Upton

- October 16, 2006

Health-Tech Strategy at KG Hospital Part B: Tech Strategy Design and Implementation

Excel logistics services.

- Sunil Chopra

- January 01, 2004

Daewoo Shipbuilding and Heavy Machinery

- October 01, 1994

Designing a Surgical Quality Improvement Project at Eastern State Medical Center

- Amy P. Cohen

- Nancy M. Kane

- May 15, 2014

Mastering the Dynamics of Innovation

- James M. Utterback

- August 16, 1996

Operations Management Reading: Managing Quality with Process Control

- Roy D. Shapiro

- September 10, 2013

Applying the Service Activity Sequence in the World of Culture

- Beatriz Munoz-Seca Fernandez-Cuesta

- Susana Llerena

- September 21, 2012

Pete & Gerry's

- Jose B. Alvarez

- Natalie Kindred

- November 30, 2016

Operations Management Reading: Managing Quality

- Roger E. Bohn

- June 27, 2013

Sandra Brown Goes Digital (A): The Promise and Perils of Social Movements in a Healthcare Company

- Rosabeth Moss Kanter

- Jonathan Cohen

- March 27, 2018

John Smithers at Sigtek

- Todd D. Jick

- October 05, 1990

Account Opening in Blue Bank - Part B: Root Cause Analysis

- March 31, 2023

Hans Wilsdorf and Rolex, Teaching Plan

- Geoffrey G. Jones

- Jessica Burch

- October 22, 2015

Scoping the Problem: Performance Challenges Facing the U.S. Health Care System

- Michael E. Porter

- Elizabeth Olmsted Teisberg

- May 25, 2006

Gene Cattie Enterprises, Teaching Note

- Elliott N. Weiss

- January 28, 2013

Happy Family: Investing for the Future, Teaching Note

- Fanyin Zheng

- April 06, 2020

Assessing Data Quality: A Managerial Call to Action

- Tadhg Nagle

- David Sammon

- May 15, 2020

Popular Topics

Partner center.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Organizational approach to Total Quality Management: a case study

Related Papers

Afizan Amer

Management Science Letters

Yuni Pambreni

Assoc. Prof. Cross Ogohi Daniel

This study came to examine the impact of Total Quality management (TQM) as instrument in achieving on the organisational performance. TQM is defined as a policy that essentially aimed at establish and deliver high quality products and services that cover all their client's demands and achieve a high level of customer satisfaction. Total Quality Management (TQM) is a management is an administrative approach for firms focused on quality, in light of the cooperation and every individuals and aims at long haul accomplishment through consumer's loyalty and advantages to all individuals from the associations and society. The impact of many organisations failure to properly implement TQM by all administration level, challenges the organisation ability to organise frequent employee training have been a big problem. This research work attempt to find out the effect of TQM execution in the board inclusion, challenges disturbing the usages, impact of employee training and TQM standard application to the accomplishment of organisational goal. The key discoveries demonstrated that rehearsing TQM but it is yet to implement it to the highest level of subscribing to a quality reward system. The implementation of TQM is at the quality assurance level. It was discovered that administration inactions undermined initiative promise to quality and rendered TQM rehearsal insufficient. It is through questionnaires method and oral interview that data are collected from the aforementioned organisations. References were made to journals, related books, internet the aforementioned organization concurred that TQM have in hierarchical execution.

Proceedings of International Conference on Business Management

Dr. S.T.W.S. Yapa

Present-day customers are very conscious of the quality of products and services. They are ready to pay a higher price for a quality product or service. A company that meets such demands gains a competitive advantage in the market over its competitors. One of the best approaches to address this challenge is the implementation of Total Quality Management (TQM). TQM, a systematic management approach and a journey to meet competitive and technological challenges, has been accepted by both service and manufacturing organizations globally. It is commonly agreed that by adopting TQM, the overall effectiveness and performance of organizations can be improved. Despite TQM offers numerous benefits, it is not an easy task to implement it. It is generally experienced that implementation of TQM is hard and painful due to certain barriers that inhibit the successful implementation of TQM. Understanding the factors that are likely to obstruct TQM implementation enables managers to develop more ef...

International Public Management Journal

Teddy Lian Kok Fei , Hal Rainey

This research highlights the factors that have contributed to the implementation and impact of Total Quality Management (TQM) in Malaysian government agencies and to compare agencies that have won quality awards to those that have not.

Quality and Quantity

Ahamad Bahari

Maged Awwad

In the current market economy, companies are constantly struggling to achieve a sustained competitive advantage that will enable them to improve performance, which results in increased competitiveness, and of course, profit. Among the few competitive advantages that can become sustainable competitive advantages, quality plays a crucial role. Recent research shows that about 90% of buyers in the international market, consider quality as having at least equal importance with price in making the decision to purchase. In the opinion of some specialists in economic theory and practice, total quality refers to the holistic approach of quality, which actually means, addressing all aspects of economic and social development and technical of quality. Thus, the holistic approach of quality at organisation-wide involves procedural approach of quality, in this respect, the study focuses on this type of quality approach, i.e. the procedural approach, taking into account the strategic aspects of the continuous improvement of quality, which means in fact, the quality management. Total Quality Management is seen as a way to transform the economies of some countries to be more competitive than others. However, Total Quality Management brings not and will not produce results overnight, it is not a panacea for all the problems facing the organization. Total Quality Management requires a change in organizational culture, which must focus on meeting customer expectations and increasing the involvement of all employees to meet this objective, as an expression of the ethics of continuous improvement. In general, research on quality aiming identify why an organization should adopt the principles of total quality management, but attempts to identify the failing companies' attempts to implement total quality management principles are not so visible. Concerns companies to introduce quality management systems are becoming more pronounced, therefore, in this study we try to identify and present the main reasons that prevent achieving quality and implementation of total quality management system, in other words, we are interested in identify barriers to implementation and development of a quality management system.

Aliza Ramli

Haile Shitahun Mengistie

The main purpose of this paper was to investigate the effect of Total Quality Management practices on organizational performance the case of Bahir Dar Textile SC. It adopted an explanatory research design. The sample size of 71 respondents was drawn using stratified random sampling technique. The study findings of correlation analysis showed that all constructs of total quality management (customer focus, employee's empowerment, top management commitment, continuous empowerment, supplier quality management, process approach) were positively and significantly affect organizational performance. The findings of the multiple regressions analysis showed that the observed changes in organizational performance attributed by the elements of total quality management practice is 49.4% (adjusted r2=.494). The study also reveals from six major elements of total quality management practices, customer focus, top management commitment, continuous improvement, employee's empowerment, and supplier quality management has a positive effect on organizational performance, while process approach doesn't have a significant effect.

Dr. Faisal Talib

RELATED PAPERS

José Luís M. Rodrigues

The Southern Journal of Philosophy

Andrew Ward

Biswanath Dutta

Respiratory research

James Donohue

Irpps Working Papers

Adriana Valente

Tubias Capaina

Gerald Kembellec

Soedirman Economics Education Journal

Jaryono Jaryono

Universal Journal of Educational Research

Joseph Ogutu Owino

jorge rosasco

TANRA: Jurnal Desain Komunikasi Visual Fakultas Seni dan Desain Universitas Negeri Makassar

Dian Cahyadi

Jonathan Boreyko

Neuro-oncology

Kurt Jaeckle

Journal of Community Hospital Internal Medicine Perspectives

vincent figueredo

Academy of Management Proceedings

Maria Nathan

Analytica Chimica Acta

María Dolores RUBIANES

Ruth Jurberg

รายงานสืบเนื่องจากการประชุมวิชาการระดับชาติ สำหรับนักศึกษา มหาวิทยาลัยราชภัฏกำแพงเพชร ครั้งที่ 4, หน้า 113-124 (22 มีนาคม 2567)

Thirawit Praimahaniyom

Jurnal Informatika, Sistem Informasi dan Kehutanan (FORSINTA)

Hetty Rohayani

Journal of Rainwater Catchment Systems

Koichi Unami

Chemistry in Australia

Ronald Smernik

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

(Stanford users can avoid this Captcha by logging in.)

- Send to text email RefWorks EndNote printer

Total quality management : key concepts and case studies

Available online.

- ScienceDirect

More options

- Find it at other libraries via WorldCat

- Contributors

Description

Creators/contributors, contents/summary.

- Chapter 1: Total Quality Management: An Overview

- Chapter 2: Evolution of Total Quality Management

- Chapter 3: Quality Gurus

- Chapter 4: Leadership and TQM

- Chapter 5: Scientific Management

- Chapter 6: System Approach to Management Theory

- Chapter 7: Strategic Planning

- Chapter 8: Cost of Quality

- Chapter 9: Organization for TQM

- Chapter 10: Customer Satisfaction

- Chapter 11: Total Employee Involvement

- Chapter 12: Supplier Partnership

- Chapter 13: Total Productive Maintenance

- Chapter 14: Quality Awards

- Chapter 15: Quality Circles

- Chapter 16: Fundamentals of Statistics- Part I

- Chapter 17: Fundamentals of Statistics- Part II

- Chapter 18: Process Capability

- Chapter 19: Inward Inspection

- Chapter 20: Seven Traditional Tools of TQM

- Chapter 21: The Seven Modern Tools of TQM

- Chapter 22: Kaizen and Continuous Improvement

- Chapter 23: 5S

- Chapter 24: Six Sigma

- Chapter 25: Lean Management

- Chapter 26: Failure Modes and Effects Analysis

- Chapter 27: Reliability Engineering

- Chapter 28: Business Process Reengineering

- Chapter 29: Benchmarking

- Chapter 30: Quality Function Deployment

- Chapter 31: Quality Loss Function

- Chapter 32: Design for Quality

- Chapter 33: Value Engineering

- Chapter 34: ISO 9000 Quality Systems

- Chapter 35: ISO 14000 Quality Systems

- Chapter 36: Terminology Used in Japanese Management Practices.

- (source: Nielsen Book Data)

Bibliographic information

- Stanford Home

- Maps & Directions

- Search Stanford

- Emergency Info

- Terms of Use

- Non-Discrimination

- Accessibility

© Stanford University , Stanford , California 94305 .

To read this content please select one of the options below:

Please note you do not have access to teaching notes, total quality management from theory to practice: a case study.

International Journal of Quality & Reliability Management

ISSN : 0265-671X

Article publication date: 1 May 1993

Most quality professionals recommend a core set of attributes as the nucleus of any quality improvement process. These attributes include: (1) clarifying job expectations; (2) setting quality standards; (3) measuring quality improvement; (4) effective super‐vision; (5) listening by management; (6) feedback by management; and (7) effective training. Based on a survey of employees at a medium‐sized manufacturing firm in the United States, it was found that management philosophy and actions can undermine even a proven total quality management (TQM) programme. For the many firms which hire outside consultants to set up a TQM programme, makes recommendations to management to ensure its successful implementation.

- MANAGEMENT PHILOSOPHY

- QUALITY ASSURANCE

- QUALITY MANAGEMENT

Longenecker, C.O. and Scazzero, J.A. (1993), "Total Quality Management from Theory to Practice: A Case Study", International Journal of Quality & Reliability Management , Vol. 10 No. 5. https://doi.org/10.1108/02656719310040114

Copyright © 1993, MCB UP Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey