- SEO SOLUTIONS

TOTAL FREE HEALTH AND SAFETY DOCUMENTS DOWNLOADING SOURCE

- _HSE Trainings

- EHS Guidelines

- Risk Assessments

- Safety Posters

- Method Statements

- Health and Fitness

Friday, July 1, 2022

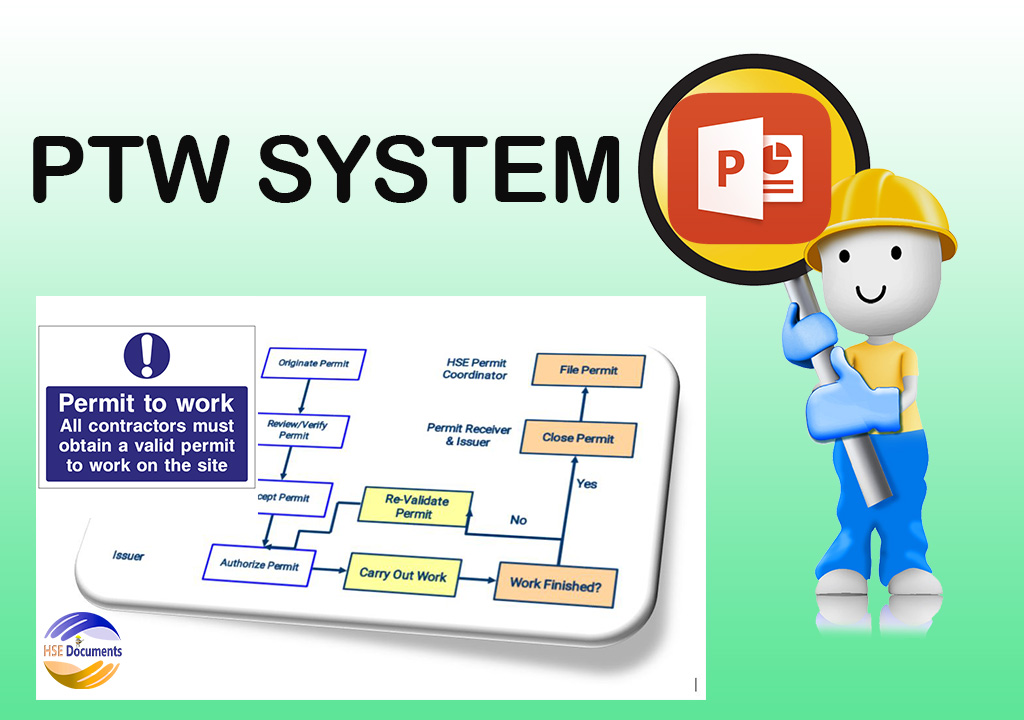

Permit to work system-powerpoint training.

What is Permit To Work System

- The PTW system is a formal written procedure used to control access and activities of personnel in the construction

- To ensure the safety of personnel and to prevent damage to equipment

- It is also a means of communication between site management, supervisors, and operators, who carry out the work PTW normally implemented in work activities near or inside the operating facilities, there's Buried or close to the operational device, or wherein the clients assume that PTW is deemed important or near operational system or where the clients think that PTW is deemed necessary

How is work controlled within the Permit?

- To Work, SystemWork is controlled by following various steps detailed in the permit to work procedures and by using special documents called WORK PERMIT.

- Work permits are not simple permission to carry out work, but they determine how the work can be carried out safely.

Types of Permit To Work

Hot work permit, confined space entry permit.

- Electrical Permit (Energizing and Deenergizing)

Excavation Permit

Radiography permit.

- Crane Critical Lifts Man-basket Operation

- Cold Work Permit

Classified as any sort of work which involves real or ability resources of ignition and which is accomplished in a place where there can be a risk of fire or Explosion, or which contain the emission of toxic fumes from the utility of heat.

Is generally used to specify the precautions to be taken to get rid of the hazards of risky fumes, gases liquids, or solids of loss of oxygen, dangerous residues radiation, or transferring machinery from confined space or any other source before a person is permitted to enter a confined space.

Electrical Permit (Including Energizing and De-energizing)

Is normally used to cover any work on electrical equipment and precautions to be taken to eliminate the risk of electric shock/electrocution to people carrying out the work or damage to property

- Is required for any work to be carried out where existing lines or services may be buried or encountered.

- Any excavation deeper than 0.3-meter Excavation activities near existing structures (i.e. Electrical posts, buildings, Permanent Equipment, etc…)

- For excavation activities in an area classified as a safe area for excavation, a blanket permit may be requested for a long duration of time

Is normally used to cover industrial radiography – safe working practices and precautions to be taken to eliminate the risk associated with radioactive sources.

Crane Critical Lifts Permit

- A permit is needed when lifting requires Rigging Study;

- Load is 40 Tones and above Crane, lifts are performed in a “High-Risk Environment”

- Load is too big/wide to be lifted

- Lifting where 2 or more cranes are required

Man-Basket Operation

- Before the use of any man-basket suspended from a crane for hoisting personnel, the highest level of Project management must determine and be sure that conventional means are more

- Dangerous or impossible due to structural layout or worksite conditions, approval has to be signed.

- A trial lift is required before the actual riding of personnel inside the basket to make sure that the operator can safely position the man basket in the intended location

Permit Issuer Responsibilities

- In the case of an operational plant, the Company normally has its permit system.

- The manager of the affected section of the plant or his specified consultant shall be the permitted provider.

- In a non-operational area where existing facilities are already in place, The Contractor Area Construction Managers or Company Section head shall be the issuers of the permits.

- The Issuer has the sole authority to issue the permit.

- The Issuer shall be fully aware of site conditions, the type of work to be carried out, and all the requirements stated in the permit.

- The Issuer shall conduct an onsite inspection jointly together with the Receiver to make sure that website situations are secure to permit the paintings and that all necessities stated in the allow are applied earlier than the issuance of the permit.

- The Issuer shall conduct an onsite inspection together collectively with the Receiver to ensure that site conditions are safe to permit the work and that all necessities stated inside the allow are implemented earlier than the issuance of the allow.

- The Issuer shall withhold the issuance of the permit if the requirements are not met, or site conditions are not safe for the work to carry out.

- The Issuer shall, if noticing the presence of any other potential hazards, risks that may jeopardize the safety of the worker, tools, or equipment advice the Receiver of appropriate countermeasures to be taken.

- The Issuer shall ensure that all required safety monitoring measurements are properly done and so stated in the permit.

- The Issuer shall ensure all personnel involved in the work are fully aware of Emergency procedures.

- Once informed the work is completed, the Issuer shall visit the site jointly with the Receiver to ensure that the work is ceased and the site is kept clean and tidy without any smoldering existing.

- Task supervisors who are directly responsible for the work stated in the permit shall be the Receiver of the Permit. He shall define the job to be done, the exact location, and the nature of the work. Also to ensure that the situations at the allow are met incomplete

- The Receiver shall be fully aware of all requirements stated in the permit and comply with them at all times.

- The Receiver shall fully brief the work crew to ensure that requirements are clearly understood by the crew under his supervision.

- The Receiver shall ensure the work is performed by the conditions specified in the permit. He shall continue to be on the work website to supervise the work.

- The Receiver shall ensure that under no circumstances shall by his discretion or his crew change the original scope of the work, which is described in the permit.

Permit Receiver Responsibilities

- The Receiver shall request a new permit in the event a change in the scope of the work becomes necessary.

- Whenever website situations are notably changed, the Receiver shall right away forestall the paintings and tell the Issuer of the change for similarly training from him.

- Upon the occurrence of an emergency, the Receiver shall immediately stop the work and shut down all equipment.

- The Receiver shall report the completion of the work or the expiration of the validity of the permit to the Issuer and ensure that the site is kept clean and tidy without any smoldering/ignition sources.

- If the work in progress requires extending the validity stated in the permit, the Receiver shall suspend the work and request the issuance of the new permit.

HSE Permit Coordinator Responsibilities

- The HSE Permit Coordinator detailed with the aid of Area Construction Managers is answerable for the everyday coordination of the painting permits.

- He is responsible for full clerical control of the system including retention of the closed-out Work Permits for one month.

- Has the full overview of the planned, open, and suspended work permits on visual display in his permit to work office.

Operational Procedures for the Work Permit System

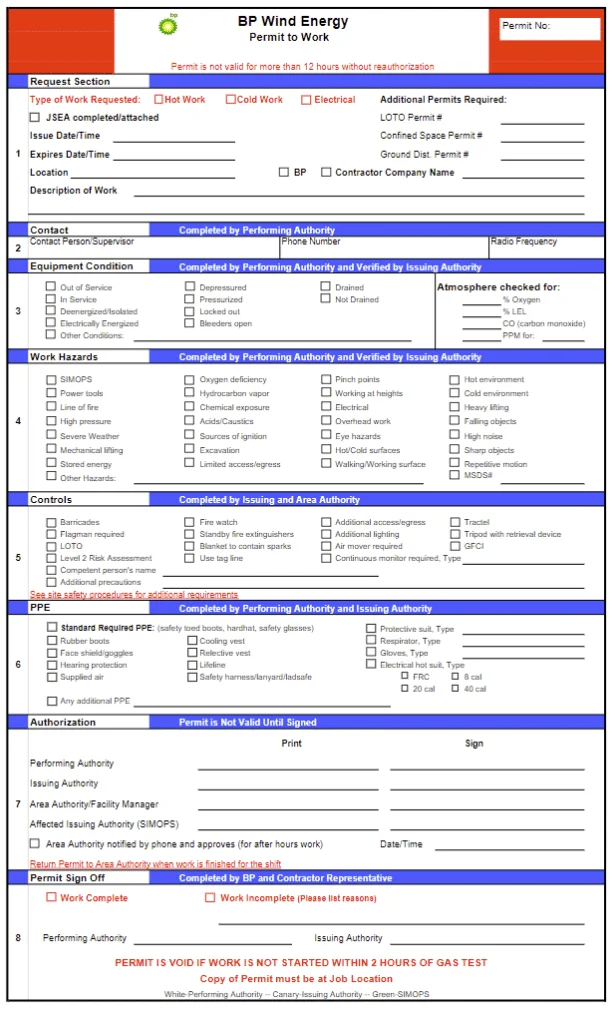

- A Work Permit consists of a hard and fast of three pages. The White page shall be kept by using the Receiver and stored on the work location, the Yellow page will be kept via the Issuer and the Green web page will be stored by using the HSE Permit Coordinator.

- The description of the work shall be a precise statement of the planned activity, and the location of the work by identification of the area or equipment to be worked upon. Broad scopes of labor of a preferred nature aren't appropriate.

- Method Statements, Risk Assessments, and/or Job Safety Analyses will be produced for important sports and shall be connected to and shape part of the allow. Such extra documentation will be attached to the unique Permit.

- Where additional Permits or Certificates are required, they will be attached to and form part of the Permit to Work.

- The Receiver shall produce the permit to the Contractor responsible personnel for the work requested in the permit for review and verification by 15:00 hours a day before the commencement of the activity/work.

- As rapidly as the assessment & verification were made, the PTW Receiver shall deliver the verified allow to the HSE Permit Coordinator.

- As soon as the assessment and verification had been made, the Receiver shall deliver the verified permit to the HSE Permit Coordinator.

- The HSE Permit Coordinator shall scrutinize the allow together with safety precautions and requirements stated inside the permit and deliver it to the Receiver.

- The HSE Permit Coordinator must consult HSE personnel for expert advice or hints required to paint appropriately.

- The Receiver shall bring the permit to the Issuer who shall review the permit to ensure that all required safety precautionary measures are stated and authorize the permit.

- On the day of the work, the Issuer the person together with the Receiver shall go to the site to ensure that all requirements in the permit are met And give up the allow to the Receiver

- Issuance of the permit to the Receiver in the office shall not take place.

- Upon receipt of the permit from the Issuer, the Receiver can commence the work.

- When no further work is to take place under a permit, the Receiver shall sign off and return the permit to the Issuer to close the permit.

- Upon receipt of the permit, the Issuer, and the Receiver shall inspect the work site to ensure that no smoldering is present, the work site is clean and tidy and equipment is left in a safe and hazard/risk-free condition.

- The issuer shall return the invalid PTW to the health safety and environmental Permit Coordinator for file.

Revalidation of the Permit

- When the work calls for an extension of the permit, the Receiver shall suspend the work and request an extension of the validity to the Issuer.

- The Issuer is responsible for ensuring that all precautions and requirements are still in place and the conditions in the work site are maintained safely for personnel and equipment.

- If the issuer agrees to extend the permit he shall define the time of the expiry and sign in the permit to authorize the extension.

- The Receiver returns the extended permit to the work site and resumes the work.

Emergency Situation

- When an emergency, such as a fire incident, Toxic Gas Release, or Natural calamity has taken place the Receiver shall immediately stop all work and shut down all equipment.

- All permits shall be nullified and no work shall be resumed unless new permits have been issued by the Issuer.

- Before the issuance of a new permit, the Issuer shall visit the work site to ensure that there is no imminent hazard/risk present and that the work site is safe for work.

- The Permit to Work is designed to provide a safe system of work that can be applied to works identified under perceived risks.

- This shall be applied to the Contractor controlled Construction activities on the Project.

- Permit requirements for activities other than those mentioned in this procedure will be re-evaluated especially for potentially hazardous activities where an extra degree of work control is felt to be appropriate.

Download The File Here

Permit to work system-powerpoint training, no comments:.

Post a Comment

DOWNLOAD ANDRIOD APP

Get new posts by email:

Socially contacts, contact form.

Blog Archive

Social networks.

- Terms and Conditions

- Privacy Policy

Total Pageviews

Copyright (c) 2023 hsedocuments All Right Reseved

- Safety Officer

- Safety Quiz

- Interview Q/A

- Online Exam

- Download PPT

- Get Certificate Online

- HSE Web Story

- NEBOSH IDIP

- Fire Engineering

- Basic Safety

- Construction Safety

- Workplace Safety

- Fire Safety

- Crane Safety

- Work At Height

- Excavation Safety

- Electrical Safety

- Confined Space

- Noise Safety

- Vibration Safety

- Scaffolding

- Radiography

- HSE Calculations & Formulas

- Safety Slogan

- Tool Box Talk

- HSE Documentation

- HSE Training

- Risk Assessment

- Safety Audit

- Accident Investigation

- Privacy Policy

- Terms and Conditions

Permit To Work (PTW) | Types of Work Permit | Download PPT

Table of Contents

Introduction

Permit To Work (PTW) : In the realm of workplace safety, the term “Permit to Work” or PTW is of utmost importance. It serves as a vital tool in ensuring that potentially hazardous tasks are executed with the utmost care and precaution. This article delves into the world of PTW, explaining its significance, the various types of work permits, and how to obtain one. Moreover, we will discuss the advantages of using PTW PowerPoint presentations (PPTs) and provide you with insights into its implementation across different industries.

What is a Permit to Work (PTW)?

A Permit to Work, often abbreviated as PTW, is a formal document that authorizes specific activities within a workplace. It is commonly used in environments where there are potential risks to health and safety. The primary purpose of a PTW is to ensure that the necessary precautions are taken before any hazardous work commences.

The Importance of PTW

The significance of PTW cannot be overstated. It acts as a safeguard, ensuring that potentially dangerous tasks are carried out in a controlled and safe manner. PTW also holds individuals and organizations accountable for adhering to safety protocols, reducing the likelihood of accidents and injuries.

Types of Work Permits

There are several types of work permits, each designed for specific work environments and activities. Let’s explore some of the most common ones:

General Work Permit

This permit is typically used for routine maintenance and non-hazardous tasks.

Hot Work Permit

Hot work permits are issued for activities involving open flames or high temperatures, such as welding and cutting.

Cold Work Permit

Cold work permits are for tasks carried out in cold conditions, where exposure to extreme temperatures is a concern.

Confined Space Entry Permit

This permit is required when working in confined spaces, which pose unique risks and challenges.

Steps to Obtain a PTW

Obtaining a PTW involves a systematic process. It typically includes identifying the task, assessing the risks, implementing safety measures, and obtaining approvals from relevant personnel.

Who Needs a PTW?

PTWs are not limited to a specific industry. They are essential in any workplace where hazardous tasks are performed. This includes manufacturing, construction, oil and gas, and many others.

Downloading a PTW PPT

To aid in the dissemination of PTW information, you can download PTW PowerPoint presentations. These PPTs provide a visual and comprehensive overview of the permit process.

What is Hazard | Risk | Accident | Incident | Near Misses with 5 Examples | Download PPT

Work At Height PPT | Hazards and Safety Precautions | Download PPT

Benefits of Using PTW PPT

Using PTW PPTs offers several advantages. They help in training and educating employees, contractors, and other stakeholders about the importance of PTW. They also serve as a reference guide for adhering to safety protocols.

In conclusion, a Permit to Work (PTW) is a fundamental tool in ensuring safety in workplaces with potential hazards. It plays a pivotal role in protecting lives and preventing accidents. By understanding the various types of work permits and their implementation, we can create safer and more secure working environments.

Frequently Asked Questions

1. What is the purpose of a Permit to Work (PTW)?

A Permit to Work (PTW) serves the primary purpose of ensuring safety in the workplace. It is a formal document that authorizes specific activities, especially those with potential risks to health and safety. The PTW helps in assessing and mitigating these risks, making sure that all necessary precautions are taken before hazardous work begins.

2. Are PTWs only required in high-risk industries?

No, PTWs are not limited to high-risk industries. While they are particularly crucial in high-risk sectors like manufacturing, construction, and oil and gas, PTWs can be applicable in any workplace where potentially dangerous tasks are carried out. Safety should always be a priority, regardless of the industry.

3. How can I download a PTW PowerPoint presentation (PPT)?

You can download a PTW PowerPoint presentation (PPT) from various sources, including safety training websites, industry-specific associations, or even by creating your own based on the specific needs of your workplace. These presentations provide a visual and comprehensive overview of the PTW process and its importance.

4. What are the consequences of not following PTW procedures?

Failure to follow PTW procedures can lead to severe consequences. This may include accidents, injuries, damage to equipment, and even loss of life. Additionally, non-compliance with PTW procedures can result in legal and financial repercussions for organizations. It’s essential to adhere to PTW guidelines to ensure the safety of all individuals involved.

5. Can PTW be customized for specific industries or tasks?

Yes, PTWs can and should be customized to suit the specific requirements of different industries and tasks. Each industry and workplace may have unique risks and safety protocols. Customizing PTWs ensures that they are tailored to address these specific hazards, making them more effective in enhancing safety and compliance.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Telegram (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

RELATED ARTICLES MORE FROM AUTHOR

Road safety ppt: hazards and precautions | download ppt, job safety meeting | download ppt, heat exhaustion vs heat stroke: toolbox talk | download ppt.

This information is very useful.safety is first priority

Great training material.

Excellent training material.

LEAVE A REPLY Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Notify me of follow-up comments by email.

Notify me of new posts by email.

Popular Posts

Top 15 best safety slogan in hindi, hse engineer job vacancy : urgent requirement, easy nebosh igc exam questions and answers, top 25 best hindi safety slogan in 2024, 25 safety officer interview questions (with sample answers), 10 essential safety officer tips every workplace needs to know, industrial safety, safety officer & safety engineer, work at height | hazards | control measures, very important slip trip and fall hazards, personal fall arrest system, latest post, safety officer and safety supervisor hiring for saudi aramco project, hse officer free recruitment for qatar: salary 5500 qar, safety officer and safety engineer hiring for saudi arabia: nebosh +..., safety engineers required for aramco project: saudi, 09 nebosh safety officers urgently required in saudi arabia, (nebosh) the national examination board in occupational safety and health, 03 safety officer jobs vacancy in saudi arabia: oil and gas..., 05 hse officers urgently required in saudi arabia, 08 hse engineer jobs in uae: oil & gas project.

- Toolbox Talks

Understanding and Implementing Permit to Work Systems: A Comprehensive Guide

- by Afnan Tajuddin

- Work permit system

Table of Contents

Introduction to Permit to Work Systems

In the bustling world of the petroleum, chemical, and allied industries, safety is paramount. One of the key tools to ensure this safety is the Permit-to-Work System . This system is a formal, recorded process used to control potentially hazardous work. It serves as a means of communication between site management, plant supervisors, and those who carry out the hazardous work.

Understanding the Basics of Permit to Work PTW Systems

- A permit-to-work system is a formal written system used to control certain types of work that are potentially risky. It is a document which specifies the work to be done and the precautions to be taken. Permits are an essential part of safe systems of work for many industries.

- Before initiating any task in a specific area, it’s crucial to ensure the safety of the environment and the machinery or equipment involved. To ascertain these safe conditions, a work permit system is implemented. This system specifies the conditions and procedures for the safe execution of work, allowing tasks to be carried out under controlled risk conditions.

- A permit-to-work system is not just a permission to carry out a dangerous job. It is an integral part of a system that determines how that job can be carried out safely. The issue of a permit does not, by itself, make a job safe. That can only be achieved by those preparing for the work, those supervising the work, and those carrying it out. In addition to the permit-to-work system, other precautions may need to be taken, such as process or electrical isolation, or access barriers. These will need to be identified in task risk assessments before any work is undertaken. The permit-to-work system ensures that authorised and competent people have thought about foreseeable risks and that such risks are avoided by using suitable precautions.

Aim of the Work Permit System

The primary purpose of the work permit system is to ensure that:

- Only authorized individuals are allowed to work in clearly notified hazardous areas.

- The individuals permitted to work are aware of the various safety issues involved and understand that necessary safety precautions have been taken.

- The work permit serves as a legal document between the issuer and executor for the commencement of a job inside a refinery.

- The client has implemented the work permit system to distribute equal responsibilities for the job being performed.

The Importance of Permit-to-Work Systems in Hazardous Industries

The petroleum, chemical, and allied industries store and process large quantities of hazardous substances, including flammable and toxic materials. The potential for serious incidents is clear. To prevent such incidents, it is vital that there should be effective management of hazards, including the use of safe systems of work. A permit-to-work system is an integral part of a safe system of work and can help to properly manage the wide range of activities which can take place close to these hazardous substances.

Different Types of Permits

There are several types of permits, each designed to control specific types of work activities. These include Hot Work Permit, Cold Work Permit, Electrical Work Permit, Equipment Disjointing Certificate/Breaking Containment Permit, Confined Spaces Entry Certificate, Machinery Certificate, Isolation Certificate, Excavation Certificate/Heavy Equipment Movement Certificate, Radiation Certificate, and Diving Certificate. Each of these permits has specific requirements and control measures to ensure the safety of the workers and the environment.

The Evolution of Permit to Work Systems: From Paper to Electronic

The document is primarily written around well-established paper-based permit-to-work systems, but where possible it accounts for the newer medium of electronic-based permit-to-work systems. With the advancement of technology, electronic permits have become an integral part of permit-to-work systems. These electronic systems offer several advantages, including ease of use, improved tracking, and better record-keeping. They also facilitate the transition from paper-based to electronic systems.

The Purpose and Function of PTW Systems

The primary purpose of a permit-to-work system is to ensure the proper authorisation of designated work. This work may be of certain types or work of any type within certain designated areas other than normal operations. The system makes clear to people carrying out the work the exact identity, nature, and extent of the job and the hazards involved. It also specifies the precautions to be taken, including safe isolation from potential risks such as hazardous substances, electricity, and other energy forms.

The Role of Permit-to-Work Systems in Risk Management

A permit-to-work system aims to ensure that proper consideration is given to the risks of a particular job or simultaneous activities at site. Whether it is manually or electronically generated, the permit is a detailed document which authorises certain people to carry out specific work at a specific site at a certain time, and which sets out the main precautions needed to complete the job safely.

The Communication Aspect of Permit-to-Work Systems

The permit-to-work system is also a means of communication between site management, supervisors, and those carrying out the work. The system ensures that everyone involved in the work is aware of the risks and the necessary precautions. This communication is crucial to ensure the safety of all workers and to prevent accidents.

The Objectives and Functions of Permit-to-Work Systems

The objectives and functions of a permit to work system can be summarised as ensuring the proper authorisation of designated work, making clear to people carrying out the work the exact identity, nature, and extent of the job, and the hazards involved. It also specifies the precautions to be taken, including safe isolation from potential risks such as hazardous substances, electricity, and other energy forms.

When are Permit-to-Work Systems Required?

PTW systems are typically required for non-production work such as maintenance, repair, inspection, testing, alteration, construction, dismantling, adaptation, modification, and cleaning. They are also necessary for non-routine operations and jobs where two or more individuals or groups need to coordinate activities to complete the job safely. Additionally, they are used when there is a transfer of work and responsibilities from one group to another.

Identifying Situations that Require a Permit-to-Work System

Permit to work systems are normally considered most appropriate to non-production work, non-routine operations, jobs where two or more individuals or groups need to co-ordinate activities to complete the job safely, and jobs where there is a transfer of work and responsibilities from one group to another. However, permit-to-work systems should not be applied to all activities, as experience has shown that their overall effectiveness may be weakened. Permits-to-work are not normally required for controlling general visitors to site or routine maintenance tasks in non-hazardous areas.

The Limitations of Permit-to-Work Systems

While Work permit system are a crucial tool for managing hazardous work, they are not a panacea for all safety issues. They should not be seen as an easy way to eliminate hazard or reduce risk. The issue of a permit does not, by itself, make a job safe – that can only be achieved by those preparing for the work, those supervising the work, and those carrying it out. In addition to the permit-to-work system, other precautions may need to be taken, and these will need to be identified in task risk assessments before any work is undertaken.

The Role of Work permit system in Non-Routine Operations

Non-routine operations often involve a higher level of risk than regular operations. These operations may involve unfamiliar procedures, unfamiliar equipment, or working in unfamiliar areas. In these situations, a permit-to-work system can be particularly valuable. The system ensures that the work is properly planned, that all risks are identified and mitigated, and that everyone involved in the work is aware of the precautions they need to take.

Work Not Requiring a Permit

- Routine work in established workshops and adjacent yards with boundaries.

- Routine material handling work in warehouses and lay down areas.

- Routine office work.

- Visual inspection or checking without using any tools in operation areas with verbal permission from assistant custodians.

- Work carried out by operation employees as part of their daily start-up and shutdown of the plant.

- Work carried out in designated areas declared as work permit-free by the client.

- Any work approved by the client on special request by the contractor.

The Essentials of PTW Systems

A permit-to-work system has several essential features. These include clear identification of who may authorise particular jobs and who is responsible for specifying the necessary precautions. The

system also requires training and instruction in the issue, use, and closure of permits. Furthermore, it includes monitoring and auditing to ensure that the system works as intended.

The Key Elements of a Permit-to-Work System

The key elements of a permit-to-work system include clear identification of who may authorise particular jobs and who is responsible for specifying the necessary precautions. The system also requires training and instruction in the issue, use, and closure of permits. Furthermore, it includes monitoring and auditing to ensure that the system works as intended.

The Process of Display, Suspension, and Handover in Permit-to-Work Systems

The Work permit system should include a process for the display of permits, the suspension of work, and the handover of work. The display of permits ensures that everyone involved in the work is aware of the permit and its conditions. The suspension of work allows for the safe stoppage of work if necessary. The handover of work ensures that when work is transferred from one group to another, all parties are aware of the status of the work and the precautions that need to be taken.

Understanding Permit Interaction and Hand-back Procedures

Permit interaction refers to the situation where multiple permits are in effect at the same time. This can occur when different groups are working on different aspects of a job, or when different jobs are being carried out in close proximity. The permit-to-work system should include procedures for managing permit interaction to ensure that all work is carried out safely. Hand-back procedures are also important to ensure that when work is completed, the site is returned to a safe condition.

Attachments of Work Permit

The work permit may require several attachments, including:

- Work method statement

- Work permit risk assessment

- Issuer, Executor, and permit holder PTW card copies

- Safety certificate of equipment

- Lifting plan if lifting activity is involved

- Drawing of location

- Entrant & Attendant copy if it’s a confined space permit, etc.

Authorisation and Supervision in Permit-to-Work Systems

The authorisation and supervision of work are crucial aspects of a permit-to-work system. The system should clearly identify who may authorise particular jobs and who is responsible for supervising the work. This ensures that the work is carried out safely and in accordance with the conditions of the permit.

The Importance of Authorisation in Permit-to-Work Systems

Authorisation is a crucial aspect of a permit-to-work system. It ensures that only competent individuals who understand the risks and precautions associated with the work are allowed to carry out the work. The authorisation process also ensures that the work is properly planned and that all necessary precautions are taken.

The Role of Supervision in Ensuring the Effectiveness of Permit-to-Work Systems

Supervision is another crucial aspect of a PTW system. Supervisors play a key role in ensuring that the work is carried out safely and in accordance with the conditions of the permit. They are responsible for monitoring the work, ensuring that all necessary precautions are taken, and intervening if necessary to prevent unsafe work.

The Challenges of Supervising a Large Number of Permits

Supervising a large number of permits can be a challenging task. It requires a high level of organisation and attention to detail. Supervisors must be able to keep track of all active permits, ensure that all work is carried out in accordance with the conditions of the permits, and intervene if necessary to prevent unsafe work. Despite these challenges, effective supervision is crucial for the success of a permit-to-work system.

Responsibilities in Permit-to-Work Systems

Various roles and responsibilities are associated with a permit-to-work system. These include employers or duty holders, site or installation managers, contractors and subcontractors, supervisory personnel, and individuals. Each of these roles has specific responsibilities within the system to ensure its effective operation.

The Responsibilities of Employers or Duty Holders in Permit-to-Work Systems

Employers or duty holders have a key role in a permit-to-work system. They are responsible for ensuring that the system is properly implemented and maintained. This includes ensuring that all necessary resources are provided, that all personnel are properly trained, and that the system is regularly audited and reviewed.

The Role of Site or Installation Managers in Permit-to-Work Systems

Site or installation managers also have important responsibilities in a permit-to-work system. They are responsible for overseeing the implementation of the system, ensuring that all work is properly authorised and supervised, and that all necessary precautions are taken. They are also responsible for ensuring that all personnel are properly trained and competent to carry out their roles within the system.

Understanding the Responsibilities of Contractors and Subcontractors

Contractors and subcontractors have a crucial role in a permit-to-work system. They are responsible for ensuring that they understand and comply with the conditions of the permit, that they carry out the work safely, and that they report any issues or concerns to the supervisor. They are also responsible for ensuring that they are properly trained and competent to carry out the work.

Training and Competence in Permit-to-Work Systems

Training and competence are crucial elements of a permit-to-work system. All personnel involved in the system must receive appropriate training and demonstrate competence in their roles. This ensures that everyone understands the system and can effectively carry out their responsibilities.

The Importance of Training in PTW Systems

Training is a crucial aspect of a permit-to-work system. It ensures that all personnel understand the system and can effectively carry out their roles. Training should cover the purpose and function of the system, the roles and responsibilities of different personnel, the process of issuing, using, and closing permits, and the procedures for managing permit interaction and hand-back.

Developing Competence in Permit-to-Work Systems

Competence is another crucial aspect of a permit-to-work system. All personnel involved in the system must demonstrate competence in their roles. This includes understanding the system, being able to carry out their roles effectively, and being able to identify and manage risks. Competence can be developed through training, experience, and ongoing assessment.

The Role of Training in Enhancing Safety Performance

Training plays a crucial role in enhancing safety performance in a permit-to-work system. By ensuring that all personnel are properly trained and competent, employers can significantly reduce the risk of accidents and incidents. Training should be ongoing and should include both initial training for new personnel and refresher training for existing personnel.

The Future of Permit-to-Work Systems

With the advancement of technology and the increasing complexity of industrial operations, the future of permit-to-work systems is likely to involve significant changes. These changes may include the increased use of electronic systems, the integration of permit-to-work systems with other safety management systems, and the use of advanced analytics to improve the effectiveness of the system.

The Impact of Technological Advancements on Permit-to-Work Systems

Technological advancements are likely to have a significant impact on permit-to-work systems. The increased use of electronic systems can improve the efficiency and effectiveness of the system, making it easier to issue, track, and close permits. Technology can also facilitate the integration of the permit-to-work system with other safety management systems, providing a more holistic approach to safety management.

The Potential of AI and Machine Learning in Permit-to-Work Systems

The potential of AI and machine learning in permit-to-work systems is significant. These technologies can be used to analyse data from the system, identify patterns and trends, and provide insights that can be used to improve the effectiveness of the system. For example, machine learning algorithms could be used to predict the likelihood of accidents based on historical data, allowing for proactive measures to prevent accidents.

The Future Challenges and Opportunities for Permit-to-Work Systems

The future of permit-to-work systems is likely to involve both challenges and opportunities. Challenges may include the need to adapt to new technologies, the increasing complexity of industrial operations, and the need to integrate the permit-to-work system with other safety management systems. Opportunities may include the potential to improve the effectiveness of the system through the use of advanced analytics, the potential to improve safety performance through better training and competence development, and the potential to reduce the risk of accidents through more effective risk management.

In conclusion, permit-to-work systems are a crucial tool for managing hazardous work in the petroleum, chemical, and allied industries. By ensuring the proper authorisation of work, providing a means of communication between different parties, and specifying the necessary precautions, these systems can significantly reduce the risk of accidents and incidents. However, to be effective, these systems require the commitment of all personnel, from employers and managers to contractors and individuals. With the right training, competence development, and technological support, permit-to-work systems can contribute significantly to safety performance in these industries.

Legal Requirements and Standards

Relevant legal requirements.

There are several legal requirements relevant to Permit-to-Work systems. These include the Health and Safety at Work etc Act 1974 , Confined Spaces Regulations 1997 , Control of Major Accident Hazards Regulations 1999, and many more.

Various standards and guidelines provide further guidance on Permit-to-Work systems. These include The safe isolation of plant and equipment Guidance HSE Books 1997, Task Risk Assessment Guide Step Change In Safety, and others.

FAQs on Permit to Work PTW Systems

1. what is a permit to work system.

A permit-to-work system is a formal, recorded process used to control work that is identified as potentially hazardous. It serves as a means of communication between site management, plant supervisors, and those who carry out the hazardous work. It is not just a permission to carry out a dangerous job, but an integral part of a system that determines how that job can be carried out safely.

2. Why are PTW systems important in hazardous industries?

Permit-to-work systems are vital in hazardous industries like the petroleum, chemical, and allied industries that store and process large quantities of hazardous substances. These systems help prevent serious incidents by ensuring effective management of hazards, including the use of safe systems of work. They ensure that only authorised and competent people carry out specific work at a specific site at a certain time, and that all necessary precautions are taken to complete the job safely.

3. How has the permit-to-work system evolved over time?

The permit-to-work system has evolved from being a paper-based system to an electronic one. With the advancement of technology, electronic permits have become an integral part of permit-to-work systems. These electronic systems offer several advantages, including ease of use, improved tracking, and better record-keeping. They also facilitate the transition from paper-based to electronic systems.

4. When is a permit-to-work system required?

Permit-to-work systems are typically required for non-production work such as maintenance, repair, inspection, testing, alteration, construction, dismantling, adaptation, modification, and cleaning. They are also necessary for non-routine operations and jobs where two or more individuals or groups need to coordinate activities to complete the job safely. Additionally, they are used when there is a transfer of work and responsibilities from one group to another.

5. What are the key elements of a permit-to-work system?

6. how does the process of authorisation and supervision work in a permit-to-work system, 7. what are the responsibilities of different stakeholders in a permit-to-work system, 8. why is training important in a permit-to-work system, 9. how can technology impact the future of permit-to-work systems, 10. what are the challenges and opportunities for permit-to-work systems in the future, share this:, leave a reply cancel reply.

Work Permit System

Jan 04, 2020

710 likes | 1.07k Views

Work Permit System. Course Contents 1. COURSE OBJECTIVES 2. WHAT IS WORK PERMIT SYSTEM 3. SAFE PERMIT APPLICATION FLOW 4. GUIDELINES AND REQUIREMENTS. Course Objectives. To familiarize you all with the requirements of the Work Permit System .

Share Presentation

- work permit

- work permits

- permit office

- work permit system

- safe work permit coordinator

Presentation Transcript

Course Contents 1. COURSE OBJECTIVES 2. WHAT IS WORK PERMIT SYSTEM 3. SAFE PERMIT APPLICATION FLOW 4. GUIDELINES AND REQUIREMENTS

Course Objectives • To familiarize you all with the requirements of the Work Permit System. • To familiarize you all with the OPERATIONAL requirements of the Work Permit System. • To JUSTIFY the need for an effective Work Permit System.

Course Objectives • To provide Permit Signatories with sufficient knowledge of the Work Permit System to enable them to fulfil their role • To provide non-signatory participants with sufficient knowledge of the Work Permit System to enable them to contribute to the integrity of the Work Permit System during their normal work activities. • The measure of any system or procedure is not how good it looks on paper, but how well it serves its purpose and how well it is MADE TO WORK in the field. • Proper implementation, consistent operation and good monitoring will ENABLE the work covered by a Work Permit to be executed in a safe and controlled manner.

Compliance with Work Permit System Compliance with the Work Permit System is applicable to ... Subcontractors Employees All Contractors ( If they work in our Construction areas)

What is Work Permit System ? • The Health and Safety of Personnel • The integrity of the operation / Facility / Equipment ....The Work Permit System is a formal Safety System, the objective of which is to control specific work activities which are known to be potentially hazardous in relation to ...

“ A Work Permit is not a permission to carry out hazardous jobs. It is an essential part of a system which determines how that job can be carried out safely and clearly identifies the controls to be put in place.” “ The issue of a permit does not by itself make a job safe : that can only be achieved by those preparing for the work and those carrying it out.”

Activities covered included but not limited to: • All works in Live / Construction Areas • Activities liable to give rise to flammable atmospheres, e.g. Painting insulation, etc. • Hot work in live areas or areas subject to potential flammable atmospheres as above • Excavation Works. • Heavy Lifts / Crane Activities / Rigging Works • Use of Manbaskets • Explosion Devices • Confined Spaces • Radiation Etc.

Working on live electric systems • Electrical and Mechanical testing • Electrical Energisation • Pneumatic integrity pressure testing • Flushing, Blowing and line cleaning operation • Removal of handrails and gratings plus working at heights on incomplete walkways • Commissioning activities e.g. Tightness testing, simulation runs, inerting, dryouts, catalyst loading, preparing the plant for operation. • Special conditions, e.g. Emergency Permits at night • Working over water outside of fixed barriers

SAFE WORK PERMIT • Safe work permit must be reviewed and signed by Superintendent / Supervisor / Foreman. • Safe work permit must be validated and approved by (contractor / owner) HSE permit control personnel. • Safe work permit control number indicated, date/ date duration was valid and work area should be specified on its exact location & elevation. • Description of work should be more specific to identify high-risk activities. • Live systems in the work area must be identified (temporary / permanent underground electrical cable, piping etc). • Work execution plan should contain specific detail of work to be done or brief description of planned work to identify the predictable hazards. • Precautionary measures should be written specifically & accordingly appropriate to the hazards associated with the intended work.

HOT WORK PERMIT • Follow the steps in checking the safe work permit. • Work to be done must be specific. • Equipment number shall be indicated (if any). • Review all check off items on general preparation checklist and verify with work in-charge if requirement was met • If conditions are all not met a special procedure should be prepared. • Protective equipment checklist is check-off. • Supervisor to write sign his name approving the hot work permit. • If work is not completed fill in the date, time and status of the uncompleted work and sign out the safe work permit. • If work is completed ensure that area was cleaned after the work then check off the checklist & sign out the safe work permit.

CONFINED SPACE ENTRY PERMIT • Follow the steps in checking the safe work permit. • Location and description of confined space shall be specifically identified. • Purpose of entry briefly explained. • List all materials to be taken into the confined space. Counter check if all materials were removed after the completion of work. • Identify the hazards in the confined space. (Physical / atmospheric hazards. • Supervisor shall ensure that all requirement of the entry permit was met, reviewed and check-off slots marked before allowing entry.

Additional requirements could be included as part of the permit as added instructions or precautions to ensure the safety of all the authorized entrants. • All authorized entrants shall be poses an individual confined space access pass / ID. • Assign a certified confined space attendant. • Maintain an entry –exit personnel accountability log. • A competent person shall do test for atmospheric hazards. • Evaluate the confined space for physical hazards. • Contact persons name & phone number should be indicated. • Supervisor and safety in-charge should sign the bottom line of the permit as acceptance & acknowledgement that work can commence safely in the confined space.

CRANE AND LIFTING WORKS: • Fill-up the Equipment Lift Record Card • Description of work • Assigned crafts • Rigging equipments to be use. • Material / equipment to be lifted • Type of lifting device (make, model and capacity) • Responsible supervision should sign over his printed name. • Fill-up the Job Safety Plan, duly signed by the crane operator and rigger, (for above 25 tons; Rigging Supervisor & HSE Manager) • Description of work • Assigned crafts • Rigging equipments to be use. • Material / equipment to be lifted • Type of lifting device (make, model and capacity) • Ensure that requirement was met and check-off. • Attach an area plot plan clearly indicating work location and lighting positions.

WORK PERMIT APPLICATION FLOW FOR DAILY WORK ACTIVITIES: STEP 1 • Safe Work permit with the necessary attachments i.e. area plot plan, excavation, confined space, rigging / lifting, hot work etc., should be prepared by the supervisor / permit applicant one (1) day before the work execution. It must be properly filled-up and signed by the concerned supervisor (See attached guidelines for SWP requirements). • Submit Safe Work Permit to HSE Permit Coordinator at the HSE permit / training room not later than 8:00 AM one (1) day before the work execution. • Safe Work Permit must be registered at permit control logbook.

STEP 2 • Safe Work Permit Coordinator will check or review the work permits to ensure that the following were complied: • Permit duly signed and reviewed by FM, Supv’r, Supt. • Special precaution and equipment required are checked • All required attachments are provided. • Safe Work Permit control number indicated, date was valid and area of work should be specific (i.e. elevation, column no. etc.). • Brief description of work and detailed JSA for the specific job, to identify the hazards & safety precautions.

Before 10:00 AM, all work permits reviewed and approved by the HSE Permit Coordinator will be forwarded to Contractor HSE Permit office for approval, with a receiving list. • Approved SWP will be collected by HSE Permit Coordinator from Contractor permit office at 3:00 PM of the same day • At 4:00 PM (1day before work execution) or 6:00am (day of work execution), Supervisor / permit applicant should collect their work permit at the HSE training / permit office. • All work permits intended for Saturday activities shall be applied 2 days before the day of work execution (Thursday).

FRIDAY WORKS: • Every Thursday, responsible supervisors / department heads shall submit list of personnel for specific activity (see attached form, employee list for overtime works) and submit to HSE Permit Coordinator at HSE training/permit office not later than 8:00 AM. • HSE Permit Coordinator will review the Request for Overtime, including relevant work permit and other attachment, i.e. emergency contact person or duty officer / line supervision, area plot plan/location, etc. • Before 10:00 AM, all work permits reviewed and approved by the HSE Permit Coordinator will be forwarded to Contractor for approval, with a receiving list. • Contractor will release the approved extended overtime at 3:00 PM and applicants will retrieve the Permits at Permit Office, up to 4:30 PM.

Responsibilities

Construction Manager has overall responsibility for ensuring that provision are made for the implementation of safe systems of work . He is responsible for appointing all personnel who are authorized to sign Work Permits. Their names will appear on the Authorized Signatories-HSE List.

Issuing Authority The Issuing Authority should be a person of sufficient seniority and authority to determine priorities of work. He should be fully familiar with the works on-going within the areas and the nature of those works. Personnel to fulfill this role are likely to be Area Construction Manager, or their authorized substitute. The application of the “Work Permit” Procedure, for any Area or System, shall be the responsibility of the Area Construction Manager / Shift Supervisors who are responsible for that Area or System at time of Issue. They will liaise with the HSE Manager in all respects.

HSE Manager • The HSE Manager has the responsibility for conducting Permit to Work training, monitoring the operation of the Permit to Work Procedure by the Field Operation Groups, updating the Authorized Signatory List: as per HSE Record and proposing the list for appointment. • The authorized signatories list shall detail the status of the signatories. • He also has responsibility to provide advice and guidance on the activities and precautions to be governed by the Work Permit System.

Permit Receiver A competent person nominated by Contractor or the Subcontractor, with supervisory responsibilities, who has been trained and is familiar with the requirements of the “Work Permit” system.

The Permit Receiver shall ensure that ... He has successfully completed Work Permit Course. The work crew has received adequate instruction / been adequately briefed in the Work Permit System.He discusses the job fully, inclusive of any integral hazards, the required safety precautions, including isolation and PPE, with the Authorized Supervisor.The permit is posted, prominently, on the job site.The work crew is briefed on the permit details, including any potential hazards, and on all precautions taken, or to be taken.

* The precautions are maintained throughout the work activity.* The workers understand that, if circumstances change, the work must be stopped and advice sought from the authorised supervisor of the permit.* The work crew stays within the limitations set on the permit (physical boundaries, type of work and validity time).* On completion or suspension of the work, the site is left in a safe condition and the Supervisor informed.

Supervisor The Supervisor shall ensure that : The Supervisor has responsibility for the work to which the Permit relates. He is responsible for ensuring that the correct precautions and isolations are detailed in the Permit and are correctly implemented in the field. He is also responsible for the daily renewal of the Permit after checking the site and set up of the work ensuring that all precautions are still in place and circumstances requiring amendments to the Permit have not arisen.

When permits are raised by Permit Receiver, the same person cannot also be the Permit Issuer.The Permit Issuer shall ensure that : • The person in charge of the job ( The Contractor/Permit Receiver fully understands the nature of the applicable work. • All the hazards associated with the work are identified. • All the necessary precautions are implemented, including isolations, before work begins. • All person, who may be affected by the work, are informed; before work begins, when work is suspended and when the work is complete.

That permit, for task that may interact, are cross-referenced. • The effective arrangements are made for the worksite to be examined; before work begins, as appropriate and upon completion of work. • Sufficient time is spent, at shift handover, to discuss all on going or closed permits, with the in-coming Authorized Person.. • The Sufficient Supervisors visits are made to the work site, during progress of the work, to confirm the consistent application of the permit requirement.

HSE Permit Coordinator The HSE Permit Coordinator is responsible for ensuring that all sections of the Permit forms are completed by authorised signatories prior to issue. He is responsible for full clerical control of the system including retention of the closed out Work Permit for the defined period. All active Permits will be marked on a plot plan displayed on the wall of the Permit Office.

OTHERS Work Permit Monitoring by: 1. HSE 2. Client Representative 3. Audit / Inspection Teams May contribute to the integrity of the Work Permit System by ..... * Ensuring that the permit copies are displayed at the Work Site and present in Work Permit office as required.

Checking that the work is being carried out in accordance with the time parameters of the permit. • Checking that the work is being carried out in accordance with the physical parameters of the permit. • Checking that all foreseeable hazards have been identified and that arrangements are in place to control or eliminate those hazards. • Asking question of work crews, to test their understanding of the Work Permit System, the permit which is in place, the job it covers, the hazards involvedand the applicable safety arrangements.

Completion of the Work Permit Form Upon completion of the job, and when isolation have taken place, the contractor / Supervisor shall, via the Client Supervisor (Authorized) request the necessary de-isolation. The authorised person shall instruct the electrician/ mechanic, as applicable to carry out the necessary de-isolation if is it do so.

REMEMBER!!!!! System such as Work Permit are only a burden BEFORE a serious incident ...... they are not a burden AFTER the incident, when the record shows clearly that YOUR responsibilities had been efficiently executed. ( Work Permit is A Legal Document )

- More by User

Hot Work Permit Program

Slide 2 (of 20). Course Objectives. Describe how CCSD Hot Work Permit Program is used to managed hot work activities.Identify responsibilities and components of the CCSD Hot Work Permit Program.. Slide 3 (of 20). Every year fires occur, which could have been prevented had employees used appropriate fire prevention measures.CCSD requires the use of the Hot Work Permit to:Protect employees and District property.Prevent ignition of combustible and flammable materials from occurring..

933 views • 20 slides

THE WORK PERMIT SYSTEM (Reference document: AIGA 011/04 «Work Permit Systems»)

THE WORK PERMIT SYSTEM (Reference document: AIGA 011/04 «Work Permit Systems»). Training Package 06/06. Asia Industrial Gases Association 3 HarbourFront Place, #09-04 HarbourFront Tower 2, Singapore 099254 Internet: http//www.asiaiga.org. Acknowledgement.

891 views • 19 slides

Work Permit & Work Experience Education

Presented by Bob Reedy Teacher/Coordinator-Colton Joint Unified School District. Work Permit & Work Experience Education.

871 views • 51 slides

Hong Kong Work Permit Visa

Hong Kong work permit Visa has different schemes in Hong Kong immigration. Hong Kong work permit requirements and application conditions are provided

204 views • 6 slides

Permit to Work System

PTWS – Permit Orientation Training. Permit to Work System. Permit Orientation Training. Typical work at our site. Introducing: Sue – who has come to repair the toilet at Z Mana Fred – who has come to install new electrical socket Jack – who has come to install a tank for a new site

5.02k views • 39 slides

Corporate Permit to Work System - Songa Offshore

Corporate Permit to Work System - Songa Offshore . Ref: HQS-013-02-006 – Permit to Work Procedure. Doc Control No.: HQS-013-17-002. Rev 4. Learning Objectives. At the completion of this session, personnel should be able to:

1.69k views • 44 slides

New Work Permit

New Work Permit. Service Definition :- It is a service provided by the Ministry to any establishment wishing to employ an expatriate worker who has never worked before in a state Application Form New work permit application Conditions

394 views • 9 slides

Safe Work Permit and You

Safe Work Permit and You. MEC Monthly Safety Topic/Discussion Recent Incident Follow Up. SWP Discussion:. Step #1: Get the Scope right ID tools? Job Location? Work to be completed?. SWP Discussion. Step #2: Understand the Hazards. PPE understood? Hazards of area/job?

228 views • 6 slides

PTWS – Orientation Training. Permit to Work System. Orientation Training. Typical work at our site. Introducing: Sue – who has come to repair the toilet at Z Mana Fred – who has come to install new electrical socket Jack – who has come to install a tank for a new site

1.35k views • 39 slides

Minor Work Permit

Minor Work Permit. Issuing Officer Training J. Ronald DeJuliis, Commissioner. Maryland Work Permit Process.

306 views • 8 slides

Permit Tracking System

Permit Tracking System. CTPermits. Our Mission Statement: To offer the most cost-effective, intelligent, and achievable Data Technology solutions to help cities to accomplish their daily tasks.

405 views • 19 slides

WORK PERMIT

WORK PERMIT. A.K.SINGH, SAFETY MANAGER INDIANOIL CORPORATION LTD. BARAUNI REFINERY, INDIA. ROAD MAP. The session will include the following: Presentation on BR Work Permit system followed by discussion Role of Issuing & Executing Authority Exercise how to fill the permit

3.95k views • 69 slides

Post Graduation work permit & OFF-CAMPUS WORK PERMIT

Post Graduation work permit & OFF-CAMPUS WORK PERMIT. International services & programs Abroad. Arthur Chen Manager, International Student Services GLN-B210 Brock University | International Services and Programs Abroad Niagara Region | 500 Glenridge Ave. | St. Catharines, ON L2S 3A1

501 views • 17 slides

1.66k views • 33 slides

Work Permit Procedure

Work Permit Procedure. Objective This procedure shall ensure that work identified as potentially hazardous is controlled by a documented system, that personnel performing such work are instructed in writing and that personnel affected by work are safeguarded.

1.47k views • 37 slides

Work Permit Canada - xiphiasimmigration.com

XIPHIAS Immigration helps you to get the Work Permits, Live-in Caregiver at Canada as a Process of Canada Immigration.

227 views • 2 slides

Training Work Permit Singapore

European Overseas consultants helps you to get Singapore tourist visa with full transparency from any where in India. We are Ludhiana, Punjab based immigration consultants.

420 views • 12 slides

Insights about Denmark Work Permit

Denmark is a standout amongst the most sought spot to live to have a superior life. The low atmosphere rate, legitimate general wellbeing administration and the flawless environment made Denmark as the most fancied areas for individuals. The spot is protected, secure furthermore offers some incredible open welfare benefits, all such fabulous advantages make this place more lucrative.

128 views • 2 slides

nafta work permit visa

Xiphias Immigration offers you services like it work visa for canada, Corporate migration services, nafta work permit, nafta work permit visa, visa services for engineers, Intra company transfers VISA, Corporate immigration services https://corporatevisaservices.wordpress.com/2017/05/24/north-american-free-trade-agreement-visa-nafta/

128 views • 5 slides

93 views • 8 slides

Work Permit Extension Canada

Having confusions related to work permit extension? Feel free to get in touch with us and get all your work permit, its processing time and extensions questions get answered by our team of the best Immigration Consultant Surrey.

111 views • 7 slides

Work Permit Software and Hot Work Permit Software

Want to make your work easier? SHEQ PORTAL LIMITED provides Hot work permit software, it is integrating permits like hot work, confined space, height entry etc into one system. For more details contact us on 353 21 453 6034.

101 views • 7 slides

File : Elektrostal, Moscow Oblast, Russia - panoramio (150).jpg

File history, file usage on commons.

Original file (4,288 × 2,848 pixels, file size: 5.3 MB, MIME type: image/jpeg )

Summary [ edit ]

Click on a date/time to view the file as it appeared at that time.

You cannot overwrite this file.

The following page uses this file:

- User:Stolbovsky/Recent uploads/Moscow/2017 March 1-10

This file contains additional information such as Exif metadata which may have been added by the digital camera, scanner, or software program used to create or digitize it. If the file has been modified from its original state, some details such as the timestamp may not fully reflect those of the original file. The timestamp is only as accurate as the clock in the camera, and it may be completely wrong.

Structured data

Items portrayed in this file, copyright status, copyrighted, copyright license, creative commons attribution 3.0 unported, coordinates of the point of view, 55°47'5.8942"n, 38°26'39.3252"e, captured with, 8 september 2013, source of file, file available on the internet, exposure time, 0.0025 second, focal length, 14 millimetre, instance of.

- 2013 in Elektrostal

- Elektrostal

- Moscow Oblast photographs taken on 2013-09-08

- Panoramio images reviewed by trusted users

- Photos from Panoramio

- Files with coordinates missing SDC location of creation

- Panoramio files uploaded by Panoramio upload bot

- Pages with maps

Navigation menu

IMAGES

VIDEO

COMMENTS

The Receiver shall produce the permit to the Contractor responsible personnel for the work requested in the permit for review and verification by 15:00 hours a day before the commencement of the activity/work. As rapidly as the assessment & verification were made, the PTW Receiver shall deliver the verified allow to the HSE Permit Coordinator.

Permit to Work Training. Dec 16, 2017 • Download as PPTX, PDF •. 11 likes • 10,038 views. SUDHEER KUMAR KALYANAM. All types of Works Permits respective hazards and safe preccautions and safe system of work. Engineering. 1 of 29. Download now. Permit to Work Training - Download as a PDF or view online for free.

Permit to work training. Jun 1, 2021 •. 8 likes • 12,004 views. Karnav Rana. Permit To Work Types of Permit To Work Hot Work Permit Confined Space Entry Permit Electrical Permit Excavation Permit Radiography Permit Crane Critical Lifts Permit Man Basket Operation Permit Issuer Responsibilities Permit Receiver Responsibilities HSE Permit ...

A Permit to Work (PTW) serves the primary purpose of ensuring safety in the workplace. It is a formal document that authorizes specific activities, especially those with potential risks to health and safety. The PTW helps in assessing and mitigating these risks, making sure that all necessary precautions are taken before hazardous work begins. 2.

A permit to work (PTW) system is a process to keep employees safe during hazardous and nonstandard operations. It involves assessing the risks, establishing a proper safety protocol based on the risks, and proper communication throughout the entire process. The PTW system is designed to mitigate environmental, health, sustainability, and safety ...

Permits to Work (PTW) are a formal, documented, systematic way to control certain activities that present a high level of risk. The permit forms an essential part of a safe system of work. Employers have a duty to ensure that PTW are in place when required, and employees have a duty to co-operate with the agreed terms and conditions of the permit.

A permit-to-work system is a formal written system used to control certain types of work that are potentially risky. It is a document which specifies the work to be done and the precautions to be taken. Permits are an essential part of safe systems of work for many industries.

Permit To Work Training HSE Presentation.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses permit to work training and outlines the permit to work system used to control access and ensure safety for personnel working in hazardous areas, including defining the roles and responsibilities of permit ...

Permit to Work System PI Training V3 - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document provides an orientation for Z's Permit to Work System (PTWS). It introduces 4 contractors coming to work and summarizes the key aspects of the PTWS, including: 1. The PTWS requirements to identify hazards and ensure ...

7.1.11 - Work On Electrical Systems. The procedure is applicable to all vessels when installing, testing, maintaining, repairing, altering, removing or replacing of electrical equipment where ship staff may be exposed to the risk of suffering from severe or even fatal shocks. Right to Stop Work and Cancel Permits.

PTW Slides - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides an overview of a training workshop on a PTW (permit to work) system. The objectives are to familiarize participants with the purpose and applications of the PTW system. It will cover legal requirements, definitions of key terms like employer ...

Frequently fatalities, serious injuries to seafarers or the environment are caused by failing to follow Safety Management System procedures and manuals, failure in implementation of the Permit to Work System, or the requirements have been ignored or misunderstood when the permit has been issued. 4 What is PTW System A Permit to Work is a formal ...

PTWS - Permit Orientation Training. Permit to Work System. Permit Orientation Training. Typical work at our site. Introducing: Sue - who has come to repair the toilet at Z Mana Fred - who has come to install new electrical socket Jack - who has come to install a tank for a new site. 4.99k views • 39 slides

Slide Formats. 16:9. 4:3. Leverage our Permit to Work System PPT template to describe the formal documented system that manages activities and protects workers in potentially hazardous work conditions. Managers and supervisors can use this fully editable deck to highlight the significance of this system in minimizing safety, health ...

PPT ON PERMIT TO WORK, by Ekemezie E. May 15, 2015 • Download as PPTX, PDF •. 21 likes • 14,948 views. Ekemezie Emeanuwa, NEBOSH, OSHA, ASNT II. 1 of 16. Download now. PPT ON PERMIT TO WORK, by Ekemezie E - Download as a PDF or view online for free.

3 years of teaching experience. Qualification: M.Tech. (Production Engineering) Teaches: Chemistry, English, Hindi, Physics, Drawing, Mechanical. Contact this Tutor. Permit to Work System (PTWS) Presented by: Sandeep Kumar. PTW System SCOPE DEFINITIONS PROCEDURE RESPONSIBILITIES Nominated Managers (department / functional head) shall The Safety ...

Mine Safety Training. PowerPoint Presentations. This how-to video will walk you through everything you need to know to get started using the translation features of PowerPoint. For more information on using Translator with Microsoft PowerPoint, visit here . Certain jobs always require that a Safe Work Permit be issued by a qualified individual.

PTWS - Permit Orientation Training. Permit to Work System. Permit Orientation Training. Typical work at our site. Introducing: Sue - who has come to repair the toilet at Z Mana Fred - who has come to install new electrical socket Jack - who has come to install a tank for a new site. 4.98k views • 39 slides

Search 42 Elektrostal' local handyman services to find the best handyman service for your project. See the top reviewed local handyman services in Elektrostal', Moscow Oblast, Russia on Houzz.

010 Permit to Work - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses permit to work systems which are formal procedures used to control access and activities during construction work. There are various types of permits including hot work, confined space entry, electrical, excavation, radiography ...

You are free: to share - to copy, distribute and transmit the work; to remix - to adapt the work; Under the following conditions: attribution - You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

You are free: to share - to copy, distribute and transmit the work; to remix - to adapt the work; Under the following conditions: attribution - You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

Search 87 Elektrostal' custom ironworkers to find the best ironworker for your project. See the top reviewed local ironworkers in Elektrostal', Moscow Oblast, Russia on Houzz.