Storage Location Assignment Problem in a Warehouse: A Literature Review

- Conference paper

- First Online: 23 May 2023

- Cite this conference paper

- Lucy Medrano-Zarazúa 7 ,

- Jania Astrid Saucedo-Martínez 7 &

- Johanna Bolaños-Zuñiga 7

Part of the book series: EAI/Springer Innovations in Communication and Computing ((EAISICC))

Included in the following conference series:

- International Conference on Computer Science and Health Engineering

211 Accesses

Warehouse management is one of the many companies’ operations that is a main part of the supply chain. Storage takes up between 2 and 5% of the total cost of sales in an organization (Hwang and Cho (Comput Ind Eng 51(2):335–342, 2006)). The storage allocation of products is an activity inside the warehouses that help managing a good flow of the products. It is a complex issue since it depends on many parameters such as the number of spaces, the quantity of products, and the number of rack levels that are in the warehouse, and the resources to move, among other things. When optimizing the flow of operations in the warehouse, good decisions have to be made, and, in this work, through a systematic literature review, different academic papers published between 2005 and 2021 on the SLAP are analyzed and classified according to the solution methodology, objectives, and other characteristics, so that the most used methods in the literature are obtained for this type of problem as well as the parameters that are most taken into account to solve it.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Durable hardcover edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Accorsi, R., Manzini, R., Bortolini, M.: A hierarchical procedure for storage allocation and assignment within an order-picking system. a case study. Int. J. Logist. Res. Appl. 15 (6), 351–364 (2012).

Google Scholar

Alvarán, G., D.F.E., Hincapié, J.A.G., Correa, J.H.R.: Aplicación de la programación entera binaria para resolver el problema simple de balanceo de linea de ensamble: un caso de estudio. Scientia et technica 2 (50), 84–89 (2012)

Ang, M., Lim, Y.F., Sim, M.: Robust storage assignment in unit-load warehouses. Manag. Sci. 58 (11), 2114–2130 (2012). https://doi.org/10.1287/mnsc.1120.1543

Article Google Scholar

Ansari, M., Smith, J.S.: Gravity clustering: A correlated storage location assignment problem approach. In: 2020 Winter Simulation Conference (WSC), pp. 1288–1299. IEEE, Piscataway (2020)

Bahrami, B., Piri, H., Aghezzaf, E.-H.: Class-based storage location assignment: an overview of the literature. In: 16th International Conference on Informatics in Control. Automation and Robotics (ICINCO 2019), pp. 390–397. Scitepress, Setúbal (2019)

BalaSundareshwaran, A., Abdul Rahaman, S., Balasubramani, K., Kumaraswamy, K., Muthuvairavasamy, R.: Habitat risk assessment along coastal Tamil Nadu, India—An integrated methodology for mitigating coastal hazards. In: Coastal Zone Management, pp. 515–542 (2018). ISBN 978-0-12-814350-6. https://doi.org/10.1016/B978-0-12-814350-6.00023-9

Ballesteros-Riveros, F.A., Arango-Serna, M.D., Adarme-Jaimes, W., Zapata-Cortes, J.A.: Storage allocation optimization model in a Colombian company. Dyna 86 (209), 255–260 (2019)

Battini, D., Glock, C.H., Grosse, E.H., Persona, A., Sgarbossa, F.: Human energy expenditure in order picking storage assignment. Comput. Ind. Eng. 94 (C), 147–157 (2016). ISSN 0360-8352. https://doi.org/10.1016/j.cie.2016.01.020

Bazaraa, M.S., Sherali, H.D., Shetty, C.M.: Nonlinear Programming: Theory and Algorithms, 3 edn. Wiley-Interscience, Hoboken (2006)

Book MATH Google Scholar

Ben-Tal, A., El Ghaoui, L., Nemirovski, A.: Robust optimization. In: Robust optimization. Princeton University Press, Princeton (2009)

Bertsekas, D.P.: Rollout algorithms for discrete optimization: A survey. In: Handbook of Combinatorial Optimization, Zu, D., Pardalos, P. (Eds.). Springer, Berlin (2010)

Besharati Givi, M.K., Asadi, P., Bag, S., Yaduwanshi, D., Pal, S., Heidarzadeh, A., Mudani, S., Kazemi-Choobi, K., Hanifian, H., Braga, D., Silva-Magalhães, A., Moreira, P., Infante, V., Vidal, C., Akinlabi, E., Akinlabi, S., Arora, H., Mukherjee, S., Grewal, H., Zolghadr, P.: Advances in Friction-Stir Welding and Processing. Elsevier, Amsterdam (2014). ISBN 978-08-57094-54-4

Bindi, F., Manzini, R., Pareschi, A., Regattieri, A.: Similarity-based storage allocation rules in an order picking system: an application to the food service industry. Int. J. Logist. Res. Appl. 12 (4), 233–247 (2009)

Bodnar, P., Lysgaard, J.: A dynamic programming algorithm for the space allocation and aisle positioning problem. J. Operat. Res. Soc. 65 (9), 1315–1324 (2014). https://doi.org/10.1057/jors.2013.64

Bolanos-Zuñiga, J., Saucedo, J., Salais, T., Marmolejo, J.: Optimization of the storage location assignment and the picker-routing problem by using mathematical programming. Appl. Sci. 10 , 534 (2020). https://doi.org/10.3390/app10020534

Bortolini, M., Botti, L., Cascini, A., Gamberi, M., Mora, C., Pilati, F.: Unit-load storage assignment strategy for warehouses in seismic areas. Comput. Ind. Eng. 87 (C), 481–490 (2015). ISSN 0360-8352. https://doi.org/10.1016/j.cie.2015.05.023

Boysen, N., Stephan, K.: The deterministic product location problem under a pick-by-order policy. Discrete Appl. Math. 161 (18), 2862–2875 (2013). ISSN 0166-218X. https://doi.org/10.1016/j.dam.2013.07.002 . https://www.sciencedirect.com/science/article/pii/S0166218X13003120

Brynzér, H., Johansson, M.I.: Storage location assignment: using the product structure to reduce order picking times. Int. J. Prod. Econ. 46 (1), 595–603 (1996)

Charris, E., Rojas-Reyes, J., Montoya-Torres, J.: The storage location assignment problem: a literature review. Int. J. Ind. Eng. Comput. 10 , 07 (2018). https://doi.org/10.5267/j.ijiec.2018.8.001

Chen, L., Langevin, A., Riopel, D.: The storage location assignment and interleaving problem in an automated storage/retrieval system with shared storage. Int. J. Prod. Res. 48 (4), 991–1011 (2010)

Article MATH Google Scholar

Chiang, D.M.-H., Lin, C.-P., Chen, M.-C.: The adaptive approach for storage assignment by mining data of warehouse management system for distribution centres. Enterp. Inf. Syst. 5 (2), 219–234 (2011). https://doi.org/10.1080/17517575.2010.537784

Cormen, T.H., Leiserson, C.E., Rivest, R.L., Stein, C.: Introduction to Algorithms. MIT Press, Cambridge (2022)

MATH Google Scholar

Cruz-Aceves, I., Cervantes-Sanchez, F., Hernandez-Aguirre, A., Hernández-González, M.A., Solorio-Meza, S.: Binary descriptor design for the automatic detection of coronary arteries using metaheuristics. In: Advanced Machine Vision Paradigms for Medical Image Analysis, pp. 169–188. Elsevier, Amsterdam (2021)

Cruz-Domínguez, O., Santos-Mayorga, R.: Artificial intelligence applied to assigned merchandise location in retail sales systems. South African J. Ind. Eng. 27 (1), 112–124 (2016)

Curtin, K.M.: Operations research. In: Kempf-Leonard, K. (ed.) Encyclopedia of Social Measurement, pp. 925–931. Elsevier, New York (2005). ISBN 978-0-12-369398-3. https://doi.org/10.1016/B0-12-369398-5/00534-X . https://www.sciencedirect.com/science/article/pii/B012369398500534X

Dantzig, G.B.: Reminiscences about the origins of linear programming. Oper. Res. Lett. 1 (2), 43–48 (1982)

Article MathSciNet Google Scholar

Dawn Thompson, J.: Statistical alignment approaches. Statist. Bioinformat. 1 , 43–51 (2016)

Dechter, R.: chapter 7-stochastic greedy local search. In: Constraint Processing, The Morgan Kaufmann Series in Artificial Intelligence, pp. 191–208. Morgan Kaufmann, Burlington (2003)

Dijkstra, A., Roodbergen, K.J.: Exact route-length formulas and a storage location assignment heuristic for picker-to-parts warehouses. Transport. Res. Part E Logist. Transport. Rev. 102 , 04 (2017). https://doi.org/10.1016/j.tre.2017.04.003

Ene, S., Öztürk, N.: Storage location assignment and order picking optimization in the automotive industry. Int. J. Adv. Manufact. Technol. 60 , 1–11 (2011). https://doi.org/10.1007/s00170-011-3593-y

Ene, S., Küçükoğlu, İ., Aksoy, A., Öztürk, N.: A genetic algorithm for minimizing energy consumption in warehouses. Energy 114 , 973–980 (2016)

Flórez, J.M.C.: Métodos exactos y heurísticos en la solución de problemas de redes de transporte en las cadenas de suministros. Lupa Empresarial 1 , 44–63 (2017)

Franzke, T., Grosse, E.H.,, Glock, C.H., Elbert, R.: An investigation of the effects of storage assignment and picker routing on the occurrence of picker blocking in manual picker-to-parts warehouses. Int. J. Logist. Manag. 1 , 7–17 (2017)

Frazelle, E.H.: Stock location assignment and order picking productivity. PhD Thesis, Georgia Institute of Technology (1989)

Fumi, A., Scarabotti, L., Schiraldi, M.M.: Minimizing warehouse space with a dedicated storage policy. Int. J. Eng. Business Manag. 5 , 21 (2013). https://doi.org/10.5772/56756

Gagliardi, J.-P., Renaud, J., Ruiz, A.: On sequencing policies for unit-load automated storage and retrieval systems. Int. J. Prod. Res. 52 (4), 1090–1099 (2014)

Gu, J., Goetschalckx, M., McGinnis, L.F.: Research on warehouse operation: a comprehensive review. Eur. J. Operat. Res. 177 (1), 1–21 (2007). ISSN 0377-2217. https://doi.org/10.1016/j.ejor.2006.02.025 . https://www.sciencedirect.com/science/article/pii/S0377221706001056

Gu, J., Goetschalckx, M., McGinnis, L.F.: Solving the forward-reserve allocation problem in warehouse order picking systems. J. Operat. Res. Soc. 61 (6), 1013–1021 (2010). https://doi.org/10.1057/jors.2009.39

Guerriero, F., Musmanno, R., Pisacane, O., Rende, F.: A mathematical model for the multi-levels product allocation problem in a warehouse with compatibility constraints. Appl. Math. Modell. 37 (6), 4385–4398 (2013). ISSN 0307-904X. https://doi.org/10.1016/j.apm.2012.09.015 . https://www.sciencedirect.com/science/article/pii/S0307904X12005124

Guerriero, F., Pisacane, O., Rende, F.: Comparing heuristics for the product allocation problem in multi-level warehouses under compatibility constraints. Appl. Math. Modell. 39 (23–24), 7375–7389 (2015)

Ho, Y.-C., Liu, C.-F.: A design methodology for converting a regular warehouse into a zone-picking warehouse. J. Chinese Instit. Ind. Eng. 22 (4), 332–345 (2005)

Howard, R.A.: Dynamic programming. Manag. Sci. 12 (5), 317–348 (1966)

Hwang, H.S., Cho, G.S.: A performance evaluation model for order picking warehouse design. Comput. Ind. Eng. 51 (2), 335–342 (2006). ISSN 0360-8352. https://doi.org/10.1016/j.cie.2005.10.002 . https://www.sciencedirect.com/science/article/pii/S0360835206000994 . Special Issue: Logistics and Supply Chain Management

Jana, M., Biswas, S.: Intelligent and smart enabling technologies in advanced applications: recent trends. Recent Trends Comput. Intell. Enabled Res. 1 , 355–365 (2021)

Kim, B.S., Smith, J.S.: Slotting methodology using correlated improvement for a zone-based carton picking distribution system. Comput. Ind. Eng. 62 (1), 286–295 (2012)

Lacey, A., Luff, D.: Qualitative Data Analysis. Trent Focus, Sheffield (2001)

Larco, J., De Koster, R., Roodbergen, K.J., Dul, J.: Managing warehouse efficiency and worker discomfort through enhanced storage assignment decisions. Int. J. Prod. Res. 55 , 1–16 (2017). https://doi.org/10.1080/00207543.2016.1165880

Le-Duc*, T., De Koster, R.M.B.M.: Travel distance estimation and storage zone optimization in a 2-block class-based storage strategy warehouse. Int. J. Prod. Res. 43 (17), 3561–3581 (2005)

Malekian, A., Chitsaz, N.: Concepts, procedures, and applications of artificial neural network models in streamflow forecasting. In: Advances in Streamflow Forecasting, pp. 115–147. Elsevier, Amsterdam (2021)

Manzini, R., Bindi, F., Pareschi, A.: The threshold value of group similarity in the formation of cellular manufacturing systems. Int. J. Prod. Res. 48 (10), 3029–3060 (2009)

Martınez-Alfaro, H., Gomez-Garcıa, S.: Mobile robot path planning and tracking using simulated annealing and fuzzy logic control. Expert Syst. Appl. 15 (3–4), 421–429 (1998)

Martínez, J.A.S.: VerificaciÓn y empleo computacional de un modelo matemÁtico utilizado para un layout en un centro de distribuciÓn. Repositorio UANL (2005)

Meneghetti, A., Monti, L.: Multiple-weight unit load storage assignment strategies for energy-efficient automated warehouses. Int. J. Logist. Res. Appl. 17 (4), 304–322 (2014)

Ming-Huang Chiang, D., Lin, C.-P., Chen, M.-C.: Data mining based storage assignment heuristics for travel distance reduction. Expert Syst. 31 (1), 81–90 (2014)

Pan, J.C.-H., Shih, P.-H., Wu, M.-H., Lin, J.-H.: A storage assignment heuristic method based on genetic algorithm for a pick-and-pass warehousing system. Comput. Ind. Eng. 81 , 1–13 (2015)

Park, C., Tsui, K.-L.: A profile monitoring of the multi-stage process. Qual. Technol. Quantit. Manag. 16 (4), 407–423 (2019)

Pérez, M.M.: Optimización en la disposición del espacio de almacenaje en un centro de distribución. Repositorio UANL (2005)

Quintana Peña, A.: Metodología de investigación científica cualitativa (2006). http://biblioteca.udgvirtual.udg.mx/jspui/handle/123456789/2724

Ramtin, F., Pazour, J.A.: Product allocation problem for an AS/RS with multiple in-the-aisle pick positions. IIE Trans. 47 (12), 1379–1396 (2015). https://doi.org/10.1080/0740817X.2015.1027458

Roy, K., Kar, S., Das, R.N.: Understanding the Basics of QSAR for Applications in Pharmaceutical Sciences and Risk Assessment. Academic, Cambridge (2015)

Sampat, A.M., Martin, E., Martin, M., Zavala, V.M., Optimization formulations for multi-product supply chain networks. Comput. Chem. Eng. 104 , 296–310 (2017)

Sharma, S., Shah, B.: A proposed hybrid storage assignment framework: a case study. Int. J. Prod. Perform. Manag. 64 , 870–892 (2015)

Sörensen, K.: Metaheuristics–the metaphor exposed. Int. Trans. Oper. Res. 22 (1), 3–18 (2015)

Article MathSciNet MATH Google Scholar

Sormaz, D., Sarkar, A.: Process sequencing for features with multiple processing requirements. Procedia Manufact. 38 , 726–734 (2019). https://doi.org/10.1016/j.promfg.2020.01.098

Todd, P.M.: Heuristics for decision and choice. In: Smelser, N.J., Baltes, P.B. (eds.) International Encyclopedia of the Social & Behavioral Sciences, pp. 6676–6679. Pergamon, Oxford (2001). ISBN 978-0-08-043076-8. https://doi.org/10.1016/B0-08-043076-7/00629-X . https://www.sciencedirect.com/science/article/pii/B008043076700629X

Tompkins, J.A., White, J.A., Bozer, Y.A., Frazelle, E.H., Tanchoco, J.M.A., Trevino, J.: Facilities Planning, pages 36–47, 2nd edn. Willey, Hoboken (1996)

Tu, M., Yang, M.-F., Kao, S.-L., Lin, F.-C., Ming-Hung, W., Lin, C.-K.: Using a heuristic multi-objective genetic algorithm to solve the storage assignment problem for CPS-based pick-and-pass system. Enterpr. Informat. Syst. 15 (9), 1238–1259 (2021)

Verhoeven, M.G.A., Aarts, E.H.L., Swinkels, P.C.J.: A parallel 2-opt algorithm for the traveling salesman problem. Future Gener. Comput. Syst. 11 (2), 175–182 (1995)

Viveros, P., González, K., Mena, R., Kristjanpoller, F., Robledo, J.: Slotting optimization model for a warehouse with divisible first-level accommodation locations. Appl. Sci. 11 (3), 936 (2021)

Wutthisirisart, P., Noble, J.S., Alec Chang, C.: A two-phased heuristic for relation-based item location. Comput. Ind. Eng. 82 (C), 94–102 (2015). ISSN 0360-8352. https://doi.org/10.1016/j.cie.2015.01.020

Xiao, J., Zheng, L.: A correlated storage location assignment problem in a single-block-multi-aisles warehouse considering BOM information. Int. J. Prod. Res. 48 (5), 1321–1338 (2010)

Yang, M.-F.: Using simulation to object-oriented order picking system. Informat. Technol. J. 7 (1), 224–227 (2008)

Yang, T., Peters, B.A.: Flexible machine layout design for dynamic and uncertain production environments. Eur. J. Oper. Res. 108 (1), 49–64 (1998)

Yang, P., Miao, L., Xue, Z., Qin, L.: An integrated optimization of location assignment and storage/retrieval scheduling in multi-shuttle automated storage/retrieval systems. J. Intell. Manufact. 26 , 11 (2013). https://doi.org/10.1007/s10845-013-0846-7

Yang, P., Peng, Y., Ye, B., Miao, L.: Integrated optimization of location assignment and sequencing in multi-shuttle automated storage and retrieval systems under modified 2n-command cycle pattern. Eng. Optim. 49 (9), 1604–1620 (2017). https://doi.org/10.1080/0305215X.2016.1261128

Yilmaz Balaman, S.: Modeling and optimization approaches in design and management of biomass-based production chains. Basic Concepts Methodol. 185–236 (2019). ISBN 9780128142783. https://doi.org/10.1016/B978-0-12-814278-3.00007-8

Yu, Y., De Koster, R.B.: On the suboptimality of full turnover-based storage. Int. J. Prod. Res. 51 (6), 1635–1647 (2013)

Yuan, R., Li, J., Wang, W., Dou, J., Pan, L.: Storage assignment optimization in robotic mobile fulfillment systems. Complexity 2021 , 1–11 (2021)

Zaerpour, N., De Koster, R.B.M., Yu, Y.: Storage policies and optimal shape of a storage system. Int. J. Prod. Res. 51 (23–24), 6891–6899 (2013)

Zhang, G., Nishi, T., Turner, S., Oga, K., Li, X.: An integrated strategy for a production planning and warehouse layout problem: modeling and solution approaches. Omega 68 , 85–94 (2017). https://doi.org/10.1016/j.omega.2016.06.005

Zhang, R.-Q., Wang, M., Pan, X.: New model of the storage location assignment problem considering demand correlation pattern. Comput. Ind. Eng. 129 , 210–219 (2019)

Zhang, G., Shang, X., Alawneh, F., Yang, Y., Nishi, T.: Integrated production planning and warehouse storage assignment problem: an IoT assisted case. Int. J. Prod. Econ. 234 , 108058 (2021)

Zhou, K., Wan, W., Chen, X., Shao, Z., Biegler, L.T.: A parallel method with hybrid algorithms for mixed integer nonlinear programming. In: Computer Aided Chemical Engineering, vol. 32, pp. 271–276. Elsevier, Amsterdam (2013)

Download references

Acknowledgment

Supported by PAICYT 547-IT-2022.

Author information

Authors and affiliations.

Universidad Autónoma de Nuevo León, San Nicolás de los Garza, Mexico

Lucy Medrano-Zarazúa, Jania Astrid Saucedo-Martínez & Johanna Bolaños-Zuñiga

You can also search for this author in PubMed Google Scholar

Editor information

Editors and affiliations.

Engineering Department, National Autonomous University of Mexico, Mexico City, Distrito Federal, Mexico

José Antonio Marmolejo-Saucedo

Facultad de Ciencias Economicas Y Empresariales, Universidad Panamericana, Ciudad de Mexico, Mexico

Roman Rodríguez-Aguilar

Universiti Teknologi Petronas, Tronoh, Perak, Malaysia

Pandian Vasant

Graduate Program in Systems Engineering, Nuevo Leon State University, San Nicolás de los Garza, Mexico

Igor Litvinchev

School of Engineering, Universidad Anahuac México, Naucalpan de Juárez, Mexico

Brenda M. Retana-Blanco

Rights and permissions

Reprints and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper.

Medrano-Zarazúa, L., Saucedo-Martínez, J.A., Bolaños-Zuñiga, J. (2024). Storage Location Assignment Problem in a Warehouse: A Literature Review. In: Marmolejo-Saucedo, J.A., Rodríguez-Aguilar, R., Vasant, P., Litvinchev, I., Retana-Blanco, B.M. (eds) Computer Science and Engineering in Health Services. COMPSE 2022. EAI/Springer Innovations in Communication and Computing. Springer, Cham. https://doi.org/10.1007/978-3-031-34750-4_2

Download citation

DOI : https://doi.org/10.1007/978-3-031-34750-4_2

Published : 23 May 2023

Publisher Name : Springer, Cham

Print ISBN : 978-3-031-34749-8

Online ISBN : 978-3-031-34750-4

eBook Packages : Engineering Engineering (R0)

Share this paper

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

Blog about all things SAP

ERProof » SAP PP (Production Planning) » SAP PP Training » SAP Storage Location

SAP Storage Location

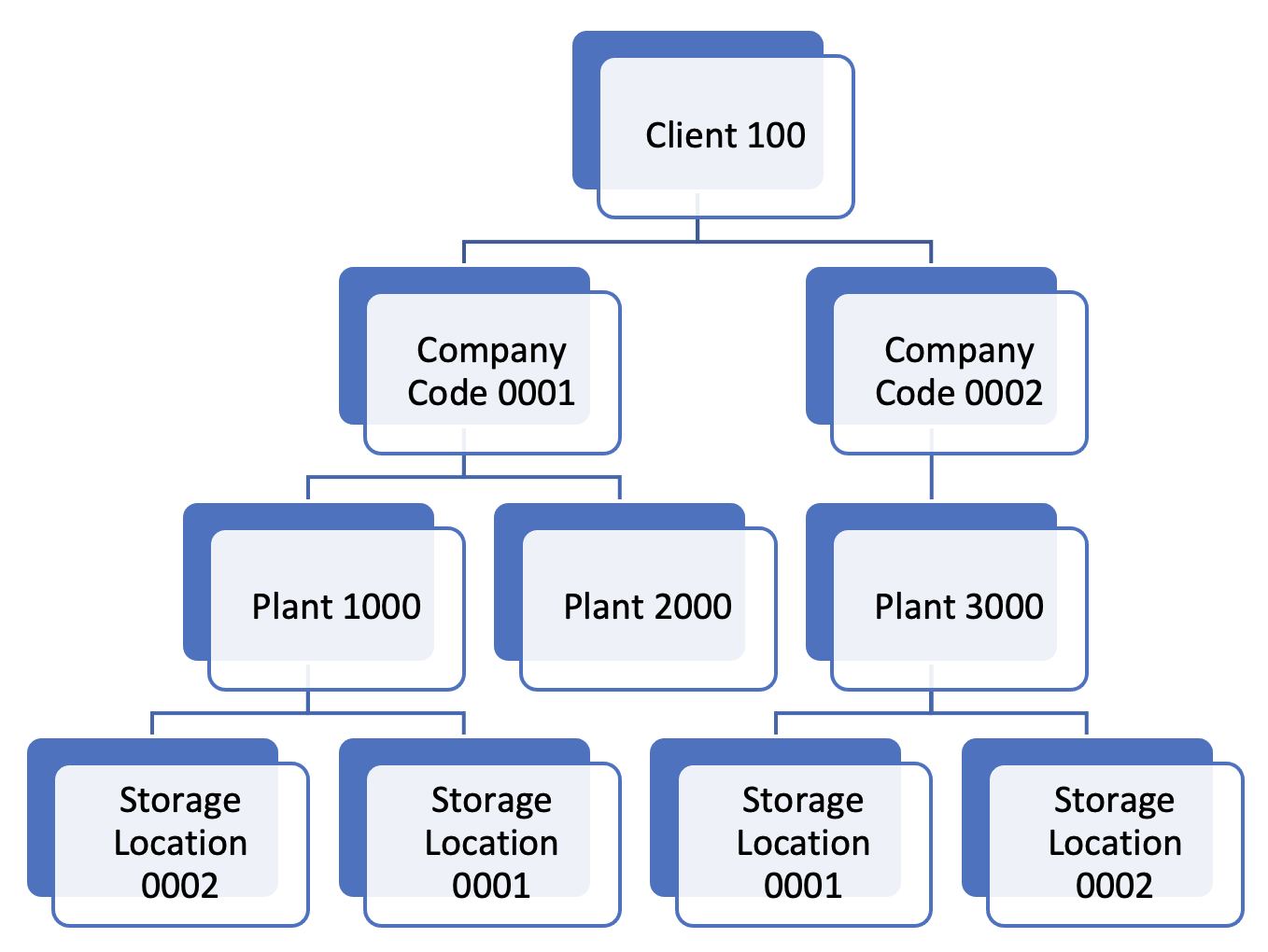

Organization levels are defined in SAP to represent the legal or the organizational views of a company. Defining the organization level is a key element in any SAP implementation project. First, we need to analyze the structural and process organizations within the company where SAP is going to be implemented. Then these elements are mapped with the SAP organization levels. It is important to get the organization level definition done accurately in the first attempt. This is because it is difficult to change this assignment once done.

There are mainly five organizational levels in SAP. These are:

- Company code

- Storage location

- Purchasing organization / purchasing groups

Out of these, storage location is a key organizational level. Storage location is an organizational unit which differentiates material stocks within a plant. In SAP, inventory management is done at storage location level.

Storage location is assigned to a plant when the organization structure is defined. Storage location is defined by means of four-character alphanumeric key. This key is unique for the plant. This means that a plant can have multiple storage locations, but each storage location can only be assigned to one plant. Within the client, same storage location key can be used but not within a single plant. Physical inventory is also carried out at storage location level.

A storage location can be physical or virtual. Raw material store is an example for a physical storage location. Scrap storage location can be taken as an example for a virtual storage location. It is not possible to give a capacity for a storage location. If we want to give a capacity, it can be done in SAP warehouse management.

Define New Storage Location

New storage locations can be defined in customizing. To create a new storage location, follow the below IMG path (transaction SPRO ).

IMG -> Enterprise Structure -> Definition -> Material Management -> Maintain Storage Location

We can input the transaction code OX09 and directly go to the storage location definition screen. Before defining the storage location, first we need to select the plant which the storage location is associated with. This is mandatory because as mentioned earlier, storage locations are assigned to a plant. Once the plant is entered, we can see the storage locations which are already defined for the given plant, if there are any.

To create a new storage location, click on the “new entry” button. Now, enter the four-digit alphanumeric code which we want to use with the storage location. We can also give a description for the storage location. Example: “Finished Good Store”.

Next, click on “addresses of storage locations”. Next, click on “new entry” button. A new screen will open. In this screen we can define further details of the storage location. If there is an address for the storage location, we can enter it here. We can also enter the search terms, communication methods such as email, mobile number, and fax. These details are not mandatory. Once the details are entered click on save button. Now the new storage location will be added to the plant. This concludes the storage location definition.

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully, it’s something we can address for you in the improvement of our free SAP PP tutorials.

Navigation Links

Go to the next lesson: SAP PP Master Data

Go to the previous lesson: Demand Management in SAP

Go to overview of the course: SAP PP Training

2 thoughts on “SAP Storage Location”

Your article helps me a lot. Thank you

How do I get a list of all the storage locations for my warehouse

Leave a Reply Cancel reply

Do you have a question and want it to be answered ASAP? Post it on our FORUM here --> SAP FORUM !

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Define Storage Location in SAP S/4Hana

What is storage location.

Storage location is a physical location within a plant where the materials are stored and managed. Storage locations in SAP S/4 Hana can be defined based on stock ownership, types of materials, etc.

Storage location is the lowest organizational unit of inventory management without implementation of SAP EWM in SAP S/4 Hana.

Storage Locations in SAP Hana – Scenarios

- One plant can have many storage locations as per requirements of an organization, but one storage location can be assigned to only one plant

- If you are not using SAP Extended Warehouse Management EWM, then you can assign one ore more storage locations to plant

- Storage locations are defined for a specific plant during creation of plant, so separate assignment of storage location to plant not required.

- In SAP EWM and WM, use one storage location, then you are allowed to create multiple warehouses under the storage locations.

How to Define Storage Location in SAP S/4 Hana

You can maintain storage locations in SAP S/4Hana by using the following configuration steps

- IMG Path: Enterprise Structure -> Definition -> Materials Management -> Maintain Storage Location

- Transaction Code: Ox09

By using IMG path or transaction code, you can navigate to storage location definition screen in SAP Hana System.

Step 1: From SAP Easy Access screen, enter sap transaction code “OX09” in the SAP command field and enter to continue.

Step 2: On determine work area entry screen, you need to specify the work area or plant for which you want to maintain the storage location in SAP S/4 Hana.

Step 3: In the next screen – change view “storage locations” overview, click on New Entries option to maintain new storage location in SAP Hana system.

Step 4: Storage location is defined with 4 character alphanumeric code. update the following details.

- Sloc : Enter the 4 digits key that define storage location in SAP Hana system.

- Description : Enter description of storage location.

Step 5: After providing the storage location key and description, you need to maintain addresses of storage locations. To update the address for storage location- select the storage location and double on the Addresses of storage location in the dialog structure of left side.

Step 6: Click on New Entries option and enter the number for a storage location address and click address option to maintain the address details for storage location.

Update the required details and click on save option to save the configured details of storage location in SAP S/4Hana system.

Successfully we have created storage locations in SAP Hana.

- TutorialKart

- SAP Tutorials

- Salesforce Admin

- Salesforce Developer

- Visualforce

- Informatica

- Kafka Tutorial

- Spark Tutorial

- Tomcat Tutorial

- Python Tkinter

Programming

- Bash Script

- Julia Tutorial

- CouchDB Tutorial

- MongoDB Tutorial

- PostgreSQL Tutorial

- Android Compose

- Flutter Tutorial

- Kotlin Android

Web & Server

- Selenium Java

- SAP MM - Home

- SAP MM Tutorial

- SAP MM Enterprise Structure

- Define Plant in SAP

- Define Company Code

- Assign Plant to Company Code

- Define Purchasing Organization in SAP

- Maintain Storage Location in SAP

- Define Purchasing Group in SAP

- Assign Company code to Company

- Assign Purchasing Organization to Company code

- ADVERTISEMENT

- Assing Purchasing Organization to Plant

- Assing Standard Purchasing Organization to Plant

- SAP MM - Material Master Data

- What is material master

- Attributes for material type

- Create material types

- Number range interval for material type

- Define material groups

- Company code for material management

- Create material master record

- Purchase Info record

- Maintain Plant parameters

- SAP MM - Vendor Material Master Data

- SAP MM - Vendor account groups

- SAP MM - Number ranges for Vendor accounts

- SAP MM - Assign number ranges to vendor accounts

- SAP MM - Sundry Creditors Account

- SAP MM - Vendor master record

- SAP MM - Quotation

- SAP MM - Number ranges for RFQ

- SAP MM - Document types for RFQ

- SAP MM - Screen Layout at Document Level

- SAP MM - Maintain Quotation Components

- SAP MM - Text types for RFQ/ Quotations

- SAP MM - Purchase Requistion (PR)

- SAP MM - Number ranges for PR

- SAP MM - Document types for PR

- SAP MM - Define Processing time for PR

- SAP MM - Setup authorization check for G/L account

- SAP MM TCodes

- ❯ SAP MM Tutorial

- ❯ Maintain Storage Location in SAP

How to Maintain Storage Location in SAP

What is Storage Location in SAP?

Storage location is the sub-division of plant where the stocks are physically stored and maintained within a plant . Each storage location can have its own address within a plant.

- It is required to maintain at least one storage location for one plant.

- One plant can have number of storage locations.

How to define storage location in SAP

You can configure storage location by using one of the following navigation method.

- Transaction code: – OX09

- Menu path: – SPRO > IMG > Enterprise Structure > Definition > Material management > Maintain Storage Location.

Step 1) Enter T-code “OX09” in the SAP command field and enter.

Step 2) Now you are prompted to enter the plant key, update the plant code in the given work area field as shown below and press enter to continue.

Step 3) On change view “storage locations” overview screen, click on new entries button to define the new storage locations as per requirements.

Step 4 ) On new entries storage location screen, update the following details.

- SLoc: – Enter the four digits key that identifies the storage location in SAP.

- Description: – Update the description of storage location.

Step 5) Now select the storage location key and click on address of storage location in the dialogue structure.

On change view addresses of storage locations overview screen, click on new entries button to update a number for the storage location address.

Update the number in the field No, you can update up to three characters. After updating No, press enter to continue and you are directed to another screen for the entry of secondary information.

Update the required details like details address with telephone no, city, etc.

After updating all the required details, click on save button and save the configured storage location details.

Successfully we have maintained storage location in SAP systems .

Popular Courses by TutorialKart

App developement, web development, online tools.

COMMENTS

The storage location assignment problem (SLAP) is an important step when we are designing a warehouse layout, and this step influences in the arranging, picking process, sorting, routing, and sequencing of requests [ 19 ]. The problem is to decide the corresponding areas in which the products should be allocated.

Storage location is an organizational unit which differentiates material stocks within a plant. In SAP, inventory management is done at storage location level. Storage location is assigned to a plant when the organization structure is defined. Storage location is defined by means of four-character alphanumeric key.

In this work, we deal with the Storage Location Assignment Problem, often referred to as the SLAP, in an E-commerce Distribution Center (EDC). With E-commerce steadily increasing in popularity over the past decades, it has become a key part of the logistics industry. Due to the direct link with the customer, EDC's are forced into a ...

The Storage Location Assignment Problem (SLAP) revolves around the allocation of products to storage locations. It depends on various factors, including warehouse characteristics, product types ...

This research focuses on improving the order-picking efficiency by developing efficient storage location assignment, whereas the picker routing problem is solved via a heuristic and batching is not considered. The storage location assignment problem (SLAP) involves determining the allocation of items to storage locations to maximize the order ...

The warehousing industry is faced with increasing customer demands and growing global competition. A major factor in the efficient operation of warehouses is the strategic storage location assignment of arriving goods, termed the dynamic storage location assignment problem (DSLAP). This paper presents a real-world use case of the DSLAP, in which deep reinforcement learning (DRL) is used to ...

The storage location assignment may be performed immediately after the reception of a product or periodically. Its purpose is to place products in convenient locations where they can be easily picked during the picking process. Order picking refers to the activities performed to retrieve products from their storage locations to satisfy demands ...

Storage location assignment is of great significance in warehouse management. According to the characteristics of task scheduling, time-based, multi-objective models for storage allocation and scheduling optimization are proposed in this paper. Then, a genetic algorithm is used to solve the multi-objective optimization problem for storage ...

In this paper, we analyze academic contributions on the storage location assignment problem published between 2005 and 2017. The literature is classified according to the solution methods, objectives, and related considerations. Suggestions are also provided for future research. Storage location assignment problem. Storage assignment.

To view existing assignments, you can use appropriate search criteria in the Storage Location Assignment Search tile. To add, modify or delete an assignment, use the Storage Location Assignments tile. Note. After assigning storage locations to employees, you synchronize to share this data with the CRM Server and SAP ECC. ...

2022. TLDR. An Iterated Local Search algorithm is proposed to solve the Storage Location Assignment Problem with Product-Cell Incompatibility and Isolation Constraints in a pharmaceutical product warehouse and shows a relevant improvement with respect to a greedy full turnover procedure commonly adopted in real life operations. Expand.

Storage Locations. Tolerances for Customers and Suppliers. Credentials and End Points. Assign Network ID to Company Code. Map Company Codes for Invoice Verification. Map Tax Codes for Invoice Verification. Activate cXML Message Types. Production Supervisor. Assign Picking Location.

What is Storage Location. Storage location is a physical location within a plant where the materials are stored and managed. Storage locations in SAP S/4 Hana can be defined based on stock ownership, types of materials, etc. Storage location is the lowest organizational unit of inventory management without implementation of SAP EWM in SAP S/4 Hana.

You can configure storage location by using one of the following navigation method. Menu path: - SPRO > IMG > Enterprise Structure > Definition > Material management > Maintain Storage Location. Step 1) Enter T-code "OX09" in the SAP command field and enter. Step 2) Now you are prompted to enter the plant key, update the plant code in the ...

Storage location assignment is an important decision problem in warehouse operations management. Because the main purpose of the storage location assignment system is to create various parameters to facilitate the diagnosis and positioning of the products in the warehouse. In addition, time spent on storage activities is an important factor in the demand cycle.

This site uses cookies and related technologies, as described in our privacy statement, for purposes that may include site operation, analytics, enhanced user experience, or advertising.You may choose to manage your own preferences.

DOI: 10.1016/j.cie.2019.01.027 Corpus ID: 68237844; New model of the storage location assignment problem considering demand correlation pattern @article{Zhang2019NewMO, title={New model of the storage location assignment problem considering demand correlation pattern}, author={Ren-qian Zhang and M. Wang and Xing Pan}, journal={Comput.

All material data specific to warehouse management and relating to a particular warehouse number is stored at warehouse number level. This includes, for example, data on palletizing, stock placement, and stock removal. Storage Type. A physical or logical storage area that can be defined for a warehouse in the Warehouse Management (WM) system.