Explore Lean Thinking and Practice / Problem-Solving

Problem-Solving

Explore the process that’s foundational to assuring every individual becomes engaged by arming them with methods they can use to overcome obstacles and improve their work process.

Overcoming obstacles to achieve or elevate a standard

In a lean management system, everyone is engaged in ongoing problem-solving that is guided by two characteristics:

- Everything described or claimed should be based on verifiable facts, not assumptions and interpretations.

- Problem-solving is never-ending; that is, it begins rather than ends when an improvement plan is implemented. The implementation process is a learning opportunity to discover how to make progress toward the target condition.

Lean thinkers & practitioners understand that the problem-solving process is impeded if you make the common mistake of mechanically reaching for a familiar or favorite problem-solving methodology or, worse, jump quickly to a solution.

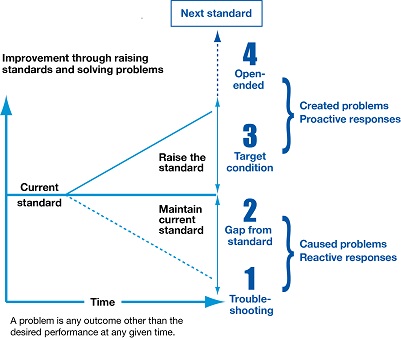

Leaders and teams avoid this trap by recognizing that most business problems fall into four categories, each requiring different thought processes, improvement methods, and management cadences.

The Four Types of Problems

Type 1: Troubleshooting: reactive problem-solving that hinges upon rapidly returning abnormal conditions to known standards. It provides some immediate relief but does not address the root cause.

Type 2: Gap from Standard: structured problem-solving that focuses on defining the problem, setting goals, analyzing the root cause, and establishing countermeasures, checks, standards, and follow-up activities. The aim is to prevent the problem from recurring by eliminating its underlying causes.

Type 3: Target Condition: continuous improvement ( kaizen ) that goes beyond existing standards of performance. It may utilize existing methods in new, creative ways to deliver superior value or performance toward a new target state of improvement.

Type 4: Open-ended: innovative problem-solving based on creativity, synthesis, and recognition of opportunity. It establishes new norms that often entail unexpected products, processes, systems, or value for the customer well beyond current levels.

By helping everyone in the organization to understand the importance of taking ownership of seeing and solving all types of problems, lean thinking & practice:

- Engenders a sense of empowerment and autonomy in all workers, which in turn promotes engagement in and ownership of the work process

- Enables organizations to overcome obstacles at their source, so they do not become more significant problems upstream

Ultimately, building a problem-solving culture creates a competitive advantage that is difficult for competitors to match.

Relevant Posts

Problem Solving

Why the A3 Process Involves More than Filling in Boxes

Article by Tracey Richardson

Big Problems? Start Small

Article by Josh Howell

What’s your problem

Article, Video by John Shook

Recent Posts

Revolutionizing Logistics: DHL eCommerce’s Journey Applying Lean Thinking to Automation

Podcast by Matthew Savas

Transforming Corporate Culture: Bestbath’s Approach to Scaling Problem-Solving Capability

Teaching Lean Thinking to Kids: A Conversation with Alan Goodman

Podcast by Alan Goodman and Matthew Savas

Relevant Products

Four Types of Problems

by Art Smalley

Managing to Learn: Using the A3 management process

by John Shook

Getting Home

by Liz McCartney and Zack Rosenburg

Steady Work

by Karen Gaudet

Relevant Events

August 05, 2024 | Coach-Led Online Course and Oakland University in Rochester, Michigan

Managing to Learn

November 05, 2024 | Morgantown, PA

Building a Lean Operating and Management System

November 12, 2024 | Coach-Led Online Course

Improvement Kata/Coaching Kata

Be the first to learn of new learning opportunities and the latest practical, actionable information. subscribe to an lei newsletter., join us on social, privacy overview.

How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

Elisabeth Swan is the co-author of “The Problem-Solver’s Toolkit” and co-host of “The Just-in-Time Cafe Podcast.” She’s been a process improvement consultant, speaker, and innovator for over 30 years. She’s the Chief Learning Experience Officer for GoLeanSixSigma.com, a former cast member of ImprovBoston, and – if asked – may still be able to ride a unicycle.

Surgeon Atul Gawande made headlines when he told the world that a simple checklist could drastically reduce unnecessary deaths in The Checklist Manifesto .

Yet, checklists conjure images of forklift drivers on loading docks with clipboards counting boxes. How could they transform healthcare?

“ He has… produced a 90-second checklist which reduced deaths and complications by more than one-third in eight hospitals around the world – at virtually no cost and for almost any operation. ” – James Clarke, reviewing The Checklist Manifesto, Ulster Med J. 2011 Jan; 80(1): 54.

Aviation was transformed decades earlier when management and engineers at Boeing Corporation created the pre-flight checklist after the 1935 crash of the prototype Boeing B-17 at Wright Field in Dayton, Ohio. Checklists have become so essential to the airline industry that most crashes can be traced to the misuse or failure to complete a checklist.

A New York Times reviewer noted, “no matter how expert you may be, well-designed checklists can improve outcomes”. Since the purpose of process improvement is improving outcomes, Lean Six Sigma and checklists are natural companions.

To prove that, this Process Street blog post will show the relationship between checklists and lean six sigma, and provide you with a free DMAIC Improvement Project Tollgate Checklist that you can use right now.

Use the links below to jump to that section of the post:

Lean Six Sigma and the role of problem-solving

Lean six sigma & the checklist, introduction phase, define phase, measure phase, analyze phase, improve phase, control phase, checklists and lean six sigma, use process street to reduce error.

Or, if you just want the checklist, check it out below!

Let’s get started.

For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.

It’s a customer-focused, 5-step problem-solving model that engages entire workforces to constantly seek a better way of doing things.

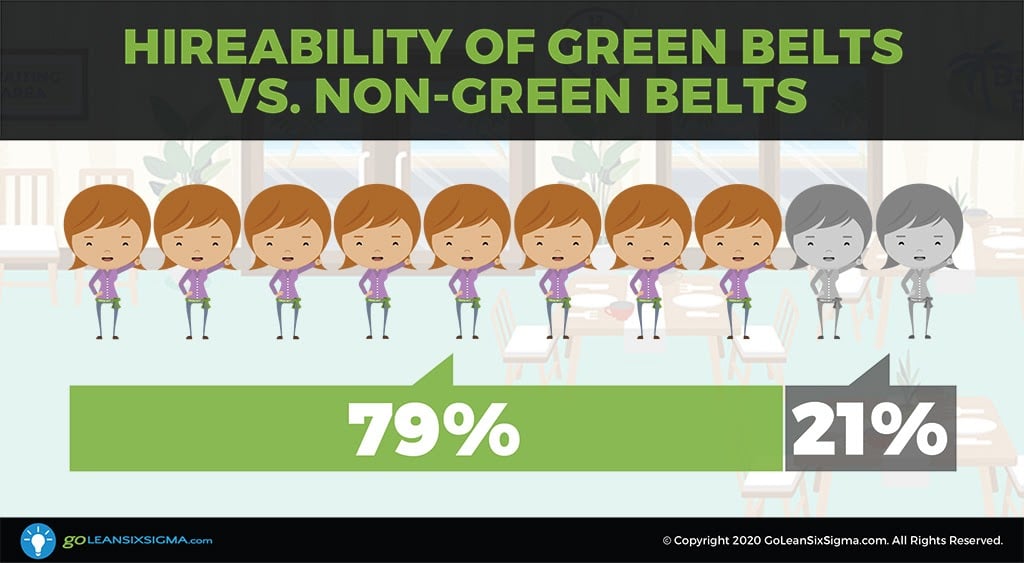

Proof of Lean Six Sigma’s influence is evident in today’s hiring practices. A poll by GoLeanSixSigma highlights that hiring managers prefer a person who is “ Green Belt Certified ” – having substantial Lean Six Sigma skills – by an almost 80% margin. In an interview with the former head of Twitter, problem-solving emerged as the top skill sought by today’s most influential hiring managers.

In other words, problem-solving (especially via Lean Six Sigma) is an absolutely vital skill.

If problem-solving is a must-have skill and checklists are key to good outcomes, then combining the two makes sense.

DMAIC – Define, Measure, Analyze, Improve & Control – is the 5-Step model for Lean Six Sigma and there’s a set of required tollgates at the end of each phase. These tollgates outline what has to be done in order to move the problem-solving process forward.

Using the tollgates as an outline, we created a dynamic Process Street template that you can use for free and run checklists from to track your progress!

Before you can start solving problems, you need a problem to solve.

Picking a process issue – and finding someone in leadership to support you – are two required tasks in this first tollgate. Scoping the project is important (bigger than a “just-do-it” and smaller than “solving world hunger”) but even more critical is finding a Sponsor.

Finding a Sponsor

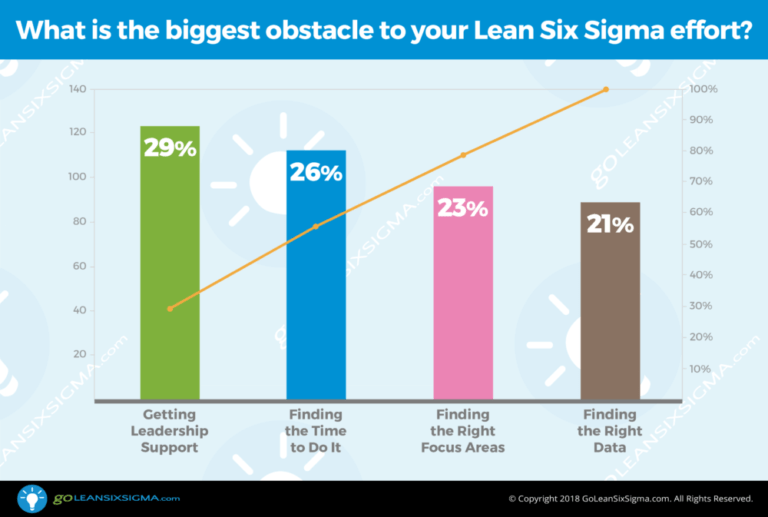

In a poll asking Lean Six Sigma practitioners what they considered the biggest obstacle to process improvement success, “Getting Leadership Support” accounted for almost a third.

When we coach team leads who tell us they can’t find someone to back their project, we let them know, “No Sponsor, no project”. If nobody in charge has any skin in the game, there’s no point in attempting the process fix. Find a different project that leadership supports.

One thing that helps when searching for leadership backing is being able to explain what Lean Six Sigma is and why it makes a difference. Since the checklist template is dynamic we inserted a video in the Define Phase within the checklist item, “Enlist a Project Champion/Sponsor who will support you and the project”. The team lead can share the video with managers or directors who they consider Sponsor candidates.

There’s also a Project Selection Guide Template embedded in the checklist so users can take a project idea and put it through a few screening questions. Is it a repeating problem? Is there a way to measure it? The checklist serves as a reminder, a source of templates, supporting videos and other just-in-time guidance.

The next set of tollgate tasks cover the Define Phase of DMAIC. This is where problem-solvers clarify the problem, the process impacted and customers of the process.

There is a journey of discovery during this phase as everyone agrees on the issue to solve. One of the big challenges is the tendency of ambitious team leads—or equally ambitious Sponsors—to try to “shoot the moon.”

Shooting the moon

They might want to reduce cycle time, reduce defects , improve margins, and increase customer satisfaction all by next Tuesday. But a project that focuses on everything accomplishes nothing. It’s okay to measure the cost reduction that results from reducing defects. But pick one of those to be the goal. Success is more possible if you focus on one goal at a time .

It takes practice and discipline to develop a manageable goal statement. Another moon shot is aiming for perfection out of the starting gate. When we see a goal statement that claims the team will, “reduce defects from 25% to 0%” then we know there is a sizable risk of failure and disappointment.

That’s why the Define Phase of the checklist includes a Goal Builder Template along with a blog providing tips on how to create well-crafted goal statements.

The primary focus of the Measure Phase is to baseline the process. If you’re trying to reduce defects, you need to know how you’re doing at that now. What’s your track record? You need to know the baseline of the process in order to measure whether or not you made a difference with your improvement when you get to the Improve Phase.

You need to know the gap, so you can close the gap.

The data’s in the system, somewhere…

One of the issues we run into in this phase is problem solvers assuming that data is sitting in a system somewhere waiting to be accessed. If they simply run a report, they’ll have the baseline. Check that off the list. But that rarely goes according to plan.

Maybe there’s system data, but was it entered with care? Is it reliable? We’ve seen teams struggle to use data that didn’t make sense. They could access cycle time data, but it didn’t take into account that the workday ended at 5:00. I had another team looking at why healthcare invoices had to be manually adjusted. They looked up the defect codes and the biggest category was “Other”. System data existed, but it was useless.

Most of the time, it helps to collect some data manually. In order to think through your approach, you need a Data Collection Plan. That involves listing the data you want and considering things like stratification factors—the “who, what, when, where” of data. If you’re looking at defects, should you collect data on defects by product? Defects by the fields on a form? Defects by customer type?

Within the task: “Develop a Data Collection Plan with Operational Definitions and create Check Sheets as Needed”, we’ve embedded a template (The Data Collection Plan) and a video to guide the process.

You’ll learn a lot by collecting the data firsthand, so if the perfect data set is not magically sitting in the system, it helps to have a plan.

Analyze is the crux of the DMAIC method. This is where learners drill down and discover the root cause of the process problem they’ve been chasing. Once you do that, you can solve the problem for good.

But if you have not determined the root cause then you might be solving a “symptom,” putting a bandaid on the problem or implementing a change based on a hunch. All of this means there’s a high likelihood the problem will remain and the efforts will have been in vain.

Finding the smoking gun

If you’ve always been told, “don’t bring me a problem, bring me a solution,” that’s an encouragement to jump right past this step into the fun of solutions. I’ve seen teams go with their assumptions regardless of what the data says or the process analysis reveals. I’ve seen Sponsors who tell teams what solutions they want to be implemented right from the get-go.

How do you stick with analysis long enough to find the smoking gun? The trick is to keep collecting the clues in the Cause & Effect Diagram , aka The “Fishbone Diagram”. It’s an aptly named tool, popularized by Dr. Ishikawa , which resembles a fish skeleton. Its construction allows teams to develop root cause theories around a problem as they build their knowledge of the process.

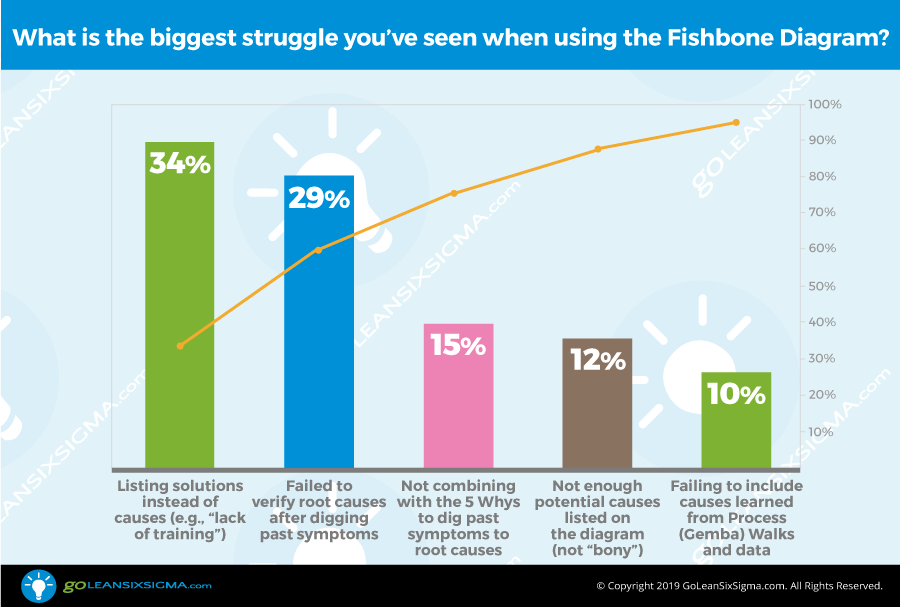

Each time they collect data, interview process participants on a Gemba Walk or map the process steps, they uncover potential reasons for defects. Making the most of the Fishbone Diagram is key but, during a poll, users reported where they fell short.

Solutions masquerading as problems

Over a third of respondents reported the issues of “listing solutions” on the Fishbone instead of causes. What we hear are phrases like, “the root cause is a lack of training”.

The problem with “lack of” anything is that it’s a sneaky way of putting a solution on the Fishbone.

The question is, “what is the training addressing?” Is it lack of user knowledge? If that’s the problem, could it be solved with helpful visuals, a simpler process? There are a lot of ways to address user knowledge before jumping to more employee training.

This is when you want to behave like the persistent detective – think Columbo, the classic 70’s TV icon. Every question helps you accumulate clues. People working through the process may have the answer without knowing it. The trick is to keep looking upstream until you find potential culprits. Dig past the symptoms.

To help with this phase, the checklist includes both a Fishbone Diagram Template as well as a video on how to get the most out of the Fishbone.

The Improve Phase is a long-anticipated step in the journey. It’s the step teams generally want to jump to from the start. Testing countermeasures, piloting solutions, watching the problem disappear, that’s the fun of process improvement. If you’ve done a proper job of Define, Measure, and Analyze, this phase falls nicely into place.

The ripple effect

The catch? Unintended consequences.

If you toss a stone into a lake you can see the ripples flow out from the center. The same principle holds true for process change. If you remove a step, change a form, skip an approval , will things fall apart? For that, we look to the Failure Modes & Effects Analysis or FMEA for short.

It’s a methodical way of assessing the potential for things to go wrong. It Involves deciding the potential severity and frequency of future problems and then mistake-proofing the process to prevent them. The technique originated at NASA since they couldn’t risk trial and error when sending men to the moon. By thinking through the risks of change they developed the kind of contingency plans you saw on display in movies like Apollo 13.

That’s why there’s an FMEA Template and a video on how to use it tucked into the main checklist from this post.

It’s okay to make changes. It’s simply key to think through the impact of those changes on other parts of the business.

Process Improvement can happen quickly and have a dramatic impact, but it’s critical to “stick the landing.” The Control Phase exists to see the improvement through to stability.

If teams move on and everyone takes their eyes off the ball, things may start to slip. What they need is the ability to continuously see the performance of the new process.

Sticking the landing

Have you ever tried to watch a game without a scoreboard? How would you know who was winning? Or how much time was left?

It’s the same with process work.

How does your team know how they’re doing? How do you stay aware of how the new process is performing?

By making the data visible.

Keeping an eye on Process Performance can be done with a single metric — you need to focus on one thing. If the goal was to reduce defects, then the single metric would be tracking the daily percentage of defects. A great way to measure success is with a Control Chart.

Control Charts are time charts. You might know them as Line Charts or Run Charts. They include a measure of variation so they are often referred to as “Run Charts that went to college”. They can be created in Excel , but they can also be drawn by hand.

Teams often set up whiteboards in the shared workspace to track things like defects. People can rotate responsibility for updating the chart. If people can see the measure and are responsible for it—they pay attention to it. What gets measured gets managed.

The Control Chart Template is embedded in the checklist for the Control Phase.

Process Improvement is a mainstay of Operational Excellence and checklists are simple but effective ways to make sure you get the outcomes you want. The following quote comes from the interim CEO/President of the Association for Manufacturing Excellence ( AME ).

“ I am a big fan of checklists for ensuring quality at the source. They serve an important purpose in reminding us of all that’s needed in a particular process or project. Without checklists, we risk missing or overlooking something by mistake. Checklists work best when ticking off items as they are completed, not en masse once the entire project is done. The key point is to use and follow them, not “pencil-whip” them from memory after the fact. While not foolproof, checklists can help us cover the details and result in more thorough, successful improvement efforts. ” – Jerry Wright , President, AME

Checklists have transformed healthcare, aviation, and countless other industries. Run this Process Street DMAIC Tollgate Checklist and make sure your next improvement effort gets great results.

Process Street is a powerful piece of workflow software that lets you crush the human error in your organization.

By creating process templates (like the free DMAIC checklist in this post) you can give your whole team a central location for them to see what they have to do, and how exactly they should do it.

No more confusion, no more errors.

Take advantage of our powerful feature set to create superpowered checklists, including:

- Form fields

- Conditional logic

- Variable user permission levels

- Exporting and printing templates

- And much, much more!

Check out our intro webinar to see the app in action!

Stop leaving the success of your processes up to chance. Get started with a free trial of Process Street today!

How do you manage quality control in your business? Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Ben Mulholland

Ben Mulholland is an Editor at Process Street , and winds down with a casual article or two on Mulholland Writing . Find him on Twitter here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- The Art of Effective Problem Solving: A Step-by-Step Guide

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: February 6, 2023

- Learn Lean Sigma

- Problem Solving

Whether we realise it or not, problem solving skills are an important part of our daily lives. From resolving a minor annoyance at home to tackling complex business challenges at work, our ability to solve problems has a significant impact on our success and happiness. However, not everyone is naturally gifted at problem-solving, and even those who are can always improve their skills. In this blog post, we will go over the art of effective problem-solving step by step.

You will learn how to define a problem, gather information, assess alternatives, and implement a solution, all while honing your critical thinking and creative problem-solving skills. Whether you’re a seasoned problem solver or just getting started, this guide will arm you with the knowledge and tools you need to face any challenge with confidence. So let’s get started!

Problem Solving Methodologies

Individuals and organisations can use a variety of problem-solving methodologies to address complex challenges. 8D and A3 problem solving techniques are two popular methodologies in the Lean Six Sigma framework.

Methodology of 8D (Eight Discipline) Problem Solving:

The 8D problem solving methodology is a systematic, team-based approach to problem solving. It is a method that guides a team through eight distinct steps to solve a problem in a systematic and comprehensive manner.

The 8D process consists of the following steps:

- Form a team: Assemble a group of people who have the necessary expertise to work on the problem.

- Define the issue: Clearly identify and define the problem, including the root cause and the customer impact.

- Create a temporary containment plan: Put in place a plan to lessen the impact of the problem until a permanent solution can be found.

- Identify the root cause: To identify the underlying causes of the problem, use root cause analysis techniques such as Fishbone diagrams and Pareto charts.

- Create and test long-term corrective actions: Create and test a long-term solution to eliminate the root cause of the problem.

- Implement and validate the permanent solution: Implement and validate the permanent solution’s effectiveness.

- Prevent recurrence: Put in place measures to keep the problem from recurring.

- Recognize and reward the team: Recognize and reward the team for its efforts.

Download the 8D Problem Solving Template

A3 Problem Solving Method:

The A3 problem solving technique is a visual, team-based problem-solving approach that is frequently used in Lean Six Sigma projects. The A3 report is a one-page document that clearly and concisely outlines the problem, root cause analysis, and proposed solution.

The A3 problem-solving procedure consists of the following steps:

- Determine the issue: Define the issue clearly, including its impact on the customer.

- Perform root cause analysis: Identify the underlying causes of the problem using root cause analysis techniques.

- Create and implement a solution: Create and implement a solution that addresses the problem’s root cause.

- Monitor and improve the solution: Keep an eye on the solution’s effectiveness and make any necessary changes.

Subsequently, in the Lean Six Sigma framework, the 8D and A3 problem solving methodologies are two popular approaches to problem solving. Both methodologies provide a structured, team-based problem-solving approach that guides individuals through a comprehensive and systematic process of identifying, analysing, and resolving problems in an effective and efficient manner.

Step 1 – Define the Problem

The definition of the problem is the first step in effective problem solving. This may appear to be a simple task, but it is actually quite difficult. This is because problems are frequently complex and multi-layered, making it easy to confuse symptoms with the underlying cause. To avoid this pitfall, it is critical to thoroughly understand the problem.

To begin, ask yourself some clarifying questions:

- What exactly is the issue?

- What are the problem’s symptoms or consequences?

- Who or what is impacted by the issue?

- When and where does the issue arise?

Answering these questions will assist you in determining the scope of the problem. However, simply describing the problem is not always sufficient; you must also identify the root cause. The root cause is the underlying cause of the problem and is usually the key to resolving it permanently.

Try asking “why” questions to find the root cause:

- What causes the problem?

- Why does it continue?

- Why does it have the effects that it does?

By repeatedly asking “ why ,” you’ll eventually get to the bottom of the problem. This is an important step in the problem-solving process because it ensures that you’re dealing with the root cause rather than just the symptoms.

Once you have a firm grasp on the issue, it is time to divide it into smaller, more manageable chunks. This makes tackling the problem easier and reduces the risk of becoming overwhelmed. For example, if you’re attempting to solve a complex business problem, you might divide it into smaller components like market research, product development, and sales strategies.

To summarise step 1, defining the problem is an important first step in effective problem-solving. You will be able to identify the root cause and break it down into manageable parts if you take the time to thoroughly understand the problem. This will prepare you for the next step in the problem-solving process, which is gathering information and brainstorming ideas.

Step 2 – Gather Information and Brainstorm Ideas

Gathering information and brainstorming ideas is the next step in effective problem solving. This entails researching the problem and relevant information, collaborating with others, and coming up with a variety of potential solutions. This increases your chances of finding the best solution to the problem.

Begin by researching the problem and relevant information. This could include reading articles, conducting surveys, or consulting with experts. The goal is to collect as much information as possible in order to better understand the problem and possible solutions.

Next, work with others to gather a variety of perspectives. Brainstorming with others can be an excellent way to come up with new and creative ideas. Encourage everyone to share their thoughts and ideas when working in a group, and make an effort to actively listen to what others have to say. Be open to new and unconventional ideas and resist the urge to dismiss them too quickly.

Finally, use brainstorming to generate a wide range of potential solutions. This is the place where you can let your imagination run wild. At this stage, don’t worry about the feasibility or practicality of the solutions; instead, focus on generating as many ideas as possible. Write down everything that comes to mind, no matter how ridiculous or unusual it may appear. This can be done individually or in groups.

Once you’ve compiled a list of potential solutions, it’s time to assess them and select the best one. This is the next step in the problem-solving process, which we’ll go over in greater detail in the following section.

Step 3 – Evaluate Options and Choose the Best Solution

Once you’ve compiled a list of potential solutions, it’s time to assess them and select the best one. This is the third step in effective problem solving, and it entails weighing the advantages and disadvantages of each solution, considering their feasibility and practicability, and selecting the solution that is most likely to solve the problem effectively.

To begin, weigh the advantages and disadvantages of each solution. This will assist you in determining the potential outcomes of each solution and deciding which is the best option. For example, a quick and easy solution may not be the most effective in the long run, whereas a more complex and time-consuming solution may be more effective in solving the problem in the long run.

Consider each solution’s feasibility and practicability. Consider the following:

- Can the solution be implemented within the available resources, time, and budget?

- What are the possible barriers to implementing the solution?

- Is the solution feasible in today’s political, economic, and social environment?

You’ll be able to tell which solutions are likely to succeed and which aren’t by assessing their feasibility and practicability.

Finally, choose the solution that is most likely to effectively solve the problem. This solution should be based on the criteria you’ve established, such as the advantages and disadvantages of each solution, their feasibility and practicability, and your overall goals.

It is critical to remember that there is no one-size-fits-all solution to problems. What is effective for one person or situation may not be effective for another. This is why it is critical to consider a wide range of solutions and evaluate each one based on its ability to effectively solve the problem.

Step 4 – Implement and Monitor the Solution

When you’ve decided on the best solution, it’s time to put it into action. The fourth and final step in effective problem solving is to put the solution into action, monitor its progress, and make any necessary adjustments.

To begin, implement the solution. This may entail delegating tasks, developing a strategy, and allocating resources. Ascertain that everyone involved understands their role and responsibilities in the solution’s implementation.

Next, keep an eye on the solution’s progress. This may entail scheduling regular check-ins, tracking metrics, and soliciting feedback from others. You will be able to identify any potential roadblocks and make any necessary adjustments in a timely manner if you monitor the progress of the solution.

Finally, make any necessary modifications to the solution. This could entail changing the solution, altering the plan of action, or delegating different tasks. Be willing to make changes if they will improve the solution or help it solve the problem more effectively.

It’s important to remember that problem solving is an iterative process, and there may be times when you need to start from scratch. This is especially true if the initial solution does not effectively solve the problem. In these situations, it’s critical to be adaptable and flexible and to keep trying new solutions until you find the one that works best.

To summarise, effective problem solving is a critical skill that can assist individuals and organisations in overcoming challenges and achieving their objectives. Effective problem solving consists of four key steps: defining the problem, generating potential solutions, evaluating alternatives and selecting the best solution, and implementing the solution.

You can increase your chances of success in problem solving by following these steps and considering factors such as the pros and cons of each solution, their feasibility and practicability, and making any necessary adjustments. Furthermore, keep in mind that problem solving is an iterative process, and there may be times when you need to go back to the beginning and restart. Maintain your adaptability and try new solutions until you find the one that works best for you.

- Novick, L.R. and Bassok, M., 2005. Problem Solving . Cambridge University Press.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Waste Walk: 5 Expert Tips to Improve Your Waste Walks

Why COPQ Matters: The Relationship Between Quality and Customer Satisfaction

Free lean six sigma templates.

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

LEI's Learning Portal

Intro to problem solving.

Problem solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all your senses to understand what is truly happening.

All too often, people create countermeasures to perceived problems without digging deeper, asking the right questions, and thinking more.

Throughout the entirety of the course, we use a case example to illustrate the problem-solving approach as you are learning. In addition, you will deepen your understanding by applying this new way of thinking to a problem of your choice.

This course breaks down lean problem-solving concepts and techniques into simple, easily understood pieces.

How do you solve problems?

Learning objectives.

This course works for people new to the concepts of lean and continuous improvement, for individuals looking to improve their lean understanding and skills, and for organizations wanting to level set the lean knowledge of their workforce to speed progress.

Build a foundational understanding of problem types and problem solvingIdentify the four types of problems

Resolve business challenges by using scientific method, PDCA-based problem solving

Apply A3 thinking to solve problems

Clearly define problems, beginning with grasping the situation at gemba

Learn to break down vague problems to specific problems that can be solved to root cause

Time Estimates Per Unit*

*Actual times may vary.

Course Units

Expand to view lessons

Course Introduction

0.1 Welcome!

0.2 Platform Tour (optional)

0.3 Copyright Acknowledgment

0.4 Curriculum Concept Map (Visual Syllabus)

0.5 Supplemental Textbook

Unit 1: Lean Problem Solving

1.1.1 | Welcome to Introduction to Problem Solving!

1.1.2 | Lean Transformation Framework

1.1.3 | How We View Problems

1.1.4 | Lead with a Questioning Mindset

1.2.1 | What's a Problem

1.2.2 | Problems Problems Problems

1.2.3 | Four Types of Problems

1.2.4 | Four Types of Problem Solving

1.2.5 | Make the Problem Clear

1.2.6 | Problem Breakdown Analysis

1.2.7 | Unit 1 Personal Reflection

Unit 2: What is an A3?

2.1.0 Helpful information for working on Your A3

2.1.1 | Introduction to A3

2.1.2 | A3 Basics

2.1.3 | Simple A3 Example

2.1.4 | A3 as Good Storytelling

2.1.5 | It's Not a Template

2.1.6 | 5-Step A3 Example

2.1.7 | Your A3: Title and Owner

2.1.8 | Introduction and Chapter 1 (optional)

2.2.1 | Develop Problem Solvers

2.2.2 | Developing Problem Solvers at Herman Miller

2.2.3 | The A3 Process

2.3.1 | Basic Thinking, Mindset, Assumptions

2.3.2 | Porter’s First A3: Rush to a Solution

2.3.3 | Rethinking Thinking by Trevor Maber

2.3.4 | What do I need to know

2.3.5 | Chapter 2: Grasp the Situation—Part 1 (optional)

2.3.6 | Unit 2 Personal Reflection

Unit 3: Your A3

3.1.1 | Grasp the Situation at the Gemba

3.1.2 | Gemba Is More than a Place from Managing to Learn (optional)

3.1.3 | Go See, Ask Why, Show Respect

3.1.4 | Chapter 2: Grasp the Situation—Part 2 (optional)

3.1.5 | Porter’s First Revised A3

3.1.6 | Problem-solving Funnel (Part 1)

3.1.7 | Your A3: Background & Current Condition

3.2.1 | Analysis (part 1)

3.2.2 | Problem-solving Funnel (Part 2)

3.2.3 | Chapter 3: Goals and Analysis—Part 1 (optional)

3.2.4 | Your A3: Background & Current Condition - update

3.2.5 | Analysis (part 2)

3.2.6 | The Five Whys

3.2.8 | The Five Whys Animation

3.2.9 | Problem-solving Funnel (Part 3)

3.2.10 | Your A3: Goal, Target and Analysis

3.3.1 | Choose Countermeasures

3.3.2 | Countermeasures vs. Solutions (optional)

3.3.3 | PICKing Countermeasures

3.3.4 | Your A3: Countermeasures

3.4.1 | Create a Plan

3.4.2 | Nemawashi from Managing to Learn (optional)

3.4.3 | Consensus/Agreement from Managing to Learn (optional)

3.4.4 | From Position Based Authority to Pull-Based Authority (optional)

3.4.5 | Chapter 5: Plan and Followup—Part 1 (optional)

3.4.6 | PDCA from Managing to Learn (optional)

3.4.7 | PDCA Improvement

3.4.8 | Your A3: Plan

3.5.1 | Followup

3.5.2 | Chapter 5: Plan and Followup—Part 2 (optional)

3.5.3 | Detailed A3 Template

3.5.4 | Your A3: Followup

3.5.5 | Conclusion and Getting Started (optional)

3.5.6 | Unit 3 Personal Reflection

3.5.7 | Course Summary

Final Course Survey and Certificate of Completion

Final Course Survey

Certificate of Completion

Continue Your Lean Learning

Extra Resources

More books from the Lean Enterprise Institute

A3 Thinking Questions

More learning experiences from the Lean Enterprise Institute

More on the 'Ladder of Inference'

More on 'Leading with a Questioning Mindset'

About this course

- 0.5 hours of video content

Senior Instructor John Shook

Shook co-authored Learning to See, the book that introduced the world to value-stream mapping. He also co-authored Kaizen Express, a bi-lingual manual of the essential concepts and tools of the Toyota Production System. With Managing to Learn, Shook revealed the deeper workings of the A3 management process that is at the heart of Toyota’s management and leadership.

Worth every minute spent!

Christy leite.

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handlin...

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handling a problem. Problem definition is where most teams fall short. This training covers that well with excellent application examples. Definitely worth taking!

Wish i learned this at the beginning of my career

Jonathan fairweather.

would have saved alot of headake on alot of problem solving arguements ect and got to the root problem

Outstanding

William butdorf.

Very organized and professionally delivered.

It's Not Just a Piece of Paper

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should ...

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should do. Then apply the A3 methodology... I bet you find it isn't one simple problem and you might just discover how complex the problem is, what else is affected that you never realized, or who else might be aware or impacted by it. It's just thinking outside the box and being open to solving the problem. I think to many people don't want to expose a problem because they don't know how to fix it or that it's a failure to have problem at all

Additional Courses

Learning to See Using Value Stream Mapping - with Live Coaching

This workshop shows you how to make and apply this fundamental and critical tool based on the Lean Enterprise Institute's groundbreaking value-stream mapping workbook, Learning to See, which has introduced the mapping tool to thousands of people.

NEW Intro to Lean Thinking & Practice

This online course serves as an introduction to the key concepts, philosophies, and tools associated with lean thinking and practice.

Lean Fundamentals Bundle

Buy all three fundamentals courses at reduced cost. Purchase for yourself or your entire enterprise.

Stay connected on all things lean thinking and practice.

Add your email to LEI's mailing list to get the latest updates.

Please enter a valid email address

Please check this box if you wish to proceed

Oops, something went wrong. Please try again with a different email address.

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

Margin Size

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

6.4: Lean Processes

- Last updated

- Save as PDF

- Page ID 50787

- Michael Laverty and Chris Littel et al.

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

Learning Objectives

By the end of this section, you will be able to:

- Discuss the lean process methodology

- Understand the phases of the lean problem-solving process.

You have learned about different problem-solving approaches that entrepreneurs take to lead their startups and work with others. Most of these approaches have had to do with the entrepreneur’s cognitive or creative mindsets. Now we will learn about an approach that is more rooted in process, called lean process . Lean problem solving has been used as an entrepreneurial methodology in new and emerging ventures, and it’s interesting that it comes from a large corporate, manufacturing background that focuses on efficiencies. The Six Sigma methodology, pioneered at Motorola in the 1970s and 1980s, and adopted by many companies, is a disciplined, data-driven approach that provides companies tools to improve the capability of their business processes. According to the American Society for Quality, “Six Sigma views all work as processes that can be defined, measured, analyzed, improved and controlled. A set of qualitative and quantitative tools is used to drive process improvement. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.” 26 GE copied it and created the “Process Excellence” programs that millions of managers and others have taken to get certified at various “belts.” Although Six Sigma and Process Excellence do not fit strictly in terms of entrepreneurship, as they are used mainly by large, mature companies, many of the methods fit in the lean model.

Toyota pioneered the lean process in the 1980s. The term “lean manufacturing” is the most common, but it is much more than manufacturing. The lean process is a systematic method for the maximizing of continuous improvement and the minimization of surplus or unused material in the production of a process. The entrepreneur begins the startup with a sense the original product will be the product carrying the organization to success in the long term. In most cases, the good or service will require modification to maintain a process, technology, or up-to-date product offering. Lean problem solving means the entrepreneur’s entire team scans both the company’s internal and external environments for continuous improvement and methods for bringing additional revenue to the startup by cost improvement processes that promote sustainable value. The external environment encompasses customers, industry trends, and competition. The internal environment comprises the factors inside the enterprise, such as employees, and internal practices and processes. In lean manufacturing, for example, improving efficiencies in the internal environment should lead to advantages in the external environment (whether that be cost savings to customers, competitive advantage from more output/superior product, etc.).

For example, every mile saved per day per UPS truck driver results in approximately $50 million in savings per year, according to Juan Perez, the company’s chief information and engineering officer. Using customer data and artificial intelligence, the company created a system dubbed ORION, which is an acronym for On-Road Integrated Optimization and Navigation. 27 To date, the system has resulted in $400 million in savings to UPS. By applying the lean process, everything that UPS saves on the input (by reducing mileage) leads to savings on the output, which leads faster deliveries, lower costs for consumers, and more profit for UPS.

Lean Problem-Solving Process

The lean problem-solving process is a cycle of observation, assessment, and continual evaluation. As shown in Table 6.4.1, this cycle typically involves eight specific steps.

The lean problem-solving, step-wise process allows the business to observe, assess, and continually evaluate.

ARE YOU READY?

Too much too late.

Many entrepreneurs create a startup with an idea that they develop without any feedback from potential customers, relying on their own knowledge or assumptions about the market. Consider the story of Rapid SOS: https://hbr.org/2018/05/do-entrepren...eed-a-strategy . What would most likely happen when they decided to go forward with their product? Will it be a fit to the customer’s needs or solve their problems? How is lean process different from this?

Lean Problem-Solving Phases

Observation is the phase in which the entrepreneur studies the challenge and notes all facets of the challenge requiring solution. In this phase, the entrepreneur asks questions and conducts research about the change needed for a successful product, outcome, or service. The entrepreneurs must determine why the change is needed. What is the purpose of the endeavor? Feedback is extremely important in this phase.

For example, a community asked a group of entrepreneurs to help address the youth obesity problem in a middle school. The entrepreneurs began to study the intake of food by the children and determined that both the content of the school lunch menu and the lifestyle of the majority of the children were affecting the obesity rate in the community. They then defined the purpose of the project as finding a low-cost, low-risk method of changing the lunch menu and agreed that the primary outcome would be a 30 percent reduction in the obesity rate of the children. The entrepreneurs began to assess the cost of changing the lunch menu and observing what else the kids ate. The entrepreneurs discovered that the lunch menu change required to reduce the obesity rate was beyond the financial capability of the school district. Research also showed that many of the children, products of single-parent homes, were eating high-calorie, high-fat, take-out foods for dinner. Further observation revealed that the children did not engage in physical activity after hours because the local surroundings were not safe. The community needed a process to transform the wellness of the children, and the entrepreneurs recommended using a lean process approach to help the children as quickly as possible.

After the observation of the problem comes assessment , the phase in which the entrepreneur experiments and analyzes the potential process and its capabilities. The entrepreneur leverages creative tools and resources to arrive at a solution and assesses each step of a possible solution. Each step must add value to the solution, or that step in the solution is unnecessary. In addition, the step must be capable of solving the issue and add flexibility to the solution. How is the process or product being improved? In this phase, a prototype of the product is developed and delivered. The entrepreneur must ask the customer if all needs and wants are satisfied with the prototype. If the prototype is being developed for mass production, surveying customers about potential sales is essential. In the school lunch example, the school system would have been the customer of the new food menu (prototype) in the assessment phase.

Evaluation is the phase in which behaviors are analyzed to assess success. The entrepreneur continually studies each phase of the solution to observe the effectiveness of outcomes desired by the client. The entrepreneur ensures that transformation is built into the habits of the school to obtain, maintain, and develop the desired outcomes.

In a real-world example of a company applying lean processes, the New Balance Company, which designs and manufactures both athletic and casual shoes, used a batching approach in the early 2000s that organized production by departments, so that all of the cutting took place in one department, all of the stitching took place in another, and so forth. While it seems that batching tasks would improve efficiency, at New Balance, it meant that production of one pair of shoes took nine days. Executives observed piles of inventory sitting between floors and departments, and noticed employees waiting while there were delays in the production line. They also noticed that the pay structure contributed to the piles of works in process because employees were paid by the piece, which encouraged them to produce as much as possible.

The company applied lean principles to rearrange the production floor by value streams, or the making of a product by sharing similar processing steps. On one side was “cut and stitch” products using US materials of leather and mesh, while another side used premade products from overseas for soles, inserts, and kits. This change cut the time to make a pair of shoes down to four hours, meaning that domestic plants could ship some orders in twenty-four hours, while competitors may need as much as 121 days to ship when they outsourced manufacturing to Asia.

An often-used lean problem-solving tool is whiteboarding ( Figure 6.16 ). Whiteboarding is a type of graphing that permits the entrepreneur to plot each step in a process to build comprehension and detailing of the process. The entrepreneur draws each step on the whiteboard using a linking-type diagram, and draws arrows to show how processes affect other processes. Seeing the flow of the process allows the entrepreneur to note where functions in the process are duplicated or inconsistent.

For example, in a community garden, storing tools, such as hoes and hand trowels for weeding, in different sheds wastes time when preparing to begin the process of weeding. These tools should be stored collectively to eliminate multiple trips and wasted time. Seeing the process on a whiteboard or other medium brings awareness to how processes can be improved. After the process is changed, it is graphed again for further scrutiny.

ENTREPRENEUR IN ACTION

The origin of lean.

Would it surprise you to know the origin of lean, in modern times, is considered to be Henry Ford’s production line? Although we don’t necessarily think of the creation of automobiles as an entrepreneurial venture in today’s world, Henry Ford was truly an entrepreneur for his time when the manufacture of automobiles was just beginning. Not only did he recognize the opportunity inherent in the sale of automobiles, he recognized the need to create an efficient process for automobile production that could decrease costs and, consequently, the selling price of the vehicle. As the first entrepreneur to join the use of interchangeable parts with moving conveyance to develop fabrication processes, Ford was able to turn over inventory in a very short time; however, Ford’s process could not deliver variety. In fact, Ford was quoted as saying of the Model T’s color, “You can have any color as long as it's black.” 29 It had the fastest drying time; hence, it was the only color he used for a number of years.

The Ford system was built around one static product. In the 1930s, when the market demanded product variety, the company was not set up to address this challenge. Kiichiro Toyoda (Figure \(\PageIndex{2}\)), the second president of Toyota Motor Corporation, visited the Ford plant in Michigan to learn more about their application of the assembly line concept. After observing, he proposed a new production system that would strive to “right size” equipment to better match tasks and the volume of work, as well as introducing quality assurance steps in each sequence of the work process. Toyoda’s approach shifted the focus from machinery to process, optimizing efficiency while maintaining quality.

Approaching problem solving more effectively

FEATURE – As they progress on their lean journey, organizations need to learn to adjust their stance to the different types of problems they face. Introducing his new book, the author offers precious tips on problem solving.

Words: Art Smalley , President of Art of Lean, author and speaker

Last year, the Lean Enterprise Institute published a book I authored, entitled Four Types of Problems . The book emphasizes the importance of looking at problems from different angles and not always getting locked into one way of viewing the situation at hand.

The four types described are 1) good troubleshooting routines, 2) gap from standard deviation situations, 3) target state improvement opportunities, and 4) more open-ended or innovation-based routines. There is some overlap between adjacent types, of course, but each has its own purpose and methods associated with it.

My goal in writing the book was to explain how these four types function in a company like Toyota, where I previously worked, and help organizations navigate their own problem-solving journey more effectively.

The book has a short chapter on the history of problem solving in the 20th century and covers many of the influential parties. As I point out in the chapter, I think it is fair to claim that all problem-solving routines are loose derivatives of the scientific method of inquiry in concept. However, I don’t think that all problem-solving routines meet the requirements of actual science in practice. (As an aside, I worked with a national laboratory for many years on their improvement journey. As I was lectured many times by career scientists, the actual bar for the scientific method is quite high – e.g. conduct double-blind studies, publish your full data sets and investigation methods, subject yourself to peer review, have others replicate your results independently, publish in a journal, and establish some type of new knowledge or discovery in the process, etc. OK, we don’t go that far in problem solving but we loosely embody some of the elements.)

The first two categories in the 4 Types framework involve higher degrees of critical analytical thinking and look for proverbial root causes. They tend to reactively deal with problems that have occurred due to some type of causal factor or error. The latter two types are proactively created and not necessarily caused. In other words, you choose to take something to a higher standard. This usually involves higher degrees of lateral or divergent style creative thinking methods and you look for better solutions even when there is no problem per se.

There is a Japanese proverb that essentially states, “a fool knows one way of doing things while an expert knows many.” In other words, it is easy to force all problem-solving routines into one specific box – whether it be Toyota’s current 8-step method, Six Sigma methodologies, Triz, 8D, Kepner Tregoe, rapid Kaizen, Design Thinking, or whatever flavor you are most comfortable with. And we can, of course, just become extremely abstract or non-prescriptive and say it is all loosely science or PDCA for that matter. However, that superficial approach does not really provide much in the way of practical advice for moving forward. And unfortunately, I see many organizations get stuck with this line of thinking and consequently struggle to achieve the desired results. If you are experiencing success in your organization then I suggest you stay with what is working. If your organization is experiencing some trouble with problem solving or improvement, then altering your viewpoint or framework might be of some use.

I often get asked this follow-up question: “Why do you recommend these specific four types and why are they all necessary?” Let me try to explain my thinking. First off, these four types are essentially the patterns I personally observed from my mentors while working inside of Toyota Japan at Kamigo Engine plant (Taiichi Ohno’s facility). These four types line up with my observations and experiences watching various experts over many years at work during their career. Also, a retired gentleman named Isao Kato, who was a major force in the development of problem-solving training at Toyota for decades, urged me to look at every problem from multiple angles and not just one. He often invoked the phrase “Kata ni hamaranai” – a common Japanese expression that translates into “not getting trapped into one way or method”. Subsequently, here is the way I attempt to describe the types and necessities.

THE FOUR TYPES, MORE IN DETAIL

In a perfect world, we would not need Type 1 Troubleshooting routines… but the world is not perfect. Resources are finite and very much constrained in the short term. During a major vehicle launch in Toyota, for example, data collection indicates that the andon chord is pulled signaling an abnormal condition up to 10,000 times in a 24-hour period. Anyone remember those Elon Musk tweets about “production hell” and “logistics hell” while Tesla attempted to ramp up production volumes? Minor problems abound and not all of them are equal. Some form of triage is essentially enacted, with the most critical getting the most attention and others getting lesser amounts of consideration. Some are pursued more deeply in terms of 5 Why thinking (ideally again all of them would be), but many are dealt with in a safe expedient manner to get production back on track. For example, the machine is unjammed, the error is reset, the software is re-booted, the alignment of something is re-centered, etc. etc. How many of you have ever turned your internet router or phone on or off to resolve some type of connectivity issue? Sometimes the short-term fix is allowable under the circumstances.

There is a tendency to put down what I term the Type 1 Troubleshoot routines as not real problem solving, but I think this is ill advised for many reasons. For starters, it is not always so easy to be a first responder in any organization. Most of my trips to ER, for example, ended in pain medication, antibiotics, or other reactive treatments. One can argue those are just troubleshooting techniques dealing with the symptoms and not the real underlying problem. An entire movie starring Tom Hanks was made about Apollo 13 and the famous phrase, “Houston we have a problem”, when an oxygen tank ruptured during a mission. However, the movie then depicted the heroic troubleshooting required to get home, overcoming equipment malfunctions, CO2 build-up, low temperatures, lack of food and potable water, and many manual course adjustments. The real problem of the tank rupture and root cause (incorrect heater thermostatic switch) was figured out much later and not really covered in the movie. My point is that sometimes circumstances force you into Type 1 Troubleshooting responses and you need to be good at it on a daily basis. Also, from a “respect for people” point of view, involving everyone right away in Type 1 routines is a vital concept in Toyota. Most organizations I visit are not as strong at Type 1 problem solving as they seem to believe.

Type 2 problems and the classic gap from standard pattern of problem solving exist because of the inherent limitations of Type 1 responses. All problems are not equal in terms of impact – i.e. there is always some type of Pareto distribution. Of course, sometimes a problem must be handled at a more fundamental level even if it affects safety or quality severely. Many of the techniques developed in the 20th century focus on this type of situation. In order to really fix something you have to understand the proverbial root cause and implement a countermeasure to prevent it from occurring again. Penicillin and pain medication, for example, are great… but what caused the infection in the first place? Why did the Apollo 13 oxygen tank malfunction and rupture? Why are we suddenly experiencing so many defects in the fabrication department? These problems require more diligent investigation. The thinking pattern must shift from addressing the emergency condition to the underlying causal factors involved.

Most organizations struggle with Type 2 problem-solving routines as they are usually more difficult. Problem solving requires skill and teamwork as well as proper support structures. Heroic individuals usually can’t resolve Type 2 problems by themselves as the causal factors cross multiple lines or require certain expertise. We flew an induction hardening and materials expert all the way from Toyota Japan to the United States once during start up, to deal with a specific problem on a piece of equipment that my staff and I could not resolve. Most Type 2 problems, however, can be solved internally by proper usage of tools, methods, and persistence. Some fall into what I call the logic family of analysis (5 Why or Fishbone), some into the one variable at a time (OVAT) statistical family, and some in the multiple variable at a time (MVAT) statistical category. Not everyone needs to be proficient in all of these techniques, but all organizations need some degree of ability in them.

Type 3 routines are critical and different from the previous two types as there is not necessarily a problem to address in a classic sense. Everything is stable and at standard, which is great! Annually, however, organizations set higher goals for internal improvement or out of concern for the competition. Customers expect improvement as well. Sports is a good analogy here. Whatever you ran the 100 meters in or pole-vaulted last year is fine. How much better are you going to be this next year? Game on.

These types of problems are what we historically called Kaizen or continuous improvement inside of Toyota. The bar is raised and a new standard of performance (safety, quality, delivery, productivity, cost, etc.) is targeted. In these cases, traditional convergent root cause thinking is not as useful since the answer is not in the past or a single root cause per se. The 20th century also flourished with creativity-based routines to come up with a better combination of existing resources to optimize the current state. Creative brainstorm is the classic example where judgement is intentionally suspended, a quantity of ideas is targeted, and set of better methods is identified for one example. This line of thinking is intentionally exploratory and requires a higher tolerance for trial and error for the purposes of learning, etc. I semi-jokingly use the phrase “wishbone” instead of cause-and-effect “fishbone” to accentuate the difference.

Type 4 routines might require the least amount of explanation, but generate the most amount of debate. Open-ended innovation is needed in the first place to create an industry and some type of new product or new service. In the grand scheme of things, without Type 4 problems society does not grow or develop new technologies, etc. There are many areas for open-ended thinking and opportunities for improvement, but very little agreement on how to produce it. Most Type 4 practitioners consider it to be a special category in itself. Noted innovation expert Matthew May, upon kindly reviewing early drafts of my book, for example, commented there was “innovation” and then “just everything else”. Most innovation experts cringe at the notion that dogmatically adhering to specific steps or just answering questions will result in a specific outcome. Creativity is often messy and iterative in nature and not always sequential. Paradoxically, while it employs science, it is not all that scientific itself in terms of practice. In other words, similar methods don’t always produce the same results, which is one of the hallmarks attributes of science. This is partly why I suspect societies are so enamored of eccentric artists and inventors like Da Vinci, Edison, Tesla, or more recently Steve Jobs or Elon Musk.

If this sort of thinking interests you or your organization is not achieving desired results in problem solving, then this book might be of value. It is perfectly fine in the beginning to cling to one way of doing things and have a standard, for example. I can play golf quite well with just one swing and a 7 iron or play a decent game of tennis with just a forehand volley. Advanced players, however, employ multiple techniques depending upon the situation. Without first-hand observation or factual data, I don’t like to make specific recommendations. You have to be the captain of your own ship, so to speak, and plot your own course and periodically adjust. I personally believe that Toyota is successful because it is flexible enough to recognize various problems and respond to them in a multitude of appropriate ways over time. As Isao Kato frequently cautioned to me, “Kata ni hamaranai”.

To purchase your copy of the book, click here .

FEATURE - Two weeks ago, the authors shared their thoughts on mindset. In part 2, they discuss how to grasp the true spirit of lean.

FEATURE – At the 2016 Olympics in Rio, the Japanese Men’s 4x100m relay team went from being the underdogs to winning a silver medal by apply lean problem solving.

COLUMN - In the first installment of her new column, the CIO of Finnish defense company Patria shares her thoughts on what makes lean management so critical in the life of the leader of an IT department.

RESEARCH - In the last 10 years lean has made its way in many hospitals and healthcare systems, often with impressive results. Professor Dan Jones looks back at the lessons learned throughout the decade.

Subscribe for our newsletter and get early access to all exclusive Planet Lean articles.

Wednesday, November 15, 2017

- The Seven Steps of Problem Solving

- Select the issue.

- Search for data to describe the situation.

- Analyze the facts to obtain root cause(s) of the performance gap.

- Select a solution.

- Conduct a pilot test.

- Evaluate performance.

- Standardize the gains, reflect, and repeat the process.

No comments:

Post a comment.

Search A Lean Journey

Twitter updates.

- Facebook Updates

- Advertising

Subscribe Now

Get new posts by email:

A Lean Journey LinkedIn Group

Recent comments, search this blog, top 10 posts.

- Celebrating my 500th Blog Post

- Visual Management Board

- Guest Post: Reduce, Reuse, Recycle...

- What Do We Mean By True North?

- The Six-Step Problem-Solving Process

- Five Lean Games Every Company Can Benefit From

- 10 Characteristics of a Good Measure and 7 Pitfalls to Avoid

- DOWNTIME and the Eight Wastes

- The 8 Common Wastes in an Office That Cause Downtime

- Lean Leadership: Lessons from Abe Lincoln

Blog Archive

- ► May (12)

- ► April (13)

- ► March (13)

- ► February (12)

- ► January (14)

- ► December (11)

- ► November (13)

- ► October (12)

- ► September (13)

- ► August (13)

- ► July (8)

- ► June (13)

- ► May (14)

- ► April (12)

- ► February (13)

- ► January (13)

- ► December (12)

- ► October (13)

- ► August (14)

- ► July (13)

- ► May (13)

- ► August (10)

- ► March (14)

- ► July (14)

- ► December (10)

- ► June (12)

- ► April (9)

- ► December (13)

- ► October (14)

- ► September (12)

- Lean Roundup #102 - November, 2017

- Lean Tips Edition #117 (1756-1770)

- Lean Quote: Gratitude is Something We Have to Prac...

- Happy Thanksgiving!

- Be Thankful This Thanksgiving

- Lean Quote: Developing Excellent Communication Ski...

- Guest Post: Empowering Others

- Lean Quote: Priorities and the Rule of Three

- Lean Administration: Time based Improvement Not Co...

- Guest Post: The Best Online Kanban Board Tools for...

- Lean Quote: Lean Goes Beyond Tools

- Lean Tips Edition #116 (1741 -1755)

- ► January (12)

- ► October (15)

- ► December (14)

- ► November (12)

- ► January (15)

- ► August (17)

- ► July (19)

- ► June (16)

- ► May (19)

- ► April (18)

- ► March (17)

- ► February (16)

- ► January (18)

- ► December (19)

- ► November (18)

- ► October (20)

- ► September (18)

- ► August (22)

- ► July (23)

- ► June (21)

- ► April (17)

- ► February (18)

- ► January (20)

- ► December (18)

- ► November (19)

- ► October (17)

- ► September (22)

- ► July (20)

- ► June (20)

- ► May (21)

- ► April (19)

- ► March (20)

- ► February (17)

- ► January (17)

- ► December (20)

- ► November (15)

- ► August (18)

- ► July (17)

- ► April (14)

- ► November (17)

- ► July (15)

- ► June (9)

- ► May (5)

- A Lean Journey (80)

- A Year Ago (8)

- ASQ's Influential Voices (40)

- Book Review (64)

- Change Management (53)

- Communication (13)

- Conference (10)

- Culture (38)

- Customer Focus (2)

- Daily Management (1)

- Development/Training (13)

- Empowerment (19)

- Engagement (37)

- Exercises/Games (8)

- Facilitation (2)

- Feedback (3)

- Guest Post (167)

- In the News (69)

- Innovation (2)

- L.A.M.E. (5)

- Leadership (220)

- Lean and Green (12)

- Lean Basics (109)

- Lean Definition (24)

- Lean Fun (10)

- Lean in Practice (55)

- Lean Management (152)

- Lean Office (14)

- Lean Products (4)

- Lean Quote (725)

- Lean Resources (44)

- Lean Roundup (198)

- Lean Thinking (5)

- Lean Tips (233)

- Meet-up (29)

- Podcast (5)

- Problem Solving (21)

- Product Review (2)

- Project Management (6)

- Quality (48)

- Respect For People (57)

- Sharing Best Practices (129)

- Soft Skills (3)

- Strategy (6)

- Supply Chain (1)

- Talking Lean (1)

- Teamwork (42)

- Visual Factory (31)

- Webinar (23)

Lean Blogs I Like

- 2 Lean Principles

- 5S Supply Blog

- Avoiding The Corporate Death Spiral

- Be More Careful!

- Curious Cat

- Daily Kaizen

- Evolving Excellence

- Gemba Panta Rei

- Gemba Tales

- Got Boondoggle?

- Gotta Go Lean Blog

- Improve With Me

- Jamie Flinchbaugh

- Kaizen Notebook

- Lean Builder

- Lean Communications

- Lean For Everyone

- Lean Healthcare Exchange

- Lean Homebuilding

- Lean Insider

- Lean Is Good

- Lean Leadership

- Lean Pathways

- Lean Printing

- Lean Reflections

- Lean Simulations

- Lean Six Sigma Academy

- LeanCor Blog

- Learn Lean Manufacturing

- Learning About Lean

- Old Lean Dude Blog

- The A3 Post

- The Lean Edge

- The Lean Library

- The Lean Logistics Blog

- The Lean Thinker

- The Lean Way Consulting

- TimeBack Blog

- To The Gemba

- Training Within Industry

- Visual Management Blog

Other Sites I like

- AME's Target Magazine

- AnythingLean.com

- Art of Lean

- Bosch Rexroth Lean Production

- CIRAS - Theory of Constraints

- Chasing The Rabbit

- Corporate Event Management

- Creative Safety Supply

- Creative Safety Supply 5S Resource Page

- Fuss & O'Neill SPL

- Gemba Academy

- Grassroots Innovation

- IndustryWeek

- Lean Enterprise Institute

- Leanovations

- Learn More McGraw-Hill

- MEP University

- Manufacturers BlogNotions

- Manufacturing Business Technology

- Manufacturing Pulse

- Modern Machine Shop

- Running A Hospital

- Superfactory

- The 5S Store

- Unclutterer

- Visual Workplace

- Xtreme Lean Consulting

- catalyst for change

- freeleansite.com

wibiya widget

A lean journey blog - copyright © 2009-2024 tim mcmahon - all rights reserved.

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Wiki , Six Sigma

DMAIC Model | The 5 Phase DMAIC Process to Problem-Solving

- 5 mins to read

- July 1, 2020

- By Reagan Pannell

Summary: An Introduction to DMAIC

Dmaic – the dmaic model.

The 6 Sigma DMAIC model remains the core roadmap for almost all Lean Six Sigma problem-solving approaches that drive quality improvement projects. It is used to ensure a robust problem-solving process is followed to give the best chance of the best solution being found.

A note about the structure and the approach used in this article.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

What is the DMAIC Model?

DMAIC is short for: Define, Measure, Analyse, Improve and Control. These are the key phases that each project must go through to find the right solution. This flow is the concept behind DMAIC Analysis of an issue and its the DMAIC cycle all projects must go through.

As you can quickly see from the 5 DMAIC phases they follow a logical sequence as we will go through in more detail below. But they also make sure you do not try to jump to implementing a solution before you have properly, defined and measured what you are going to be an improvement.

We all love to jump to solutions, but the DMAIC problem-solving structure helps us have a more rigorous approach so that we do not short cut the process and perhaps miss the best solution or perhaps implement the wrong solution as well. It can help companies better structure their problem-solving approaches and be more robust in their approach.

DMAIC – The 5 DMAIC Process Phases

The phases throughout the DMAIC model have and can be broken down in many different ways. One of the best approaches we have found is from Opex Resources which shows how to examine the existing processes, and with a project team, and the sigma improvement process, we can solve complex issues.

DMAIC Define Phase

The purpose of the Define phase is ultimately to describe the problems that need to be solved and for the key business decision-makers to be aligned on the goal of the project. Its about creating and agreeing the project charter .

All too often, teams have identified solutions without actually defining what it is they will actually be trying to do or perhaps not do. This can lead to internal confusion and often solutions which completely miss the business requirements and needs.

- Define the Business Case