- A Step-by-Step Guide to A3 Problem Solving Methodology

- Learn Lean Sigma

- Problem Solving

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies.

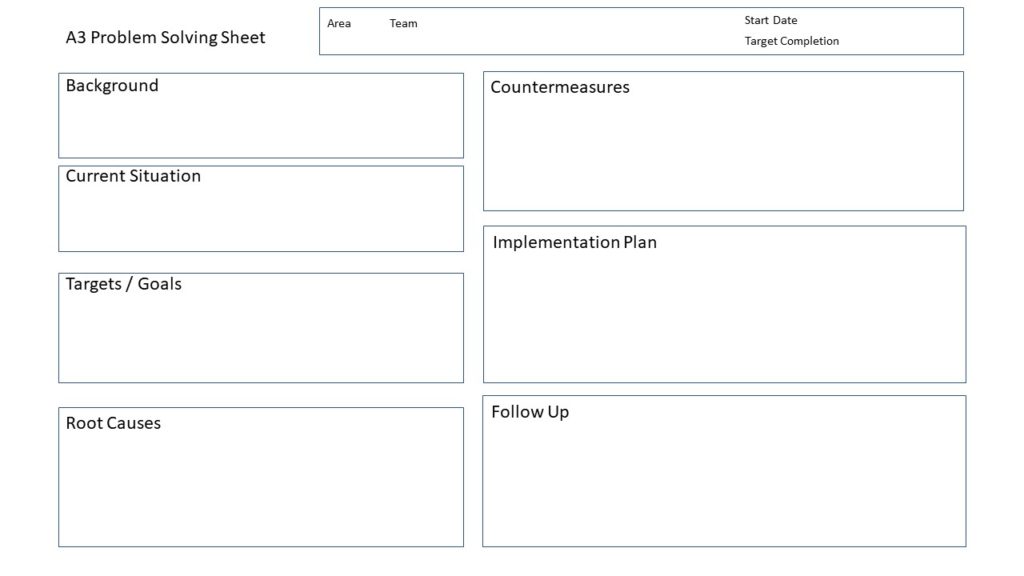

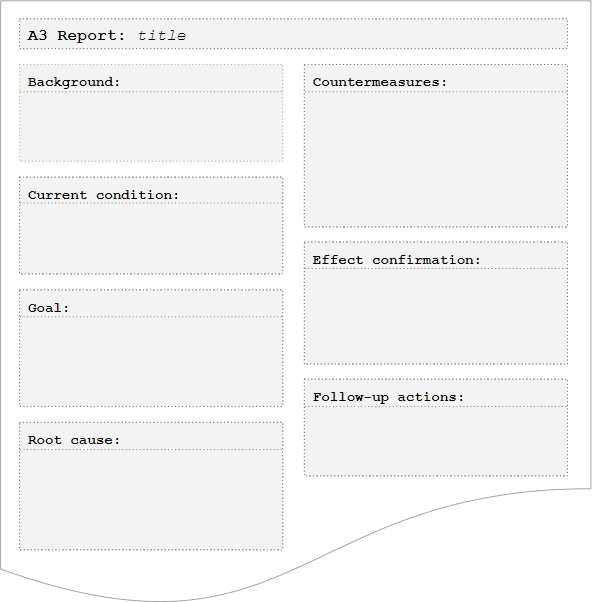

A3 Problem solving is a structured and systematic approach to problem-solving that originated with the lean manufacturing methodology. It visualizes the problem-solving process using a one-page document known as an A3 report. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner.

A3 Problem Solving has numerous advantages, including improved communication, better decision-making, increased efficiency, and reduced waste. It is a powerful tool for businesses of all sizes and industries, and it is especially useful for solving complex and multi-faceted problems.

In this blog post, we will walk you through the A3 Problem Solving methodology step by step. Whether you are new to A3 Problem Solving or simply want to improve your skills, this guide will help you understand and apply the process in your workplace.

Table of Contents

What is a3 problem solving.

A3 Problem Solving is a structured and systematic approach to problem-solving that makes use of a one-page document called an A3 report to visually represent the process. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner. The method was created within the framework of the Lean manufacturing methodology and is based on the principles of continuous improvement and visual management.

Looking for a A3 Problem solving template? Click here

Origin and History of A3 Problem Solving

A3 Problem Solving was developed by Toyota Motor Corporation and was first used in the manufacture of automobiles. The term “A3” refers to the size of the paper used to create the report, which is an ISO standard known as “A3”. The goal of the A3 report is to provide a visual representation of the problem-solving process that all members of the organisation can easily understand and share. A3 Problem Solving has been adopted by organisations in a variety of industries over the years, and it has become a widely used and recognised method for problem-solving.

Key Principles of A3 Problem Solving

The following are the key principles of A3 Problem Solving:

- Define the problem clearly and concisely

- Gather and analyze data to gain a deep understanding of the problem

- Identify the root causes of the problem

- Develop and implement effective solutions

- Evaluate results and continuously improve

These principles serve as the foundation of the A3 Problem Solving methodology and are intended to assist organisations in continuously improving and achieving their objectives. Organizations can effectively solve problems, identify areas for improvement, and drive results by adhering to these principles.

Step 1: Define the Problem

Importance of clearly defining the problem.

The first step in the A3 Problem Solving process is critical because it lays the groundwork for the remaining steps. To define the problem clearly and accurately, you must first understand the problem and identify the underlying root cause. This step is critical because if the problem is not correctly defined, the rest of the process will be based on incorrect information, and the solution developed may not address the issue effectively.

The significance of defining the problem clearly cannot be overstated. It aids in the collection and analysis of relevant data, which is critical for developing effective solutions. When the problem is clearly defined, the data gathered is more relevant and targeted, resulting in a more comprehensive understanding of the issue. This will enable the development of solutions that are more likely to be effective because they are founded on a thorough and accurate understanding of the problem.

However, if the problem is not clearly defined, the data gathered may be irrelevant or incorrect, resulting in incorrect conclusions and ineffective solutions. Furthermore, the process of collecting and analysing data can become time-consuming and inefficient, resulting in resource waste. Furthermore, if the problem is not accurately defined, the solutions developed may fail to address the root cause of the problem, resulting in ongoing issues and a lack of improvement.

Techniques for Defining the Problem

The first step in the A3 Problem Solving process is to clearly and accurately define the problem. This is an important step because a clearly defined problem will help to ensure that the appropriate data is collected and solutions are developed. If the problem is not clearly defined, incorrect data may be collected, solutions that do not address the root cause of the problem, and time and resources may be wasted.

A problem can be defined using a variety of techniques, including brainstorming , root cause analysis , process mapping , and Ishikawa diagrams . Each of these techniques has its own advantages and disadvantages and can be used in a variety of situations depending on the nature of the problem.

Best Practice for Defining the Problem

In addition to brainstorming, root cause analysis, process mapping, and Ishikawa diagram s, best practices should be followed when defining a problem in A3 Problem Solving. Among these best practices are:

- Define the issue in a specific and quantifiable way: It is critical to be specific and concise when defining the problem, as well as to quantify the problem in terms of its impact. This will help to ensure that all stakeholders understand the problem and that data collection is focused on the right areas.

- Focus on the problem’s root cause: The A3 Problem Solving methodology is intended to assist organisations in identifying and addressing the root cause of a problem, rather than just the symptoms. Organizations can ensure that their solutions are effective and long-lasting by focusing on the root cause of the problem.

- Ascertain that all stakeholders agree on the problem’s definition: All stakeholders must agree on the definition of the problem for the A3 Problem Solving process to be effective. This ensures that everyone is working towards the same goal and that the solutions developed are relevant and appropriate.

- Consider the problem’s impact on the organisation and its stakeholders: It is critical to consider the impact of the problem on the organisation and its stakeholders when defining it. This will assist in ensuring that the appropriate data is gathered and that the solutions developed are relevant and appropriate.

Organizations can ensure that their problem is defined in a way that allows for effective data collection, analysis, and solution development by following these best practices. This will aid in the development of appropriate solutions and the effective resolution of the problem, resulting in improvements in the organization’s processes and outcomes.

Step 2: Gather Data

Gathering data in a3 problem solving.

Data collection is an important step in the A3 Problem Solving process because it allows organisations to gain a thorough understanding of the problem they are attempting to solve. This step entails gathering pertinent information about the problem, such as data on its origin, impact, and any related factors. This information is then used to help identify root causes and develop effective solutions.

One of the most important advantages of data collection in A3 Problem Solving is that it allows organisations to identify patterns and trends in data, which can be useful in determining the root cause of the problem. This information can then be used to create effective solutions that address the problem’s root cause rather than just its symptoms.

In A3 Problem Solving, data collection is a collaborative effort involving all stakeholders, including those directly impacted by the problem and those with relevant expertise or experience. Stakeholders can ensure that all relevant information is collected and that the data is accurate and complete by working together.

Overall, data collection is an important step in the A3 Problem Solving process because it serves as the foundation for effective problem-solving. Organizations can gain a deep understanding of the problem they are attempting to solve and develop effective solutions that address its root cause by collecting and analysing relevant data.

Data Collection Methods

In A3 Problem Solving, several data collection methods are available, including:

- Observations

- Process diagrams

The best data collection method will be determined by the problem being solved and the type of data required. To gain a complete understanding of the problem, it is critical to use multiple data collection methods.

Tools for Data Analysis and Visualization

Once the data has been collected, it must be analysed and visualised in order to gain insights into the problem. This process can be aided by the following tools:

- Excel Spreadsheets

- Flow diagrams

- Pareto diagrams

- Scatter Plots

- Control diagrams

These tools can assist in organising data and making it easier to understand. They can also be used to generate visual representations of data, such as graphs and charts, to communicate the findings to others.

Finally, the data collection and analysis step is an important part of the A3 Problem Solving process. Organizations can gain a better understanding of the problem and develop effective solutions by collecting and analysing relevant data.

Step 3: Identify Root Causes

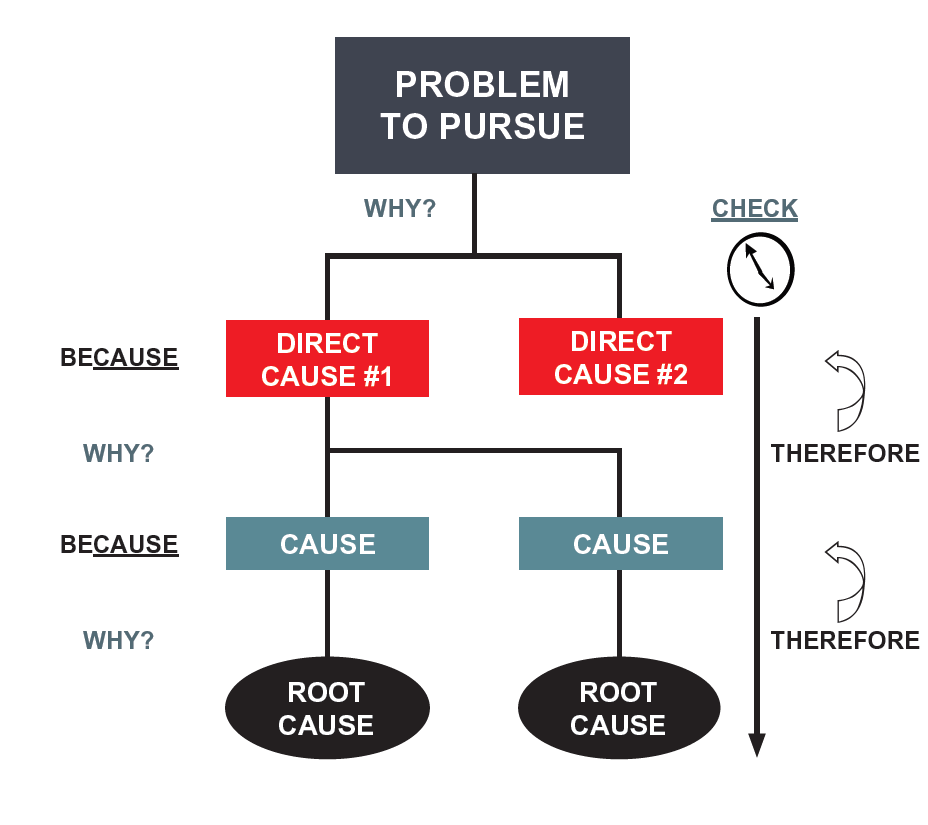

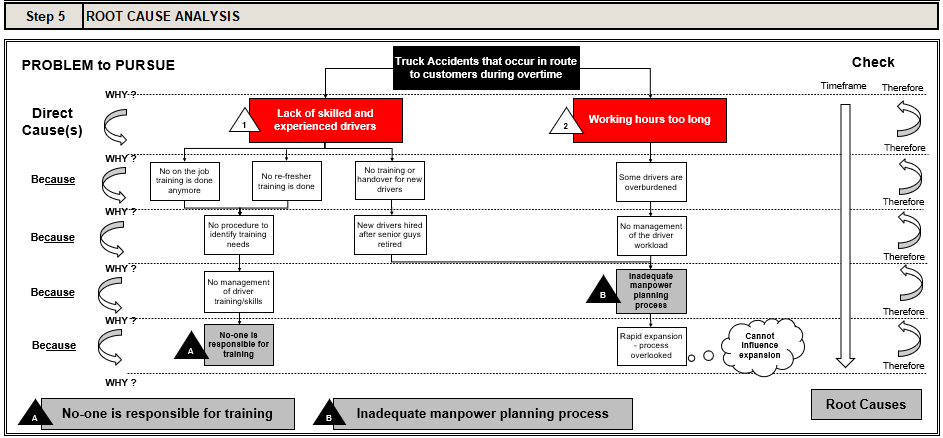

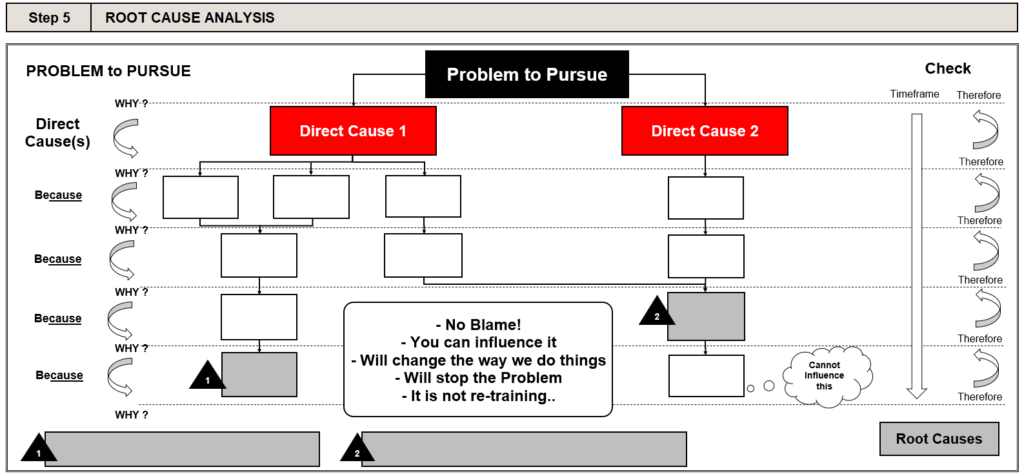

Identifying the root causes of the problem is the third step in the A3 Problem Solving process. This step is critical because it assists organisations in understanding the root causes of a problem rather than just its symptoms. Once the underlying cause of the problem is identified, it can be addressed more effectively, leading to more long-term solutions.

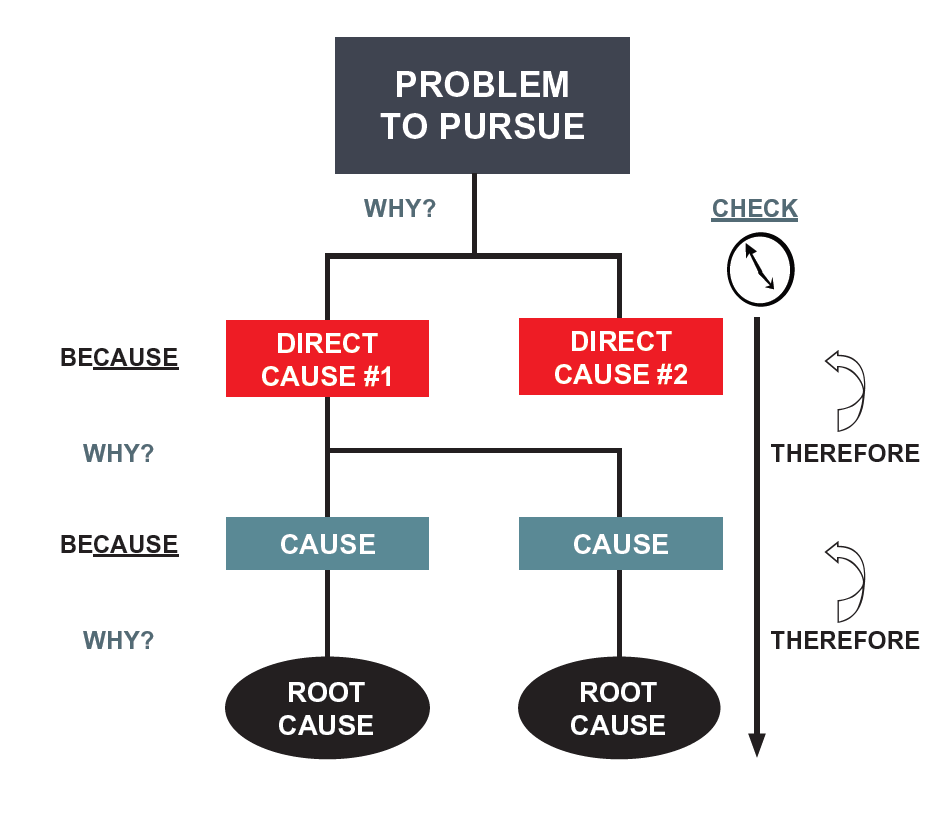

Overview of the Root Cause Analysis Process

The process of determining the underlying causes of a problem is known as root cause analysis. This process can assist organisations in determining why a problem is occurring and what can be done to prevent it from recurring in the future. The goal of root cause analysis is to identify the underlying cause of a problem rather than just its symptoms, allowing it to be addressed more effectively.

To understand Root cause analysis in more detail check out RCA in our Lean Six Sigma Yellow Belt Course Root Cause Analysis section

Techniques for Identifying Root Causes

There are several techniques for determining the root causes of a problem, including:

- Brainstorming

- Ishikawa diagrams (also known as fishbone diagrams)

- Root Cause Tree Analysis

These methods can be used to investigate the issue in-depth and identify potential root causes. Organizations can gain a deeper understanding of the problem and identify the underlying causes that must be addressed by using these techniques.

Best Practices for Conducting Root Cause Analysis

It is critical to follow these best practices when conducting root cause analysis in A3 Problem Solving:

- Make certain that all stakeholders participate in the root cause analysis process.

- Concentrate on determining the root cause of the problem rather than just its symptoms.

- Take into account all potential root causes, not just the most obvious ones.

- To identify root causes, use a systematic approach, such as the 5 Whys or root cause tree analysis.

Organizations can ensure that root cause analysis is carried out effectively and that the root cause of the problem is identified by adhering to these best practises. This will aid in the development of appropriate solutions and the effective resolution of the problem.

Step 4: Develop Solutions

Developing solutions is the fourth step in the A3 Problem Solving process. This entails generating ideas and options for dealing with the problem, followed by selecting the best solution. The goal is to develop a solution that addresses the root cause of the problem and prevents it from recurring.

Solution Development in A3 Problem Solving

A3 solution development Problem solving is an iterative process in which options are generated and evaluated. The data gathered in the previous steps, as well as the insights and understanding gained from the root cause analysis, guide this process. The solution should be based on a thorough understanding of the problem and address the underlying cause.

Techniques for Developing Solutions

There are several techniques that can be used to develop solutions in A3 Problem Solving, including:

- Brainwriting

- Solution matrix

- Multi voting

- Force field analysis

These techniques can help to generate a range of options and to select the best solution.

Best Practice for Developing Solutions

It is critical to follow the following best practices when developing solutions in A3 Problem Solving:

- Participate in the solution development process with all stakeholders.

- Make certain that the solution addresses the underlying cause of the problem.

- Make certain that the solution is feasible and achievable.

- Consider the solution’s impact on the organisation and its stakeholders.

Organizations can ensure that the solutions they develop are effective and sustainable by adhering to these best practises. This will help to ensure that the problem is addressed effectively and that it does not reoccur.

Step 5: Implement Solutions

The final and most important step in the A3 Problem Solving methodology is solution implementation. This is the stage at which the identified and developed solutions are put into action to address the problem. This step’s goal is to ensure that the solutions are effective, efficient, and long-lasting.

The implementation Process

The implementation process entails putting the solutions developed in the previous step into action. This could include changes to processes, procedures, and systems, as well as employee training and education. To ensure that the solutions are effective, the implementation process should be well-planned and meticulously executed.

Techniques for Implementing Solutions

A3 Problem Solving solutions can be implemented using a variety of techniques, including:

- Piloting the solution on a small scale before broadening its application

- Participating in the implementation process with all relevant stakeholders

- ensuring that the solution is in line with the goals and objectives of the organisation

- Monitoring the solution to determine its effectiveness and make any necessary changes

Best Practice for Implementing Solutions

It is critical to follow these best practices when implementing solutions in A3 Problem Solving:

Make certain that all relevant stakeholders are involved and supportive of the solution. Have a clear implementation plan that outlines the steps, timeline, and resources required. Continuously monitor and evaluate the solution to determine its efficacy and make any necessary changes. Encourage all stakeholders to communicate and collaborate openly. Organizations can ensure that solutions are effectively implemented and problems are effectively addressed by adhering to these best practices. The ultimate goal is to find a long-term solution to the problem and improve the organization’s overall performance.

In conclusion, A3 Problem Solving is a comprehensive and structured methodology for problem-solving that can be applied in various industries and organisations. The A3 Problem Solving process’s five steps – Define the Problem, Gather Data, Identify Root Causes, Develop Solutions, and Implement Solutions – provide a road map for effectively addressing problems and making long-term improvements.

Organizations can improve their problem-solving skills and achieve better results by following the key principles, techniques, and best practices outlined in this guide. As a result, both the organisation and its stakeholders will benefit from increased efficiency, effectiveness, and satisfaction. So, whether you’re an experienced problem solver or just getting started, consider incorporating the A3 Problem Solving methodology into your work and start reaping the benefits right away.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Visual Management

Standard Work Instructions

Free lean six sigma templates.

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

Lean Manufacturing Tools

Lean manufacturing tools, techniques and philosophy | lean and related business improvement ideas.

A3 Problem Solving | A3 Root Cause Analysis

Problems are inevitable, no matter how hard we plan and what precautions we take, they will eventually creep up and bite us. Rushing in and trying to fix the problems quickly, however, rarely seems to truly make these problems go away. Often, they come back time after time. The reason for this is that we fail to use a methodical approach to identify the true root causes of the problems and fail to put in a robust fix that will prevent the problem reoccurring.

A3 problem solving is one easy way to put in place a process that will help you to solve problems permanently as well as making improvements to your processes.

What is A3 Problem Solving

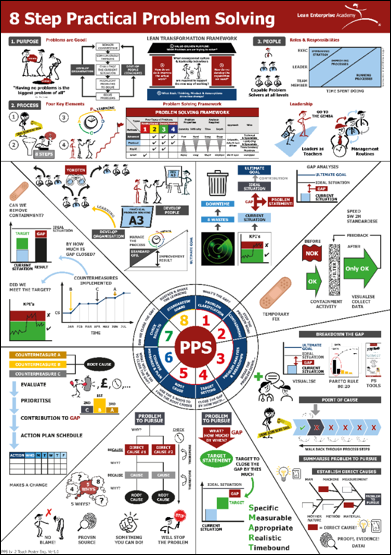

As with many things from Toyota, A3 problem solving attempts to make things as simple and as visual as possible. A3 refers to the paper size used for the reporting and all the process is contained within the confines of this single sheet of 11” by 17” paper. Some suggest that the reason for the single piece of paper is down to the rumored refusal of Taiichi Ohno to read any more than a single page of any report.

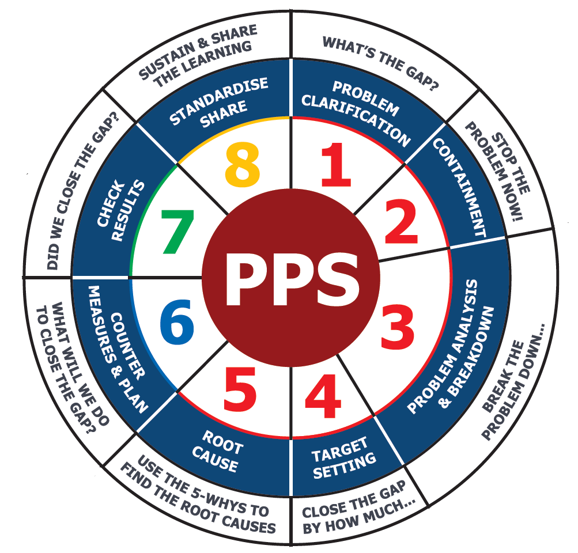

There is nothing magical or revolutionary about the process either. It simply follows the Deming’s Plan-Do-Check-Act Cycle or PDCA. It is also very similar to other processes and layouts that other companies have used over the years such as Ford’s 8D process for problem solving.

The effectiveness of the form however lays more in the attitude of the teams implementing the A3 process than the form itself. Problems are opportunities to improve what you are doing and should never simply be seen as just a “problem”.

A3 problem solving sheets are not going to be a magic wand that you can wave over your problems to solve them. Without a dedicated team to follow the process they are unlikely to help you.

The A3 Problem Solving Process

The A3 root cause analysis process is usually broken down into 7 steps, some break it down into 8 or 9, however the total number of steps and what they are called are not important as long as you follow the idea behind them. The steps follow the PDCA process and take you through a logical step by step route to clearly identify:

- What is the problem

- Why we need to fix it

- What is the actual root cause

- How we will contain the problem in the short term

- Plan how we fix the root cause

- Confirmation that the countermeasures fix the issue

- Changes to standardized work to fix the issue permanently

- Share any changes within the company

Often these steps are broken down under the following headings on the A3 worksheet:

Current Situation

- Targets or Goals

Root Cause Analysis

Countermeasures.

- Implementation Plan

This is what should be considered and detailed within each section:

- What is the actual issue that you are looking to correct?

- How does it impact the business objectives? Why do we need to fix it?

It is always best to take your team to where the problem is occurring to see the problem firsthand. Talking about something in a remote location is never going to be as effective as actually observing at the Gemba (Workplace).

The team should carefully detail the problem. This should cover all relevant information such as how often something happens, when, where, etc. Depending on the complexity of the issue it may be necessary to collect data in the form of graphs and control charts or to conduct process mapping exercises to understand what is happening.

Targets / Goals

What does the team see as the ideal solution to the problem? What are we going to achieve? Your objectives should be clearly stated, and a time frame agreed so that all can agree on what you hope to do through your team.

There are of course many ways that you can arrive at the root cause of your problems depending on the complexity of the problem that you face. The right quality improvement tools should be selected and used from Pareto charts to fishbone diagrams or the 5 whys.

Ensure that your A3 root cause analysis comes up with agreed reasons for your problems. Remember, that there are often multiple causes that may need to be fixed.

Once you have your root cause(s) identified you can get to work to brainstorm the changes that you need to make to fix the problems. Remember that all fixes should aim to achieve the goals that you have identified earlier in the process.

Action Plan

This is your plan of action to fix the problem that you have identified. This plan should be detailed and include what is to be done, who is responsible, and of course when it will be done by. You should also consider the expected outcome from each action so that you will have a clear idea of whether the action has had any effect on your issue.

Once the plan has been detailed it should be implemented effectively by the team.

Too often teams will stop at the plan implementation stage. They make the changes that they have suggested and then fail to check if those actions have been effective. You must verify the effectiveness of your actions to confirm that they have fixed the root causes that you have identified. Otherwise the problems could easily return.

If the changes have not managed to fix the problem, then the process needs to be revisited. The team needs to work through the cycle once again to see what they have missed and to make alternative plans to fix the problems.

Changes should be made permanent if they are found to be effective through changes to standardized work and other procedural documentation.

Teams should also share what they have learned and implemented within the company. Often there is the opportunity to mirror the changes made to prevent issues occurring in other parts of your business.

Why Use A3 Reporting

The A3 reporting format does not have to limited to simply problem solving. Toyota use it for a number of things such as status reports, improvement suggestions and proposals. Other companies have developed similar reports for things such as coaching. Your imagination and business needs are your only limitation.

The A3 lean process is highly flexible and provides you with a highly visible way to communicate everything from your problem solving to continuous improvement initiatives. Used well with trained and dedicated teams it can really make a huge difference to your company.

Related posts:

- Top 50 Lean Tools | Comprehensive List for Lean Manufacturing and Service

- VSM Value Stream Mapping

Post navigation

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

- Agile Education Program

- The Agile Navigator

A3 - Root Cause Analysis

The A3 is a tool for identifying root causes to deep problems and building consensus on how to remedy them.

Estimated time for this content : 20 minutes Audience : Scrum Masters facing a reoccurring impediment Suggested Prerequisites : Retrospective , Muda

Upon Completion you will:

- Have a base-line knowledge of lean principals as practiced by Toyota

- Know how lean and agile practices utilize the Plan Do Check Act cycle

- Understand the pre-cursors to doing root cause analysis

- Understand how to perform root cause analysis

- Be able to complete a step-by-step process for the A3

The A3 tool was pioneered by Toyota to document and address problems with their production process. Anyone at Toyota can initiate the process and they do it for almost all problems they encounter. To capture their analysis, they use the largest sheet of paper that fit into a copy machine, the A3 or Tabloid (two 8.5x11 sheets side-by-side.)

The A3 process is based on the Plan, Do, Check, Act , or PDCA Cycle. To initiate the A3 all the stakeholders should gather. The owner is the person who is responsible for ushering the process through to its end and the mentor is typically a high-ranking executive who can help implement the actions that result from the process. An A3 is meant to simplify complex problems, so using just one large sheet of paper follow the example in the slides. The title should be something catchy so it is easy to remember and to refer to.

A3 Template

A3 Template in Google Docs (Opens in a New Tab) A3 Problem Solving Template v1.2 (April 2015) by Henrik Kniberg and Tom Poppendieck License: Creative Commons Attribute 4.0 International Original link: http://www.crisp.se/lean/a3-template

Step 1: Plan

The first cell is used to describe the background of the problem. It is important that all stakeholders participate in this phase so everyone involved has a clear idea of what the problem is. The A3 is a process so even if the problem is obvious, it is important to discuss it and make sure everyone is literally on the same page. Often, the background is a macro problem that affects multiple parts of the Scrum process.

With the background established, the discussion moves on to establishing the current conditions. This will be a list of symptoms like decreased Velocity or poor morale. It is important to make sure that the group is able to include some Metrics in this cell. Loss of revenue is always helpful because it gets management’s attention but any number of metrics will do. The important part is that they are precise and measurable.

Next, the group should decide on what the ideal outcome will be when the problem is solved. (The ideal state is similar to an Acceptance Test or Definition of Done for a Product Backlog Item .) Metrics are helpful here as well. It is important to have a well-defined target condition because it will help align all stakeholders around a common vision.

The last part of the planning phase is root cause analysis (see video) and this is the core of the A3. Establishing the problem and what life will be like after the problem is solved is relatively easy, agreeing on what the root causes are may involve some uncomfortable truths.

It sounds very high minded, but quality root cause analysis actually requires channeling your inner five-year old. The technique is called the Five Whys . Basically, the group needs to start with the most obvious problem and ask why. Here is an example:

Sprints are failing. “Why?” A: People think that the Team is lazy. “Why?” A: Because morale is low. “Why?” A: The Team is getting mixed messages from the Product Owner. “Why?” A: The Product Owner is getting conflicting orders from two managers. “Why?” A: The organization incentivizes competition rather than cooperation.

The point of the exercise is to get at least five layers deep into any problem. Five layers is a general rule of thumb. Root causes can be found three or seven layers deep. It is really important to invest a lot of time here. Often the stakeholders think they have arrived at a few root causes only to have to repeat the process later. Another good rule of thumb is that once the group thinks it has discovered the root causes, they should then put in again as much time as they’ve just spent. It is important to be exhaustive. (There are other root cause analysis techniques. A variety can be found here .)

There will likely be multiple root causes to a problem. In the above example, the Product Owner role has broken down, managers are probably talking to the team outside of their scope and the organization’s incentives are flawed.

Finding a root cause is a bit of an art. Here are a few characteristics to help guide your process: first, a root cause will resonate with stakeholders. Second, root causes also tend to be actionable, meaning that the group will have an idea how to approach the specific challenge. And, third it will have a certain amount of specificity. In the above example, “people think the Team is lazy” doesn’t have any granularity. Further inquiry helped pinpoint a more detailed root cause.

In Systems Theory, if multiple solutions are implemented at once, it is impossible to trace the effect of each. Therefore, it is important to implement only one solution at a time. The A3 is a living document so the group should continually note the results of each solution implemented and update the A3 as conditions change.

Step 3: Check

It is important to confirm that the countermeasure has the ideal state identified in step one. In order to know if the countermeasure worked, it is important to have objective criteria to judge it against. That is why having metrics in the current and target conditions makes for a better A3. It may be that multiple countermea sures are necessary to achieve the ideal state.

Step 4: Act

Hard Truths

When an A3 fails it is usually because the group didn’t delve deep enough into the problem or that the problem was beyond the ability of the team to solve or recognize. Solving the root cause can be the end result of a successful A3. However, that’s not always the case. A successful A3 can show that the root cause is beyond the ability of the organization to change like in the above example where there wasn’t enough market demand for the product. A good A3 can reveal deep challenges within the organization like conflicting core values, poor leadership or a critical lack of resources. The A3 isn’t a silver bullet; rather it’s a tool to bring transparency to dysfunction. How the stakeholders handle the dysfunction is their responsibility.

Paper: Lean as a Scrum Troubleshooter

Related Posts via Categories

- Leaders Leveraging the OODA Loop for Value Stream Management

- The Effort Estimation Matrix – A Tool for Estimating Agile Story Points

- Scrum@Scale for Organizational Success: Insights from a Scrum of Scrums Master

- Leaders Leveraging the OODA Loop in a Scrum@Scale Environment

- Scrum Inc. Webinar with JJ Sutherland and Jeff Sutherland

- SI Consulting Chats: Why Agile Transformations Fail

- Decoding Agility: Asset-Based Prioritization

- Debunking Sustainable Pace with Dr. Jeff Sutherland

- The Shifting Landscape of Business Agility and Consulting

- Scrum@Scale: Navigating Modern Challenges

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Culture , Lean Training , Lean Wiki , Tools

A Deep Dive into the A3 Problem-Solving Approach

- 11 mins to read

- June 20, 2023

- By Reagan Pannell

In today’s fast-paced and fiercely competitive business world, organisations must find ways to continuously adapt, evolve, and excel. Amidst the myriad methods and techniques for achieving improvements and driving continuous improvement, few have proven as profound and transformative as Toyota’s A3 problem-solving approach.

A significant driving force behind the company’s rise to global prominence, the A3 process fosters a culture where problems are embraced as opportunities for growth and learning. In this article, we’ll explore the origins and underlying principles of the A3 approach and uncover the secrets to its success in unlocking the power of improvements.

Understanding the A3 Approach

The A3 methodology is an integral part of the Toyota Production System (TPS), a set of principles and practices that have shaped the company’s approach to manufacturing, management, and continuous improvement over the years. Named after the A3 sheet of paper that was historically used to capture the plan, analysis, and follow-up on a single page, the A3 process represents a simple, yet powerful, tool for addressing complex challenges and discovering lasting solutions.

At its core, the A3 approach is rooted in three key elements:

1. Thorough problem analysis: The foundation of the A3 process lies in digging deep to diagnose the true nature and root cause of an issue, rather than jumping to hastily devised fixes that merely address symptoms.

2. Structured documentation: The A3 report serves as both a communication tool and an iterative planning device, with each section building on the previous ones to guide problem solvers through a comprehensive analysis, solution development, and execution process. It’s the foundation of good continuous improvement.

3. Cyclical learning and improvement: Leadership and employees alike are encouraged to commit to hypothesis-driven inquiry, observation, experimentation, and reflection, leading to a culture that actively seeks and leverages opportunities for growth by solving problems.

How to Implement the A3 Process in Your Organisation

The Lean Thinking A3 approach can be distilled into seven essential steps:

1. Identify the problem:

Clearly articulate and define the issue at hand, avoiding the temptation to jump to solutions or assume important facts to be self-evident..

When identifying the problem, it is important to ensure that all relevant stakeholders in the organisation are consulted. This helps to ensure that the issue is accurately described and understood from multiple perspectives. A thorough problem analysis should also include conducting research into possible causes or root issues, and clearly documenting any observed symptoms of the problem. Additionally, it is essential to identify any major risks associated with not finding a solution and recognise any constraints (both external and internal) that may exist which could limit potential solutions. Lastly, it is important to consider any potential opportunities which may arise from addressing the issue that may have been overlooked at first glance. This is the problem statement part which is a critical component that identifies the difference between the current condition and the target condition.

At this stage, we are not looking at how to solve problems being faced or at the potential solution to solving problems. It’s about developing a good understanding of how the actual results differ from the expected results and providing an in-depth systematic approach to process improvement and developing problem-solving skills.

2. Establish the context and background:

Provide a high-level overview of the problem, describing the stakeholders involved, relevant data, and the broader organisational context in which the challenge has arisen..

It is important to ensure that all stakeholders are properly considered when identifying any potential solutions as their perspectives can play a vital role in determining an effective solution. All related data should be thoroughly analysed to understand the full scope of potential solutions. This includes resources, costs, timelines, and any legal or regulatory issues that may need to be considered. Additionally, it is important to consider how well-proposed solutions fit within existing organisational policies and procedures as this could impact implementation success. Finally, understanding how proposed solutions would interact with other initiatives or processes currently taking place in the organisation can help inform decisions about whether or not they are viable options. It may include conducting some value stream mapping to dig deeper into the current state.

It is important to fully explore any underlying factors that may be contributing to the issue at hand and ensure in-depth problem analysis. This includes looking deeper into existing systems, structures, and processes related to the problem in order to identify potential areas of improvement or optimisation. Additionally, it is essential to consider any relevant industry trends or external influences that could impact how the problem manifests within the organisation.

When analysing a problem, collecting data from various sources is important to get a more comprehensive understanding of how a particular issue can be addressed. This includes mapping the current process using the VSM, SIPOC, Process Mapping or Flowcharting techniques. Additionally, interviews and surveys can be conducted with stakeholders to gain insights into how they perceive the issue and their perspectives on potential solutions. Lastly, it is important to observe any real-world activities related to the problem to uncover key areas where time, effort, resources, money etc is being wasted. This is the time improvement that may not have been identified otherwise.

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, fundamentals of lean.

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LEAN SIX SIGMA GREEN BELT

Get 3-days free access to our green belt course, accelerate your career, 3. set a goal:, now that you have identified the problem and outlined the relevant context, it is time to set a project goal or outcome..

This involves clearly articulating the desired state of affairs and any key deliverables of the proposed solution. Whether it is reducing operational costs, increasing efficiency, improving customer experience, or something else entirely – defining specific objectives with measurable metrics can help ensure that project teams stay focused and remain aligned on their ultimate destination.

At this stage, it is also important to consider how long it will take to reach the desired outcome. Establishing an implementation timeline will help safeguard progress and provide a framework for tracking results along the way. Setting milestones for achieving particular goals at certain points in time can be especially helpful in keeping teams accountable throughout the process. Additionally, having a plan for evaluating success after reaching the end target will allow stakeholders to gain further insights into how effective their approach has been in addressing underlying problems, as well as how well-proposed solutions have fared once implemented.

4. Investigate root causes:

Use a variety of techniques (e.g., the 5 whys, fishbone diagrams, pareto charts) to probe the problem’s underlying causes and avoid settling on proximate reasons..

The process of identifying root causes is essential when using data-driven tools. We always want to find the simplest root cause approach.

One of the most widely used methods for root cause analysis is the ‘5 Whys’ technique. This method involves asking a series of ‘why’ questions to determine the underlying cause of a particular symptom or issue. The goal is to keep asking “Why?” until you reach an answer that can provide insight into how to address the problem and prevent it from occurring in the future.

Another commonly used tool for root cause analysis is the fishbone diagram (also known as Ishikawa diagrams). This approach involves visualising all potential causes which could be causing a symptom or issue in a logical format, allowing users to identify patterns and uncover links between root causes and their respective effects. This technique can be helpful in identifying and focusing on key areas for improvement, as well as helping to identify interdependencies between components within an organisation’s systems.

Finally, Pareto Charts are useful for analysing data collected from surveys, interviews, observations, etc., concerning the severity or frequency of occurrence. This type of chart helps users quickly identify which factors are contributing most significantly towards an issue, allowing them to focus resources towards addressing those areas first and foremost. Additionally, Pareto charts can also be used to prioritise different solutions based on their estimated effectiveness in addressing an issue.

In conclusion, understanding the root cause of an issue through rigorous techniques such as 5 Whys, fishbone diagrams, and Pareto charts provides invaluable insight into how best to address it effectively while preventing it from reoccurring in the future. By leveraging these tools along with other data-led approaches such as process mapping and flowcharting, organisations can ensure that any proposed solutions are well-informed by both qualitative and quantitative data sources as well as ensure they are building consensus across the entire organisation.

5. Countermeasures:

Identify the right countermeasures (corrective actions) to implement that will directly impact the root causes identified..

Brainstorming is a useful tool for identifying potential improvements. It involves coming up with ideas and solutions in an open and collaborative manner, without judgement or criticism. By allowing team members to share their thoughts freely, brainstorming can help uncover innovative solutions that may have otherwise gone unnoticed. Additionally, looking at how waste reduction, flow and pull can be used to improve processes can also provide valuable insights into where improvement opportunities lie.

Brainstorm potential solutions that directly target the root causes and create detailed action plans for implementation, complete with assigned roles, responsibilities, and timelines.

Once the countermeasures are identified, it is important to design an implementation plan and assign roles & responsibilities. This will help ensure that all stakeholders understand their part in the implementation and can work together to achieve the desired outcome. Additionally, it is important to track progress along the way – setting measurable milestones that can be tracked against goals established during the initial problem-solving phase will help keep teams accountable and allow for course corrections if needed.

By utilising A3 Problem Solving Tools such as a template, organisations can easily document and share their analyses with relevant stakeholders throughout each stage of the project. Having detailed record-keeping like this also helps teams stay on target over time while providing insights into how proposed solutions may need to be re-evaluated down the line. This implementation plan provides the entire organisation with a clear project status on a one-page report.

6. Evaluate the results:

Measure the impact of your countermeasures against the problem, using well-defined success criteria, key performance indicators, or other relevant metrics..

Once the countermeasures have been implemented, it is essential to measure and evaluate their success. This can be done by tracking performance against the initial objectives established during the goal phase, as well as establishing key performance indicators to gauge how well the proposed solutions have fared.

Additionally, stakeholders should also consider conducting a post-implementation evaluation in order to assess how successful their approach has been in addressing underlying issues and determining what lessons can be learned from the experience. This will enable teams to identify strengths and weaknesses within their existing processes and make any necessary adjustments going forward. By understanding the outcomes of their improvements, organisations are able to gain valuable insights into how well they’ve succeeded in achieving their goals and ensure continued success moving forward.

Once the countermeasures have been implemented and their success measured, it is important to compare the results against the initial objective. This can be done in a variety of ways, including graphical analysis such as charts, process maps or flow diagrams. Graphical analysis helps to visualise the differences between results achieved before and after the implementation of new measures in a meaningful way. It also provides an increased level of clarity when assessing whether the desired outcomes have been achieved or not.

Process maps can be useful in understanding how changes made during the improvement phase have impacted processes within an organisation. By mapping out existing processes and then comparing them against those following implementation of countermeasures, teams can easily pinpoint where improvements were made and analyse how they led to improved performance overall.

Charts, on the other hand, enable users to quickly identify trends that may have emerged from data collected during the project. For example, if performance metrics are tracked before and after countermeasures are implemented, users can use charts and graphs to more clearly observe any patterns that may indicate an improvement or regression in performance over time – providing further insights into which areas need further attention or adjustment moving forward.

Finally, dashboard views provide an effective means of displaying results at a glance while highlighting any anomalies that might warrant further investigation. Dashboards allow stakeholders to gain access to important information quickly and easily while also helping them keep track of progress towards goals set out during initial problem-solving phases. Additionally, because dashboards support data visualisation capabilities they offer a highly interactive user experience which can help teams understand underlying trends with greater clarity and precision.

7. Standardise and share:

If a countermeasure proves successful, integrate it into the organisation’s standard operating procedures and share it with other teams as a best practice..

Once the countermeasures have been successfully implemented and measured against the initial objectives, these changes need to be integrated into the organisation’s standard operating procedures (SOPs) and shared with other teams as best practices. This will ensure that any improvements made during the problem-solving phase are consistently applied across all teams within the organisation.

In order to ensure that these improvements become part of the organisation’s long-term strategy, process maps should be updated to reflect the new improved way of working. Process maps provide a visual representation of how workflows are structured within an organisation, and by updating them in line with newly-implemented countermeasures, organisations can ensure that their processes continue to remain up-to-date and efficient moving forward. It may also be necessary to build a follow-up plan if not all tasks are fully completed as well as develop a Lean-focused PDCA cycle to ensure long-term effective collaboration on the solutions that were implemented.

Process documentation should also be updated in order to keep track of changes made during problem-solving. By documenting not just the solutions that were proposed but also why they were proposed, teams can gain valuable insights into their decision-making process which they can leverage for similar future problems.

Furthermore, it is important to update key performance indicators (KPIs) to accurately reflect any progress made during problem-solving. By tracking performance against objectives established before and after countermeasures were implemented, organisations will be able to identify any areas that may still need improvement or require further adjustment going forward. Additionally, tracking KPIs over time will help teams understand whether or not their current strategies are leading them towards meeting their goals in a timely manner or if additional measures may need to be taken in order to achieve desired results more quickly.

Finally, organisations should share successful solutions with other teams in order to promote collaboration and knowledge sharing amongst stakeholders throughout different parts of the business. This will allow for ideas generated through one team’s problem-solving efforts to benefit multiple departments – helping foster creativity and innovation while ensuring that everyone is on board with necessary changes being made throughout the organisation. The last step is key to Toyota’s PDCA management system designed for the entire organisation.

By breaking down the problem-solving process into these seven discrete stages, the A3 method offers practitioners a comprehensive, end-to-end framework for tackling complex challenges and driving improvements in any organisation.

- Corporate Training

- Courses for Individuals

Training the team on A3

To get A3 started, everyone in the entire organisation needs to learn how to use this single-sheet or single-page document. This means training people across all parts of the company so that everyone knows how to use the A3 Problem Solving Tool and A3 template. Training will help make sure that everyone follows a structured approach when using A3.

Getting the organisation fully onboard with A3 Problem Solving is not an easy task and will require a dedicated effort to ensure its successful implementation. To this end, it is important to start with specific areas of the business – whether it be operations, finance or marketing – by setting up targeted training sessions for both operational teams and senior managers. This will help everyone understand how and why A3 is used, as well as the potential benefits it can bring to their business.

Once everyone has mastered the basics of working with an A3 template, companies should look to regularly review and evaluate its effectiveness. This could include setting up quarterly reviews or running workshops where teams discuss successes and areas for improvement when using the A3 tool. Doing this will ensure that any issues are identified early on, allowing the team to quickly adjust accordingly.

At Leanscape, we understand that transitioning to A3 Problem Solving can be a daunting task. With our team of specialists, we can provide your teams with the necessary training and coaching to ensure that they are able to adapt quickly and efficiently. Our comprehensive approach to A3 will equip your team with the knowledge and skills needed to successfully use this powerful tool for improving performance in all areas of your business.

We are committed to helping you develop a culture of continuous improvement within your organisation by teaching best practices and providing guidance through every step of the problem-solving process. Through our specialised training programs, we will help your teams learn how to use the A3 template more effectively, as well as how to interpret data visualisations quickly and accurately – enabling them to take action swiftly when required. Our experienced coaches will also share insights from industry experts on how best to integrate countermeasures into standard operating procedures (SOPs) and process maps, keeping up-to-date with industry trends in order to stay ahead of the competition.

By leveraging Leanscape’s expertise in A3 Problem Solving, you can rest assured knowing that your team is in good hands. Our team is dedicated to providing you with the support needed for successful implementation so that you can achieve sustained performance improvements over time.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

The implementation of A3 Problem Solving provides a comprehensive framework for organisations looking to successfully address complex problems in an efficient and cost-effective manner. By breaking down the problem-solving process into seven distinct stages, users can structure their approach and track the progress of their countermeasures over time.

In order to ensure successful implementation, organisations should dedicate time towards training their teams on how to use the A3 Problem Solving Tool and A3 template. This will give everyone a solid foundation for carrying out future problem-solving activities more effectively, as well as provide insights into the effectiveness of certain countermeasures over time.

Through Leanscape’s specialised training programs, you can ensure that your team is fully equipped with the necessary skills to successfully adopt and incorporate A3 Problem Solving into all areas of your business. Our experienced coaches are committed to helping you develop a culture of continuous improvement within your organisation – providing guidance through every step of the process

Final Thoughts

The A3 approach is an invaluable tool for unlocking the power of improvements within any organisation. By leveraging its structured framework and cyclical learning approach, businesses can remain agile and responsive to ever-changing conditions, allowing them to navigate change more successfully and emerge stronger than ever before. Ultimately, this makes Toyota’s A3 problem-solving process one of the most effective ways to ensure long-term success in today’s fast-paced and competitive market.

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, poka yoke: the lean concept of mistake proofing, what are some of the benefits of using benchmarking in lean six sigma, data distributions explained | what are the different types of distribution, 90-day facility management turnaround with 27% lift in performance, unlocking the power of the balanced scorecard: maximizing efficiency and driving growth, how “timwoods” and the 8 wastes of lean drive efficiencies in business process, what makes the best lean six sigma certification program, what are the benefits of cpd for lean certifications, facilitation skills for project managers: learning to lead change management, the assessment criteria for solutions, what is the difference between lean & six sigma, principle 4: create balance | heijunka | principles of lean.

- | lean , lean thinking , problem solving , toolkit , tools

Related Articles

Dpmo: defects per million opportunities explained, using the probability plot | probability distribution tool, the analysis of variance (anova) explained, what is a priortisation matrix, a comprehensive guide to integrating hoshin kanri into strategic planning, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

- Learn center

- Project management

How to use Toyota’s legendary A3 problem-solving technique

Georgina Guthrie

February 21, 2020

If you came home one day and found your kitchen taps on full-blast and your house full of water, what’s the first thing you’d do? Grab a bucket and start scooping — or turn off the tap?

When it comes to problem-solving, many of us take a rushed, reactionary approach rather than fixing the issue at the source. So in other words, we see the water, panic, and start scooping. If this sounds like something you’ve done recently, then don’t feel too bad: when the pressure’s high, we often jump towards the quickest fix, as opposed to the most effective one.

This is where the A3 technique comes in. It’s a problem-solving approach designed to efficiently address the root cause of issues.

What is the A3 technique?

The A3 technique is a structured way to solve problems. It’s part of the Lean methodology , developed by Toyota back in the mid-’40s. This doesn’t mean you need to implement a Lean way of working to take advantage of this process — it can work as a standalone exercise.

Granted, A3 isn’t an inspiring name, but the story of its origins is actually pretty interesting. Rumour has it that Taiichi Ohno, inventor of the Toyota Production System, refused to read past the first page of any report. In response, his team created A3 address and summarize problem-solving on one side of A3-sized paper. The A3 technique played a huge part in Toyota’s success and all kinds of industries have since adopted it. Here’s how to get started.

How to solve a problem with A3

The first thing to remember is this: A3 is collaborative and relies on good communication. It’s not something you should do by yourself.

There are three main roles involved:

- Owner (that’s you or someone under your charge)

As you’ve probably guessed, these aren’t roles that already exist in your company; you must create them for the purpose of this process. Here’s what they mean.

The owner is responsible for leading the exercise. They are the lynchpin between the two other roles, fostering good communication and keeping documents up to date. It’s tempting to think of the owner as the head of this trio, but that’s not true: everyone is equal here.

The mentor is someone with solid problem-solving experience. It’s their job to coach the owner and steer them towards finding a solution. It’s not their job to find the answers themselves.

And finally, there are the responders . This is someone (or a group of people) who have a vested interest in the outcome of the A3 project. Responders might include the client, stakeholders, or managers. A potential problem here is gaining access to them: if you work somewhere with a strict hierarchy — and you’re somewhere near the bottom of that structure — you may face challenges. There’s no easy way around this. Essentially, you need your organization to support this way of working and make it easy for you to access those at the top if needed.

How to create an A3 report

True to its origins, the A3 report is a one-page document. It typically contains 5-7 sections that systematically lead you towards a solution. These are the most commonly used steps, but feel free to modify them.

- Background: Explain your project in a few sentences, including its context.

- Problem statement: Explain the current problem. You can use process mapping to see the different tasks that surround the issue. This isn’t essential, but it will make it easier for you to locate the root cause.

- Goals: Define your desired outcome, and include metrics for measuring success. You won’t know everything until you reach the end, so you may find you need to come back and refine stages 1-3.

- Root cause analysis: This is a big stage of the process. You need to work out what you think the root problem is. You can use different methods to help you here, including 5 whys or a fault tree analysis .

- Countermeasures: Once you’ve worked out your root cause, you can start proposing solutions.

- Implementation: Work out how you’ll implement these solutions, including an action list with clearly defined roles and responsibilities. Project management software is a useful tool here because it can help everyone on the team track each other’s progress in real-time.

- Follow-up: Using your metrics for success, decide whether the problem was solved. Report your results back to the team/organization. In the spirit of Lean (continuous improvement), you should go back and modify your plan if the results weren’t as expected. And if they were, you should make this process the new standard.

Final thoughts

A3 is an efficient, methodical way to solve problems at their source. When issues rear their head, rising stress can lead people to panic. Having a clearly designed system in place to guide you towards a solution minimizes the chances of people settling for a ‘quick fix’ or failing to act altogether.

Beyond being a guiding light in times of pressure, A3 is a great team-building exercise because it encourages individuals to work together towards a common goal — across all areas of the organization. Combine this with collaborative tools designed to help teams track progress and work together more effectively, and you’ll be unstoppable.

Solve problems like a pro with Root Cause Corrective Action

Lean to Six Sigma: process improvement methodologies explained

Subscribe to our newsletter.

Learn with Nulab to bring your best ideas to life

As I introduced A3 problem solving in my last column, I will now discuss in detail the steps involved with this problem solving approach. Background of A3 Problem Solving A3 problem solving is quite similar to other problem solving approaches which mirror Deming’s Plan-Do-Check-Act (PDCA) cycle. The comparison between A3 problem solving and PDCA is depicted in Table 1. Table 1

Don't miss any news, updates or insider tips from PEX Network by getting them delivered to your inbox. Sign up to our newsletter and join our community of experts.

Embrace Change, Achieve Transformation

All Access: Change Management For Business Transformation will feature case studies from organizations that have successfully implemented change management to drive business growth. The content series will provide you with the knowledge, tools, and resources you need to successfully implement change management in your organization and achieve your business goals. Register now and get access to this free PEX Network webinar series.

Upcoming Events

Preventing financial and reputational risk with process intelligence.

23 May, 2024 Online

Using AI to improve master data processes

30 May, 2024 Online

The power of a process repository in building a digital twin

06 June, 2024 Online

All Access: Intelligent Automation 2024

June 18 - 19, 2024 Free PEX Network Webinar Series

Business Transformation Exchange Europe

June 26 - 27, 2024 London Heathrow

All Access: OPEX Financial Services 2024

July 09 - 10, 2024 Free PEX Network Webinar Series

Subscribe to our Free Newsletter

Insights from the world’s foremost thought leaders delivered to your inbox.

Latest Webinars

2024-06-06 11:00 AM - 12:00 PM EDT

2024-05-30 11:00 AM - 12:00 PM EDT

2024-05-23 11:00 AM - 12:00 PM EDT

RECOMMENDED

FIND CONTENT BY TYPE

- White Papers

- Press Releases

Process Excellence Network COMMUNITY

- Advertise With Us

- What is Process Excellence

- User Agreement

- Cookie Policy

- PEX Network App

- All Access from PEX Network

- Become a Member Today

- Media Partners

ADVERTISE WITH US

Reach Process Excellence professionals through cost-effective marketing opportunities to deliver your message, position yourself as a thought leader, and introduce new products, techniques and strategies to the market.

JOIN THE Process Excellence Network COMMUNITY

Join Process Excellence Network today and interact with a vibrant network of professionals, keeping up to date with the industry by accessing our wealth of articles, videos, live conferences and more.

Process Excellence Network, a division of IQPC

Careers With IQPC | Contact Us | About Us | Cookie Policy

Become a Member today!

PLEASE ENTER YOUR EMAIL TO JOIN FOR FREE

Already an IQPC Community Member? Sign in Here or Forgot Password Sign up now and get FREE access to our extensive library of reports, infographics, whitepapers, webinars and online events from the world’s foremost thought leaders.

We respect your privacy, by clicking 'Subscribe' you will receive our e-newsletter, including information on Podcasts, Webinars, event discounts, online learning opportunities and agree to our User Agreement. You have the right to object. For further information on how we process and monitor your personal data click here . You can unsubscribe at any time.

- > Use A3 Process Mapping for Root Cause Problem-Solving

Use A3 Process Mapping for Root Cause Problem-Solving

Posted by Matt Banna

Aug 5, 2021 8:13:00 AM

One company that figured it out is Toyota. Toyota's approach to continuous improvement is among the most studied and copied in the world. Many of the tools and techniques they practice are replicated in organizations of all types and sizes across the globe. One such method is called A3 process mapping. When used with the PDSA improvement cycle , it can significantly impact an organization's improvement efforts and deliver structured change that impacts critical business metrics.

What is A3 Process Mapping?

The A3 process mapping methodology was first used by Toyota in the 1960s and subsequently adopted by leaders who implemented Lean, Total Quality Management, Six Sigma, and other structured approaches to continuous improvement. "A3" refers to a European paper size of about the same size as an American 11-inch by 17-inch tabloid-sized paper. Using the A3 process mapping, teams create a one-page PDSA (Plan, Do, Study, Adjust) improvement project report. By keeping the report to one page, it must be concise and include only relevant information needed to solve problems.

Why Use A3 Process Mapping?

There are several reasons that A3 thinking is so popular. Among them are:

- Accelerated problem-solving: By applying a step-by-step visual process with logical reasoning and insisting on root-cause identification, teams ensure that issues are resolved, not just temporarily covered up.

- Team development: The use of a consistent tool across the company promotes cross-functional collaboration and widespread knowledge sharing.

- Company growth: A3 process mapping helps document company knowledge, sustain strategy deployment, and build a strong culture rooted in problem-solving rather than abstract ideas.

- Increased employee engagement: When people know precisely what is expected and have the right tools to document and measure their efforts, they are more likely to identify opportunities for improvement and engage in constructive change.

The 7 Steps in an A3 Project

Of course, every company uses the A3 technique in its own way, but generally, there are seven steps in an A3 project.

1: Background

2: Problem Definition

This section outlines the specifics of the problem. Details may include the scope of the problem, where and when the problem occurs, and the problem's impact on business metrics. By having these specifics on a quantitative scale, the A3 report brings the problem to life for the organization.

3: Goal Statement

This section outlines what the team is trying to accomplish by initiating the A3 process mapping project. Clearly state the goals you are trying to achieve and set a timeframe for completion.

4: Root Cause Analysis

Once the problem is apparent, the team will conduct a root cause analysis to find the most fundamental reasons for this problem. The 5 Whys technique can be an effective way to make sure the fundamental reason for the issue is found.

5: Countermeasures

With the root causes clear, the next step is to document the countermeasures that you will use in solving the problem. This section forms a detailed plan outlining who will deploy the countermeasures and when they will be completed.

6: Confirmation

Once the countermeasures are implemented, it is time to analyze the results. Now you can determine whether the results prove that your countermeasures were effective in meeting your goals.

7: Follow Up Activities

Once you've achieved the desired results, deploy the infrastructure for sustaining the gains, including standardization, reports, and visualization. It is ideal to share the information across the organization. In Japanese, this process is called Yoko-narabi-tenkai, meaning "lateral deployment of findings to other groups."

![a3 problem solving root cause analysis [WEBINAR] A Deep Dive into A3 Thinking](https://no-cache.hubspot.com/cta/default/326641/a78d9f1b-c108-4709-8a9d-9dd5a8a020b3.png)

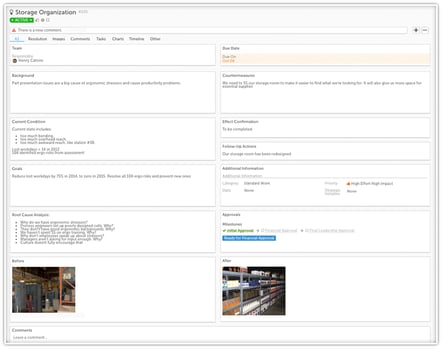

Software for A3 Process Mapping

As we mentioned, A3 is literally named after a piece of paper. However, modern organizations have improved on the pen and paper days by leveraging software to support this problem-solving method. With A3 software , your team will enjoy:

A Standard Approach to Solving Problems: It is best to have standard A3 reports used across the organization. Software makes this easy by giving everyone a set of fields and a layout that will be the same every time a new A3 project is started. You can configure your A3 input and reporting screens to match the specific needs of your organization.

Broad Visibility: It is difficult for leaders to understand what improvement projects are underway if they are managed on physical pieces of paper or even in spreadsheets. With an A3 process mapping platform, leaders get real-time visibility into all improvement activities. As a result, supervisors and managers can provide proactive coaching and remove obstacles. This level of visibility also increases accountability and allows for the broadcasting of successful improvements.

Cross-Functional Collaboration: It is often the case that the most challenging challenges require the involvement of cross-functional teams. Cloud-based A3 software with built-in collaboration tools works so well because the right people can be involved in each A3 project, regardless of where they are located. Everyone who needs it gets access to all of the details whenever they like.

Visual Management: At its heart, A3 is a visual management tool. A3 process software supports the consistent visualization of data and the inclusion of related charts and graphs. When someone looks at a digital A3 process map, they instantly understand the problem, the solution, and the impact.

The A3 process mapping technique is a simple yet effective approach to solving even the most complex problems. Closely following the steps, standardizing on the essential elements for your organization, and implementing technology will help achieve widespread adoption and increase the chances that you'll enjoy the long-lasting results you set out to achieve.

Topics: Continuous Improvement Software , Improvement Process , Improvement Methodology , Lean Software

Add a Comment

Subscribe via email, recent posts.

- Our Customers

Why KaiNexus

- Collaboration

- Standardization

- Customer Success Manager

- Lean Strategy

- Solutions Engineering

- Customer Marketing

- Configuration

- Continuous Enhancements

- Employee Driven

- Leader Driven

- Strategy Development

- Process Driven

- Daily Huddles

- Idea Generation

- Standard Work

- Visual Management

- Advanced ROI

- Notifications

- Universal Badges

- Case Studies

- Education Videos

Copyright © 2024 Privacy Policy

- A3 Problem-Solving: Fight the Root Cause

The A3 problem-solving tool is a bright example of how problems should be treated to be eliminated efficiently. Scroll down to learn more about A3 and how to use it.

- What Is Lean Management?

- The 5 Principles of Lean

- What Is Shared Leadership?

- What Is Lean Manufacturing?

- What Is Value in Lean?

- 7 Wastes of Lean

- What Is Mura?

- What Is Muri?

- What Is 5S?

- What Is the Cost of Delay?

- What Is Value Stream Mapping?

- What Is a Pull System?

- What Is a Bottleneck?

- Just-in-Time Manufacturing

- Implementing a Kanban Pull System

- Pull System on the Portfolio Level

- What Is Kaizen?

- What Is Continuous Improvement?

- Built-In Quality Management

- What Is the Poka-Yoke Technique?

- What Is the PDCA (Plan Do Check Act) Cycle?

5 Whys: The Ultimate Root Cause Analysis Tool

Gemba Walk: Where the Real Work Happens

- How To Perform Root Cause Analysis?

- Root Cause Analysis Tools

- What Is a Pareto Chart?

- What Is a Scatter Diagram?

- What Is a Fishbone Diagram?

- What Is Hoshin Kanri?

- What Is Hoshin Kanri Catchball?

- Demystifying the Hoshin Kanri X Matrix

- The Lean Transformation Model Explained

- Lean Transformation Roadmap - 8 Comprehensive Steps

- What Is Cycle Time?

- What Is Little's Law?

- What Is Takt Time?

- What Is Heijunka?

- What Is Jidoka?

- What Is Andon?

- Lean Six Sigma Principles

- Lean Six Sigma Tools

- Lean Six Sigma Implementation

- What Is Six Sigma?

- What Is DMADV?

- What Is DMAIC?

- Lean Project Management

A great part of our daily work routine is actually related to solving problems. Either small or big, problems are an inevitable part of our workday. However, if you decide to act fast and remove a problem as swiftly as possible, you may face the same issue repeatedly.

Instead of fighting only the symptoms, you need to dig deeper and discover the root cause. By doing so, you will be able to protect the work process from recurring problems. This is where the A3 methodology comes into play.

Implementing an A3 problem-solving tool is a bright example of how problems should be treated to be eliminated efficiently. Based on some simple steps and ideas, the model gives directions on dealing with problem-solving issues through simple structuring, good collaboration, and active communication.

What Is A3 Thinking?

First of all, let’s briefly touch upon the mindset that A3 thinking aims to develop. It can be summarized in 7 elements:

- Logical Thinking – A3 represents a step-based thinking process.

- Objectively presenting information – there are no hidden agendas here.

- Results and Processes – sharing what end results were achieved as well as the means of achieving them.

- Sharing only essential information and putting it into a visual format whenever possible.

- Whatever actions are taken, they must be aligned with the company’s strategy and objectives.

- The focus is on developing a consistent perspective that can be adapted across the entire organization.

- Developing a structured approach to problem-solving.

Origin of the A3 Problem-Solving Tool

The A3 report is one of the many Lean management tools developed as part of the Toyota Production System (TPS).

There isn’t a single inventor of the A3 reporting method. In fact, Isao Kato (former manager at Toyota) describes it as a hybrid between the PDCA cycle and Toyota’s philosophy to make things visible.

There is also a legend that Taiichi Ohno often refused to read further than the first page of any written report. This is why the A3 is a one-page report.

The name A3 comes from the European A3 paper size corresponding to 11-inches by 17-inches or 29.7cm x 42cm.

A3 thinking played a major role in Toyota’s commercial success. Consequently, it became a widespread tool, now used in various industries.

Let’s explore the A3 problem-solving tool in detail.

Foundations of the A3 model