Dell: Roadmap of a Digital Supply Chain Transformation

Dec 16, 2021 | News

By Dr. Inma Borrella, Dr. Maria Jesus Saenz, and Dr. Elenna Revilla

The case illustrates the process that allows a company to successfully implement a digital transformation strategy in its supply chain. It provides a powerful illustration of Dell Technologies Inc.’s strategic decisions and how the company influenced different steps in its digital transformation.

This case is suitable for graduate- and executive-level courses on strategy, operations, supply chain management, or digital transformation. Ideally, students should have had some exposure to formal supply chain management and processes before discussing this case. After working through the case and assignment questions, students will be able to

- examine the importance of aligning a common vision among different areas of the company, particularly considering the intrinsic challenges in a giant and diverse enterprise;

- identify new business opportunities and value propositions behind the implementation of digital capabilities as a necessary component of a supply chain strategy;

- understand the value of three digital transformation pillars: transparency, predictive analytics, and automation;

- identify the key incentives that drive the digitalization of the supply chain;

- explore the process that a large established company with legacy systems and complex operations follows to start its digital supply chain transformation;

- explore how to implement digital tools on supply chain operations to create value, by integrating capabilities, processes, and key actors; and

- discuss the challenges that organizations face in achieving digital transformation.

Check out the latest case study publication on Dell’s roadmap towards digital supply chain transformation.

- Publications

Dell’s Supply Chain Model: 7 Powerful Insights into the Future of Efficiency

Table of Contents

I. introduction.

Hold on to your seats and brace yourself for an exciting journey into the intricate world of supply chain management! Today, we’re zeroing in on Dell Technologies, a name that’s no stranger to any of us. A titan in the tech industry, Dell’s array of nifty gadgets has long been captivating consumers worldwide. But behind every captivating device lies an intricate ballet of processes, strategies, and people that often remains unseen. These behind-the-scenes maneuvers, collectively known as the supply chain, are the true unsung heroes of any product’s journey.

You see, the supply chain is essentially the backbone of any product-based company, dictating everything from production costs to customer satisfaction and brand reputation. When done right, it can pave the path to success and market dominance. Dell, as we’ll uncover, is a shining example of this power.

In this article, we’ll pull back the curtain on Dell’s supply chain , examining the nuts and bolts of its operations. We’ll delve into the evolution of Dell’s supply chain, the unique strategies they’ve adopted, and the transformative role technology plays. Along the way, we’ll glean insights from their response to supply chain disruptions and draw valuable lessons from their innovative practices.

So buckle up, sit tight, and get ready for a thrilling deep-dive into the fast-paced world of Dell’s supply chain management!

II. Understanding Dell’s Supply Chain Management

When it comes to understanding the intricacies of Supply Chain Management (SCM), imagine orchestrating a massive, worldwide relay race. Each participant, from raw material suppliers to manufacturers, distributors, retailers, and finally, the end customer, must pass the baton smoothly, without dropping it. This crucial relay race is what keeps a company’s wheels turning and its products flowing.

Now, onto the big fish we’re tackling today: Dell’s SCM. Dell has successfully disrupted the traditional SCM model with its unique ‘Direct-to-Customer’ approach. Picture this: Instead of a confusing maze of intermediaries and tangled processes, Dell’s supply chain is more like a superhighway – swift, streamlined, and straightforward.

At the very core of Dell’s SCM lies a principle that’s as simple as it is revolutionary: Make it personal. Instead of churning out one-size-fits-all gadgets, Dell goes the extra mile to customize products based on individual customer preferences. The result? A computer that’s not just a tool, but a reflection of the user’s needs and personality.

What makes this system even more interesting is Dell’s clever use of a just-in-time manufacturing approach. This strategy cuts down on unnecessary storage and inventory costs. Instead, products are built to order, using components that arrive just in time for assembly.

Finally, Dell has pushed the envelope by bringing its suppliers physically closer to its manufacturing hubs. This proximity allows Dell to foster stronger relationships with its suppliers, ensuring better coordination and swift problem resolution.

From this comprehensive analysis, it’s clear that Dell’s SCM isn’t just about moving products from Point A to Point B. It’s a finely tuned system that combines customer focus, smart strategies, and close supplier relationships to deliver value at every step of the product’s journey.

III. The Evolution of Dell’s Supply Chain

Just as great wines mature with age, Dell’s supply chain has been refined and perfected over time, making it a powerful force in the tech industry. It wasn’t a sudden transformation but a journey characterized by strategic shifts and game-changing decisions.

In the early stages, Dell, like many other companies of its time, relied on a traditional supply chain model. The manufacturing process began long before any customer placed an order, following forecasted demands. However, Dell soon realized that this model was a road laden with inefficiencies, chiefly in the form of excess inventory and the risk of unsold products becoming obsolete.

In a bold move that redefined industry norms, Dell adopted a unique Direct Model in the mid-1990s. This strategy, designed to eliminate middlemen, connected Dell directly with its customers. The model was based on a simple yet powerful idea: why build computers that might sell when you can build computers you know will sell?

Thus began Dell’s journey towards a build-to-order and direct-to-customer strategy. It effectively addressed the issue of inventory costs, as computers were now assembled based on actual customer orders, not forecasts. Dell also implemented just-in-time manufacturing, where components would arrive exactly when needed, further reducing inventory costs.

Another significant evolution was Dell’s initiative to create supplier hubs near their assembly plants. This move not only sped up the production process but also allowed for better collaboration and problem-solving between Dell and its suppliers.

In recent years, Dell’s supply chain has continued to evolve, leveraging the power of digitization and AI to enhance its efficiency. With these tools, Dell can now forecast demand with pinpoint accuracy, improve its logistics, and deliver an even more personalized experience to its customers.

From its humble beginnings to its current state-of-the-art supply chain, Dell has consistently stayed ahead of the curve, setting the pace in an ever-changing, dynamic tech landscape. It’s a testament to Dell’s vision and its unwavering commitment to meet its customers’ needs while maintaining efficiency and cost-effectiveness.

IV. Benefits of Dell’s Supply Chain Model

Dell’s unique approach to supply chain management is the secret sauce behind its market prowess. It’s akin to a well-oiled machine that drives significant benefits across the board. From cost-efficiency to customer-centricity and innovation, the pay-offs of Dell’s model are as varied as they are impressive.

One of the most standout advantages is the model’s cost efficiency. You know what they say about a penny saved being a penny earned, right? Well, Dell’s mastered the art of penny-pinching in all the right ways! Their just-in-time approach and the direct-to-customer model drastically cut down on storage and inventory costs. Why pile up expensive warehouses with products when you can build them just in time, based on actual customer orders?

And speaking of customers, they’re the real winners in Dell’s supply chain model. Dell’s approach to supply chain puts customers in the limelight, crafting each product to their unique needs and preferences. It’s like having a personal tech genie, ready to make your gadget wishes come true! And let’s face it, who doesn’t like the sound of that?

But the benefits of Dell’s supply chain model don’t stop at cost savings and customer happiness. The model also fosters a culture of innovation and adaptability, essential ingredients in the fast-paced tech industry. It’s like having a built-in radar that constantly scans for changes and swiftly adapts to meet them head-on. This agility has helped Dell stay ahead in the game, continuously reinventing its products to match the evolving needs of its customers.

Lastly, let’s not forget how Dell’s supply chain model gives the company a competitive edge. By directly connecting with customers and maintaining efficient operations, Dell has carved out a strong position in the market, a vantage point that many competitors find hard to match.

In a nutshell, Dell’s supply chain model is the golden ticket that balances efficiency, customer satisfaction, innovation, and competitive advantage. And that, folks, is no small feat in today’s challenging business landscape.

V. Dell’s Supply Chain in the Era of Digital Transformation

If you thought Dell’s supply chain couldn’t get any more cutting-edge, then brace yourself for another wave of innovation! The digital transformation era has rolled in, and Dell is surfing the wave like a true champ. With digitization and AI now reshaping industries, Dell’s supply chain is evolving to keep pace, transforming into a data-driven dynamo ready to push boundaries even further.

Let’s break down the role of digitization in Dell’s supply chain. Picture a network of digital threads weaving through every stage of the supply chain, from production to delivery. These threads enable real-time monitoring and data analysis, paving the way for more efficient, transparent operations. Need to track the journey of a product? No problem. Want to streamline your logistics? Piece of cake. With digitization, Dell’s supply chain becomes a crystal-clear panorama, where each process is visible, trackable, and optimizable.

Now, let’s throw AI into the mix. Artificial Intelligence , with its ability to process and analyze vast amounts of data, becomes a valuable ally in Dell’s supply chain. AI helps Dell forecast demand more accurately, reducing the risk of overproduction or stockouts. It can predict potential disruptions and recommend preventive measures. In essence, AI is like the supply chain’s crystal ball, foreseeing what lies ahead and helping Dell plan accordingly.

One shining example of AI in action is Dell’s Automated Workload Deployment. This feature, powered by AI, can customize a computer based on a customer’s needs in record time. This level of customization would have been unthinkable a few years ago but is now a reality, thanks to AI.

In the era of digital transformation, Dell’s supply chain is emerging as a model of innovation. It’s not just about embracing new technologies; it’s about harnessing them to enhance efficiency, personalize customer experiences, and adapt to a rapidly evolving market.

As we venture into the future, one thing is clear: With digital transformation as its compass, Dell’s supply chain is steering the company towards uncharted territories of innovation and success.

VI. Case Study: Dell’s Response to Supply Chain Disruptions

To truly appreciate the strength of Dell’s supply chain, let’s turn our attention to how it responds to disruptions. As the old adage goes, it’s not the calm but the storm that truly tests a sailor’s skill. For Dell, these “storms” have come in various forms, from the Asian financial crisis in the late ’90s to the global COVID-19 pandemic in the 2020s.

During the Asian financial crisis, Dell showcased its remarkable agility and adaptability. While many competitors were caught off-guard, suffering from excess inventory and reduced demand, Dell managed to stay afloat. Thanks to their direct-to-customer and just-in-time manufacturing approach, they were able to swiftly adjust to the changing market conditions, reducing production and avoiding the risk of holding obsolete inventory.

Fast forward to the COVID-19 pandemic, a time of unprecedented disruption for global supply chains. Companies worldwide grappled with a multitude of challenges, from factory shutdowns to logistics bottlenecks. In the face of such adversities, Dell’s supply chain stood resilient.

Dell’s proactive measures, backed by its data-driven approach, allowed the company to navigate this crisis with remarkable agility. Advanced analytics tools helped Dell anticipate potential disruptions and reconfigure their supply chain accordingly. They ramped up communication with suppliers to stay informed about any potential disruptions, and their close supplier relationships paid off in ensuring continuous supply even during challenging times.

Perhaps one of the most impressive aspects was Dell’s commitment to its customers. Despite the upheaval, the company continued to deliver personalized products, maintaining high standards of customer service and satisfaction.

These case studies underscore how Dell’s robust supply chain, characterized by its agility, adaptability, and customer-centric approach, has been key in weathering supply chain disruptions. It’s a testament to their strategic foresight, innovative practices, and unwavering commitment to delivering value to their customers.

VII. Lessons from Dell’s Supply Chain Model

From Dell’s fascinating journey through the realms of supply chain management, there’s a treasure trove of lessons to be learned. These lessons aren’t just academic theories; they’re practical insights gleaned from Dell’s real-world experiences, ready to be applied in any business context.

First up is the power of a customer-centric approach. Dell has shown us that putting customers at the heart of the supply chain isn’t just good ethics; it’s good business. By customizing products based on individual customer preferences, Dell has been able to stand out from the competition and build strong customer loyalty. So the lesson here? Know your customers, cater to their needs, and they’ll reward you with their loyalty.

Next is the importance of innovation and agility. In a dynamic business environment, change is the only constant. Dell’s supply chain has remained resilient and competitive by constantly innovating and adapting to market changes. Whether it’s shifting from a traditional model to a direct-to-customer approach or embracing digital transformation, Dell has been quick to adapt and innovate. The lesson? Stay nimble, embrace change, and never stop innovating.

The role of close supplier relationships is another crucial lesson from Dell’s supply chain. By creating supplier hubs and fostering strong supplier relationships, Dell has been able to ensure better coordination, faster problem-solving, and continuous supply. This highlights the importance of viewing suppliers not as mere vendors but as valuable partners in your business journey.

Lastly, Dell’s supply chain teaches us the value of leveraging technology. From using analytics for demand forecasting to harnessing AI for customization, Dell has adeptly used technology to enhance its supply chain efficiency. This is a powerful reminder for businesses to embrace the digital era and use technology as a tool to drive efficiency and innovation.

In a nutshell, the lessons from Dell’s supply chain model can serve as valuable guideposts for any business striving to build an efficient, resilient, and customer-centric supply chain. And in today’s competitive business landscape, these lessons are more pertinent than ever.

VIII. Success Stories from Dell’s Supply Chain Management

Story 1: Navigating the Asian Financial Crisis

In the late ’90s, the Asian financial crisis sent shockwaves across global markets. Many tech companies, caught off-guard, faced significant losses due to excess inventory and plummeting demand. However, Dell’s unique supply chain model came to its rescue. Leveraging its direct-to-customer and just-in-time manufacturing approach, Dell swiftly adjusted to the changing market conditions. They scaled down production to avoid holding onto obsolete inventory, thereby effectively navigating the financial storm.

Story 2: Overcoming the COVID-19 Pandemic Challenges

The COVID-19 pandemic posed a daunting challenge to supply chains worldwide. From factory shutdowns to logistics bottlenecks, companies found themselves grappling with unprecedented disruption. Dell, however, with its robust supply chain, managed to stay resilient. By leveraging advanced analytics, they could anticipate potential disruptions and swiftly reconfigure their supply chain. Their close relationships with suppliers ensured a continuous supply, even in such trying times. Despite the upheaval, Dell maintained high standards of customer service and satisfaction, reflecting the strength and resilience of its supply chain.

Story 3: Reducing Inventory Costs

For years, Dell struggled with high inventory costs, a common pain point in the tech industry. However, the introduction of their direct-to-customer model and just-in-time manufacturing approach brought about a dramatic change. By building computers based on actual customer orders rather than forecasts, Dell managed to significantly reduce its inventory costs. This strategic shift not only improved Dell’s bottom line but also increased its agility and responsiveness to market changes.

Story 4: Enhancing Customer Satisfaction

When Dell shifted to a customer-centric supply chain model, it resulted in a dramatic increase in customer satisfaction. By customizing products based on individual customer preferences, Dell began offering a personalized experience that set it apart from competitors. This commitment to customer satisfaction not only resulted in repeat business but also enhanced Dell’s reputation as a customer-focused company, driving its market growth and success.

Story 5: Embracing Digital Transformation

As the digital era dawned, Dell seized the opportunity to enhance its supply chain management. They harnessed the power of AI and analytics, using these tools to improve demand forecasting, streamline logistics, and offer an even more personalized customer experience. For instance, Dell’s Automated Workload Deployment, powered by AI, can customize a computer based on a customer’s needs in record time. These digital advancements have positioned Dell at the forefront of the tech industry, ready to tackle future challenges and opportunities.

IX. Conclusion

Stepping back to admire the grand tapestry of Dell’s supply chain, it’s clear that it’s more than just a business process. It’s a strategic masterpiece, a blend of innovation, customer-centricity, and agility that has catapulted Dell to new heights in the tech industry.

Over the years, Dell has refined and perfected its supply chain model, pioneering a direct-to-customer and just-in-time manufacturing approach that has redefined industry norms. These strategic shifts have not only driven significant cost efficiencies but have also put customers at the heart of the supply chain, offering them a personalized and engaging experience.

But what truly sets Dell apart is its unwavering commitment to innovation. From its early decision to eliminate middlemen to its recent embrace of digitization and AI, Dell has consistently stayed ahead of the curve. It has proven that in a world where change is the only constant, the ability to adapt, innovate, and evolve is critical.

It’s worth noting, too, that Dell’s supply chain is not just about its own success. It’s a story of resilience in the face of challenges, from the Asian financial crisis to the global COVID-19 pandemic. These experiences underscore the importance of a robust supply chain in navigating disruptions and maintaining business continuity.

As we draw lessons from Dell’s supply chain model, it becomes clear that it’s a goldmine of insights for any business striving for efficiency, resilience, and customer-centricity. Whether it’s the importance of a customer-centric approach, the value of close supplier relationships, or the power of digital transformation, these lessons can serve as valuable guideposts in our own business journeys.

In conclusion, Dell’s supply chain is more than just a success story; it’s a testament to the power of strategic foresight, customer focus, and innovation in driving business success. It’s a reminder that in today’s dynamic business landscape, a robust and efficient supply chain can indeed be a game-changer. As Dell continues to push boundaries and redefine norms, there’s no doubt that its supply chain will remain a pivotal part of its journey, steering the company towards uncharted territories of success and innovation.

KEY CONCEPTS

What is unique about dell’s supply chain model.

Dell’s model is unique for its direct-to-customer and just-in-time manufacturing approach, which reduces costs and enhances customer satisfaction.

How did Dell respond to the Asian financial crisis?

During the crisis, Dell swiftly adjusted its production to avoid holding obsolete inventory, successfully navigating the financial storm.

What role has digitization played in Dell’s supply chain?

Digitization allows real-time monitoring and data analysis, enabling Dell to enhance its supply chain’s efficiency and transparency.

How did Dell handle the COVID-19 pandemic’s supply chain challenges?

Dell used advanced analytics to anticipate disruptions and reconfigure their supply chain, ensuring continuous supply and customer satisfaction.

How has Dell’s supply chain model benefited the company?

The model’s cost efficiency, customer-centricity, and agility have significantly contributed to Dell’s market growth and success.

What lessons can businesses learn from Dell’s supply chain model?

Key lessons include the importance of a customer-centric approach, embracing change and innovation, fostering strong supplier relationships, and leveraging technology.

How does Dell use AI in its supply chain?

Dell uses AI to improve demand forecasting, streamline logistics, and offer more personalized customer experiences.

What impact has Dell’s supply chain model had on customer satisfaction?

By offering customized products based on individual customer preferences, Dell’s supply chain model has significantly enhanced customer satisfaction.

How did Dell’s supply chain model help during the COVID-19 pandemic?

Dell’s robust supply chain, backed by data-driven measures, helped maintain business continuity and high standards of customer service during the pandemic

What role do suppliers play in Dell’s supply chain model?

Suppliers are viewed as valuable partners, with strong relationships ensuring better coordination, faster problem-solving, and a continuous supply.

Psychological Warfare: An Analysis of Its Impact and 5 Success Stories

Uncover the history, tactics, and techniques of psychological warfare and its impact on modern conflicts. Learn about propaganda, disinformation, cyber warfare, and effective defense strategies.

Cognitive Flexibility: 7 Important Aspects on The Mind’s Agile Adaptability

Unleash your brain’s potential! Explore cognitive flexibility—your mind’s superpower for learning, problem-solving, and mental well-being.

The Revolutionary World of Robotics: Applications, Innovations, and 5 Success Stories

Discover the fascinating world of robotics, its evolution, applications across industries, future trends, and ethical considerations in this comprehensive overview.

7 Key Aspects of New AI: Discover the Power and Potential of Advanced Artificial Intelligence

Unlock the mysteries of new AI, delve into its history, marvel at its power and potential, and envision an AI-powered future.

IT Service Management: 5 Transformative Benefits Unleashing Success in the Digital Age

Unlock the transformative power of ITSM. Explore its evolution, key components, benefits, implementation challenges, and the future.

Jaak Panksepp: 7 Important Aspects of his Life and Theories

Dive into Jaak Panksepp’s groundbreaking journey in neuroscience, unearthing emotions’ mysteries and reshaping our understanding of life.

Coping Mechanisms: 7 Important Aspects for Managing Stress and Enhancing Mental Health

Master the art of coping mechanisms. Navigate life’s challenges with resilience and grace for a stress-free life.

7 Powerful Steps to Transformative Self-Improvement: Unlock Your Ultimate Potential

Discover powerful steps to transformative self-improvement, helping you unlock your ultimate potential and achieve lasting personal growth.

Do You Want To Boost Your Business?

We noticed you're visiting from Netherlands. We've updated our prices to Euro for your shopping convenience. Use United States (US) dollar instead. Dismiss

- Preferences

Dell and Supply Chains - PowerPoint PPT Presentation

Dell and Supply Chains

Markets ripe for commoditization where there are established, common standards. what's special about ... article suggests that dell is a 'one trick pony. ... – powerpoint ppt presentation.

- MI021/CS021Computers in Management

- What are the characteristics of market segments that Dell chooses to attack?

- Markets ripe for commoditization where there are established, common standards

- What's special about Dell's value chain? How does this differ from HP, Sony, Toshiba, Gateway, etc.?

- Dell only sells direct

- Can build product only when it's needed

- Avoid bullwhip effect

- PG and the beer game

- With no middleman it can eliminate the margin others have to share with retailers

- Lowering prices

- Selling more

- Boosting its own margins

- About 15 years ago, dell had 20-25 days of inventory spread across a network of warehouses.

- How many warehouses does it have today?

- How many hours of inventory does it hold in its factories?

- 72 hrs. average

- 2 hrs at weak link

- Why is eliminating inventory so important for Dell?

- Moore's Law product rapidly depreciates.

- Our official definition Processing power per dollar doubles every 18 months.

- Price Per GFLOPS

- 1997 about US 30,000

- May 2000 640

- August 2003 82

- February 2006 about 1

- March 2007 0.42

- Depreciates a half to a full point each week1/2 to 1 percent.

- Turn that into money

- Dell had 55B in revenues in 2006. How much do you save if shave a week off of inventory (roughly)?

- Cut 3 weeks in past 13 years 1.65B

- 2006 profits 3B. Over half profits come from efficient supply chain.

- It's like fish", "you can literally see it rot", "it's a financial imperative"

- Dell's suppliers move their products into up to 110 Dell factory bays.

- When does Dell take possession of product?

- When customer order has been made product is pulled

- And how is 'possession' recorded? Does someone run out to the floor type this in?

- Pallet moves across a white line in the factory, it's tracked by a scanner, possession changes hands.

- Typical PC maker, pays for parts 30 days before sold.

- That means typical manufacturer pays the marginal cost for the product in advance of the product's sale.

- Once that computer is built it's sitting on a shelf somewhere for 30 days before it's sold, is it earning interest?

- Can you invest it?

- Can you use it to hire people

- or expand your operations?

- Thats why inventory death

- money is being wasted.

- Cash conversion cycle the period of time between an outlay of cash for parts and the collection of payments for goods made from them

- When does Dell have to pay suppliers for the parts it used to build the product?

- Not until 36 days (average) after it has received payment from customers.

- If inventory depreciates at 1/ week, how much is that worth?

- What's Dell's cash conversion cycle?

- Negative 36 days (assumes credit cards clear right away)

- Why do you suppose Dell gets such good terms?

- When youre Dell, suppliers do what you want to get your business.

- By collecting money from customers before it pays its suppliers, its suppliers finance its operations

- Dell has a negative cash conversion cycle. It sells product faster than it pays.

- Inventory Turns

- Number of times go through whole inventory in a year

- Value of product sold in a year and divide it by the value of product in inventory (on average)

- What's Dell's inventory turns number?

- 107 times a year

- What are HPs IBMs inventory turns?

- 8.5 and 17.5 times a year

- If inventory death, low inventory

- Do other firms manufacture PCs in the US?

- Why doesn't it outsource like everyone else?

- For Dell, manufacturing is a source of competitive advantage

- Dell produces 700 PCs in an hour

- Eliminated screws so parts can be snapped together in how short a time?

- How long from start to finish to build a PC?

- 4-8 hrs. depending on configuration

- Software burning testing takes the most time, several hours.

- How long do suppliers have to truck inventory to Dell's plants?

- Can they do this from Singapore?

- No, they have to be in Austin, TX.

- Why do companies do it?

- Scale they want Dell's business. Big Dell can dictate terms

- How many Sushi restaurants in Bentonville, AK?

- Dell has squeezed inventory down to less than 4 days. Is it gone from value chain?

- Not entirely, have to pay for it through suppliers costs.

- How much inventory do suppliers hold?

- Required to hold 8-10 days of stock in multi-vendor warehouses within 90 minutes of the factories.

- So Dell's scale gives it bargaining power. How do suppliers get more of Dell's business?

- Suppliers are ranked against competitors

- Vendors compete on cost, technology, supply predictability service

- Rank determines the percentage of Dell's business they earn

- So that's the back end of the system. How does Dell help suppliers understand buying patterns?

- It does forecasting

- Pays attention to customer buying upgrade patterns

- How accurate?

- What does Dell do during the times when Dell guesses wrong is caught with low stocks in key inventory (say 15" monitors)?

- Runs a special on 17" monitors

- What do supply chain experts call this?

- Demand shaping

- It can leverage demand shaping more than rivals

- because it has a direct-to-customer model

- What's Dell's profit margin advantage over rivals?

- How much does HP make on a PC? What are its profit margins?

- Less than 1 margins

- So Dell cuts two points from its margins and it buries HPs profits!

- Why doesnt Gap copy Zara?

- It cant, because it would have to redo everything.

- Supply chaining is hard.

- More complex in Dells case

- Who doesnt like disintermediation?

- Retailers dont want to be cut out of the process.

- Channel Conflict.

- Companies cannot afford to do without retailers in the short term, retailers wont let them move gradually to disintermediate over long-term.

- We recognize that a vendor has the right to sell through whatever distribution channels it desires. However, we too have the right to be selective in regard to the vendors we select and we trust that you can understand that a company may be hesitant to do business with its competitors. Home Depot memo to suppliers

- Dells been struggling lately. Why?

- Company can develop sustainable competitive advantage if its resources/ products have 4 characteristics

- Inimitable (not able to be copied easily)

- Non-substitutable (there arent any alternative products available).

- Yes, but not as valuable as it used to be.

- Moores Law. Computer technology has gotten cheaper.

- Dells profit margin is 8.

- I paid 3500 (for my first computer out of college)

- 8 margins 280

- Lots of money, buy direct

- I paid 500 (for wifes computer moving to Boston. Note also 80x more powerful than my college computer)

- 8 of 500 40

- Not so much, maybe want to see feel.

- As continued to cut, may have cut some things that customers valuedservice and product quality.

- Trying to be like Wal-Mart cost before quality only cut PC support so far.

- Used to create rare product in that it could be customized.

- Configure computer for your particular needs

- As computing power has gotten greater, now the standard computer is sufficient for most needs of average user (save CAD).

- Storagejust get an external hard drive.

- Processormost people never use all the processing power they have.

- New technologies (grid or utility computing) beginning to take advantage and harness all the extra computing power out there.

- SETI, AIDS research, PS3 Network for molecular folding.

- Increased computing power introduced substitutes to the desktop.

- Laptops not a huge price difference anymore.

- PDA/Smart Phone The PDAs today are as powerful as computers 5-10 years ago.

- Game Stations Carving off entertainment market.

- Does Dell make many of these products?

- Is their advantage as strong as in desktops

- May be a disadvantage for some (e.g. LCD)

- Supply chaining is hardbut not impossible.

- Others have begun to close The Gap here (pun intended).

- Article suggests that Dell is a one trick pony.

- Have not been able to innovate to counter competitors that have begun to copy.

- Goal of business strategy, give a long-term edge that a company has over its competitors.

- Dell has been able to sustain its competitive advantage for 15 years (2006 25 on Fortune 500, started 1984 in UTx dorm room).

- No question that Dell has been one of the most successful companies of past decade.

- No question Dell still lean mean is doing stuff as well as they always have.

- Question is whether what Dell has built can sustain to next 10 years?

- Are Dells resources still VRIN?

- Selling in China

- Selling in WalMart

PowerShow.com is a leading presentation sharing website. It has millions of presentations already uploaded and available with 1,000s more being uploaded by its users every day. Whatever your area of interest, here you’ll be able to find and view presentations you’ll love and possibly download. And, best of all, it is completely free and easy to use.

You might even have a presentation you’d like to share with others. If so, just upload it to PowerShow.com. We’ll convert it to an HTML5 slideshow that includes all the media types you’ve already added: audio, video, music, pictures, animations and transition effects. Then you can share it with your target audience as well as PowerShow.com’s millions of monthly visitors. And, again, it’s all free.

About the Developers

PowerShow.com is brought to you by CrystalGraphics , the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Our product offerings include millions of PowerPoint templates, diagrams, animated 3D characters and more.

Dell Inc. Case Study

Mar 29, 2019

560 likes | 1.01k Views

By: Dan McLindon Kyle McDaniel Jeremy Smiley Tom Anderson Ray Moorman. Dell Inc. Case Study. Key Question for Dell . Can Dell overtake HP as the world leader in personal computers with its current strategies of Build to Order and Direct to Consumer sales?.

Share Presentation

- strategy contribution

- efficient build

- strategy direct sales contribution

- limited success

- dedicated department head

Presentation Transcript

By: Dan McLindon Kyle McDaniel Jeremy Smiley Tom Anderson Ray Moorman Dell Inc. Case Study

Key Question for Dell Can Dell overtake HP as the world leader in personal computers with its current strategies of Build to Order and Direct to Consumer sales?

Secondary Questions What contributed to Dell’s success and rapid growth in the late 1990’s? Why is Dell choosing to become more like HP? What does Dell do well and where does it struggle? Can Dell ever be successful in B2C market in developing countries with Direct to Consumer distribution? What is Dell? A computer manufacturer? A consumer electronics company? An IT service partner? What is their focus? What is Dell doing today to set itself apart from the competition in the highly competitive and rapidly evolving personal computer industry?

Dell Computer Company Overview

PEST Analysis for Dell

What is going on in the PC industry?

Industry Overview (Supply) Porter’s five forces: Threat of substitute products High Rivalry among existing competitors High Bargaining power of buyers High Bargaining power of suppliers Low for generics High for key parts Threat of new entrants Low

Porter’s Five Forces

What is HAPPENING WITH DEMAND?

Currently A $1.5 Trillion IT Industry • Explosion of the digital era • World’s data doubles every 3 years • Social networking craze • Blogs, online video, My Space, Facebook • Emerging markets with ½ the world’s population • All working together to create DEMAND!

Is There Further Growth Out There in the PC Market? Shipments of PC’s(millions) 1980 - 2012

2007 PC Vendor Market Share Dell’s PC business model has not translated into global leadership. But the growth opportunity is there!

What contributed to Dell’s success and rapid growth in the late 1990’s?

Build to Order Conclusion – Dell has spent its time and money on innovation to become an efficient manufacturer of computer hardware. Was that an effective use of their resources?

Is Dell’s Build to Order model still a competitive advantage or has it become a liability?

Build to Order

What has Dell done to separate itself from the competition?

Dell Inc. Product Timeline Conclusion – Expanding product set into several highly competitive markets with well established players. Strategy is be the low cost leader.

Internal Analysis – Core Competencies Red – Easy for competitors to develop Yellow – Possible for competitors to develop Green – Very difficult for competitors to develop

What does Dell do well and where does it struggle?

Dell's Geographic Performance(Operating Incomes) U.S. Business & EMEA markets showing strongest growth trends.

Internal Analysis – Markets Served Conclusion – Dell is strong in the US B2B market, but that strategy does not translate to success in B2C. Only 39% of sales generated outside US, compared to 67% global sales by HP.

Internal Analysis - Manufacturing Conclusion – Dell already starting to outsource its competitive advantage. Can it still compete with HP in the B2C market? Will outsourcing manufacturing impact their advantage in B2B market?

SWOT Analysis for Dell

Will dell’s strategy allow it to achieve the growth it desires? Which business models are dated and which can still prove a competitive advantage?

Elements of Strategy Cost Efficient Build to Order • Competition has tried to emulate with limited success • ýAlthough other vendors have not replicated Dell’s strategy, they’ve done enough to close the cost advantage gap. • ýDell’s lean manufacturing techniques work best in production of desktop PCs. Consumer tastes have shifted to laptops. Dell’s Strategy Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy Partner with Suppliers • ýIBM, HP, Sony, Toshiba, Fujitsu abandoned vertical integration for strategic outsourcing of components in the early 1990s. • Partnering with suppliers to utilize their expertise is a given at this point, no contribution to competitive advantage. Dell’s Strategy Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy • þCompetitors have not been able to shorten their supply chain as effectively as Dell • þCompetitors have had difficulty implementing the sell direct strategy because it cannibalizes other sales channels. • ýDisadvantage in some foreign markets where small business and individual customers want more of a hands on shopping experience. Dell’s Strategy Direct Sales Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy • Industry is evolving with new products. Dell has demonstrated success in entering product segments and succeeding as the low cost provider. Examples are servers and networking equipment. • Name recognition from desktops and notebooks gives consumers confidence to try other products. • Opportunity for growth is large outside of PCs and servers where Dells market share is negligible. Market share is ≤5% in data storage, networking, printers, and IT services. Dell’s Strategy Expansion of products and services Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy • Dell’s growing pains with off shoring support services are behind them. Processes and best practices standardized world wide. • Voice of the customer – regional forms, IdeaStorm • Custom websites for large customers, product design services, value add services • ýBelow customer satisfaction goal in Americas Dell’s Strategy Customer Service and Technical Support Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy • Advocate for customers needs – useful, cost effective technologies • Quality Control streamlines the assembly process and reduces costs • Growing budget -- $600M in 2008 • Facilitates entry into new products and services Dell’s Strategy R&D focused on customer needs Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy Use of Standardized Technologies • More cost effective than proprietary technology • Standardized technologies are upgradeable • ýStrategy is easily replicated Dell’s Strategy Contribution towards a future competitive advantage… Cooling Warming

Elements of Strategy Contribution towards a future competitive advantage… Cooling Warming

How does dell’s current position compare to HP?

US Market Share – Dell vs. HP Conclusion – From 2005, declining trend in Market Share for Dell. HP has gained market share during that time. Possible reason for HP’s success is acquisitions (Compaq 2002, EDS 2008)

Contributors to HP's Operating Income HP acquires EDS Dell should continue focusing efforts on growing IT services business and look for acquisition of IT services company to continue to compete and hold market share against HP.

Leading Providers of Information Technology (2007) Acquisition of CSC would give Dell increased IT services market share of 3.3% vs. HP’s 5.3% combined market share (with EDS)

What does Dell need to do in order to take the lead again?

Recommendations • Acquire a larger IT services company to supplement Dell's current IT services department - CSC is a possibility • Gain immediate market share • Focus on critical customers by creating dedicated department head's with authority to meet the demands of the following groups: • Large Companies (larger than 400 employees) (already exists, continue current services) • - Small-Med companies (less than 400 employees) • - Government Agencies • - Higher Education Universities • - K-12 Primary School Systems • Focus on speed of service, customization to meet needs of each organization, build loyalty with groups who have more frequent demand and servicing needs.

Recommendations • Hire product development specialists from product/branding focused companies. • Helps Dell to get a fresh perspective on their product and new ideas for development. • Redesign laptop and PC brands to make them more exciting for personal use consumers. • Dell's competing with HP and Apple who are creating products customers desire. • Financials indicate consumer products are struggling vs. competition. • Increase R&D budget to create more exciting models.

Recommendations • Sell only a couple standard model PC's and laptops in retail centers like Wal-Mart and Best Buy – out of sight, out of mind mentality for consumers. • Allows Dell to appeal to everyday customers who don't desire custom computers. • Use suppliers/manufacturers to build these standard models with no changes to the specs – keep costs down. • Continue to build PC’s and custom laptops in-house to take advantage of logistics and efficiencies • This also builds brand awareness with consumers who may want custom computers. • Allow current marketing programs to target higher-end users who desire personalized PC’s. • Acquire Chinese PC/laptop maker to enter Chinese market – Increase revenues from Asia-Pacific/Japanese market.

- More by User

Dell Inc. Mary Voss November 16, 2004. Recommendation. Recommendation: Hold Currently, hold 500 shares at the market price of 40.70 Market Value of 20350. We purchased these shares on December 10,1999 for 41.75 Cost Basis of 20875. Dell has never paid a dividend

615 views • 22 slides

By: Dan McLindon Kyle McDaniel Jeremy Smiley Tom Anderson Ray Moorman. Dell Inc. Case Study. Key Question for Dell. Can Dell overtake HP as the world leader in personal computers with its current strategies of Build to Order and Direct to Consumer sales?.

228 views • 0 slides

Dell inc. Presented by group 6: Jannie, Sabrina & Kasper. Agenda 26-9-2012. Dell’s history The strategy of Dell Assessing China by the SLEPT framework Market rivals Dell’s setbacks in China Strategy 2012 - China. Dell’s history. 1984: Founded by Michael Dell, Texas

597 views • 13 slides

Case study- Dell

Case study- Dell. Presented by: Siddhartha Sanghi (10714) Vaibhav Patni (10783) . Part I- Analytics for Marketing Part II- Analytics for production strategy. Case I:Analytics for Marketing Strategy. Business Problem: To develop marketing strategies based on the customer purchase data

266 views • 8 slides

By: Dan McLindon Kyle McDaniel Jeremy Smiley Tom Anderson Ray Moorman. Dell Inc. Case Study. Key Question for Dell. Can Dell overtake HP as the world leader in personal computers with its current strategies of Build to Order and Direct to Consumer sales?. Secondary Questions.

746 views • 39 slides

By: Dan McLindon Kyle McDaniel Jeremy Smiley Tom Anderson Ray Moorman. Dell Inc. Case Study. Key Question for Dell. What is Dell? A computer manufacturer? A consumer electronics company? An online retailer? An IT service partner? What is their focus?. Secondary Questions.

498 views • 26 slides

DELL Inc. Prepared by Zhanna Tulekova MGT 490. Organizational Background.

1.03k views • 59 slides

VMware, Inc. Case Study

VMware, Inc. Case Study. Presentation By: Bradley Atherton, Leslie Lainez , Mark Balingit , Roy Sanchez, Tony Vuong , Kyle Schuler. Background. First to the market to provide a virtualization solution for x86 based format and dominated the market Founded By: Edourad Bugnion

835 views • 33 slides

Dell Inc. Tina Cecil Nicole Drvar Krista Marko Sandra Markovic. Dell’s setup Customization Leads industry in low costs/prices. HPs setup Mass production Will require significant cost-cutting efforts (post Carly). Dell Vs. HP . Dell Vs. HP – Market Analysis. ACCORDING TO IDC:

350 views • 14 slides

Case study : hackme , inc.

Case study : hackme , inc. Section 5.2 Network Forensics TRACKING HACKERS THROUGH CYBERSPACE. The mission.

1.17k views • 40 slides

WP INC CASE STUDY PROJECT

MGMT 580 By Samuel & Adrienne 18 December 2013. WP INC CASE STUDY PROJECT. The problem at hand is the spray nozzles , which frequently clog with particles, causing the parts washer to shut down. The part washer has been identified as one of the most troublesome or difficult operation

356 views • 21 slides

WP Inc. case study

WP Inc. case study. Lisa M. Cochran MGMT580PA Quality Management & Statistical Analysis Southwestern College Dr. Michael Corriere 13 June 2012. CASE STUDY OVERVIEW. WP Inc. manufactures small metal parts Uses customer’s design

412 views • 15 slides

Dell Inc. Christine Celia Section: 006 September 29, 2010 . History. Founded by Michael Dell in 1984. Sold computers out of his dorm year during his freshman year of college at University of Texas. Achieved $6 million first year of business. Jumped to $40 million in second year.

271 views • 8 slides

Toy Producers Inc Case Study

Toy Producers Inc Case Study. Clive Vlieland-Boddy . Group Discussion. Summaries the risks and rewards of switching to linear production?. Key Issues. What is the Company? What is the Industry? What is the decision to be made? Who is to make the decision?. The Company. Toy Manufacture.

418 views • 32 slides

Case Study of Monster Inc.

Case Study of Monster Inc. By Donatas Sumyla. Content. Introduction Online Brokers Company Overview Monster.com GBF Winner Takes All?. Introduction. Founded in 1967, Monster is the leading global online careers and recruitment resource property.

355 views • 24 slides

Dell, Inc. Ian Christensen Course Section7 7. Brief History. Dell was founded in 1984 by Michael Dell. Michael Dell dropped out of school in order to focus full-time on his fledgling business, after getting about $300,000 in expansion-capital from his family.

1.38k views • 8 slides

Dell Inc. Hazreena Alli Section 008. Founder and Creator of Dell Inc. Dell Inc was created to meet the individual need of Individuals!. Michael Dell, Founder of the Dell Inc. Dell Inc Products. Growth of Company. Dell Inc Financial Growth.

385 views • 8 slides

Dell Computers, Inc.

HUSAM YASEEN 120060148. Dell Computers, Inc. About Dell Computers, Inc. Is global technology corporation that develops, manufactures, sells, and supports personal computers and other computer-related products. Based in Round Rock, Texas. History of Dell Computers, Inc.

480 views • 15 slides

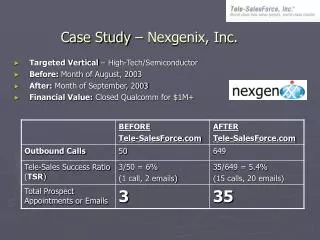

Case Study – Nexgenix, Inc.

Case Study – Nexgenix, Inc. Targeted Vertical – High-Tech/Semiconductor Before: Month of August, 2003 After: Month of September, 2003 Financial Value: Closed Qualcomm for $1M+. Case Study – Nexgenix, Inc. Targeted Vertical – Entertainment

256 views • 2 slides

779 views • 42 slides

FormFactor, Inc Case Study

Enterprise Applications Support for Global Leader in Semiconductor Manufacturing Reduces Day-to-Day Support Costs by 30%

27 views • 2 slides

Case Study: Hancock Carriers, Inc.

Case Study: Hancock Carriers, Inc. Ronald L. Hancock. Company Information. Hancock Carriers transports power cable, steel and steel products throughout the United States. Company Background. Hancock Carriers started in March of 1986 with only one truck.

101 views • 9 slides

IMAGES

VIDEO

COMMENTS

DELL supply chain management. Dec 19, 2015 • Download as PPTX, PDF •. 28 likes • 43,861 views. A. Ashwarya Chaudhary. Supply Chain of Dell Inc. Covering the foll. topics: - Overview -Value Chain -Pull/Pull view -Responsiveness v/s efficiency -strategic fit -Drivers of supply chain -Distribution. Read more. Retail.

Dell revolutionized supply chain management with its direct model, configure-to-order (CTO) manufacturing, just-in-time inventory model and impressive cash-to-cash conversion cycle. The company has been a staple in the top five of the AMR Supply Chain Top 25 every year since it started in 2004.

It is known particularly for its innovative supply chain management. Ecosystem Pain Point In this case study, we will outline how Dell uses the concepts of circular economy to address the wider ecosystem pain points described in this section of the case study.

Dell Supply Chain Management - Download as a PDF or view online for free. Submit Search. Upload. Dell Supply Chain Management ... Dell case study (management) Dell case study (management) Vineeth Kamisetty ... B2b Dell Presentation.

SUPPLY CHAIN MANAGEMENT 1ST SEMESTER 2020/2021 CASE STUDY#2 Case Study #2: Dell's Supply Chain Integration Dell, a 57-billion-dollar industry, employs its supply chain systems unlike any other PC maker on the planet. The company was one of the first to introduce a configure-to-order model where customers could have millions of configurations to

The case illustrates the process that allows a company to successfully implement a digital transformation strategy in its supply chain. It provides a powerful illustration of Dell Technologies Inc.'s strategic decisions and how the company influenced different steps in its digital transformation. This case is suitable for graduate- and ...

Dell Case Study Management Presentation - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site.

Dell pioneered a unique model of selling PCs directly to the consumers, bypassing the resellers. The model is popularly known as the Direct Model. This case ...

The document provides information on supply chain management practices of Dell and Hewlett-Packard. It discusses Dell's build-to-order and just-in-time inventory strategies. It also discusses how Hewlett-Packard partnered with FedEx to develop a direct-to-consumer online sales channel for refurbished products, with FedEx providing solutions for order management, warehouse management, inventory ...

Five years later, revenues had climbed to $500 million, and by the end of 2000, Dell's revenues had topped an astounding $25 billion. The meteoric rise of Dell Computers was largely due to innovations in supply chain and manufacturing, but also due to the implementation of a novel distribution strategy. By carefully analyzing and making ...

Corporate Strategy- Supply Chain Management- Dell Case Study - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Corporate Strategy vis-a-vis Supply Chain Management Prof. Rushen chahal. The Corporate Strategy dictates the detailed strategies for each functional area (i.e., Operations, Marketing, Information Technology, Human ...

Case Study: Dell's Response to Supply Chain Disruptions. To truly appreciate the strength of Dell's supply chain, let's turn our attention to how it responds to disruptions. As the old adage goes, it's not the calm but the storm that truly tests a sailor's skill. ... Success Stories from Dell's Supply Chain Management Story 1 ...

The Dell Supply Chain Dell takes a holistic approach to protecting its supply chain and delivering solutions that customers can trust. The strategy of "defense-in-depth" and "defense-in-breadth" involves multiple layers of controls to mitigate threats that could be introduced into the supply chain. These controls, along with effective risk

Dell Supply Chain Case Study. SUBMITTED BY: GROUP #7. Introduction. Dell organization was built up in November 4, 1984. It is an American multinational data innovation company situated in Round Rock, Texas, United States, that creates, offers and backings PCs and related items and administrations. The organization is one of the biggest ...

dell ppt.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Dell has an efficient supply chain management system that provides it with competitive advantages. It uses a build-to-order strategy where computers are assembled only after receiving customer orders. This allows Dell to avoid holding large inventories.

Title: Dell and Supply Chains. 1. Dell and Supply Chains. MI021/CS021Computers in Management. 2. (No Transcript) 3. Dells Business. What are the characteristics of market segments.

Dell Inc. Product Timeline Conclusion - Expanding product set into several highly competitive markets with well established players. Strategy is be the low cost leader. Internal Analysis - Core Competencies Red - Easy for competitors to develop Yellow - Possible for competitors to develop Green - Very difficult for competitors to develop.