- Crafting a Comprehensive Wheat Flour Mill Business Plan in Ethiopia

Are you thinking about starting a wheat flour mill business in Ethiopia? Do you want to invest in a profitable and successful business?

Ethiopia is a country with a rich agricultural heritage and a growing population. Wheat is widely consumed in various forms as one of the main crops, making wheat flour an important commodity. At the same time, the Ethiopian government recognizes the importance of the flour mill industry, promoting investment and supporting local wheat flour production.

Therefore, setting up a wheat flour mill plant in Ethiopia can be a lucrative business. However, to ensure the success of your venture, you need a solid wheat flour mill business plan .

Relaetd Posts: Setting up a flour mill in Pakistan>>

In this article, we will cover the steps to customize a wheat flour mill business plan for the Ethiopian market , to help you achieve your business goals. If you have any questions while reading, don't be shy about consulting us for professional answers!

How to Create a Wheat Flour Business Plan in Ethiopia: A Complete Guide

Developing a business plan for your wheat flour processing business is critical to ensuring the success of operation. It provides direction and goals for setting up a wheat flour mill and is a guide for entrepreneurs to ensure the success and sustainability of the business.

Here are the key components and writing points of a wheat flour business plan:

1 Executive Summary

Your business plan should begin with a concise executive summary that provides a high-level view of your business . This section should capture the essence of your flour mill business, including its vision, mission, and goals.

2 Market Research and Analysis

Thorough market research is the cornerstone of your business plan. You must gain an in-depth understanding of the Ethiopia wheat flour market , including its size, demand, and competition. Gather data on wheat production, consumption, and trends, and consider factors such as regional differences in consumption, the quality of wheat produced, and local consumer preferences. (Read More: Flour mill market analysis column>> )

3 Company Description

In this section, provide a detailed overview of your wheat flour mill factory . Describe the history and background of your flour mill company, its location, and legal structure. Potential investors or partners will use this information to assess the viability of your business.

4 Products & Services

What types of wheat flour mill products do you plan to produce? These may include different grades of flour for a variety of uses, such as bread, pastries, or traditional Ethiopian dishes such as injera. In addition, please consider value-added services, such as packaging or distribution.

5 Sales and Distribution

How will you sell your products? Describe your sales strategy in this section, whether you plan to sell directly to consumers, wholesalers, or retailers. Discuss the distribution channels you will use to ensure that your flour products reach the right place at the right time.

6 Management and Organization

Introduce your management team and their role in the organization. Explain the organizational structure of your wheat flour mill business, showing how responsibilities are divided.

7 Capital Requirements

Setting up a wheat flour mill plant requires capital for commercial wheat flour mill machine , facilities, and operating expenses. Estimate the capital you will need and explain how you plan to obtain it. Whether through personal savings, loans, or investors, define your financial requirements. (Related Posts: Wheat flour mill plant cost>> )

It should be noted that investment in starting a wheat flour mill mainly includes the following aspects: Wheat flour mill machinery and equipment cost Raw materials-wheat purchase cost Labor costs Infrastructure and land plant costs Other costs and expenses

8 Risk Analysis and Mitigation

Identify potential risks your business may face and describe strategies to mitigate them. Address issues related to market volatility, competition, or operational challenges.

9 Appendices

Include any additional information that supports your business plan for wheat flour production. This could be market research data, resumes of key team members, legal documents, or any other relevant information.

Promising Investment Prospects in Ethiopian Wheat Flour Milling Industry

Ethiopia, a nation with a rich agricultural heritage and a burgeoning economy, presents compelling investment prospects in its milling industry. There are mainly these advantages conducting wheat flour milling business in Ethiopia:

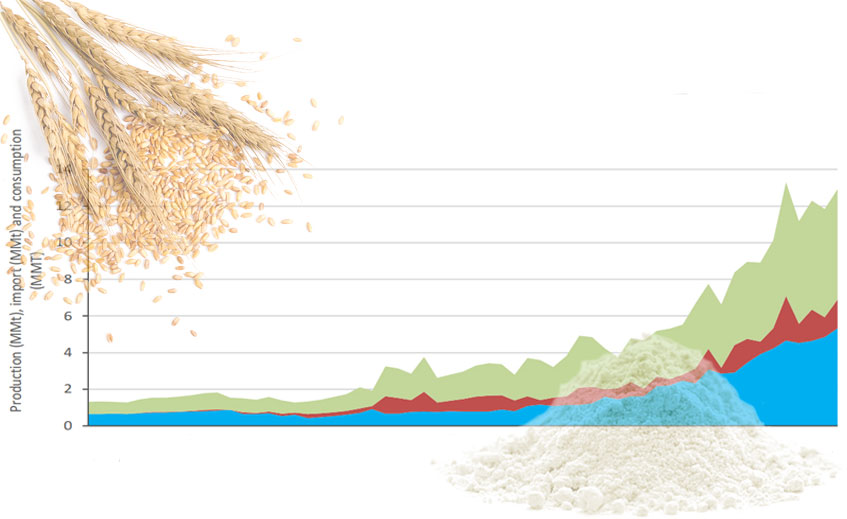

- Abundant wheat resources: Wheat production and consumption have both increased in Ethiopia despite the existence of strong markets for potential substitute grains.

- Government support: The Ethiopian government has played an active role in wheat markets, such as making large investments in extension programs and adopting protectionist policies to ensure government control of all commercial grain imports.

- Low labor costs: With a relatively low labor cost environment, businesses can maintain competitive pricing structures.

- Development opportunities: As a developing country, Ethiopia is undergoing rapid economic growth, providing development opportunities across various industries, including the food processing sector.

Project Report for Wheat Flour Mill Business in Ethiopia-ABC Machinery

FAQs of Starting Wheat Flour Processing Business in Ethiopia

- How much does it cost to set up wheat flour mill plant in Ethiopia?

- If you are planning to start a small flour mill business, you will need about 50,000 to 60,000 Ethiopian Birr. A large wheat flour mill will cost around 140,000 Ethiopian birr or more, with a variable ceiling. It also depends on the type of flour mill machine required for the business and the complexity of the wheat milling process .

- What licenses are required to start a flour mill in Ethiopia?

- The specific licenses and permits you will need may vary depending on the size and location of your flour mill company. You may need these licenses and permits: Business Registration, Environmental Permit, Food Processing License, Tax Identification Number (TIN), Health and Safety Permits, etc.

- 10-20TPD Wheat Flour Mill

- 30-60 TPD Wheat Flour Mill

- 70-200TPD Wheat Flour Mill

- 200-500 TPD Wheat Flour Mill

- 500-1000TPD Wheat Flour Mill

- 10-20TPD Maize Flour Mill

- 30-100TPD Maize Flour Mill

- 100-200TPD Maize Flour Mill

- bean peeling plant

- chili powder making machine

- Cassava Starch Production Plant

- Soy Protein Isolate Production Line

40 TPD Maize Flour Mill Plant Project Setup in Uganda

30TPD Maize Flour Milling Plant Setup in Chad

100TPD Soybean Protein Isolate Plant Project Built in Uzbekistan

- Buying Flour Mill Machine for Home: What You Need to Know

- Guide to Flour Mill Machine Price in India | Considerations Before Buying

- Launch Your Maize Flour Mill Business with Proven Strategies

Zambia 2024 is coming up with AGRITECH EXPO ZAMBIA exhibition at GART Research Centre, Chisamba (April 18th to April 20th) . ABC Machinery will be participating in this years Exhibition. We cordially invite you to visit our booth (A19) and...

Recently, our Ethiopia client ordered a 60TPD Wheat Flour Plant to produce wheat flour. The main equipment of the wheat flour manufacturing plant includes a combined cleaning sieve, wheat washing machine, wheat scourer, rotary sieve classif...

Recently, a new customer in Burundi ordered a complete 10TPD maize flour mill production line from ABC Energy Machinery.He has just opened a flour mill factory and plans to buy this small-scale maize flour machine....

Wheat Flour Mill Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Agriculture Sector » Agro Processing

Are you about starting a wheat flour mill? If YES, here is a complete sample wheat flour production business plan template & feasibility report you can use for FREE .

Okay, so we have considered all the requirements for starting a wheat flour production business. We also took it further by analyzing and drafting a sample wheat flour mill marketing plan template backed up by actionable guerrilla marketing ideas for wheat flour production businesses. So let’s proceed to the business planning section.

As an aspiring entrepreneur who is looking towards starting a business and becoming your own boss, one of the businesses that you can successfully start if you have the financial requirement and of course business expose is to open a wheat flour production mill.

Although this type of business is not a business that you can start making profits from instantly, but a you are sure going to make good profits in the long run if you are determined and proactive in running the business. The reason is not far – fetched; you will require huge capital to set – up a standard wheat flour production mill. This type of business can somewhat be capital intensive.

Beyond every reasonable doubt, wheat flour is consumed in all parts of the world either as flour or the flour is used in the production of bread and other baked foods.

This goes to show that there is indeed a large market both locally and internationally for wheat flour production companies. Below is a sample wheat flour production mill business plan template that can help you to successfully write your own.

A Sample Wheat Flour Production Mill Business Plan Template

1. industry overview.

Wheat flour production companies in basically engaging in milling wheat grains into flour and then package and sell them to wholesale distributors, grocery wholesalers or other food-related business. They purchase wheat grain inputs from wholesalers or directly from growers.

The main fact that wheat flour mills provide goods that are considered diet staples, the industry will remain relevant in the years to come. The revenue and profit generated from this industry will depend on the price and production of wheat. As companies vertically integrate and merge operations to take advantage of economies of scale, revenue will rise.

According to a report released by IBISWORLD, the Flour Milling industry of which Wheat Flour Mill Production line of business is a part of is characterized by a low level of market share concentration. The report stated that in 2016, the top three players are expected to account for less than 31.0 percent of industry revenue.

While the industry exhibits low concentration, the industry is expected to approach moderate concentration over the next five years in line with the entrance of larger flour milling companies.

The report also stated that, in 2014, Ardent Mills entered the industry, as a result of ConAgra Mills and Horizon Milling, which is a joint venture between Cargill and CHS, combining their flour milling operations. Overall, larger operations will enable flour milling companies to use their large size to leverage lower costs for input commodities, such as wheat and grains

The Flour Production Mill industry of which wheat flour mill production line of business is subset of is a thriving sector of the economy of the united states of America and they generates a whooping sum of well over billion annually from more than 403 registered and licensed wheat flour mill production companies scattered all around the United States of America.

The industry is responsible for the employment of well over 24,938 people. Experts project the wheat flour mill production industry to grow at a -1.2 percent annual rate. Archer Daniels Midland Company, Ardent Mills, ConAgra Mills and Horizon Milling are the market leaders in the wheat flour production mill industry; they have the lion market share in the United States of America.

With this kind of business, if you want to start on a small scale, you can choose to start servicing your local community. All you would need is contacts, packaging, networking and good marketing and customer service skills. However, if you intend starting it on a large scale, then you should consider spreading beyond your local community to state level and even national level.

Over and above, the wheat flour production mill line of business is a profitable industry and it is open for any aspiring entrepreneur to come in and establish his or her business; you can chose to start on a small scale servicing a community or you can chose to start on a large scale with several distribution outlets in key cities all around the United States of America.

2. Executive Summary

Sammy Jay® Wheat Flour Production Company is a licensed and standard wheat flour mill production company that will be located in an industrial area in Springfield – Illinois. We have been able to secure a long term lease for a facility in a strategic location close to a big wheat farm with an option of a long term renewal on an agreed terms and conditions that is favorable to us.

The facility has government approval for the kind of business we want to run and it is easily accessible and we are deliberate about that to facilitate easy movement of raw materials (wheat grains and packaging materials et al) and finished products (well packaged wheat flour).

We are in the wheat flour mill production business to engage in processing, packaging and retailing wheat flour. We are also in business to make profits at the same to give our customers value for their money; we want to give people and businesses who patronize our well – packaged wheat flour the opportunity to be part of the success story of Sammy Jay® Wheat Flour Production Company.

We are aware that there are several big scale and small scale wheat flour mill production companies scattered all around the United States and Canada whose products can be found in every nooks and crannies of The United States and Canada.

Which is why we spent time and resources to conduct our feasibility studies and market survey so as to enable us locate the business in an area that will support the growth of the business and also for us to be able offer much more than our competitors will be offering.

We ensured that our facility is easy to locate and we have mapped out plans to develop a wide distribution network for wholesalers all around Springfield – Illinois and throughout the United States of America.

Much more than producing healthy, well processed and well packaged wheat flour, our customer care is going to be second to none. We know that our customers are the reason why we are in business which is why we will go the extra mile to get them satisfied when they visit purchase our wheat flour warehouse and also to become our loyal customers and ambassadors.

Sammy Jay® Wheat Flour Production Company will ensure that all her customers (wholesale distributors) are given first class treatment whenever they visit our flour mill or warehouse.

We have a CRM software that will enable us manage a one on one relationship with our customers (wholesale distributors) no matter how large the numbers of our customer base may grow to. We will ensure that we get our customers involved when making some business decisions that will directly or indirectly affect them.

Sammy Jay® Wheat Flour Production Company is family business that will be owned and managed by Sammy Jay and his immediate family members. Sammy Jay who is the Chief Executive Officer of the Company is Graduate of MicroBiology (B.Sc.) and he holds a Master’s Degree in Business Management (MBA).

He has well over 10 years of experience working in related industry as a senior manager prior to starting Sammy Jay® Wheat Flour Production Company. He will be working with a team of professionals to build the business and grow it to enviably height.

3. Our Products and Services

Sammy Jay® Wheat Flour Production Company is going to operate a standard and licensed wheat flour mill production company whose products will not only be sold in Springfield – Illinois but also throughout the United States of America.

We are in this line of business to make profits and also to give our customers value for their money. We are going to do all that is permitted by the law of the United States to achieve our business aim and ambition. Our product offering will be;

- Processing, packaging and retailing wheat flour in commercial quantities

4. Our Mission and Vision Statement

- Our vision is to establish standard Wheat Flour Production Company whose products will not only be sold in Springfield – Illinois, but also throughout the United States of America and Canada.

- Our mission is to establish a standard and world class Wheat Flour Mill Production Company that in our own capacity will favorably compete with leaders in the industry. We want to build a wheat flour mill production business that will be listed amongst the top 10 wheat flour mill brands in the United States of America and Canada

Our Business Structure

Sammy Jay® Wheat Flour Production Company is a business that is established with the aim of competing favorably with other leading wheat flour brands in the United States of America and Canada. This is why we will ensure that we put the right structure in place that will support the kind of growth that we have in mind while setting up the business.

We will ensure that we only hire people that are qualified, honest, hardworking, customer centric and are ready to work to help us build a prosperous business that will benefit all the stakeholders (the owners, workforce, and customers).

As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of five years or more depending how fast we meet our set target. In view of that, we have decided to hire qualified and competent hands to occupy the following positions;

- Chief Executive Officer (Owner)

Plant Manager

Human Resources and Admin Manager

Merchandize Manager

Sales and Marketing Manager

- Machine Operators

- Accountants / Cashiers

Distribution Truck Drivers

5. Job Roles and Responsibilities

Chief Executive Officer – CEO (Owner):

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- Creates, communicates, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Responsible for signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Responsible for overseeing the smooth running of the wheat flour mill

- Part of the team that determines the quantity of wheat flour bags that are to be produced

- Maps out strategy that will lead to efficiency amongst workers in the plant

- Responsible for training, evaluation and assessment of plant workers

- Ensures that the steady flow of both raw materials to the plant and easy flow of finished products through wholesale distributors to the market

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Ensures that the plant meets the expected safety and health standard at all times.

- Responsible for overseeing the smooth running of HR and administrative tasks for the organization

- Updates job knowledge by participating in educational opportunities; reading professional publications; maintaining personal networks; participating in professional organizations.

- Enhances department and organization reputation by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

- Defines job positions for recruitment and managing interviewing process

- Carries out staff induction for new team members

- Responsible for training, evaluation and assessment of employees

- Oversees the smooth running of the daily office and factory activities.

- Manages vendor relations, market visits, and the ongoing education and development of the organizations’ buying teams

- Helps to ensure consistent quality of wheat grains and packaging materials are purchased

- Responsible for the purchase of raw materials and packaging materials (wheat grains and packaging materials et al)

- Responsible for planning sales, monitoring inventory, selecting the merchandise, and writing and pricing orders to vendors

- Ensures that the organization operates within stipulated budget.

- Manages external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Models demographic information and analyze the volumes of transactional data generated by customer purchases

- Identifies, prioritizes, and reaches out to new partners, and business opportunities et al

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develops, executes and evaluates new plans for expanding increase sales

- Documents all customer contact and information

- Represents the company in strategic meetings

- Helps to increase sales and growth for the company

Accountant / Cashier

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyzes financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization

Client Service Executive

- Ensures that all contacts with customer (e-mail, walk-In center, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with customers on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Manages administrative duties assigned by the store manager in an effective and timely manner

- Consistently stays abreast of any new information on Sammy Jay® Wheat Flour Production Company products, promotional campaigns etc. to ensure accurate and helpful information is supplied to clients when they make enquiries

Production Workers / Machine Operators:

- Responsible for processing and packaging (bagging) wheat flour

- Assists in packaging and loading wheat flour (bags) into distribution trucks

- Any other duty as assigned by the plant manager.

- Assists in loading and unloading wheat grains and wheat flour (bags)

- Maintains a logbook of their driving activities to ensure compliance with federal regulations governing the rest and work periods for operators.

- Keeps a record of vehicle inspections and make sure the truck is equipped with safety equipment

- Assists the transport and logistics manager in planning their route according to a delivery schedule.

- Local-delivery drivers may be required to sell products or services to stores and businesses on their route, obtain signatures from recipients and collect cash.

- Transports finished goods and raw materials over land to and from manufacturing plants or retail and distribution centers

- Inspects vehicles for mechanical items and safety issues and perform preventative maintenance

- Complies with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures

- Collects and verifies delivery instructions

- Reports defects, accidents or violations

6. SWOT Analysis

We are well informed that there are several wheat flour mill production companies both large and small in the United States of America and Canada which is why we are following the due process of establishing a business so as to compete favorable with them.

We know that if a proper SWOT analysis is conducted for our business, we will be able to position our business to maximize our strength, leverage on the opportunities that will be available to us, mitigate our risks and be welled equipped to confront our threats.

Sammy Jay® Wheat Flour Production Company employed the services of an expert HR and Business Analyst with bias in start – up business to help us conduct a thorough SWOT analysis and to help us create a Business model that will help us achieve our business goals and objectives. This is the summary of the SWOT analysis that was conducted for Sammy Jay® Wheat Flour Production Company;

Part of what is going to count as positives for Sammy Jay® Wheat Flour Production Company is the vast experience of our management team, we have people on board who are highly experienced and understands how to grow business from the scratch to becoming a national phenomenon.

So also, proximity to one of the largest wheat grain farms in Springfield – Illinois, our large national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

A major weakness that may count against us is the fact that we are a new wheat flour mill production company and we don’t have the financial capacity to engage in the kind of publicity that we intend giving the business.

- Opportunities:

The fact that wheat flour is stable food in the United States and in all the countries of the world means that the opportunity available to us is enormous.

As a result of that, we were able to conduct a thorough market survey and feasibility studies so as to enable us properly position our business to take advantage of the existing market for wheat flour and also to create our own new market. We know that it is going to requires hard work, and we are well prepared to achieve it.

We are quite aware that just like any other business, one of the major threats that we are likely going to face is economic downturn and unfavorable government policies . It is a fact that economic downturn affects purchasing power.

Another threat that may likely confront us is the arrival of a new wheat flour mill production company in same location where ours is located. Changing diet preference may also pose a threat to wheat flour mill production companies.

7. MARKET ANALYSIS

- Market Trends

IBISWORLD published a report that stated that the Flour Milling industry of which Wheat Flour Mill Production line of business is a part of is characterized by a low level of market share concentration.

The report stated that in 2016, the top three players are expected to account for less than 31.0 percent of industry revenue. While the industry exhibits low concentration, the industry is expected to approach moderate concentration over the next five years in line with the entrance of larger flour milling companies.

The report also stated that, in 2014, Ardent Mills entered the industry, as a result of ConAgra Mills and Horizon Milling, which is a joint venture between Cargill and CHS, combining their flour milling operations.

Overall, larger operations will enable flour milling companies to use their large size to leverage lower costs for input commodities, such as wheat and grains.

If you are conversant with the trends in amongst wheat flour mill production companies, you will realize that in the bid to expanding their brand and generate enough income, they do not just settle for just the production of wheat flour, they also engage in related activities such as producing flour from corn, producing flour mixes from a variety of grain crops, milling rough rice, producing malt from a variety of cereal grains, and producing meal and animal feed

They are able to achieve this because the processes and machine involved are same as that required for milling wheat grains into fine wheat flour. With this, they are able to maximize their capacity and make good profits from the business.

8. Our Target Market

When it comes to selling wheat flour, there is indeed a wide range of available customers. In essence, our target market can’t be restricted to just a group of people, but all those who resides in our target market locations. In view of that, we have conducted our market research and we have ideas of what our target market would be expecting from us.

We are in business to engage in wholesale distribution and to retail well – packaged wheat flour in different sizes to the following groups of people;

- Restaurants and Canteens

- Event Planners and Caterers

- Everybody in our target market location

Our Competitive Advantage

A close study of the wheat flour mill production industry reveals that the market has become much more intensely competitive over the last decade. As a matter of fact, you have to be highly creative, customer centric and proactive if you must survive in this industry.

We are aware of the stiffer competition and we are well prepared to compete favorably with other wheat flour mill production companies in Springfield – Illinois and throughout the United States and Canada.

Sammy Jay® Wheat Flour Production Company is launching a standard wheat flour brand that will indeed become the preferred choice of residence of Springfield – Illinois and every city where our well – packaged wheat flour will be distributed and retailed.

Part of what is going to count as competitive advantage for Sammy Jay® Wheat Flour Production Company is the vast experience of our management team, we have people on board who are highly experienced and understands how to grow business from the scratch to becoming a national phenomenon.

So also proximity to one of the largest wheat grain farms in Springfield – Illinois, our large national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

Lastly, our employees will be well taken care of, and their welfare package will be among the best within our category (startups wheat flour mill production companies) in the industry, meaning that they will be more than willing to build the business with us and help deliver our set goals and achieve all our aims and objectives.

We will also give good working conditions and commissions to freelance sales agents that we will recruit from time to time.

9. SALES AND MARKETING STRATEGY

- Sources of Income

Sammy Jay® Wheat Flour Production Company is established with the aim of maximizing profits in the wheat flour mill production industry in both the United States of America and Canada and we are going to go all the way to ensure that we do all it takes to sell our well processed and well – bagged wheat flour to a wide range of customers.

Sammy Jay® Wheat Flour Production Company will generate income by processing, packaging, distributing and retailing wheat flour.

10. Sales Forecast

One thing is certain when it comes to wheat flour production business, if your wheat flour are well – packaged and branded and if your production mill is centrally positioned and easily accessible, you will always attract customers cum sales and that will sure translate to increase in revenue generation for the business.

We are well positioned to take on the available market in Springfield – Illinois and every city where our well processed and well – packaged wheat flour will be distributed and retailed and we are quite optimistic that we will meet our set target of generating enough income / profits from the first six month of operations and grow the business and our clientele base.

We have been able to critically examine the wheat flour mill production industry and we have analyzed our chances in the industry and we have been able to come up with the following sales forecast. The sales projections are based on information gathered on the field and some assumptions that are peculiar to startups in Springfield – Illinois.

Below are the sales projection for Sammy Jay® Wheat Flour Production Company, it is based on the location of our business and other factors as it relates to small scale and medium scale wheat flour production company start – ups in the United States;

- First Fiscal Year-: $240,000

- Second Fiscal Year-: $450,000

- Third Fiscal Year-: $950,000

N.B : This projection is done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same products and customer care services as we do within same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

Before choosing a location for Sammy Jay® Wheat Flour Production Company we conduct a thorough market survey and feasibility studies in order for us to be able to be able to penetrate the available market in our target market locations.

We have detailed information and data that we were able to utilize to structure our business to attract the numbers of customers we want to attract per time and also for our products to favorable compete with other leading wheat flour brands in the United States of America and Canada.

We hired experts who have good understanding of the wheat flour production industry to help us develop In other to continue to be in business and grow, we must continue to sell our well – bagged wheat flour to the available market which is why we will go all out to empower or sales and marketing team to deliver our corporate sales goals.

In summary, Sammy Jay® Wheat Flour Production Company will adopt the following sales and marketing approach to sell our wheat flour;

- Introduce our wheat flour brand by sending introductory letters to residence, wheat flour merchants and other stakeholders in Springfield – Illinois and other cities both in the United States of America and Canada

- Open our wheat flour production company with a party so as to capture the attention of residence who are our first targets

- Engage in road show in targeted communities from time to time to sell our wheat flour

- Advertise our wheat flour in community based newspapers, local TV and radio stations

- List our business and products on yellow pages ads (local directories)

- Leverage on the internet to promote our wheat flour brands

- Engage in direct marketing and sales

- Encourage the use of Word of mouth marketing (referrals)

11. Publicity and Advertising Strategy

In as much as our wheat flour mill is a standard one with well processed and well packaged wheat flour that can favorably compete with other leading brands, we will still go ahead to intensify publicity for all our products and brand. We are going to explore all available means to promote Sammy Jay® Wheat Flour Production Company.

Sammy Jay® Wheat Flour Production Company has a long term plan of distributing our wheat flour in various locations all around the United States of America and Canada which is why we will deliberately build our brand to be well accepted in Springfield – Illinois before venturing out.

As a matter of fact, our publicity and advertising strategy is not solely for selling our products but to also effectively communicate our brand. Here are the platforms we intend leveraging on to promote and advertise Sammy Jay® Wheat Flour Production Company;

- Place adverts on both print (community based newspapers and magazines) and electronic media platforms

- Sponsor relevant community programs

- Leverage on the internet and social media platforms like; Instagram, Facebook , twitter, et al to promote our wheat flour brand

- Install our Billboards on strategic locations all around major cities in the United States of America and Canada

- Engage in road show from time to time in targeted communities

- Distribute our fliers and handbills in target areas

- Position our Flexi Banners at strategic positions in the location where we intend getting customers to start patronizing our products.

- Ensure that our wheat flour bags are well branded and that all our staff members wear our customized clothes, and all our official cars and distribution vans are customized and well branded.

12. Our Pricing Strategy

When it comes to pricing for products such as wheat flour, there are two sides to the coin. We are aware of the pricing trend in the wheat flour mill production industry which is why we have decided to produce various bags – sizes of wheat flour.

In view of that, our prices will conform to what is obtainable in the industry but will ensure that within the first 6 to 12 months our products are sold a little bit below the average prices of various wheat flour brands in the United States of America.

We have put in place business strategies that will help us run on low profits for a period of 6 months; it is a way of encouraging people to buy into our wheat flour brands.

- Payment Options

The payment policy adopted by Sammy Jay® Wheat Flour Production Company is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that Sammy Jay® Wheat Flour Production Company will make available to her clients;

- Payment via bank transfer

- Payment with cash

- Payment via Point of Sale Machine (POS)

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our client make payment for farm produces purchase without any stress on their part. Our bank account numbers will be made available on our website and promotional materials to clients who may want to deposit cash or make online transfer for the purchase of our products.

13. Startup Expenditure (Budget)

Starting a standard wheat flour mill production company is indeed a capital intensive business. This is so because the amount required setting – up a flour mill is not a piecemeal. The bulk of the start – up capital will be spent on leasing or acquiring a facility and also in purchasing grain milling machines, and packaging equipment.

Aside from that, you are not expected to spend much except for purchase and servicing of distribution trucks, paying of your employees and utility bills. This is the key areas where we will spend our start – up capital;

- The Total Fee for Registering the Business in the United States of America – $750.

- Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – $1,300.

- Marketing promotion expenses for the grand opening of Sammy Jay® Wheat Flour Production Company in the amount of $3,500 and as well as flyer printing (2,000 flyers at $0.04 per copy) for the total amount of – $3,580.

- Cost for hiring Business Consultant – $2,500.

- Insurance (general liability, workers’ compensation and property casualty) coverage at a total premium – $2,400.

- Cost for payment of rent for 12 month at $1.76 per square feet in the total amount of $105,600.

- Cost for construction of a standard wheat flour mill – $100,000.

- Other start-up expenses including stationery ( $500 ) and phone and utility deposits ( $2,500 ).

- Operational cost for the first 3 months (salaries of employees, payments of bills et al) – $100,000

- The cost for Start-up inventory (raw materials and packaging materials et al) – $80,000

- The cost for counter area equipment (counter top, sink, ice machine, etc.) – $9,500

- Cost for grain milling machines and packaging equipment – $100,000

- Cost for store equipment (cash register, security, ventilation, signage) – $13,750

- Cost of purchase of 3 distribution vans – $30,000

- The cost for the purchase of furniture and gadgets (Computers, Printers, Telephone, Fax Machines, tables and chairs et al) – $4,000.

- The cost of Launching a Website – $600

- The cost for our opening party – $10,000

- Miscellaneous – $10,000

We would need an estimate of $500,000 to successfully set up our wheat flour mill in Springfield – Illinois. Please note that this amount includes the salaries of all the staff for the first 3 month of operation.

Generating Funds / Startup Sammy Jay® Wheat Flour Production Company

Sammy Jay® Wheat Flour Production Company is a family business that is owned and financed by Sammy Jay and his immediate family members. They do not intend to welcome any external business partner which is why he has decided to restrict the sourcing of the start – up capital to 3 major sources. These are the areas we intend generating our start – up capital;

- Generate part of the start – up capital from personal savings and sell of stocks

- Source for soft loans from family members and friends

- Apply for loan from my Bank

N.B: We have been able to generate about $200,000 (Personal savings $150,000 and soft loan from family members $50,000) and we are at the final stages of obtaining a loan facility of $300,000 from our bank. All the papers and document have been signed and submitted, the loan has been approved and any moment from now our account will be credited with the amount.

14. Sustainability and Expansion Strategy

The future of a business lies in the numbers of loyal customers that they have the capacity and competence of the employees, their investment strategy and the business structure. If all of these factors are missing from a business (company), then it won’t be too long before the business close shop.

One of our major goals of starting Sammy Jay® Wheat Flour Production Company is to build a business that will survive off its own cash flow without the need for injecting finance from external sources once the business is officially running.

We know that one of the ways of gaining approval and winning customers over is to retail our well processed and well bagged wheat flour a little bit cheaper than what is obtainable in the market and we are well prepared to survive on lower profit margin for a while.

Sammy Jay® Wheat Flour Production Company will make sure that the right foundation, structures and processes are put in place to ensure that our staff welfare are well taken of. Our company’s corporate culture is designed to drive our business to greater heights and training and retraining of our workforce is at the top burner.

As a matter of fact, profit-sharing arrangement will be made available to all our management staff and it will be based on their performance for a period of three years or more. We know that if that is put in place, we will be able to successfully hire and retain the best hands we can get in the industry; they will be more committed to help us build the business of our dreams.

Check List / Milestone

- Business Name Availability Check : Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Leasing of facility and construction of standard wheat flour mill: In Progress

- Conducting Feasibility Studies: Completed

- Generating capital from family members and friends: Completed

- Applications for Loan from the bank: In Progress

- Writing of business plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Purchase of the Needed furniture, racks, shelves, computers, electronic appliances, office appliances and CCTV: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community: In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Opening party / launching party planning: In Progress

- Establishing business relationship with vendors – wholesale suppliers / merchants: In Progress.

Related Posts:

- Chicken Processing Plant Business Plan [Sample Template]

- Tomato Processing Plant Business Plan [Sample Template]

- Vegetable Oil Production Business Plan [Sample Template]

- Shea Butter Processing Business Plan [Sample Template]

- Sunflower Oil Business Plan [Sample Template]

- ABOUT AGICO

A CASE STUDY: 40TPD WHEAT FLOUR MILLING PROJECT

Food processing can never be out of business. And one of the ways you could enter in that never-ending cycle is by supplying flour for making bread, biscuits and pasta. Flour Mills from KMEC can be installed with minimum capacity of 10 TPD of raw material crushing capacity per day to maximum 1000 TPD . Capacity suggested in this project is for mini flour milling plant of 40 TPD.

While a stable increasing trend in price of bagged wheat flour is observed in the past few years in Ethiopia, our client, Mr. Pak Mark, who lives in Jigjiga, has a source of organic wheat for around 1000 tons per month, entered a contract of 40TPD wheat flour milling turnkey project with KMEC, including the whole package procurement of equipments .

Thanks to the client's cooperation, the installation was finished in just 2 weeks:

Let us know exactly what your requirements are and we will reply you with a quick and favorable plan!

Wheat is first cleaned thoroughly to remove dust, stone and other foreign matters clean wheat is tempered before grinding by treating with water so that the bran is separated from the endosperm. The tempered wheat is crushed between corrugated rollers (Break rolls). The first break rolls are set relatively far apart to grind the wheat lightly, while successive break yield finer and finer products. The first break is separated by sieving or bolting in to very fine particles (flour), intermediate particles (middlings) and coarse particles (stock). The stock is then sent to second break rolls. This process may continue through 5 to 6 breaks. The stock contains pieces of endosperm and bran and the stock from the last break is principally bran. The middlings contain endosperm, bran and germ which are then successively classified and some of the bran removed are sent to reduction rollers. These are smooth rollers, but like the break rolls they are graduated so that successive reduction becomes finer and finer. After each reduction, sifters separate the flour, middling and stock, this process is continued until most of the endosperm has been removed as flour and most of the bran has been separated in the sifters.

If you intent to build your own flour milling plant, you would like to take care of grain cleaning equipments, milling machine, storage facilities and packing machine. KMEC provide every piece of unique equipment to meet any of your special needs in term of each procedure.

- Vibrating Separator

- Gravity Grading Destoner

- Horizontal Wheat Scourer

- Rotary Flat Sieve

- Combination Cleaning Sieve

- Wheat Milling Machine

- Corn Milling Machinery

- Rice Milling Machine

- Pepper Milling Machine

- Bean Dehulling Machine

- Storage silo

- Packing machine

Sekina Industrial PLC

Wheat flour milling company

Welcome to Sekina industrial PLC!

We are one of the best wheat flour milling companies in Ethiopia

Our product is an all-purpose flour it is your best choice! for bread and pastry making.

A homepage section

Our product is an all-purpose flour it is your best choice! for bread and pastry making

””””””””””””””””””””””””””””””””””””””””””””””””

Contact Address:

Head office Arada subcity, woreda 01, Kelifa business center, house no: 401, Addis Ababa

Tel: +251960889948

Factory Address: Debrebrhan

40TPD Small Wheat Flour Milling Plant Built in Ethiopia

40tpd small wheat flour factory built in ethiopia [photo display].

These wheat flour machines were purchased from ABC Machinery in 2011 and were used to build a 40TPD small-scale wheat flour processing plant in Jijiga, Ethiopia . As of 2023, the automated wheat flour mill has been in operation for over 10 years. Here are some equipment details of the flour mill:

- Cleaning Section: It employs more than 10 drying processes, including two sifting , two flour mill machines , two scoures, two destoners, two dampeners, and one conditioner, among others.

- Milling Section: It incorporates eight grinding machines and uses a sieving machine for flour grading and extraction.

The customer highly praised ABC Machinery 's products and services. They stated that our equipment delivers stable and reliable performance, with easy operation and proper prices , greatly improving production efficiency. The customer is impressed with our professional team, appreciating their patient responses and timely issue resolution, which has left them highly satisfied. ABC Machinery is committed to providing one-stop engineering and construction services to global clients. The successful completion of this project once again demonstrates our professional capabilities and excellent quality in the field of engineering.

If any interested clients would like more detailed information about this project, please feel free to contact us for consultation. We will wholeheartedly provide you with more information and professional solutions. ABC Machinery looks forward to cooperating with you and jointly creating a better future.

Ethiopia is an agricultural country, the capital is Addis Ababa, mainly rely on agricultural production, so flour is an important part of people's daily diet. Injera,one of the most common and popular staple foods in Ethiopia, is a fermented flatbread made from flour derived from grains, typically specific millet, barley, or wheat. In Ethiopia, people can use grain mill to grind their own flour or buy commercially available flour, though the majority of Ethiopian households opt for the latter.

Ethiopia Flour Market: Huge Growth Potential

Considering building a wheat flour factory in Ethiopia, it's crucial to understand the current state of the wheat flour market. In this part, we will provide a concise analysis.

- Market Demand and Growth: The demand for wheat flour in Ethiopia's market is on the rise. With population growth and economic development, the demand for flour and related products is continuously increasing. However, due to limitations in agricultural production and wheat flour processing capacity, the market supply remains insufficient, leading to relatively higher wheat flour prices in Ethiopia.

- Import Dependence: Currently, Ethiopia still relies on imported flour, especially high-quality flour. Imported flour primarily comes from foreign large-scale wheat flour mill plant such as Kenya, Rwanda, and other countries. This has resulted in a competitively high price in the Ethiopian wheat flour market while also constraining the growth of the local wheat flour industry.

Major Crop Production in Ethiopia (Based on Data Up to 2021)

- Local Flour Producers: Despite imported flour dominating a significant portion of the market, there are local flour producers within Ethiopia. These producers manufacture and supply various types and brands of flour products. However, due to scale and technological limitations, they still face competitive pressures in terms of market share.

- Technological and Equipment Constraints: Technological and equipment advancements in the Ethiopian flour market have lagged, particularly in flour milling machine and processing methods. Existing flour mills might have limitations in processing efficiency, product quality, and scale. Hence, introducing advanced technology and equipment will be crucial for enhancing competitiveness.

- Government Support and Regulation: The Ethiopian government is promoting local flour production and agricultural development through policy-making and regulations. Incentives such as tax exemptions, loan support, and technical training are provided to encourage investors to enter the flour industry. The government also implements controls on imported flour to stimulate domestic flour industry growth.

Why Flour Factory in Ethiopia are A Compelling Investment?

Ethiopia, as a vibrant market with diverse resources, offers unique advantages for the construction of a flour mill plant.

- Strategic Geographic Location, Connecting Multiple Markets: Situated at the heart of East Africa, Ethiopia's geographic location positions it as a crucial hub for trade and economic activities connecting Asia, Africa, and Europe. Building a wheat flour factory in Ethiopia would provide easy access to the East African Community market and neighboring countries, thanks to this geographical advantage. This proximity can shorten supply chains, reduce logistical costs, and open opportunities for diversifying your market presence.

- Abundant Agricultural Resources for Sustainable Supply: Ethiopia boasts rich agricultural resources and extensive arable land, ensuring a stable supply of raw materials for your flour mill plant. As one of Africa's agricultural centers, the country cultivates many crops required for flour production, such as wheat, barley, maize and teff. This bountiful agricultural environment helps ensure your production line receives a consistent supply of raw materials and lays a solid foundation for future expansion and growth.

- Growing Consumer Market with Tremendous Potential Demand: With a population exceeding 110 million and rapid urbanization and economic growth, Ethiopia presents a significant consumer market. This population growth and rising living standards lead to a substantial increase in food demand, with flour products playing a pivotal role in the local diet. Building a wheat flour factory in Ethiopia positions you to meet the expanding market demand, catering to local consumers' desire for healthy and convenient food options.

- Technology Transfer and Knowledge Sharing for Enhanced Productivity: Investors can introduce advanced wheat flour processing technology and managerial expertise to Ethiopia, engaging in training and technological exchanges with local employees. This collaborative effort can elevate local technological capabilities, leading to increased production efficiency and product quality.

- Government Support Policies for a Profitable Business Environment: The Ethiopian government actively encourages foreign investment and offers various forms of support and incentives for investors. These policies can include tax exemptions, land incentives, export benefits, and more, contributing to a profitable business environment and potential returns for investors.

After thorough consideration, it's clear that Ethiopia presents favorable conditions for investing in a flour mill plant setup. However, selecting a wheat flour factory in Ethiopia setup requires careful evaluation of investment strategies, understanding wheat flour mill plant investment costs, and ensuring wise and sustainable decisions are made in the process of setting up an automatic wheat flour mill plant in the country.

Flour Factory Investment Costs in Ethiopia

Investing in a wheat flour factory in Ethiopia does require careful consideration of various costs. Apart from the basic physical and financial aspects, there are several other costs and factors that need to be taken into account. Here are some key aspects to consider:

- Land and Construction Costs: Investing in a flour mill requires buying or leasing suitable land and setting up factory buildings and facilities. The costs of land and construction will vary depending on the geographical location, land use, and market demand. Land costs are typically higher in urban areas, while they may be relatively lower price in rural areas. If the selected area faces intense market competition, land costs may be higher.

- Equipment and Machinery Costs: Flour production requires investment in various wheat flour processing machine, including grinder, cleaners, packaging machines, crushing machine and more. The cost of equipment and machinery will depend on the scale, technological level, and brand choices. ABC Machinery Company, a wheat flour mill machine supplier and manufacturer, can offer you high-quality flour maker and relating machines at factory prices along with professional after-sales services, helping your wheat flour business succeed. (Read More: 160TPD Wheat Flour Plant Built in New Zealand )

- Raw Material Costs: The main raw materials for flour production are crops like wheat and corn. The cost will be influenced by agricultural product prices, supply stability, and seasonal fluctuations. Additionally, government support policies, tariffs, export and import regulations, and other policy measures in Ethiopia may also affect the prices of wheat and grains.

- Labor Costs: The various stages of a flour mill plant, from sourcing raw materials to production and sales, require workforces. Ethiopia has abundant labor forces, thus labor costs are relatively lower.

- Logistics and Transportation Costs: Transporting and distributing flour involves considerations of logistics and transportation costs, including trucking, warehousing, and distribution. Some regions in Ethiopia may experience traffic congestion, which can impact transportation time and costs.

- Energy and Water Costs: Flour processing requires the consumption of electricity and water resources, so energy and water costs need to be considered. Ethiopia has the second-highest hydroelectric potential in Africa, which results in lower costs compared to other African countries.

- Administrative and Licensing Costs: A flour milling plant setup in Ethiopia requires compliance with relevant administrative regulations and obtaining necessary licenses. Applying, registering, and obtaining approvals in these areas will incur certain costs.

- Tax and Related Costs: Importing flour milling machine and raw materials may involve paying customs duties and import taxes. Additionally, investing in a flour mill will also entail local taxation and fees, such as income tax, sales tax, and business license fees.

TOP10 List of Wheat Flour Factory in Ethiopia

- Grain Cleaning & Hulling

- Flour Milling

- Starch Processing

- 10~30 ton/day Wheat Flour Mill

- 30~60 ton/day Wheat Flour Mill

- 60~150 ton/day Wheat Flour Mill

- 150~300 ton/day Wheat Flour Mill

- 300~1000 ton/day Wheat Flour Mill

- Flour Mill Machinery Pakistan

- 20TPD Maize Milling Plant Shipped to Uganda

- Commercial Maize Milling Machine Price in Kenya| Low Cost Processing

- Customized Maize Flour Processing Plant by ABC Machinery

- Africa’s No.1 Food Manufacturing, Retail & HORECA Industry Magazine

- PAST MAGAZINE ISSUES

- ABOUT FOOD BUSINESS AFRICA MAGAZINE

- SUBSCRIBE TO OUR E-NEWSLETTERS

- ADVERTISE WITH US

- MEDIA KIT & EDITORIAL CALENDAR

- PRESS RELEASES

- AFMASS FOOD EXPOS

- AFRICA BUSINESS SUMMIT

- AFRICA FOOD SAFETY SUMMIT

- DAIRY MANUFACTURING AFRICA EXPO

- AFRICA BEVERAGES EXPO

- AFRICA MEAT & POULTRY EXPO

- AFRICA FRESH PRODUCE EXPO

- AFRICA HEALTH EXPO

- FOOD SAFETY AFRICA

- MILLING MIDDLE EAST & AFRICA

- SUSTAINABLE PACKAGING AFRICA

- FRESH PRODUCE MIDDLE EAST & AFRICA

- DAIRY BUSINESS AFRICA

- HEALTHCARE MIDDLE EAST & AFRICA

- AFRICA CEO VOICES

Select Page

Ethiopian US$6.3m biscuit and flour processing plant set to commence operations

May 6, 2020

ETHIOPIA – Vita Hydro Agro-Processing Plc, sister company of Belayab Food Production Plc, franchise owner of Pizza Hut and Cold Stone Creamery brands in Ethiopia has constructed a flour and biscuit processing plant worth 210 million Br (US$6.3m).

The new plant which rests on two hectares of land has been under construction for the past three years and is expected to be fully operational within four months.

According to Aschalew Belay, co-owner of Vita Hydro, the company applied for a loan from the Development Bank of Ethiopia (DBE) to import the machines and once approved installation will take place.

Upon completion, the factory will have the capacity to process between 42tn to 60tn of flour a day and between 1.5tn and two tonnes of biscuits an hour.

The plant is expected to offer job opportunities to between 150 and 200 people.

In addition to that the firm will source wheat from local farmers who work around the factory to make the biscuits. The by-product from the wheat will be used for poultry and livestock feed production.

Vita Hydro will be joining more than 45 companies registered by the Food Beverage & Pharmaceutical Industry Development Institute to produce biscuits from wheat and other cereals.

Ethiopia has an estimated production capacity of over 2.5 million quintals of biscuits a year.

The domestic production of biscuits in the last fiscal year reached an estimated 193,773tn, according to data from the Central Statistical Agency’s report.

“There is a biscuit and flour manufacturing gap in the country, and this company is primarily dedicated to bridging this and making the products accessible to the local market,” said Fikru Hailemariam, general manager of the plant.

In addition to domestic production, biscuits are also imported from various parts of the world. In the last fiscal year, the nation imported 1,762tn of biscuits.

“Currently, our primary target is local customers, but we will export as soon as we increase our production capacity,” said Fikru.

Related Posts

Kenyan producer of NuVita brand Malbros undertakes technological advancements in operations

February 6, 2021

Nigeria food imports drops by N74 billion in Q2 2015

September 9, 2015

Collaboration explores solutions to advance food traceability across the supply chain

June 11, 2020

Dairy farmers in Kenya to form a union to help overcome constraints in the dairy sector

December 15, 2022

Leave a reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

LATEST DIGITAL MAGAZINE

News Archives

Terms and Conditions - Privacy & Cookies Policy

Ethiopian Monitor

Daily News from Ethiopia

MIDROC’s Sheger Bakery inaugurated

ADDIS ABABA – Sheger Bread Factory, the largest bakery and flour factory with a potential of baking 2 million loaves of bread every day in three shifts has started production on Thursday.

While inaugurating the bakery, Prime Minister Abiy Ahmed Factory, which took 10 months from conception to finalization, “is symbolic of our path to prosperity”.

He said the factory, with a capacity of producing 80,000 pieces of bread per hour, will avail its breadto residents of Addis Ababa “at affordable prices” and “will contribute to food security”.

The factory – owned by Ethiopian born Saudi billionaire Sheikh Mohammed Al Amoudi – and its distribution network in Addis Ababa is expected to create 3,400 job opportunities.

Built by MIDROC Ethiopia, it has cost the billionaire up to 900 million Birr or about $26 million and installed the state-of-the-art bakery.

The bakery, which uses automated machinery, will source flour from a plant that was built next to the bakery.

Distribution

Resting on 4.1ha, the bakery and the flour processing plant is located in Akaki Kality District. MIDROC imported the machinery for the bread and flour from Italy, while the transformers were shipped in from China.

The bakery has four silos each with a storage capacity of 30,000ql of wheat, 12 ovens, 13 mixers, and two cooling towers capable of cooling 140,000 loaves of bread a minute. It has 357 permanent employees, 50 janitors, 47 chauffeurs and 23 food vans each capable of carrying 24,000 loaves of bread at once.

The flour factory can produce 2,224ql of flour a day, from which the bakery uses 1,200ql, and the excess 1,024ql of flour will go to the market, said Abennet Gebremeskel, CEO of the project management office and general manager at MIDROC Construction Ethiopia.

The flour factory will source its wheat supply from Horizon Plantation’s farm and other cooperative unions, as well as through import.

Deputy Mayor’s initiative

The project was initiated by the Deputy Mayor, according to Feven Teshome, press secretary of the Addis Abeba City Administration Mayor’s Office.

The Addis Abeba City Administration and Sheger Bread & Flour Factory agreed to sell the products at reasonable prices.

The company has procured 150,000ql of wheat from Ukraine that will be used for three months of production. The first of six batches of the supply has reached the factory.

The plant consumes five megawatts of power during peak hours, according to electrical engineers of the Factory. It has three stand-alone generators that produce 3.2MW in total.

The Factory has so far prepared 23 food vans to distribute the bread to 10 districts throughout the capital. Unemployed youth are organized by the City’s Job Creation and Enterprise Development Bureau across 116 woredas.

You May Also Like

PM Abiy Holds Talks with Indian PM Modi over COVID-19 Challenge

ADDIS ABABA – Ethiopian Prime Minister Abiy Ahmed has held talks with his Indian counterpart, Narendra Modi, by phone on

UN honors Three Ethiopian Peacekeepers Posthumously

ADDIS ABABA – The United Nations is set to honors three Ethiopian peacekeepers posthumously today ahead of the International Day

Ethiopia Records 452 New Coronavirus Infections, 13 Deaths

ADDIS ABEBA – Ethiopia has registered 452 more coronavirus infections Friday, bringing the total number of confirmed to close to

Lemecha, Getnet cruise to final as Team Ethiopia Begins World Champ Campaign

Lemecha Girma and Getnet Wale cruised through to the men’s 3000m steeplechase finals as team Ethiopia begin their campaign at

Boeing Says ‘Sorry’ over 737 Max Crashes

ADDIS ABEBA – Boeing executive says ‘sorry’ to airlines and families of victims of 737 Max crashes in Indonesia and

Traffic Accident Kills Seven in Southern Ethiopia

ADDIS ABABA – Seven people including two policemen have been killed in a traffic accident in southern region of Ethiopia,

3 thoughts on “ MIDROC’s Sheger Bakery inaugurated ”

Pingback: Addis Gets Bekary & Flour Factory with Baking Capacity of a Million Bread Per Day – Ethiopian Monitor

Pingback: Addis Gets Bekary & Flour Factory with Baking Capacity of a Million Bread Per Day – mytzta.com

Pingback: Cabinet Approves 1.9bln Birr Fund to Support Free Meal for Students in Addis Ababa – Ethiopian Monitor

Comments are closed.

- Our Approach

- The Refugee Lens

- Initiatives

- Investment Opportunities Map

- Success Stories

- RIN & Partner News

Brothers Flour and Biscuit Factory PLC

- R3: Refugee-Supporting

- R4: Refugee-Supporting, Host-Weighted

- Agriculture

Didn’t find what you were looking for?

Or do you want to submit an investment opportunity to be added to the map?

Founded in 2000 by Mohammed Seid and his brother Ahmed Beshir, Brothers Flour and Biscuit Factory produces wheat flours and eight varieties of biscuits for the local market. Their facility is located on the edge of Adama city limits and has a production capacity of 30 to 40 tons of wheat flour and 25 to 30 tons of biscuits per day. The company produces some of the most popular brands of biscuits in Ethiopia, such as Fegegta Hard Cracker and Glory Cream, which enjoy a considerable market share.

Investment Thesis

Brothers Flour and Biscuit Factory already holds a strong market share, producing some of the better-known biscuit names in the market. They are a large employer in the city with opportunity to further expand employment through their growth.

Refugee Impact

Brothers’ business model presents numerous opportunities to engage the host and refugee community around Adama. First, expansion of operations will naturally increase employment opportunities. With the appropriate guidance from the RLI network, recruitment could target refugee populations, as well as the host community. As an agro-processing operation, there is also significant opportunity to engage and source from smallholder farmers in the wheat value chain. Refugee and refugee populations are frequently engaged in agriculture, so this is a natural pathway to RLI inclusion.

With Mohammed Seid as the current Owner and General Manager as well as Ahmed Beshir as Management Support, each of Brothers’ five operational departments has a manager who is overseen by a deputy manager. The company has a total of 1572 employees.

Read Full Investment Snapshot

Related Opportunities

Asili agriculture.

Location: Uganda

Gulu Agricultural Development Company

Location: Lebanon, UAE

African Clean Energy

Location: Kenya, Uganda, The Netherlands, Lesotho, Cambodia

- Business News

- Business Directory

- Add Your Business / ድርጅቶትን ያስመዝግቡ

Select Page

- Manufacturing & Industry

Flour Manufacturers in Ethiopia

This is a list of Flour Manufacturing Companies, Factories, Industries and Suppliers in Ethiopia

If you want to add your business in this category submit your business details now. / ድርጅቶን ከላይ ያለው ዝርዝር ላይ ማስገባት ከፈለጉ ፤ አሁኑኑ ድርጅቶን ያስመስግቡ ።

Featured Businesses

Foreign Exchange Market Rates for Major Currencies against Ethiopian Birr (ETB)

Recent Posts

- Admas Digital Lottery 021 Megabit 2016 (Apr 3, 2024) Results & Winning Numbers

- Admas Digital Lottery 019 Tir 2016 (Feb 3, 2024) Results & Winning Numbers

- YeGena Sitota Lottery Draw for Jan 2024 (ታህሳስ 2016) Winning Numbers Released

- Wegegan Bank Earns 1.2bln birr profit for 2023/2022 budget year, EPS jumps to 22.7%

- Bunna Bank Earns 1.3bln br Profit for 2023/2022 budget year, Paid-up capital reaches 4.2 bln

- Most Profitable, Best Banks in Ethiopia for 2023/2022 Budget Year, Capital, Assets, Loans, Income and other Financial Indicators

- Global Insurance Company Earns 85.3mln br Profit for 2023/2022 budget year

- United Insurance Grosses 390.7mln br Profit before Tax for 2023/2022 F.Y, Increases EPS to 47%

Business Sectors

- Advertising, Promotion, Media & Entertainment

- Agriculture

- Associations & NGOs

- Business & Professional Services

- Construction, Engineering & Real Estate

- Education / University, School & Training

- Family, Recreation & Community

- Food & Beverages

- Foreign Suppliers to Ethiopia

- Government and Other Organizations

- Hospitality

- Information Technology

- Tour / Travel / Car Rental

Popular Business Sectors

- Export Companies

- Coffee Exporters

- Sesame Exporters

- Import Companies

- Construction Companies

- Real Estate Companies

- Tour and Travel Companies

- Car Rental Companies

- Law Offices, Attorneys and Lawyers

- Industries & Manufacturing Companies

Maize (Corn) Flour

No production data available.

Explore More Through Our Services

Data & analytics, find suppliers, find buyers.

The leading global sourcing hub of food & agriculture

Related countries, related exporters and importers, related information, people who viewed maize (corn) flour also viewed, other products in grains, cereal & legumes, other products in milling products.

IMAGES

VIDEO

COMMENTS

flour factory_proposal_study11 - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. 1. The document proposes establishing a wheat flour factory in Ethiopia with a capacity to produce 85,000 quintals annually. 2. The total investment cost is 10,080,009.80 ETB and will create 92 jobs. 3. The flour will be sold locally and in surrounding areas to ...

If you are planning to start a small flour mill business, you will need about 50,000 to 60,000 Ethiopian Birr. A large wheat flour mill will cost around 140,000 Ethiopian birr or more, with a variable ceiling. It also depends on the type of flour mill machine required for the business and the complexity of the wheat milling process .

Flour Mill project Business Plan - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free.

Open for business. Ethiopia's bread wheat and durum wheat value chains are strategically important to the Government of Ethiopia (GoE). In Ethiopia's Growth and Transformation Plan-2 (GTP II), the GoE has prioritized wheat as a major ... $390 million worth of wheat and wheat flour in 2013, demonstrating the scale of the opportunity for ...

Cost for hiring Business Consultant - $2,500. Insurance (general liability, workers' compensation and property casualty) coverage at a total premium - $2,400. Cost for payment of rent for 12 month at $1.76 per square feet in the total amount of $105,600. Cost for construction of a standard wheat flour mill - $100,000.

Wheat Flour and Biscuit Production Project Proposal Feasibility Study Business Plan in Ethiopia - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

A CASE STUDY: 40TPD WHEAT FLOUR MILLING PROJECT. Food processing can never be out of business. And one of the ways you could enter in that never-ending cycle is by supplying flour for making bread, biscuits and pasta. Flour Mills from KMEC can be installed with minimum capacity of 10 TPD of raw material crushing capacity per day to maximum 1000 ...

We are one of the best wheat flour milling companies in Ethiopia. ... Kelifa business center, house no: 401, Addis Ababa. Tel: +251960889948. Factory Address: Debrebrhan. Find Us. Contact Address: Head office Arada subcity, woreda 01, Kelifa business center, house no: 401, Addis Ababa ...

The objective of the study was to review the status of wheat production and marketing in Ethiopia. The data are analyzed using graphs, figures, tables and narrations. Ethiopia shows remarkable economic growth, and the agricultural sector takes the highest contribution. Crops take the highest share in total production and area coverage which ...

A glance at Table 3.1 easily reveals that the commercial production of flour in Ethiopia is marked by a general growth trend. The highest level of production, i.e, about 206,000 tonnes, ... Plan sifter 2 9. Purifier 2 10. Bran finisher 4 11. Flour cyclone with airlock 27 27. Flour filter 1 13. Detacher 8 14. Pneumatic conveyor 1

The newly inaugurated factory is the first of the 10 factories that the Office of the First Lady's plan to build ten major cities across the country. These factories will have a capacity to produce 400 quintals of flour per day. The new factory is the second major industrial level bakeries inaugurated in about a year.

A business plan proposal to establish and operate a flour mill in Arsi zone in Oromia - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free.

HOME > Projects > Flour Milling Plant. Project Name: Small Wheat Flour Milling Plant. Grain: Ethiopia Wheat. Client: DUR DUR Flour Mill Company. Location: Ethiopia. Factory Size: 24m*7m*7m. Investment Cost: Around 60,000 USD (Equipment Only) Capacity: 40~60 Tons Per Day (TPD) Power Consumption Per Ton Wheat: 70KW.H.

ETHIOPIA - Vita Hydro Agro-Processing Plc, sister company of Belayab Food Production Plc, franchise owner of Pizza Hut and Cold Stone Creamery brands in Ethiopia has constructed a flour and biscuit processing plant worth 210 million Br (US$6.3m).. The new plant which rests on two hectares of land has been under construction for the past three years and is expected to be fully operational ...

The flour factory can produce 2,224ql of flour a day, from which the bakery uses 1,200ql, and the excess 1,024ql of flour will go to the market, said Abennet Gebremeskel, CEO of the project management office and general manager at MIDROC Construction Ethiopia. The flour factory will source its wheat supply from Horizon Plantation's farm and ...

Summary. Founded in 2000 by Mohammed Seid and his brother Ahmed Beshir, Brothers Flour and Biscuit Factory produces wheat flours and eight varieties of biscuits for the local market. Their facility is located on the edge of Adama city limits and has a production capacity of 30 to 40 tons of wheat flour and 25 to 30 tons of biscuits per day.