share this!

September 4, 2020 report

New insights into the global silicon cycle

by Bob Yirka , Phys.org

An international team of researchers has learned more about the global silicon cycle by studying ancient soil samples in Australia. In their paper published in the journal Science , the group describes their study of soil of different ages and what they learned about it. Joanna Carey with Babson College, has published a Perspective piece in the same journal issue outlining the connection between the carbon and silicon cycle and the work done by the team in this new effort.

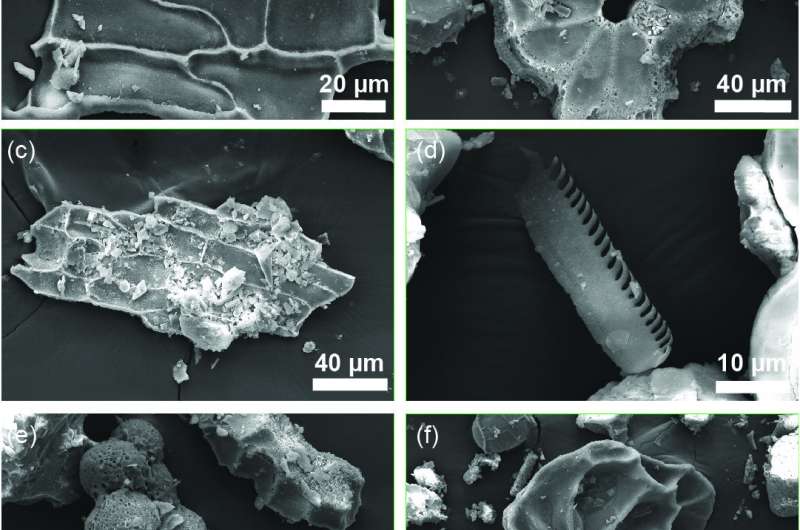

Silicon is the second-most abundant element in Earth's crust and it plays a vital role in plant life, both on land and in the sea. Silicon is used by plants in tissue building, which helps to ward off herbivorous animals. In the ocean, phytoplankton consume enormous amounts of silicon ; they get a constant supply courtesy of rivers and streams. And silicon winds up in rivers and streams due to erosion of silicon-containing rocks. Land plants also use silicon. They get it from the soil. In this new effort, the researchers began by noting that the terrestrial biogeochemical cycling of silicon (how it moves from plants back to the soil and then into plants again) is poorly understood. To gain a better understanding of how it works, they ventured to a part of Western Australia that, unlike other parts of the world, has not been impacted by Pleistocene glaciations. The soil there gave the researchers a look at the silicon cycle going back 2 million years.

In analyzing soil samples from multiple depths, the researchers were able to compare old and comparatively new soil. They determined that as the soil aged, it contained less silicon—it had become depleted likely by rainwater carrying it away. But the newer soil above it had more silicon as rock broke down, releasing its silicon content. The researchers suggest their findings indicate that silicon cycling shifts from geochemical to biological control over time, with plants as the regulating element. They further suggest that such cycling allows plants to absorb as much silicon as they need, even in soil that has been depleted in other ways. Carey adds that more knowledge about how the silicon cycle works should lead to a better understanding of the carbon cycle, because the two are linked in many ways.

Joanna Carey. Soil age alters the global silicon cycle, Science (2020). DOI: 10.1126/science.abd9425

Journal information: Science

© 2020 Science X Network

Explore further

Feedback to editors

Researchers establish commercially viable process for manufacturing with promising new class of metals

34 minutes ago

Chimps shown to learn and improve tool-using skills even as adults

Advanced experimental setup expands the hunt for hidden dark matter particles

2 hours ago

New research confirms that Beethoven had lead poisoning—but it didn't kill him

How NASA's Roman mission will hunt for primordial black holes

Geologists reveal mysterious and diverse volcanism in lunar Apollo Basin, Chang'e-6 landing site

3 hours ago

Using algorithms to decode the complex phonetic alphabet of sperm whales

Researchers 'unzip' 2D materials with lasers

How a 'conductor' makes sense of chaos in early mouse embryos

4 hours ago

Decoding development: mRNA's role in embryo formation

Relevant physicsforums posts, the secrets of prof. verschure's rosetta stones.

May 2, 2024

Large eruption at Ruang volcano, Indonesia

Tidal friction and global warming.

Apr 20, 2024

Iceland warming up again - quakes swarming

Apr 18, 2024

M 4.8 - Whitehouse Station, New Jersey, US

Apr 6, 2024

Major Earthquakes - 7.4 (7.2) Mag and 6.4 Mag near Hualien, Taiwan

Apr 5, 2024

More from Earth Sciences

Related Stories

Perovskite mineral supports solar-energy sustainability

Aug 3, 2020

Silicon: An important element in rice production

Apr 28, 2015

Adding silicon to soil to strengthen plant defenses

Aug 15, 2017

Freeze-dried soil is more suitable for studying soil reactive nitrogen gas emissions

Mar 5, 2020

Silicon 'plant stones' for strong rice: Fertilizing and recycling Si in Vietnamese fields

Oct 1, 2015

Planting non-native trees accelerates the release of carbon back into the atmosphere

Jun 17, 2020

Recommended for you

Discharge of scrubber water into the Baltic Sea is responsible for hundreds of millions in costs

10 hours ago

Computer models show heat waves in north Pacific may be due to China reducing aerosols

6 hours ago

Study identifies early warning signals for the end of the African humid period

Researchers show that slow-moving earthquakes are controlled by rock permeability

Earthquakes are moving northeast in Midland Basin of Texas, scientists find

23 hours ago

Researchers find Northern Hemisphere glaciation enhances orbital- and millennial-scale Asian winter monsoon variability

May 6, 2024

Let us know if there is a problem with our content

Use this form if you have come across a typo, inaccuracy or would like to send an edit request for the content on this page. For general inquiries, please use our contact form . For general feedback, use the public comments section below (please adhere to guidelines ).

Please select the most appropriate category to facilitate processing of your request

Thank you for taking time to provide your feedback to the editors.

Your feedback is important to us. However, we do not guarantee individual replies due to the high volume of messages.

E-mail the story

Your email address is used only to let the recipient know who sent the email. Neither your address nor the recipient's address will be used for any other purpose. The information you enter will appear in your e-mail message and is not retained by Phys.org in any form.

Newsletter sign up

Get weekly and/or daily updates delivered to your inbox. You can unsubscribe at any time and we'll never share your details to third parties.

More information Privacy policy

Donate and enjoy an ad-free experience

We keep our content available to everyone. Consider supporting Science X's mission by getting a premium account.

E-mail newsletter

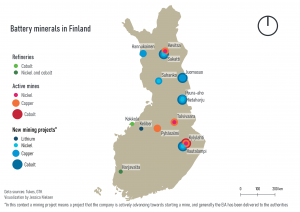

University of Helsinki

Dirty side of green technology

Geographies of Inequalities 2021

Exploring the Negative Impacts of Mining Minerals

Lithium production, its negative impacts and distribution globally, text by nella koivula.

Global lithium production

Lithium is one of the most important minerals used for green technologies and therefore an important mineral to consider regarding sustainable development of the future. Due to the shift from fossil fuel vehicles to electric vehicles, the demand for lithium is estimated to explode in the future. According to Roskill, in 2019, rechargeable batteries that are used in most green technologies, accounted for 54% of total lithium demand (Roskill, 2020). Statista reports that an estimated total of 82,000 metric tons of lithium was produced globally in 2020 while ten years earlier production was just 28,000 metric tons (Garside, 2021). Similarly, according to Roskill lithium consumption for rechargeable batteries increased 14% from 2007 to 2017 (Roskill, 2020).

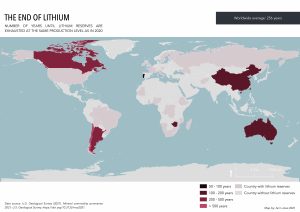

The rapidly growing demand for lithium-ion batteries raises the question whether there is enough lithium in the world for the transition to green technologies? Some argue that the global resources of lithium will not be enough for the future demand and therefore, there is a need to find solutions for the recycling of materials (Hunt, 2015; Willuhn, 2020). Lithium demand is expected to grow 5 times higher in the next decade and due to this the EU has added lithium to the list of critical metals (Kriittiset materiaalit, 2021). This massive demand for lithium is consequently reflected on lithium prices which are estimated to rise in coming years (Mining.com, 2021).

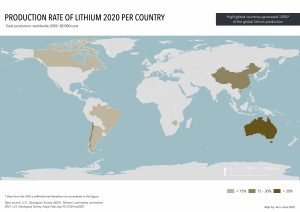

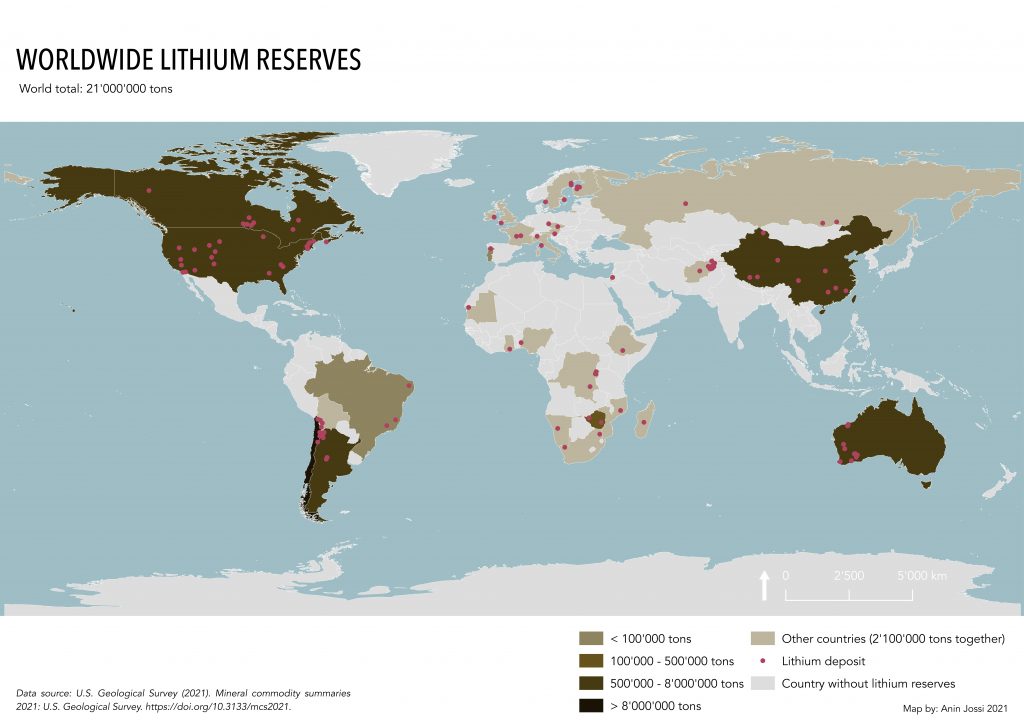

Currently the biggest lithium producers are Australia, Chile, China, Argentina, Brazil, Zimbabwe and Portugal (see map below)(Garside, 2021). There are two main ways of lithium extraction: from hard rock deposits and from salt lake deposits. In South America lithium carbonate is extracted from salt lake deposits from where it is evaporated and washed with polyvinyl chloride in shallow ponds (Garrett, 2004 as cited in Wanger, 2011). Lithium extraction from salt lake deposits demands a lot of water which can be costly for the environment and local communities because these areas already suffer from drought. South America’s lithium boom has potential to bring economic growth and development for the local communities and reduce poverty. However, profits rarely go back to the local communities and increasing mining in these areas can be costly for the environment and for the livelihoods of indigenous people.

More than half of the world’s lithium production comes from South America, mainly from Argentina and Chile (Alves, 2021). Currently Chile is the lithium-richest country in the world with 43.7 percent share of total global reserves. While Chile and Argentina have seen economic growth from the mining sector, Bolivia, even with estimated world’s largest lithium reserves, is still one of Latin America’s poorest nations. Bolivia has approximately 9 million tons of lithium reserves, but they have not yet been exploited or used commercially due to high altitude and lack of appropriate infrastructure. However, the government is eager to jump into the bandwagon of mineral production and make Bolivia one of the world’s top-producing nations. (Bloomberg News, 2018.)

Lithium can also be mined from pegmatite ores from where it is processed of spodumene, the main lithium carrier in magmatic rocks (Bridge 2004 as cited in Wanger, 2011). This is done in, for example, Zimbabwe and Canada. Also, the premeditated mine in Finland would extract lithium from hard rock deposits. Similarly to salt flat extraction, lithium mining from pegmatite ores is costly for the environment because it causes physical land rearrangements and waste products which can damage soil, biodiversity and existing ecosystems, (Bridge 2004 as cited in Wanger, 2011).

From the lithium-richest countries lithium is often shipped to China and South Korea to be used in smartphones and green technology. China is an important manufacturer, consumer and supplier of lithium batteries (The Wall Street Journal, 2021). In 2020 China produced only 11% of the raw material but refined 60% of the lithium globally (Kriittiset materiaalit, 2021; IEEE, 2012). Therefore, China is highly dependent on imports and it is the world’s largest lithium consumer accounting for approximately 50% of the global total (S&P Global Market Intelligence, 2021).

As can be seen from the map, global lithium production is currently distributed quite unevenly. From a domestic perspective, Finland is aiming to start producing lithium self-sufficiently in the coming years.

Case of South America: negative impacts of lithium extraction from salt flats

South America is one of the most important geographical areas for lithium production. Chile, Argentina and Bolivia form a ‘lithium triangle’ which is responsible for the vast majority of global lithium production (Alves, 2021). Lithium is found in the salt flats in high mountains where lithium carbonate is produced by evaporation and washing (Garrett, 2004 as cited in Wanger, 2011). Multiple studies have shown that mining poses severe reproductive social and environmental threats that may have long-term consequences to biodiversity and the livelihoods of local communities (Sonter & Ali & Watson, 2018; Mancini & Sala, 2018). For example, one of the world’s largest lithium extraction site, Salar de Atacama in Chile has seen environmental degradation of salt flats, human settlements and national reserves in terms of vegetation decline, elevating daytime temperatures, decrease of soil moisture and increasing drought conditions during the past 20 years (Liu & Agusdinata & Myint, 2019). Moreover, negative side effects of mining include for example air pollution and water shortages because lithium extraction from salt flats – in an already arid environment – demands a lot of water (DW, 2018).

Water shortage and competition over water between local communities and mining companies can cause major problems. For example, in Chile there have been conflicts with mining companies and indigenous people over water resources in Atacama salt flats (Sherwood, 2018). In Chile, water resources and management are completely privatized. Mining companies such as SQM and Albemarle own the rights to use water in the region and the state has been reluctant to ban water extraction for mining (Sherwood, 2018). Since Atacama desert is one of the driest regions on Earth and lithium extraction from salt flats uses a lot of water, lithium mining has significant negative impacts on the water reserves, indigenous people and vulnerable species in the surroundings (DW, 2018) Lithium extraction can dry out rivers, streams and wetlands, contaminate drinking water and even damage entire ecosystems (DW, 2018). For example, the ecosystem of flamingos is endangered because of an increasing amount of microbial biomass and toxic cyanobacteria due to mining (Bauld 1981 as cited in Wanger 2011; Gutierrez & Navedo & Soriano-Redondo, 2018).

In addition, lithium extraction in South America can be costly for the local communities. As mentioned before, competition over water and degradation of the environment can disturb livelihoods of local communities. There is a so-called resource paradox: on the one hand lithium production can bring wealth, economic growth and job opportunities but on the other hand this may be costly when the mineral reserves finally run out and there are no longer environmental resources or jobs for the local communities (NowThis World, 2017).

Case of Finland: Domestic lithium production in Kaustinen

Finland is attempting to start a domestic lithium production in the following years (see map below). Mining company Keliber is planning Europe’s largest lithium mine in Kaustinen with which it aims to answer the rapidly growing demand of lithium in the era of renewable energy, electric vehicles and green technology (Keliber, 2021). Keliber is owned by Finnish investment companies, private companies and leading international mining company Sibanye-Stillwater and Norwegian Nordin Mining ASA. The estimated time for mine to start operating is in 2024. In addition, Keliber has applied permission for a lithium chemical plant in the mining area of Kokkola where lithium can be refined and developed into lithium hydroxide that can be used for lithium batteries for green technologies (Keliber, 2021).

Lithium mine in Kaustinen would be internationally remarkable since it would be the first of its kind in Europe. According to Keliber the mining site would last for approximately 13 years in large scale production and it has resources of approximately 11 million tons of lithium. Moreover, it is estimated to take charge of 3-5% of global lithium production (Keliber, 2021). According to some calculations this would be enough for approximately 200 000 – 250 000 electric cars (Yle Uutiset, 2019). Therefore, could lithium mine in Kaustinen be a way to shorten the supply chain of lithium and allow Finland to be better involved in the global responsibility for green technology mineral production? A key question is whether the amount of lithium that can be produced in 13 years and its capacity to produce batteries for green technology is enough to overcome the negative environmental effects that the mine could cause?

According to Environmental Impact Assessment, the mine is assessed to cause relatively little damage for the environment (Keliber, 2021). However, there would be some impacts on land and soil, ground and surface waters, vegetation, organisms and biodiversity. It can also cause damage for habitats of some species which is why Keliber is considering finding new habitats for some endangered species such as moor frogs and golden eagles. (Keliber, 2021.) In addition, there are concerns about the negative effects on fish and fishing in the surrounding areas (Yle Uutiset, 2020). The upside is that the mines would be far away from residential areas which decreases the risk of negative impacts on the surrounding communities (Keliber, 2021).

After the Talvivaara incident, negative impacts of mining on surrounding waters is a common concern in Finland. According to EIA, mining operations in Kaustinen are not estimated to have significant effects on the condition or acidity of the waters. However, even though ELY Centre estimated the effects to the surface waters as small, waste waters and by-products is an issue that needs careful assessment. (Keliber, 2021). Wastewaters were initially aimed to be disposed of by evaporation but with technological advantages wastewaters can be more efficiently disposed of by using EWT (electric-chemical processing) and DAF (microflotation). Subsequently remaining wastewater will be sanitized in Hopeakivenlahti wastewater treatment plant where it will be released back to the ocean. Wastewaters will contain small amounts of lithium, but the concentration of minerals should be well below harmful level and once it mixes with sea water it should not harm any species that are exposed to it long-term (Keliber, 2021). In addition, Keliber aims to utilize waste rocks as much as possible in construction of Kokkola harbour and mining areas by exploiting cleantech processes in collaboration with Outotec. (Keliber, 2021). Keliber’s objective is to rehabilitate mining areas into biodiverse environments as quickly as possible by turning the pits into lakes and using the piled soil for landscaping and vegetation purposes. (Keliber, 2021).

Although Keliber has potential to respond to domestic and European demand for green technology, will Finland remain only as a producer of raw materials for green technology batteries? Finland has the capacity to shorten the supply chain which is also what Keliber is aiming for with the development of chemical plants in the Kokkola region where lithium can be used for batteries. Therefore, the lithium mine in Kaustinen has a lot of potential to increase Finland’s share of global lithium production for green technologies.

Overall, the sustainability of mining is controversial because mines are located unevenly, often in developing countries even though most of those benefiting from green technologies are in the Western world. Therefore, most of the environmental and social spillover effects of the mining industry accumulate to developing countries while some societies benefit from the ability to transform into carbon-free lifestyles without negative effects on their environment. Thus, it is important to consider how much increasing demand of minerals and metals for the green technology transition can lead to exploitation of resources and negative social, environmental and economic spillover effects in certain parts of the world. This raises a question: How can we take more global responsibility for the negative spillover effects of the mining industry to ensure sustainable development equally? As mentioned before, domestic lithium production in Finland could be one way to increase Finland’s and Europe’s responsibility for mining for green technologies.

Alves, B. (2021) Lithium in South America — Statistics and Facts. Statista. Retrieved from https://www.statista.com/topics/5894/lithium-in-south-america/

Benchmark Mineral Intelligence (2020) Lithium in 2020: Prices, Coronavirus and Tesla. Retrieved from https://www.benchmarkminerals.com/membership/lithium-in-2020-prices-coronavirus-and-tesla/

Bloomberg News (2018) Big lithium riches lure first-time miner to Bolivia’s salt flat. Retrieved from http://www.mining.com/web/big-lithium-riches-lure-first-time-miner-bolivias-salt-flat/

DW (2018) Chile’s lithium – blessing or curse? Retrieved from https://www.dw.com/cda/en/chiles-lithium-blessing-or-curse/a-43721539

Elinkeino-, liikenne- ja ympäristökeskus (2020) Yhteysviranomaisen perusteltu päätelmä litiumkemiantehdas -hankkeen ympäristövaikutusten arviontiselostuksesta.

Garside, M. (2021) Global lithium mine production 2010-2020. Statista. Retrieved from https://www.statista.com/statistics/606684/world-production-of-lithium/

Garside, M. (2021) Major countries in worldwide lithium mine production from 2010 to 2020. Statista. Retrieved from https://www.statista.com/statistics/268789/countries-with-the-largest-production-output-of-lithium/

Gutierrez, J. S. & Navedo, J. G. & Soriano-Redondo, A. (2018) Chilean Atacama site imperilled by lithium mining. Nature. Retrieved from https://www.nature.com/articles/d41586-018-05233-7

Helsingin Sanomat (2021) Sähköautojen räjähdysmäisesti kasvanut suosio on johtanut litium-pulaan – Akkumetallin hinta on jo noussut vauhdilla, ja pian sen hinta nousee pilviin. Retrieved from https://www.hs.fi/paivanlehti/22032021/art-2000007872976.html

Hunt, T. (2015) Is There Enough Lithium to Maintain the Growth of the Lithium-Ion Battery Market? Gtm. Retrieved from https://www.greentechmedia.com/articles/read/is-there-enough-lithium-to-maintain-the-growth-of-the-lithium-ion-battery-m

IEEE International Symposium on Sustainable Systems and Technology (2012) Prediction of various discarded lithium batteries in China. DOI: 10.1109/ISSST.2012.6228021

Kaunda, R. B. (2020) Potential environmental impacts of lithium mining, Journal of Energy & Natural Resources Law, 38:3, 237-244, DOI: 10.1080/02646811.2020.1754596

Keliber (2021) Lithium markets. Retrieved from https://www.keliber.fi/en/production-and-products/lithium-markets/ . Cited 24.4.2021.

Keliber (2021) Mineral resources and ore reserves. Retrieved from https://www.keliber.fi/en/geology/mineral-resources-and-ore-reserves/- Cited 24.4.2021.

Keliber (2021) YVA. Retrieved from https://www.keliber.fi/ajankohtaista/raportit-ja-julkaisut/yva/ Cited 24.4.2021.

Keliber (2021) Keliber päivitti Kokkolan kemiantehtaan prosessia ja YVA-selostusta. Retrieved from https://www.keliber.fi/ajankohtaista/tiedotteet-ja-julkaisut/81C971D5188FA114/ . Cited 24.4.2021.

Keliber (2021) We respect people and the environment. Retrieved from https://www.keliber.fi/en/sustainability/we-respect-people-and-the-environment/ . Cited 24.4.2021.

Kriittiset materiaalit (2021) Litium. Retrieved from https://www.kriittisetmateriaalit.fi/litium/ .

Liu, W. & Agusdinata, D. & Myint, S. (2019) Spatiotemporal patterns of lithium mining and environmental degradation in the Atacama Salt Flat, Chile. International Journal of Applied Earth Observation and Geoinformation. 80. 145-156. DOI: 10.1016/j.jag.2019.04.016

Mancini, L. & Sala, S. (2018). Social impact assessment in the mining sector: Review and comparison of findicators frameworks. Resources Policy 57, https://doi.org/10.1016/j.resourpol.2018.02.002

Mining.com (2021) Lithium prices continue to soar — up 88% in 2021. Retrieved from https://www.mining.com/lithium-prices-continue-to-soar-up-88-in-2021/

NowThis World (2017) South America’s Lithium Boom: A Blessing Or A Curse? Retrieved from https://www.youtube.com/watch?v=AsxjjLbn28Q

Roskill (2020) Lithium: Outlook to 2030, 17th Edition. Retrieved from https://roskill.com/market-report/lithium/ .

Sherwood, D. (2018) In Chilean desert, global thirst for lithium is fueling a ‘water war’. Reuters. Retrieve from https://www.reuters.com/article/us-chile-lithium-water/in-chilean-desert-global-thirst-for-lithium-is-fueling-a-water-war-idUSKCN1LE16T

S&P Global Market Intelligence (2021) Essential Energy Insights. Retrieved from https://www.spglobal.com/marketintelligence/en/news-insights/blog/essential-energy-insights-march-2021

Sonter LJ, Ali SH, Watson JEM. 2018 Mining and biodiversity: key issues and research needs in conservation science. Proc. R. Soc. B 285: 20181926. http://dx.doi.org/10.1098/rspb.2018.1926

The Wall Street Journal (2021) Shift to Electric Vehicles Spurs Bid to Make More Batteries in U.S. Retrieved from https://www.wsj.com/articles/u-s-mounts-a-charge-to-take-on-china- the-king-of-electric-vehicle-batteries-11611658235

Wanger, T. (2011) The Lithium future — resources, recycling, and the environment. Conservation Letters. DOI: 10.1111/j.1755-263X.2011.00166.x

Willuhn, M. (2020) How long will the lithium supply last? Pv magazine. Retrieved from https://www.pv-magazine.com/2020/09/15/how-long-will-the-lithium-supply-last/

From outsourced to insourced: sustainable development goals, green technology transformations and critical minerals in the European Union

Text by niina asikanius.

In the face of ever-growing environmental degradation and pressures to seek transformative enough solutions to sustainability issues, the European Union has put forth action plans and strategies to seek sustainable pathways to growth. Already in 2010, in the wake of the 2008 financial crisis, the EU introduced the Europe 2020 strategy, where economic and social progress as well as structural changes were ambitiously being planned to carry out through three mutually reinforcing priorities: smart growth, sustainable growth and inclusive growth. This strategy also includes seven flagship initiatives, one of which is “Resource efficient Europe” where focus is put on the decoupling of economic growth from the use of resources, shift towards a low carbon economy as well as increasing the use of renewable energy sources and promoting energy efficiency and modernizing the transport sector. (European Commission1, 2010, 3-4). A newer strategy, the European Green Deal, has been designed to further tackle climate and environment related challenges. The overall aim of this deal is to create a growth strategy that will transform the EU into a fair and prosperous society by 2050. Visions for the strategy include resource-efficiency, competitive economy as well as a promise of no net greenhouse gas emissions, continuing along earlier ideas of decoupling economic growth from resource use. The Green deal is also an integral part of the European Commission’s strategy to implement not only the United Nations sustainable development goals but also the United Nations 2030 Agenda among other political guidelines. In order to reach these ambitious climate neutrality and sustainability goals, the EC intends to mobilize industry, where resource extraction and processing of materials cause half of greenhouse gas emissions and almost all of biodiversity loss and water stress, and shift from a linear pattern of production and dependence of extracted new materials to a sustainable model of inclusive growth. The EC has also recognized the importance of access to resources which is a strategic security question for Europe and the Green Deal. Critical raw materials are recognized as necessary materials for clean technologies and other applications. Of importance seems to be diversification of both primary and secondary sources for the abovementioned visions to become reality (European Commission 2, 2019). In addition, the EC has also proposed to modernize EU legislation on batteries to promote sustainable practices and its Circular Economy Action Plan. The proposal includes aspects such as sustainable life cycles for batteries placed in the EU market and mandatory requirements which all batteries need to meet in order to have the chance to be placed in the EU market (European Commission3, 2020).

Critical raw materials: lithium

With this new focus on transformations also comes the question of what the best tools are to execute necessary change. One sector that has gained growing attention is the mineral and mining industry because of its relation to green technology transitions, particularly the battery industry. According to the EU, batteries are a key technology in the transition to climate neutrality, and even to circular economy as well as sustainable mobility and in cutting down pollution. Because of the permeating role of batteries in our lives, the demand for them is projected to grow rapidly. EU also seems to acknowledge that increasing deployment of batteries in everyday functions means that the batteries market is a strategic one at the global level, and because of this the union, in order to guarantee a smooth green transition for the European region, wants to take a more active role in the sustainable production, deployment and waste management of all batteries placed in the EU market (European Commission4, 2020).

What will be focused on next are one of the key elements of battery technology: lithium. OECD predicts that extraction of metals and the processing of key metals are going to at least double between 2017-2060. This is driven by the growing scale of materials use (OECD , 2019, 16). The global use of lithium has increased, along with other metals. Some link this increase in usage with China’s economic reforms and development. China also dominates the lithium product manufacturing industry due to its manufacturing capacity and cheap products. In addition, Chinese manufacturing companies Tianqi and Ganfeng Lithium control almost half of the world’s lithium production. Because of this dominant market role as well as previous limitations of lithium export quotas, the reliance on China’s operations in lithium production could mean potential supply security issues (Kavanagh, Keohane, Garcia Cabellos, Lloyd, & Cleary, 2018, 2-3) Lithium, with cobalt and natural graphite, have been placed on the list of critical raw materials by the EU. In addition, the EU only produces 1% of all battery raw materials and only has 8% share of the supply of battery materials. However, supply of lithium isn’t expected to be a major issue in battery supply chain in short or medium term, but for the long term an increase from current low prices are thought to be necessary to support the development of new production capacity (Bobba, Carrara, Huisman, Mathieux, Pavel, 2020, 19-20). Currently, there are also gaps in the production chains of lithium in Europe. Lithium mined in Europe is still processed outside of the EU so vulnerabilities in the supply chain need addressing to avoid disruption to manufacturing processes (European Commission5, 2020). Circular economy practices are also crucial to develop and implement. If levels of reuse and recycling remain low, mineral depletion may become an issue. This issue is especially driven by the growing use of batteries in electric vehicles. According to some scenarios, even if lithium recycling was increased to 30%, the current estimated reserves would have been extracted by 2050 (de Blas, Mediavilla, Capellán-Pérez, & Duce, 2020, 13).

The complicated geographies of critical raw materials such as lithium then can create geopolitical risks as well as economic risks if smooth supply of materials is interrupted and markets can be manipulated by singular, dominant actors. For the EU this means that diversifying the materials supply is needed. This can be executed through secure trade agreements with third countries and economic diplomacy for lithium and other raw materials. Instead of focusing on improving supply risks in outsourced production chains, improving manufacturing opportunities in the EU is also an option. This would mean increase of mining, extraction and refining of key raw materials inside the region as well as the creation of a properly functioning ecosystem for battery manufacturing for local value chains to flourish but also to attract foreign investment. Other recommendations include better recycling activities, promotion of research and development investments as well as fostering international collaboration and standardization activities (Bobba, Carrara, Huisman, Mathieux, Pavel, 2020, 23). Somewhat in line with these recommendations, The EC has set its goals towards the increase of sustainable supply of raw materials in Europe by bringing together stakeholders along strategic value chains and industrial ecosystems (European Commission6). For example, new industrial alliances such as European Raw Materials Alliance and European Battery Alliance have been founded to mobilize public and private investment as well as improve EU resilience in rare earths value chain (European Commission5, 2020). So, the EU seems to have developed its intraregional strategies regarding critical raw materials to on one hand respond to supply risks and on the other hand to deal with economic importance of critical raw materials as well as sustainable futures.

EU’s raw materials strategies have also faced criticism for its lack of considerations of environmental and social impacts. The European Environment Bureau has called the EU’s ambitious goals of self-reliance and the increase of intraregional production of critical materials and batteries a double-edged sword, arguing that environmental and societal costs must be properly assessed (Anastasio, 2020). Moreover, there have been growing concerns among environmentalists over a mining boom in the EU region since the growing relative scarcity and volatile global political conditions has led the EU to seek a more secure supply of materials from Europe. So, the outsourced supply chains of materials from mining are now thought of to be better produced inside the region. In order to make these plans work, the EC hopes to increase public acceptance of mining with the argument that resource extraction is necessary to meet climate goals and offering a narrative where mining is associated with sustainability. (Marin, 2020).

But how could an industry like mining even be marketed as something sustainable when the environmental and social impacts of the industry are known to be an issue? Lithium mining for example may have potential environmental impacts both in extraction and in processing. Concerns are related to air, water and soil pollution as well as the depletion of water resources. Research has also shown that environmental impact evaluation tools, such as life-cycle assessment, are limited in mining because of a lack of properly defined quantifiable impact categories and functional units. On a more positive note however, evidence does also suggest that lithium mining methods can be improved in a way that protects social and environmental systems without compromising economics and that alternative technologies also offer alternative ways to improve lithium extraction and processing (Kaunda, 2020, 241-243). Moreover, there are also concerns over the promotion of mining activities inside the EU because of possible social inequalities within Europe that mining projects entail.

Mining projects have the potential of putting the lives of people and wildlife at risk since mines are often set up in areas near mountains and rivers. An example of such a scenario is an EU-backed lithium mine in Caceres, Spain, Infinity Lithium’s San José de Valdeflórez lithium project, where the mine would be located a mere 800 meters from the town’s historic center which is a World Heritage site and an important location for tourism. Locals have voiced their concerns over their right of self-determination and fears of not being heard in the process of developing such mining activities (Marin, 2020, Macintosh, 2018). Environmental justice is also something to consider. The mining activities in Caceres have been reported to lack necessary permits and have even been prohibited by Caceres own General Urban Development Plan. Also, a letter of opposition signed by 134 organizations, a letter directed at President of the European Commission Ursula von der Leyen, has also tried to highlight the worries of local communities over the mining project’s likely impacts on the environment, water as well as central local economic activities of tourism. The mining project is also understood to go against the intentions of EU’s Biodiversity and European Green Deal strategies. Concerns have also been raised over the mine’s lack of social license to operate, SLO. The EU’s goals to make new frontiers of extractive industries in Europe must also then include the tackling of issues surrounding lack of proper standards, transparency, and community consultation if community opposition are to be avoided (Rhoades, 2020). Similar stories come from a village of Covas do Barroso in Portugal. Plans to excavate lithium form the largest estimated deposits of lithium in Western Europe are against the interests of locals (Carter, 2021). Aspects related to social inequalities and environmental justice are then issues the EU needs to work on if the union wants to see just, inclusive transitions to sustainable, carbon neutral lifestyles. Calls have also been made to revise the Circular Economy Action Plan to correspond more accurately to true circular economy objectives (Friends of the Earth Europe, 2020). The cases discussed above are just a few examples of how the EU’s visions of low-carbon futures might not always be welcomed in Europe. Surely, new mining projects will be needed for the ambitious climate and sustainability goals, but if negative impacts of mining are most greatly felt in local communities, it raises a question of will new mining projects lead to more inequality in Europe with the price of a more equal market role for the EU in the critical raw materials market. In the end, is the growing mining boom really about inclusive and just futures or just a short-term technical fix in the long-term battle against climate change?

Finland and lithium

For a transition to a carbon neutral economy to happen smoothly, the supply of materials needed for technology that enables said carbon neutrality must also be smooth. In the case of lithium supply, security has become a top priority for technology companies. This new focus on secure supply has resulted in joint ventures among exploration companies and technology companies to guarantee a reliable and diverse supply of lithium for manufactures and suppliers. Finland is listed as a potential location for mineral-based lithium sources (United States Geological Survey, 2020). But will Finland face similar events related to mining activities as in other above-mentioned examples from Europe? Most likely not to the same extent. A current lithium mining project of Keliber in Kaustinen and Kokkola seems to have been received positively, and reports indicate that due to its remote location the mining projects won’t have many negative impacts on the surrounding community. Moreover, when in operation, Keliber will become an important regional employer. Environmental assessments on various factors such as groundwaters, surface waters and vegetation seem to also indicate that environmental impacts will be small or moderate (Keliber, 2020). The Keliber project has been discussed in the media to be exceptionally unproblematic in terms of location and the size of the mineral deposits. Some concerns have been raised over the possible issues of profit distribution but the general opinion about it also seems to lean towards more positive (Toivonen, 2021). However, local landowners as well as the Finnish Association for Nature Conservation have voiced their concerns about Keliber’s environmental permit procedures and the possible negative impacts of the mining project to the local environment and communities (Slotte, 2019, Vihanta, 2018). But overall, in terms of lithium mining, Finland may fare rather well without major negative impacts. The Keliber mining project seems to be positively received and has gone through a strict environmental impact assessment. However, negative spillovers concerning lithium can’t be discussed further because the Keliber mining project isn’t in operation yet, but the process up till now seems to lean towards having more positive than negative impacts in the Finnish context.

Anastasio, M. (2020). Europe’s strategy for critical raw materials “a double-edged sword”. https://eeb.org/europes-strategy-for-critical-raw-materials-a-double-edged-sword/ . Accessed: 23.4.2021.

Bobba, S., Carrara, S., Huisman, J., Mathieux, F., Pavel, C. (2020). Critical Raw Materials for Strategic Technologies and Sectors in the EU: A Foresight Study. https://rmis.jrc.ec.europa.eu/uploads/CRMs_for_Strategic_Technologies_and_Sectors_in_the_EU_2020.pdf . Accessed: 23.4.2021.

Carter, B. (2021). A Portuguese village pays the high price of low carbon energy. https://www.euronews.com/2021/04/23/portuguese-village-suffers-the-high-cost-of-low-carbon-energy . Accessed: 29.4.2021.

de Blas, I., Mediavilla, M., Capellán-Pérez, I., & Duce, C. (2020). The limits of transport decarbonization under the current growth paradigm. Energy Strategy Reviews, 32 , 100543. doi:https://doi.org/10.1016/j.esr.2020.100543

European Commission1. (2010). Europe 2020. A European strategy for smart, sustainable and inclusive growth. https://ec.europa.eu/eu2020/pdf/COMPLET%20EN%20BARROSO%20%20%20007%20-%20Europe%202020%20-%20EN%20version.pdf . Accessed: 23.4.2021.

European Commission2. (2019). COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE EUROPEAN COUNCIL, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS. The European Green Deal.

https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1596443911913&uri=CELEX:52019DC0640#document2. Accessed: 29.4.2021.

European Commission3. (2020). Green Deal: Sustainable batteries for a circular and climate neutral economy.

https://ec.europa.eu/commission/presscorner/detail/en/ip_20_2312. Accessed: 29.4.2021.

European Commission4. (2020). Questions and Answers on Sustainable Batteries Regulation.

https://ec.europa.eu/commission/presscorner/detail/en/qanda_20_2311 . Accessed: 23.4.2021.

European Commission5. (2020). COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS Critical Raw Materials Resilience: Charting a Path towards greater Security and Sustainability.

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474 . Accessed: 27.4.2021.

European Commision6. Internal Market, Industry, Entrepreneurship and SMEs. Critical Raw Materials.

https://ec.europa.eu/growth/sectors/raw-materials/specific-interest/critical_en . Accessed: 27.4.2021.

Friends of the Earth Europe. (2020). A circular economy within ecological limits.

https://friendsoftheearth.eu/publication/a-circular-economy-within-ecological-limits/ . Accessed: 29.4.2021.

Kaunda, R. B. (2020). Potential environmental impacts of lithium mining. Journal of Energy & Natural Resources Law, 38 (3), 237-244. doi:10.1080/02646811.2020.1754596

Kavanagh, L., Keohane, J., Garcia Cabellos, G., Lloyd, A., & Cleary, J. (2018). Global lithium Sources—Industrial use and future in the electric vehicle industry: A review. Resources (Basel), 7 (3), 57. doi:10.3390/resources7030057

Keliber. (2020). Keski-Pohjanmaan litiumprovinssin laajennuksen YVA-selostus. https://www.keliber.fi/site/assets/files/2386/yva_selostus_keliber_2020_24112020.pdf . Accessed: 29.4.2021.

Macintosh, E. (2018). Thousands take to streets to protest Spanish mining boom. https://meta.eeb.org/2018/02/13/public-outcry-over-spanish-mining-boom/ . Accessed: 27.4.2021.

Marin, D. F. (2020). Europe’s scramble for minerals comes home. https://meta.eeb.org/2020/09/10/europes-raw-materials-ambitions-and-the-right-to-say-no/ . Accessed: 24.4.2021.

OECD global material resources outlook to 2060: Economic drivers and environmental consequences (2019). OECD.

Rhoades, H. (2020). Cáceres rejects lithium mine. https://theecologist.org/2020/jun/10/caceres-rejects-lithium-mine . Accessed: 29.4.2021.

Slotte, C-O. (2019). Keliberin ensimmäinen louhos sai ympäristöluvan, mutta rahoitus on edelleen auki – SLL aikoo jättää valituksen. https://www.keskipohjanmaa.fi/uutinen/570595 . Accessed: 29.4.2021.

Toivonen, J. (2021). Analyysi: Kaustisen suurta litiumkaivosta on vaikea vastustaa, niin hyvältä kaikki näyttää – hankkeessa on vain yksi kipukohta. https://yle.fi/uutiset/3-11805712. Accessed: 29.4.2021.

United States Geological Survey. (2020). Lithium. Mineral Commodity Summaries . https://pubs.usgs.gov/periodicals/mcs2020/mcs2020-lithium.pdf . Accessed: 27.4.2021.

Vihanta, A. (2018). Maanomistajat kritisoivat Keliberin litiumkaivoksen vesien käsittelyä – näkevät lupahakemuksessa paljon puutteita.

https://yle.fi/uutiset/3-10413889 . Accessed: 29.4.2021.

Mining of nickel: Negative Environmental Impacts

Text by eemi saarinen.

Why is nickel so crucial for green technology?

When it comes to green technology, there is often a lot of talk about lithium-ion batteries, which serve as a power source to electric cars, for example. However, despite its name, lithium-ion batteries are actually mostly produced with nickel, alongside cobalt and lithium. This has been the case so far, but there are also some actions against the use of nickel. In February 2021 the owner of Tesla, Elon Musk, announced that Tesla will in some cars replace nickel with iron (Li, 2021). Previously he has pleaded for greater production of nickel. Despite the decision of the electric car giant’s decision, the need of nickel in creating green technology is still massive. How nickel is produced globally and in Finland, and what might be the negative environmental spillover effects? How sustainable is nickel production when examining it with the SDGs of the UN?

Nickel globally and in Finland

Globally the mining production of nickel was 2,7 million tons in 2019 (Government of Canada, 2021). The growth has been significant since 2010 (not constant, though), when production of nickel was only 1,6 million tons annually. Although we are interested in nickel as material used in batteries, it must be mentioned that batteries account only 4 % of global use of nickel (Government of Canada, 2021). 71 % of nickel is used to produce stainless steel, so the electric car boom does not account for very much of the global rise of nickel production. The sovereign leader of nickel production globally is Indonesia, accounting for 29,8 % of total production. The five next greatest producers are Philippines, Russia, New Caledonia, Canada and Australia, as can be seen in the table below:

The production of nickel in Finland has grown over the past decade. Right now, there are three major mines in Finland mining nickel: Terrafame’s mine in Talvivaara, and Boliden’s mines in Kylylahti and Kevitsa (Vasara, 2019). In 2018, the total amount of nickel mined was 43 752 tons. 212 069 tons of nickel concentrate was produced. In addition, Boliden has a nickel smelter in Harjavalta, which uses nickel concentrates from the Kevitsa mine (Boliden, 2020). The smelter’s importance is significant, because it is the only nickel smelter in Western Europe. Nornickel also produces nickel products in Harjavalta.

Negative environmental impacts of nickel and the SDGs

Mining and smelting of nickel may have many environmental impacts. In Finland, there are some examples of environmental problems caused by nickel. In 2014, Nornickel’s factory leaked 66 tons of nickel sulfate in Kokemäki river, causing the death of millions of endangered freshwater pearl mussels (Centre for Economic Development, Transport and the Environment, 2017). The leak led to weakening of the entire river ecosystem, because mussels filter for example plankton and alga from the water. Concentration of nickel in the water exceeded the environmental quality norm four-hundredfold, therefore the overall quality of water was affected enormously. This example makes it clear that mining activities needed to create “green technology” can be all but green. Of course, this example illustrates a case of a single catastrophic event, but it is important to assess negative environmental spillover effects produced by everyday activity.

Even when nothing disastrous happens, there are some factors that can make one question, if mining nickel for green technology is so green after all. Nickel must be extracted from the ore with smelting, which requires a high amount of energy and produces emissions (Dunn, Gaines, Kelly, James & Gallagher, 2014). Sulfur oxide emissions are usually connected to smelting of nickel. For example in Canada sulfur dioxide emissions have caused some serious environmental damage: acid rain emissions, heavy metal soil contamination, wetland acidification and biodiversity loss, to name a few (Dunn et al., 2014). When it comes to the high energy intensity of smelting, it is important to consider whether the energy used is renewable? Because if not, creating “green technology” using high amounts of nonrenewable energy might be just another form of greenwashing. Emissions and amount of energy used relate also to laterite ore, from which nickel is often extracted. Mudd (2010) points out sustainability problems of the nickel industry: there is an evident decline in long-term ore rates in the nickel industry, meaning that more and more laterite must be processed to extract the desired amount of nickel. This is problematic in terms of energy consumption, especially when the energy used is not renewable.

There are a few main environmental issues of nickel production, which are in contrast with the UN’s SDGs. Violating the SDGs can be challenging to observe. There are some concrete targets set by the UN, alongside global indicators. However, they might not be sufficiently specific to address mining/local issues. Nevertheless, it is probable that nickel producing might be in contrast with the following environmental SDGs:

6: Clean water and sanitation, 7: Affordable and clean energy, 13: Climate action, 14: Life below water and 15: Life on land

It is evident that production of nickel may pollute water and damage life below water. The mussel deaths in Finland, and damage to soil and wildlife both below water and on land in Canada show that green technology does not come without risks for the environment. One could also question the positive effect on creating affordable and green energy and climate action, if nickel is not mined and refined using renewable energy. At least we must be aware of the possible negative environmental impacts of nickel, when we are creating so called green technology.

Boliden (2020) Boliden harjavalta. Retrieved from https://www.boliden.com/operations/smelters/boliden-harjavalta

Centre for Economic Development, Transport and the Environment. (2017, June 21). Kokemäenjoen kesän 2014 nikkelipäästö aiheutti korjattavaksi määrätyn merkittävän vesistö- ja luontovahingon (Varsinais-Suomi ja Satakunta). Retrieved from https://www.ely-keskus.fi/-/kokemaenjoen-kesan-2014-nikkelipaasto-aiheutti-korjattavaksi-maaratyn-merkittavan-vesisto-ja-luontovahingon-varsinais-suomi-ja-satakunta-#.WUpAd2YUmUk

Dunn, J. B., Gaines, L., Kelly, J. C., James, C., & Gallagher, K. G. (2015). The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy & Environmental Science , 8 (1), 158-168. https://doi.org: 10.1039/C4EE03029J

Government of Canada (2021, February 22). Nickel facts. Retrieved from https://www.nrcan.gc.ca/our-natural-resources/minerals-mining/minerals-metals-facts/nickel-facts/20519

Mudd, G. M. (2010). Global trends and environmental issues in nickel mining: Sulfides versus laterites. Ore Geology Reviews, 38(1-2), 9-26. https://doi.org/10.1016/j.oregeorev.2010.05.003

Li, Y. (2021, February 26). Musk Says Nickel Is ‘Biggest Concern’ For Electric-Car Batteries. Bloomberg. Retrieved from https://www.bloomberg.com/news/articles/2021-02-25/musk-says-nickel-is-biggest-concern-for-electric-car-batteries

Vasara, H. (2019). Toimialaraportit – Kaivoteollisuus Report prepared for Ministry of employment and the economy of Finland https://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/161860/TEM_2019_57.pdf

2 Replies to “Exploring the Negative Impacts of Mining Minerals”

Hello there I am so grateful I found your blog page, I really found you by accident, while I was researching on Google for something else, Nonetheless I am here now and would just like to say cheers for a fantastic post and a all round exciting blog (I also love the theme/design), I don’t have time to read through it all at the minute but I have book-marked it and also added your RSS feeds, so when I have time I will be back to read a great deal more, Please do keep up the superb work.

Heya i am for the first time here. I came across this board and I in finding It really useful & it helped me out a lot. I am hoping to give something again and aid others such as you helped me.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Help & FAQ

A lithium-isotope perspective on the evolution of carbon and silicon cycles

- Geosciences

- High Meadows Environmental Institute

Research output : Contribution to journal › Article › peer-review

The evolution of the global carbon and silicon cycles is thought to have contributed to the long-term stability of Earth’s climate 1–3 . Many questions remain, however, regarding the feedback mechanisms at play, and there are limited quantitative constraints on the sources and sinks of these elements in Earth’s surface environments 4–12 . Here we argue that the lithium-isotope record can be used to track the processes controlling the long-term carbon and silicon cycles. By analysing more than 600 shallow-water marine carbonate samples from more than 100 stratigraphic units, we construct a new carbonate-based lithium-isotope record spanning the past 3 billion years. The data suggest an increase in the carbonate lithium-isotope values over time, which we propose was driven by long-term changes in the lithium-isotopic conditions of sea water, rather than by changes in the sedimentary alterations of older samples. Using a mass-balance modelling approach, we propose that the observed trend in lithium-isotope values reflects a transition from Precambrian carbon and silicon cycles to those characteristic of the modern. We speculate that this transition was linked to a gradual shift to a biologically controlled marine silicon cycle and the evolutionary radiation of land plants 13,14 .

All Science Journal Classification (ASJC) codes

Access to document.

- 10.1038/s41586-021-03612-1

Other files and links

- Link to publication in Scopus

- Link to the citations in Scopus

Fingerprint

- Carbon Cycle Medicine & Life Sciences 100%

- Silicon Medicine & Life Sciences 79%

- Lithium Medicine & Life Sciences 71%

- Isotopes Medicine & Life Sciences 71%

- Lithium Carbonate Medicine & Life Sciences 47%

- Carbonates Medicine & Life Sciences 23%

- Seawater Medicine & Life Sciences 21%

- Radiation Medicine & Life Sciences 12%

T1 - A lithium-isotope perspective on the evolution of carbon and silicon cycles

AU - Kalderon-Asael, Boriana

AU - Katchinoff, Joachim A.R.

AU - Planavsky, Noah J.

AU - Hood, Ashleigh v.S.

AU - Dellinger, Mathieu

AU - Bellefroid, Eric J.

AU - Jones, David S.

AU - Hofmann, Axel

AU - Ossa, Frantz Ossa

AU - Macdonald, Francis A.

AU - Wang, Chunjiang

AU - Isson, Terry T.

AU - Murphy, Jack G.

AU - Higgins, John A.

AU - West, A. Joshua

AU - Wallace, Malcolm W.

AU - Asael, Dan

AU - Pogge von Strandmann, Philip A.E.

N1 - Publisher Copyright: © 2021, The Author(s), under exclusive licence to Springer Nature Limited.

PY - 2021/7/15

Y1 - 2021/7/15

N2 - The evolution of the global carbon and silicon cycles is thought to have contributed to the long-term stability of Earth’s climate1–3. Many questions remain, however, regarding the feedback mechanisms at play, and there are limited quantitative constraints on the sources and sinks of these elements in Earth’s surface environments4–12. Here we argue that the lithium-isotope record can be used to track the processes controlling the long-term carbon and silicon cycles. By analysing more than 600 shallow-water marine carbonate samples from more than 100 stratigraphic units, we construct a new carbonate-based lithium-isotope record spanning the past 3 billion years. The data suggest an increase in the carbonate lithium-isotope values over time, which we propose was driven by long-term changes in the lithium-isotopic conditions of sea water, rather than by changes in the sedimentary alterations of older samples. Using a mass-balance modelling approach, we propose that the observed trend in lithium-isotope values reflects a transition from Precambrian carbon and silicon cycles to those characteristic of the modern. We speculate that this transition was linked to a gradual shift to a biologically controlled marine silicon cycle and the evolutionary radiation of land plants13,14.

AB - The evolution of the global carbon and silicon cycles is thought to have contributed to the long-term stability of Earth’s climate1–3. Many questions remain, however, regarding the feedback mechanisms at play, and there are limited quantitative constraints on the sources and sinks of these elements in Earth’s surface environments4–12. Here we argue that the lithium-isotope record can be used to track the processes controlling the long-term carbon and silicon cycles. By analysing more than 600 shallow-water marine carbonate samples from more than 100 stratigraphic units, we construct a new carbonate-based lithium-isotope record spanning the past 3 billion years. The data suggest an increase in the carbonate lithium-isotope values over time, which we propose was driven by long-term changes in the lithium-isotopic conditions of sea water, rather than by changes in the sedimentary alterations of older samples. Using a mass-balance modelling approach, we propose that the observed trend in lithium-isotope values reflects a transition from Precambrian carbon and silicon cycles to those characteristic of the modern. We speculate that this transition was linked to a gradual shift to a biologically controlled marine silicon cycle and the evolutionary radiation of land plants13,14.

UR - http://www.scopus.com/inward/record.url?scp=85111114312&partnerID=8YFLogxK

UR - http://www.scopus.com/inward/citedby.url?scp=85111114312&partnerID=8YFLogxK

U2 - 10.1038/s41586-021-03612-1

DO - 10.1038/s41586-021-03612-1

M3 - Article

C2 - 34262211

AN - SCOPUS:85111114312

SN - 0028-0836

JO - Nature

JF - Nature

Tracing Si–N–P ecosystem-pathways: is relative uptake in riparian vegetation influenced by soil waterlogging, mowing management and species diversity?

- Wetland Restoration

- Open access

- Published: 18 May 2011

- Volume 674 , pages 41–50, ( 2011 )

Cite this article

You have full access to this open access article

- Eric Struyf 1 ,

- Wiktor Kotowski 2 ,

- Sander Jacobs 1 ,

- Stefan Van Damme 1 ,

- Kris Bal 1 ,

- Wout Opdekamp 1 ,

- Hans Backx 1 ,

- Dimitri Van Pelt 1 &

- Patrick Meire 1

1727 Accesses

6 Citations

Explore all metrics

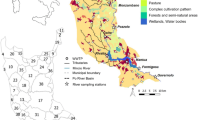

Despite the growing concern about the importance of silicon (Si) in controlling ecological processes in aquatic ecosystems, little is known about its processing in riparian vegetation, especially compared to nitrogen (N) and phosphorus (P). We present experimental evidence that relative plant uptake of N and P compared to Si in riparian vegetation is dependent on mowing practices, water-logging and species composition. Results are obtained from a controlled and replicated mesocosm experiment, with a full-factorial design of soil water logging and mowing management. In our experiments, the Si excluding species Plantago lanceolata was dominant in the mown and non-waterlogged treatments, while Si accumulating meadow grasses and Phalaris arundinacea dominated the waterlogged treatments. Although species composition, management and soil moisture interacted strongly in their effect on relative Si:N and Si:P uptake ratios, the uptake of N to P remained virtually unchanged over the different treatments. Our study sheds new light on the impact of riparian wetland ecosystems on nutrient transport to rivers. It indicates that it is essential to include Si in future studies of the impact of riparian vegetation on nutrient transport, as these are often implemented as a measure to moderate excessive N and P inputs.

Similar content being viewed by others

Soil system budgets of N, Si and P in an agricultural irrigated watershed: surplus, differential export and underlying mechanisms

Silicon Affects Nutrient Content and Ratios of Wetland Plants

Evaluation of nutrient stoichiometric relationships among ecosystem compartments of a subtropical treatment wetland. Do we have “Redfield wetlands”?

Avoid common mistakes on your manuscript.

Introduction

The uptake, storage and recycling of silicon (Si) in ecosystem biomass and soils are now recognized as important components of silicon transport through the terrestrial environment (Conley, 2002 ; Derry et al., 2005 ; Street-Perrott & Barker, 2008 ; Struyf & Conley, 2009 ), but the relative importance of the biological buffer in different ecosystems, and the impact of environmental forcing factors on the efficiency of storage, uptake and recycling still remains poorly quantified. Si is a key nutrient in determining the species composition of aquatic and coastal phytoplankton communities (Cloern, 2001 ). The commonly observed effect of increased anthropogenic inputs of nitrogen (N) and phosphorus (P) to aquatic ecosystems is a shift in the coastal phytoplankton community to one dominated by dinoflagellates (Lotze et al., 2006 ), caused by dissolved Si (DSi) limitation of diatoms (Conley et al., 1993 ). A lack of DSi can lead to a less efficient food web structure as well as to hypoxia and harmful blooms of toxic algae (e.g. Anderson et al., 2002 ). Silicon also plays an essential role in the global carbon (C) cycle. A continuous import of Si from the terrestrial environment is necessary to maintain the biological C pump in the ocean (Tréguer & Pondaven, 2000 ), and mineral weathering of silicate minerals is one of the major terrestrial sinks for carbon dioxide (CO 2 ) (Berner, 1992 ). The poor quantification of the biological Si buffer in ecosystems forms a prime challenge in constraining the silicon cycle related C sinks.

Wetlands and meadows are prime candidates to form a hot-spot in the biological Si buffer, as they can accumulate large amounts of biogenic amorphous Si (ASi) (Blecker et al., 2006 ; Struyf & Conley, 2009 ) in the form of plant phytoliths, diatoms and sponge spicules. Riparian meadows are well-established buffers in the N and P cycle. They affect the output of these nutrients to rivers through permanent or temporary uptake in vegetation, detritus and soils and through transformation processes, e.g. removal by denitrification (e.g. Güsewell, 2005 ; Olde Venterink et al., 2006 ). Riparian wetlands are often (re)established as a countermeasure against excessive N and P export from agricultural catchments. Up to now however, little research has focused on the influence of ecosystem characteristics on Si processing in riparian meadows or wetlands. Management has been observed to potentially interfere with the storage of ASi near the surface of riparian wetlands (Struyf et al., 2009 ), but experimental evidence is currently lacking (Struyf & Conley, 2009 ).

We analyzed uptake of Si by riparian vegetation in reference to N and P in mesocosm communities grown for one season under contrasting moisture and management conditions. Earlier experiments have focused on N, P and often K and C, while failing to include Si. Our study sheds new light on the impact of riparian wetland ecosystems on nutrient transport to rivers, and is new evidence of the importance of the role of vegetation in terrestrial Si fluxes.

Materials and methods

We established a full-factorial mesocosm experiment with soil water-logging and summer mowing as factors, each of them in two levels (waterlogged, anoxic vs. non-waterlogged, oxic and mown vs. unmown). The experimental set-up is described in Kotowski et al. ( 2010 ). Briefly, mesocosms were composed of PVC containers of 91 × 111 cm surface and 61 cm height. Outflow taps located at the bottom of side walls connected to PVC pipes allowed for the control of the water level. Containers were filled with 20 cm of drainage substrate (Argex clay aggregate, Argex NV, Zwijndrecht, Belgium) separated by geo-textile from a 30 cm cover of a soil mixture containing 3:1 volumetric parts of fen peat and alluvial clay. Mixing fen peat and clay ensured that the soil would have high water potential and mineral content (clay) and at the same time, high organic matter content (peat) necessary to produce reduced conditions after water-logging. Presence of peat in the soil also allowed for easier percolation of water under non-water logged conditions. To maintain eutrophic conditions throughout the experiment, an initial amount of 168 g N, 192 g P, 216 g potassium (K) and 24 g magnesium (Mg) per m 3 soil in an easily soluble form (PG-mix Floranid, COMPO Benelux nv, Deinze, Belgium), and a slow release fertilizer (6 months release time; Osmocote, SCOTTS Professional, Sint-Niklaas, Belgium) containing 300 g N, 180 g P and 180 g K per m 3 soil were added. These values are at the upper limit of annual nutrient input in European floodplains (Olde Venterink et al., 2006 ).

Forty mesocosms were placed in a block of 4 × 10. Water was supplied by sprinklers installed 30 cm above each container once (spring, autumn) or twice (summer) a day. Watering time depended on the time of the year (between 5 and 25 min per day) and specifically ensured that plants were not limited by water shortage. Excessive water could flow out of the system through the outflow pipe. In anoxic soils, the water level was held constant at 2–5 cm below soil surface, while the outflow was levelled at the bottom of the containers in the oxic soils.

The species used in the experiment were typical of Central European floodplains. We carefully selected species as to have a similar representation of typical fen, wet meadow and mesic meadow species and to assure that each of these groups contained species from various functional types and growth forms (Supplementary material). A seed mixture of 37 species was introduced on the 15th of May 2006 in a density of approximately 1,000 seeds m −2 species −1 . Soil moisture measurements at 5 cm depth carried out in mid June between two watering treatments confirmed differences between the waterlogged and the non-waterlogged treatments (soil moisture: 54.2% ± 12.1 and 32.4% ± 3.5, respectively, by weight, t test P < 0.001).

The above-ground biomass of the 20 mesocosms subjected to the summer mowing treatment was harvested at the end of June 2006. Biomass was sorted to species level, except for the meadow grasses which were grouped. Dry biomass of all species was determined separately (except for the meadow grasses) in each mesocosm after 72 h of drying at 70°C. At the end of the experiment (September 2006), the above-ground biomass of all 40 mesocosms was harvested and the sorting and drying was carried out as described above.

Nutrient analysis

N, P and Si concentrations in plant biomass for all established species were determined. If a species established in more than seven mesocosms with the same combination of mowing and aeration treatment, seven randomly chosen replicates were analyzed for their N, P and Si content.

After drying, the plant material was grounded with a motor mill and analyzed for N, P and Si content. ASi content was analyzed through incubation of 25 mg of ground, homogenized plant material for 4 h in 0.1 M Na 2 CO 3 at 80°C (DeMaster, 1981 ). Extracted dissolved silicon was subsequently analyzed spectrophotometrically on a Thermo IRIS ICP (Inductively Coupled Plasmaspectrophotometer). N and P content were analyzed according to Walinga et al. ( 1989 ) on a colorimetric segmented flow analyzer.

Nutrient uptake at the vegetation level

To allow the analysis of nutrient uptake at community level during the experiment (May–September 2006), the dry weight of every species was multiplied with the average N, P and Si content observed for the species in a certain treatment. The total N, P and Si uptake in biomass for every mesocosm was then calculated by summation of the calculated total nutrient uptake in all species. For the mown treatments, this is the summation of the May–June and July–September uptake.

Statistical analyses

A one-way ANOVA analysis was used to comparing the treatments for different variables (Biomass, N, P and Si uptake, N:P ratio, N:Si and P:Si). Classification of the treatments was performed with Post-hoc Scheffe tests. All analyses were performed in SPSS (Statistical Package for the Social Sciences) 14.0 (SPSS, 2005 ).

Vegetation patterns and biomass

In total, 26 species established in the mesocosms but only 14 were present in sufficient amounts to allow for chemical analyses (see Kotowski et al., 2010 for detailed information on species recruitment in each treatment). Three meadow grasses established (i.e. Lolium perenne L. , Poa pratensis L., and Alopecurus pratensis L.): these were grouped as one taxon within the analysis. Another grass species, Phalaris arundinacea L. was considered separately, as it is a typical wetland grass, while the other grouped species are typical meadow grasses. As such, 11 species and one group-taxon were included in the analysis: “meadow grasses ( L. perenne , P. pratensis and A. pratensis )”, Achillea millefolium L., Centaurea jacea L., Cirsium oleraceum L. Scop., Daucus carota L., Epilobium hirsutum L., Leontodon autumnalis L., Lycopus europaeus L., Lythrum salicaria L., P. arundinacea , Plantago lanceolata L. and Valeriana officinalis L..

The total above-ground biomass was higher in the non-waterlogged, oxic treatments (Table 1 ). Biomass in oxic treatments was dominated by P. lanceolata , and to a lesser extent, by P. arundinacea , D. carota and A. millefolium (Fig. 1 ). Biomass in the waterlogged, anoxic treatments was dominated by meadow grasses and P. lanceolata , and to a lesser extent by P. arundinacea (Fig. 1 ). A clear shift of the dominant species was apparent between anoxic and oxic treatments, with meadow grasses dominating the anoxic treatments and P. lanceolata the oxic treatments (Fig. 1 ). More than 80% of the decrease in total biomass under anoxic conditions could be attributed to P. lanceolata , with a strong decline in biomass, both in mown (−1,000 g dry weight m −2 of P. lanceolata biomass on average) and unmown mesocosms (−1,360 g dry weight m −2 on average). Given the importance of P. lanceolata for total biomass production, we also tested for differences in biomass excluding P. lanceolata . Although a marginally significant effect of treatment on biomass without P. lanceolata biomass existed ( P < 0.04), the post-hoc Scheffe tests did not separate any of the treatments individually (Table 1 ).

Contribution of different species to total biomass in the different treatments (averaged, n = 10 for every treatment)

Nutrient concentrations at the species level

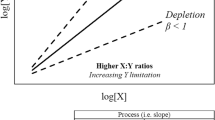

The plant nutrient concentration among the different replicates only showed small variability (Table 2 ). Results for nutrient contents will focus on the main dominant species D. carota , A. millefolium , “meadow grasses”, P. arundinacea and P. lanceolata , which represented over 90% of nutrient uptake. Average biomass for the dominant species, and average N, P and Si concentrations in the plant tissue is summarized in Table 2 . P. lanceolata and D. carota had low N, P and Si contents compared to the other dominant species . The species in the anoxic treatment generally contained less N, P and Si compared to the oxic treatments. Highest relative differences were observed for Si content in P. arundinacea , meadow grasses and A. millefolium , which had more than twice the relative Si content in oxic compared to anoxic treatments.

Nutrient uptake

Total uptake of nutrients (N, P and Si) in the oxic treatments was high compared to anoxic treatments (Fig. 2 ; Table 1 ). Under oxic circumstances, N and P uptake were higher in the mown treatments; this effect was not apparent for Si uptake (Table 1 ). The differences for N and P uptake were attributable to P. lanceolata biomass. Excluding this, no differences in total N and P uptake were apparent (Table 1 , Fig. 2 lower panel). This was not the case for Si uptake; excluding P. lanceolata biomass had no effect on Si uptake (Table 1 ; Fig. 2 ) as there is almost no Si in P. lanceolata (Table 2 ).

Total nitrogen (N), phosphorus (P) and silicon (Si) uptake in the vegetation of the different treatments. The top panels are for the total biomass, the lower panels for the biomass without P. lanceolata . The error bars indicate the standard deviation ( OM oxic, mown; ONM oxic, unmown; ANM anoxic, mown; ANNM anoxic, unmown)

In mown treatments more N and P were taken up compared to Si than in unmown treatments, both under oxic and anoxic conditions (Fig. 3 ; Table 1 ). The relative uptake of Si dropped mainly as a result of increasing P. lanceolata abundance in the mown treatments (N:Si ratio in P. lanceolata ranged between 17 and 38, while, e.g. P. arundinacea N:Si ranged between 2 and 5). Although significant differences existed in N:P ratio across the treatments (Table 1 ), these differences were very small (Fig. 3 ).

Nitrogen (N):phosphorus (P), P:silicon (Si), and N:Si weight ratios in the vegetation in the different treatments. The left panel is for the total biomass, the right panel for the biomass without P. lanceolata . The error bars indicate the standard deviation ( OM oxic, mown; ONM oxic, unmown; ANM anoxic, mown; ANNM anoxic, unmown)

If we remove P. lanceolata from the analysis, all remaining dominant vegetation consists of Si accumulators. This had little effect on N:P ratio in the vegetation across the treatments (Fig. 3 ; Table 2 ), although small significant differences still existed (Table 2 ). Removing P. lanceolata from the analysis had almost no effect on the total Si content of plants, while the N and P taken up by the vegetation decreased drastically (Fig. 2 ). The N:Si and P:Si ratio in the Si accumulator (non- Plantago ) biomass was mainly related to the water-logging in the soil (Table 1 , Fig. 3 ), although mowing had a significant effect in the anoxic treatments (Table 1 ).

In summary, the N:P ratio only differed marginally over species composition, soil moisture and mowing conditions. In contrast, the ratio at which Si was taken up relative to the other nutrients was significantly different. Mowing enhanced occurrence of P. lanceolata , and as such decreased relative uptake of Si. In the accumulator biomass, relative uptake of Si to N and P was mainly related to water logging.

Although abundant experimental studies have focused on N and P uptake in riparian vegetation, a controlled experiment which studies Si uptake (relative to N and P) in detail, under changing environmental conditions, is surprisingly lacking. Riparian meadows, of which our experimental units were small-scale versions, have a high potential to influence the Si input into rivers. Often dominated by Si-rich grasses or sedges, they are likely among the most active processors of Si of all terrestrial ecosystems (e.g. Blecker et al., 2006 ; Sommer et al., 2006 ; Struyf & Conley, 2009 ).

P concentrations in our experiment (the 4 dominant species contain on average 3.7 mg g −1 dry weight) were high compared to other studies, while N concentrations (18.7 mg g −1 dry weight) were high but not uncommon (Güsewell & Koerselman, 2002 ). Our experiment was, given the high supply of N and P through fertilisers and the relatively high concentrations of N and P in plant tissues, clearly representative for a set of riparian meadows in an eutrophied environment, with N less available compared to P (but neither should be considered limiting at measured concentrations). In such eutrophied environments, wetland restoration and protection is often implemented as a measure to reduce N and P export. It is a well-established concept that controlling N and P export upstream by implementing riparian vegetations is one of the most effective ways to control N and P fluxes through river basins, and in the end, to the coastal zone (e.g. Withers & Jarvis, 1998 ; Hattermann et al., 2006 ).

Waterlogging, mowing and relative Si uptake

In our experiment, two dominant species ( P. arundinacea and A. millefolium , which contain over 1 wt% ASi) and the meadow grass cluster can be identified as Si accumulators. This is consistent with previous literature studies (Hodson et al., 2005 ). In general, monocots (e.g. Poaceae ) contain more Si than dicots. The dicot-monocot division is only a general pattern, and deviations are not an exception. Although a dicot, A. millefolium was previously identified as a substantial accumulator of silicon (Hodson et al., 2005 ). Interestingly, nearly all the species in the waterlogged treatments had a lower ASi content compared to the non-waterlogged treatments. This contrasts with the Si content in soil solution, displaying higher concentrations in waterlogged anoxic (115 ± 32 μmol l −1 ) than in oxic conditions (45 ± 5 μmol l −1 ). Dissolved Si content in soil solution and plant Si content were thus not directly linked in our experiment, although such a link was found in other experiments (e.g. Henriet et al., 2006 ).