Standard Cassava Processing Business Plan with 3 Years Financial Analysis

We have developed a comprehensive and standardised cassava processing business plan, encompassing a range of products such as garri, flour, starch, and more. The purpose of this plan is to assist entrepreneurs in securing funds from investors, applying for bank loans, or accessing grants.

The cassava processing industry has witnessed significant growth and holds immense potential in Nigeria. As of the latest data, Nigeria stands as the largest cassava producer globally, surpassing Brazil by one-third and exceeding the production capacities of Thailand and Indonesia by almost double. Presently, Nigeria produces approximately 42 million metric tonnes (MT) of cassava annually, a figure projected to grow significantly by the year 2025 as government empowers more farmers.

Despite being the leading cassava producer, Nigeria’s involvement in the international cassava trade remains limited due to its focus on the domestic food market. The country predominantly utilises subsistence production methods, which are insufficient to meet industrial-level demands.

Recognising the need for commercial cassava production and processing both locally and internationally, recent and past governments have introduced policies to encourage and support this sector.

The Government Initiative on Cassava, aimed to highlight the potential of cassava as a foreign exchange earner for Nigeria. Additionally, it sought to develop the cassava production system to meet national demand sustainably. One of the primary objectives of this initiative was to generate more than US$7 billion in value-added cassava exports by the year 2025.

The vision for cassava encompassed rural industrial development, increasing incomes for producers, processors, and traders, and contributing to food security by shifting cassava from a primarily subsistence food to an industrial crop used in the production of ethanol, starch, pellets, and high-quality cassava flour for export.

To achieve this ambitious goal, Nigeria must adopt a demand-driven approach to promote, develop, and diversify its cassava-based industries.

By utilising our standardised business plan, entrepreneurs in the cassava processing sector can save valuable time, money, and energy. It serves as a strategic roadmap, enabling them to attract investors, secure bank loans, and access grants while leveraging Nigeria’s status as a global cassava production leader and harnessing the potential of the local and international markets.

If you are interested in starting or growing your cassava business and need a cassava business plan, we have one for you.

The cassava processing business plan comes with a 3-year financial analysis.

The complete cassava processing business plan is in Word Doc format, and the financial analysis is in Excel so that you can edit it to suit your taste.

The cassava processing business plan is fully updated with current research on how to start a cassava processing business, get the attention of the market, retain it, and make huge profits.

The cassava processing business plan also has an in-depth analysis of cassava processing equipment.

3-year automated financial model in MS Excel with complete industry research for this cassava business plan

To get this standard CASSAVA PROCESSING business plan for only N10,000

Let me give you an idea of what you should expect from the business plan:

1) Table of Contents

2) Executive Summary: The summary includes an introduction, product and service descriptions, marketing and sales, among others

3) Company Overview : This includes

- Mission Statement

- History and Current Status

- Markets and Products

- Keys to success

- Cost summary

4) Product description : All our products are described including other unique features.

5) Industry and Market Analysis

- Introduction

- Industry analysis

- Market analysis

- Customer analysis

- Competitor analysis

- SWOT Analysis

6) Marketing Strategy

- Target Market Strategy

- Product/Service Strategy

- Pricing Strategy

- Distribution Strategy

- Advertising and Promotion Strategy

- Sales Strategy

- Marketing and sales Forecasts

7) Operations

- Operations Strategy

- Scope of Operations

- Operating Expenses

8) Development

- Development Strategy

- Development Timeline

- Development Expenses

9) Management

- Company Organization

- Management Team

- Administrative Expenses

10) Summary of Financials

- Financial Assumptions

- Financial Forecasts

- Projected Cash Flow

- Income statement

iii. Balance sheet

- Profit and loss

- Profit Margin, chart etc

- Financial Risks

11) Appendices

Support for Product/Service Description (e.g., diagrams, pictures, etc.)

Support for Marketing and Sales Plan

Support for Development Plan

Support for Operations Plan

Resumes of Management Team

Financial Statements

- Income Statement [3 years]

- Balance Sheets [3 years]

- Cash Flow Statements [3 years]

- Ratio Analysis [3 years]

- Other supporting financial statements

What is the cost of the cassava processing Business Plan?

Well if I say N30,000 it is worth it but I won’t give you that amount and not even N20,000.

What about N15,000 ? I won’t still give you that amount. But for a LIMITED TIME I will allow you to pay N10,000

To access this standard cassava processing business plan, pay N10,000 into any of the accounts below:

You can pay into any of the following accounts:

Account Name: Etimate Global Services Account Number: 1150007557 Bank: Skye Bank or

Account Name: Utibe Etim Account Number: 0007852498 Bank: GTB or Account Name: Utibe Etim Account Number: 2012483183 Bank: UBA

AFTER PAYMENT: Please text or email your name, phone number, payment details, and your email address to 07031542324 or [email protected] and your cassava processing business plan will be sent to you

OTHER STANDARD CASSAVA BUSINESS PLANS

- Cassava Farming Business Plan With 3 Years Financial Analysis (N10,000) – Order Now

- Cassava Farming and Processing Business Plan With 3 Years Financial Analysis (N10,000) – Order Now

- Ethanol Business Plan With 3 Years Financial Projections (N10,000) – Order Now

We have developed over 120 business plans and you can click the the link below to check them out.

CLICK HERE TO CHECK THE FULL LIST OF ALL THE BUSINESS PLANS WE HAVE HERE

WHAT CUSTOMERS ARE SAYING

I want to say a big thank you for the business plan you sent. The plan is rich and detailed and professionally developed as explained on your web page. In fact the plan worth more than price. I have gone through the financial template and I have made some changes to suit my needs and would present it to my banker next. Am I going to present it together with the financial template or should I only present the business plan?

I have gone through the financial template and I have made some changes to suit my needs and would present it to my banker next. Am I going to present it together with the financial template or should I only present the business plan?

Can I also send it for you to help me review the financial before I submit?

Mrs. Esther Enudi

07031542324

utibeman(@)gmail.com

Thank you for reading this post, don't forget to subscribe!

Share this:

About the author.

3 thoughts on “Standard Cassava Processing Business Plan with 3 Years Financial Analysis”

HI can i get this biz plan for 5000

Am highly interested in cassava processing business plan. Can you please assist me to have it if I pay 5000 Naira?

This is very educative, lucrative and interesting

Leave a Reply Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Cost-Effective Cassava Processing: Case Study of Small-Scale Flash-Dryer Reengineering

- Open Access

- First Online: 07 April 2022

Cite this chapter

You have full access to this open access chapter

- Thierry Tran ORCID: orcid.org/0000-0002-9557-3340 6 , 7 ,

- Adebayo Abass 8 ,

- Luis Alejandro Taborda Andrade ORCID: orcid.org/0000-0001-7424-839X 9 , 10 ,

- Arnaud Chapuis ORCID: orcid.org/0000-0002-7833-2641 7 ,

- Marcelo Precoppe ORCID: orcid.org/0000-0002-7937-5782 11 ,

- Laurent Adinsi ORCID: orcid.org/0000-0001-8853-5445 12 ,

- Alexandre Bouniol ORCID: orcid.org/0000-0002-6140-424X 12 , 13 ,

- Makuachukwu Ojide ORCID: orcid.org/0000-0003-3254-8938 14 ,

- Suraju Adeyemi Adegbite ORCID: orcid.org/0000-0001-9904-4107 15 ,

- Simon Singi Lukombo ORCID: orcid.org/0000-0001-8561-4260 16 ,

- Murat Sartas ORCID: orcid.org/0000-0001-7331-4201 18 , 17 ,

- Béla Teeken ORCID: orcid.org/0000-0002-3150-1532 19 ,

- Apollin Fotso Kuate ORCID: orcid.org/0000-0002-5247-7519 20 ,

- Robert Ndjouenkeu ORCID: orcid.org/0000-0003-1808-5439 21 ,

- Martín Moreno ORCID: orcid.org/0000-0003-0326-8849 22 ,

- John Belalcázar ORCID: orcid.org/0000-0002-4418-2526 6 ,

- Luis Augusto Becerra López-Lavalle ORCID: orcid.org/0000-0003-3520-2270 6 &

- Dominique Dufour ORCID: orcid.org/0000-0002-7794-8671 7

9301 Accesses

2 Citations

The development and scaling out of flash-dryer innovations for more efficient, small-scale production of high-quality cassava flour (HQCF) and starch is described. The diagnoses of cassava-processing SMEs (small and medium enterprises) revealed their energy expenditures for drying were considerably higher than those of large-scale industrial companies, which was mostly due to suboptimal design of flash-drying systems. As a result, small-scale production of cassava starch and HQCF often incurs high production costs, incompatible with market prices of final products. Taking stock of this situation, RTB scientists have developed several innovations to optimize energy efficiency and costs, including a longer drying pipe, reengineered heat exchanger, larger blower for higher air velocity, and a higher product/air ratio. This was based on numerical modelling to determine the key design features of energy-efficient flash dryers, followed by construction and demonstration of a pilot-scale prototype. As a result, improved small-scale flash dryers are now being scaled out to the private sector in various countries, using the Scaling Readiness framework and achieving 10–15% gains in productivity and incomes. A method for diagnosis of process efficiency is also described, to identify technical bottlenecks and to document and measure the outcomes and impacts during the implementation of scaling-out projects.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Recent trends on energy-efficient solar dryers for food and agricultural products drying: a review

Innovative Technologies for Improving the Sustainability of the Food Drying Industry

An Innovative Hybrid Drying Technique for Parboiled Rice Production Without Steaming: an Appraisement of the Drying Kinetics, Attributes, Energy Consumption, and Microstructure

- Cassava processing

- Small-scale cassava flash dryer

- High-quality cassava flour

- Cassava starch

- Energy-efficient flash dryer

- Small and medium enterprises

- Energy efficiency

- Scaling readiness

1 Introduction

Postharvest processing is a key link between cassava crops and end products, determining the quality and food safety for consumers. Postharvest processing also contributes to food security by stabilizing and increasing the shelf life of perishable crops such as cassava and other roots, tubers, and bananas. Beyond product quality and safety, processing is also crucial for improving the sustainability of cassava value chains: by optimizing processing technologies, it is possible to reuse product waste while reducing energy and water consumption, product losses, production costs, and the overall environmental footprint of cassava industries. Processing is a crucial way for many small and medium farmer-processors to add value to their crops. From a gender perspective, especially in Africa, women are important in processing roles, so improving processing technologies can potentially improve their working conditions and increase their incomes. Women can benefit from processing innovations that match their dominant type of technology, i.e., small and medium scale (Taiwo and Fasoyiro 2015 ; Teeken et al. 2018 , 2021 ; Ndjouenkeu et al. 2021 ; Thiele et al. 2021 ). Processing innovations may also influence gender roles if new technologies change the processing scale or the level of involvement of different stakeholders in the value chain (Forsythe et al. 2015 , 2016 ).

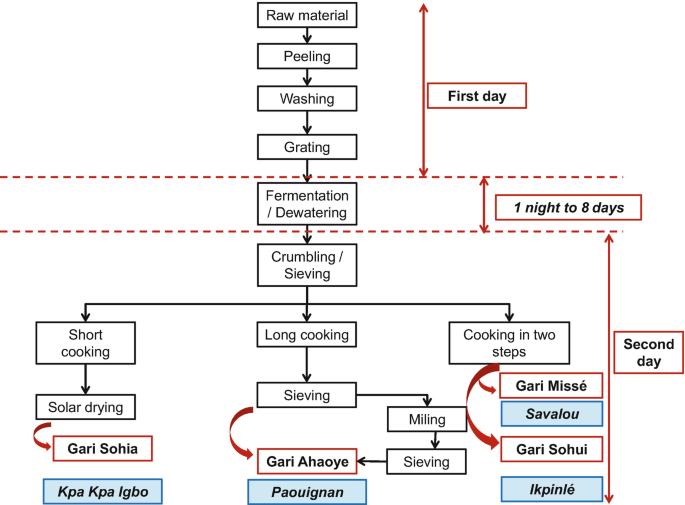

Postharvest processing of cassava involves several steps, called unit operations, to transform fresh roots into several finished products. Some unit operations are common to most cassava products, including washing, peeling, rasping/grating, and dewatering (pressing). Other unit operations are specific to certain products, particularly the cooking or drying operations such as toasting for gari, steaming for attiéké, sun drying for fufu and conventional cassava flour, and flash drying for high-quality cassava flour (HQCF) and starch. Lactic fermentation is also a specific unit operation used to preserve and confer a desirable sour taste to the end products (gari, fufu, chikwangue). Cassava processing generates large amounts of by-products (e.g., peels, fiber bagasse, and wastewater), which typically accumulate around the processing sites or pollute local water systems (Tran et al. 2015 ). Expansion of postharvest technologies must therefore include strategies for by-product management and processing to reduce environmental impacts and to create additional income streams for processors, most commonly animal feed, but also biomass to energy, such as solid fuel and biogas (Okudoh et al. 2014 ; Ozoegwu et al. 2017 ; Patrizi et al. 2020 ; Yank et al. 2016 ; Zvinavashe et al. 2011 ).

Over the past 20 years, research for development projects has identified the high potential of interventions in postharvest processing to improve working conditions and reduce inefficiencies in cassava value chains across Africa, Latin America, and Asia (Abass et al. 2013 , 2017 , 2018 ; Awoyale et al. 2017 ; Kuye et al. 2011 ; Dufour et al. 2002 ). Cassava processing is mainly a small-scale operation, in particular in Africa, at factories handling less than 5 tons of fresh roots per day or at household level. Current small-scale technologies are often suboptimal, resulting in high use of resources (energy, water, firewood, product losses) and high production costs (Adenle et al. 2017 ; Da et al. 2013 ; Kitinoja et al. 2011 ; Nzudie et al. 2020 ). Improving the efficiency of small-scale equipment, their design, safety, and ergonomics is therefore essential for the competitiveness of cassava value chains (Abass et al. 2018 ; Edeh et al. 2020 ; Oni and Oyelade 2014 ; Taiwo 2006 ; Nweke 1994 ), together with the ability of small-scale processors to access investment capital (Taborda 2018 ). The potential impacts of such interventions are to empower small-scale processors and farming communities to process more of their crops close to the production areas, resulting in more affordable products and increased food security and resilience against fluctuations in the prices of imported foods.

Improving cassava processing also encompasses food safety. African food products tend to have high microbiological and chemical contamination levels exceeding regulatory limits. Relative to industrialized countries, various deficiencies at government, sector, retail, and company levels affect performance of food safety management systems. Collective efforts needed to address food safety include developing stringent certification standards and product specifications, improving hygiene and control of raw materials, enhancing monitoring systems, developing quality assurance and supportive administrative structures, developing risk-based legislative frameworks, and strengthening food safety authorities (Kussaga et al. 2014 ).

As a staple crop, cassava cultivation and processing tend to expand in lockstep with growing populations in developing countries. From this perspective, improving the efficiency of cassava processing technologies is crucial to minimize resource consumption and environmental footprint and to avoid a business-as-usual scenario whereby current inefficient technologies multiply to handle increasing volumes of cassava, leading to unsustainable levels of pollution and resource depletion in the face of climate change and other environmental risks. This issue also has important gender ramifications: “An analysis of distributive impacts of the environment on human well-being cannot ignore features such as gender. […] Women and girls often carry a disproportionate burden from environmental degradation compared to men” (UNEP 2007 , p 15).

In recent years, researchers federated under CGIAR’s Research Program on Roots, Tubers and Bananas (RTB) have made vital contributions to a range of products and to the links between processing, product quality, and consumer expectations (Escobar et al. 2021 ; Adinsi et al. 2019 ; Alamu et al. 2019 ; Bouniol et al. 2021 ; Luna et al. 2021 ). This chapter presents the reengineering and scaling out of flash-drying technology for small-scale cassava processing, supported by the development of a methodological framework for R&D on postharvest processing of cassava.

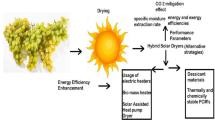

2 Optimization of Energy Efficiency for Drying of Starch and Flours

In countries with industrial production of cassava starch, such as Thailand, Vietnam, Brazil, and Paraguay, large factories produce 50–400 tons of starch per day. These factories use large, highly efficient pneumatic-conveying dryers known as flash dryers (Brennan 2011 ; Sriroth et al. 2000 ; Aichayawanich et al. 2011 ). Even so, drying often has the highest processing cost due to the energy needed for heating. In contrast, in most cassava-producing countries, less intensive cassava production, limited transport infrastructure, and a tradition of small-scale household or family-based working units predominantly using manual labor do not permit the development of large factories. As a result, most cassava processing into flour and starch for food consumption or industrial applications is done at small scale, with an average production capacity of 1–3 tons/day (Adegbite et al. 2019 ). Such processing systems are beneficial in providing jobs for many in the community, including women, thus contributing to social stability and reducing migration to cities. From that perspective, proposed technical innovations and related efficiency gains imply a trade-off between the risk of job losses and the prospect of lower production costs and consequently higher incomes for processors and lower food prices for consumers. At any rate, small-scale processing is often affected by low investment capacity and limited repair-and-maintenance services, slowing down the adoption of technical innovations.

For drying, many processors still rely on sun drying, which is low cost but has limitations, including being subject to the weather, the limited availability of flat surfaces, and contamination from animals, dust, or microbes (Precoppe et al. 2020 ; Alonso et al. 2012 ). This is a particular disadvantage to access larger markets that need regular, all-year-round supply and consistent quality (Dziedzoave et al. 2006 ). Attempts to solve these limitations in the past 20 years have involved scaling down the design of large-scale flash dryers. However, so far, there has been little use of the resulting models of locally built, small-scale flash dryers due to high energy consumption related to suboptimal design and consequently high production costs incompatible with market prices of final products. For instance, in Nigeria between 2006 and 2016, 157 cassava processors have invested in “first-generation” flash dryers to produce HQCF, most of which are no longer in use in spite of some improvements (Ojide et al. 2021 ).

Taking stock of this situation and given the strategic importance of efficient postharvest processing for the sustainable expansion of cassava value chains, research initiated in 2013 by RTB identified several critical points to optimize energy efficiency and minimize the operating costs of small-scale flash dryers. This research was based on numerical modelling of flash drying (Chapuis et al. 2017 ) and validated through the construction and testing of a pilot-scale dryer (capacity, 100 kg/h) at the International Center for Tropical Agriculture (CIAT, Colombia) that achieves the same energy efficiency as large-scale industrial flash dryers. The Scaling Readiness framework was then applied to scale out this innovation to cassava processors.

3 What Is an Efficient Dryer? Definition and Expression of Drying Efficiency and Affecting Factors

Drying of flour and starch consists of removing water by thermal treatment, inducing a phase change, generally from liquid to gas. Flash dryers use convective drying, i.e., applying a hot air stream to the product. Evaporation of liquid water requires an important quantity of energy, called latent heat of vaporization. Its value of 2500 kJ/kg of water is thermodynamically incompressible and sets the minimum energy requirement for drying. In real drying systems, energy losses are unavoidable, so an energy consumption of 3000–4000 kJ/kg water is considered efficient.

In practice, energy is delivered to the dryer by heating the air flowing into the system. Gas burners are convenient because they produce combustion gases clean enough to be in contact with the product, even food. Otherwise, heating systems using fuels such as diesel, fuel oil, or biomass require a burner coupled to a heat exchanger. These systems are more common because they allow using cheaper and widely available fuels, thus reducing operating costs.

During drying, the hot air releases heat to evaporate water and cools down as it absorbs water vapor. Efficient drying, i.e., maximum water evaporation, requires good exchange area and contact time between the air and the product and good mixing (turbulence) to promote heat exchanges. Many drying technologies are available depending on the product to dry. Flash dryers are among the most efficient for granular materials (Crapiste and Rotstein 1997 ), as they maximize the exchange area between air and suspended solids (Saravacos and Kostaropoulos 2016 ). The capacity of air to hold water vapor is limited by phase equilibrium and increases with temperature (hot air can hold more water). Therefore, the higher the initial temperature of the drying air, the better, without damaging the product. As an illustration, air heated to 200 °C can absorb 60 g water/kg air, three times more than at 80 °C (20 g water/kg air). Under optimum drying conditions, the exhaust air is saturated with moisture, and the product has reached the target moisture for a long shelf life, i.e., 12–13% wet basis (wb) in the case of starch and flour.

Finally, mechanical dewatering to reduce the water content before drying is also important, as it requires much less energy and is more cost-effective than drying by evaporation (Mujumdar 2006 ). As an illustration, drying HQCF to 12% moisture content from an initial 40% (after good dewatering) requires 1860 kJ/kg of final product, assuming a dryer using 3500 kJ/kg of water evaporated. If starting from an initial 50% moisture content (after inefficient dewatering), drying requires markedly more energy at 3020 kJ/kg of product.

4 Key Design Components for Efficient Small-Scale Flash Drying

4.1 surveys on flash-dryer designs and energy efficiency.

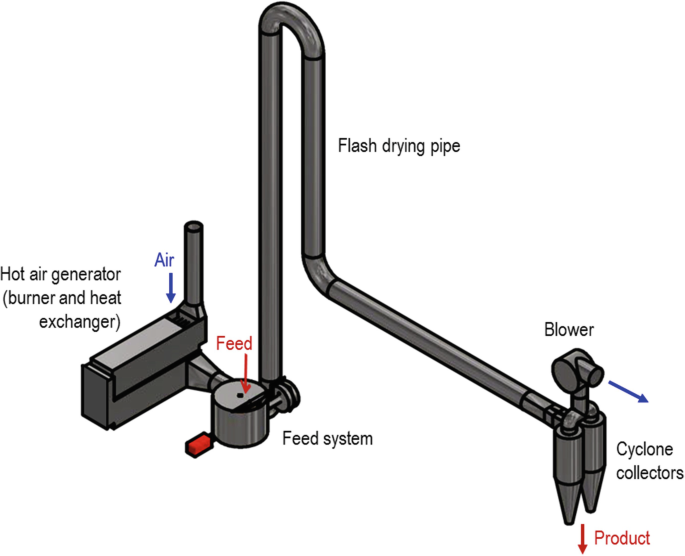

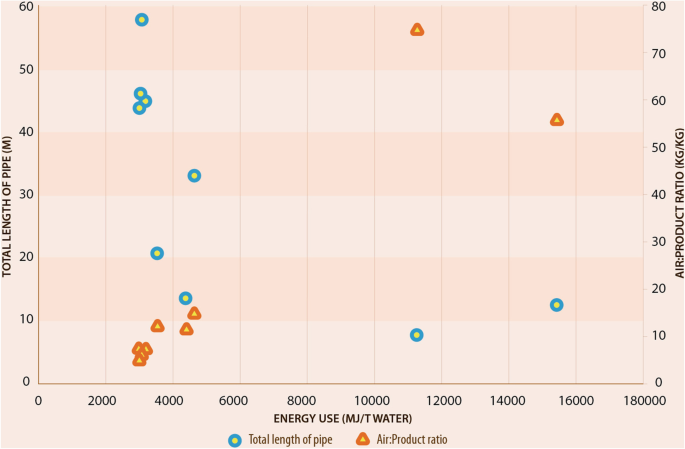

The first action of the RTB initiative to improve energy efficiency of small-scale flash drying consisted of a survey of processors owning flash dryers in various countries (Thailand, Vietnam, Tanzania, Nigeria, Colombia, and Paraguay) to identify common design features underpinning energy efficiency, such as dimensions and operating conditions (Tran et al. 2015a , b , c ; Saengchan et al. 2015 ). The physical properties of cassava particles before and after flash drying were also studied (Romuli et al. 2017 ). While the drying principle and key components remained the same across all flash dryers (Fig. 4.1 ), important variations in designs, dimensions, and operating conditions were observed (Fig. 4.2 , Table 4.1 ). Large-scale dryers had longer drying pipes (20–57 meters) than small-scale ones (7–15 m). The quantity of air used for drying varied more than tenfold between dryers, with air-to-product ratio ranging from 6 to 75 kg of air/kg of product (Table 4.1 ). Small-scale dryers tended to use more hot air per kg of product, resulting in higher energy use and drying costs.

Key components common to all flash-dryer designs

Diversity of flash-dryer designs in Thailand, Nigeria, Paraguay (dryer model from Brazil), Paraguay (dryer model from Sweden), and Argentina

Standardized drying costs ranged from 23 USD up to 400 USD/t of product (Table 4.1 ), assuming for comparison purpose that all the flash dryers used diesel fuel (energy density, 40 MJ/L; price, 1 USD/L). In reality, flash dryers are powered by various fuels, renewable or nonrenewable, including wood, biogas, agricultural biomass (palm oil kernel, cashew nut kernels), liquefied petroleum gas (LPG), heavy fuel oil, diesel, black oil (a mixture of kerosene and used motor oil), and coal. Processors owning flash dryers with high fuel consumption manage to keep drying operations profitable by using cheaper fuels than diesel. Nevertheless, flash dryers with high fuel consumption reduce the profitability of processing and contribute to small-scale factories abandoning production of HQCF or starch, often at a significant loss on their investment. In Nigeria, a recent survey of 41 HQCF processors to ascertain current perceptions on flash dryers found that 50% of them have stopped producing in the past 10 years and that most see their market prospects as limited (Ojide et al. 2021 ). Processors who remain in operation have done so through cost-saving measures: being near the source of raw materials and the end-product market, thus cutting transportation costs; replacing petroleum-based fuels with more economical coal or agricultural biomass; and diversification to produce gari or fufu when there is no demand for HQCF.

Given the small profit margins in HQCF production, small-scale processors currently select cheaper fuels, without considering the environmental costs of more polluting fuels. As a result, nonrenewable hydrocarbon fuels are still widely used. Cleaner renewable fuels such as biogas may become viable options for small-scale processing in the future, as long as the greater use of renewable energies does not also incentivize the burning of firewood, which would exacerbate deforestation. Renewable fuels are possible, and investments by large-scale cassava starch factories to generate biogas from factory wastewater can substantially reduce both drying costs and environmental impacts (Hansupalak et al. 2016 ).

The surveys revealed the absence of a consensus design among flash dryers. These variations in design and ultimately in energy efficiency and drying costs suggest that there is a huge potential for optimization, with benefits in terms of production costs and environmental impacts (fossil fuel consumption and greenhouse gas emissions). The surveys were thus followed by an in-depth study of the technical characteristics needed to achieve energy-efficient flash drying.

4.2 Numerical Modeling of Flash Drying Provided Design Guidelines for Energy Efficiency

Several physical phenomena govern drying kinetics of a particle in suspension: heat transferred from the air to the particle causes water to evaporate from the surface, which, in turn, causes water within the particle to diffuse toward the surface. At the same time, the particle is entrained by the air flow along the drying pipe. These phenomena are described using conservation equations of mass, momentum, and heat (Mujumdar 2006 ). In the case of starch and flour, the slowest phenomenon is the diffusion of water within the particles; therefore, the size of the particles and their residence time in the dryer are critical for quick drying.

Applying this theoretical framework to flash drying, a numerical model was developed to simulate various designs and predict energy efficiency and final moisture content of cassava flour and starch (Chapuis et al. 2017 ). The technical data collected during the surveys (Sect 4.4.1 ) were used to validate that the model gave accurate drying predictions. Deviations between predicted data and actual data were satisfactorily low (less than 10%) for moisture content of the end product, air temperature after drying, and energy consumption.

The numerical model was applied to investigate optimum dryer designs that minimize energy consumption and maximize the quantity of water evaporated per unit mass of hot air (Sect. 2.1 ). The main challenge was to identify a configuration where the hot air carried just enough energy to dry the product flow rate (thermodynamics design objective) and the particles stayed in contact with the hot air long enough for complete heat and water transfers (kinetics design objective). Numerical simulations showed that such configuration could be attained through the following key design components:

The target production capacity of the flash dryer defines the flow rate of water to evaporate, or drying rate (kg water evaporated/h):

Drying rate = MassFlowProductIn*MoistureIn - MassFlowProductOut*MoistureOut , where MassFlowProductIn = MassFlowProductOut*(1-MoistureOut)/(1-MoistureIn) .

The drying rate in turn defines the minimum energy input for drying and hence the required quantity of hot air to enter the dryer, or air mass flow . For efficient drying, the minimum energy input (or specific energy use) should aim for 3000 kJ/kg of water evaporated. Then.

HeatInput (kW) = SpecEnergyUse (kJ/kg)*DryingRate (kg/h)/3600 and

AirMassFlow (kg/h) = 3600*Heatinput / (HeatCapacity*(TempAirIn-TempAirAmb)) , where HeatCapacity = 1.01 kJ/K/kg.

For instance, drying from 38% to 12% moisture, using initial air temperature of 180 °C, requires about 10 kg of air per kg of final product.

Air velocity must remain high enough to keep the particles in suspension. For particles of typical size distribution (10 μm up to 2 mm), the threshold for suspension is 8–9 m/s. Air velocity should be set above the threshold, typically 12 m/s, as a safety margin. A long drying pipe (20 m or longer) gives flexibility to use higher air velocities to increase the dryer capacity without affecting energy efficiency significantly.

Air mass flow and air velocity in turn define the section and diameter of the pipe :

PipeSection (m 2 ) = AirMassFlow/(3600*AirDensity*AirVelocity) , with AirMassFlow in kg/h and AirVelocity in m/s. AirDensity (kg/m 3 ) depends on temperature (0.77 kg/m 3 at 180 °C).

The residence time for the product to fully dry depends on the particle size, initial moisture content, initial air temperature, and air velocity. For typical drying conditions of cassava starch or HQCF, a residence time of 2 s is recommended.

The length of the drying pipe is defined by residence time and air velocity, but also input moisture content and initial air temperature. A length of 17 meters is a minimum, and 20 meters or longer is recommended for energy efficiency and stability of operations. A dryer with a longer pipe is more versatile for handling variations in product moisture, air temperature, and air velocity while delivering stable moisture content in the final product.

Finally, initial air temperature should be as high as possible without damaging the product (Sect. 2.1 ), with optimum between 180 and 200 °C.

These findings helped to interpret the surveys, according to which longer pipe and lower air/product ratio achieve better energy efficiency (Table 4.1 and Fig. 4.3 ). Approaches to improve the less efficient, small-scale flash dryers were identified: First, all small-scale flash dryers surveyed had short drying pipes (7.7–13.6 m), which should be extended to 20 m to increase residence time and water evaporation. Second, with a longer drying pipe, the air/product ratio can be reduced by increasing the feed rate of the product.

High energy use by flash dryers is correlated with shorter pipe and high air/product ratio. Each point represents a different model of flash dryer (Table 4.1 )

To validate these conclusions, the next step was to build and test a prototype of a small-scale flash dryer with adjustable pipe length and adjustable air velocity.

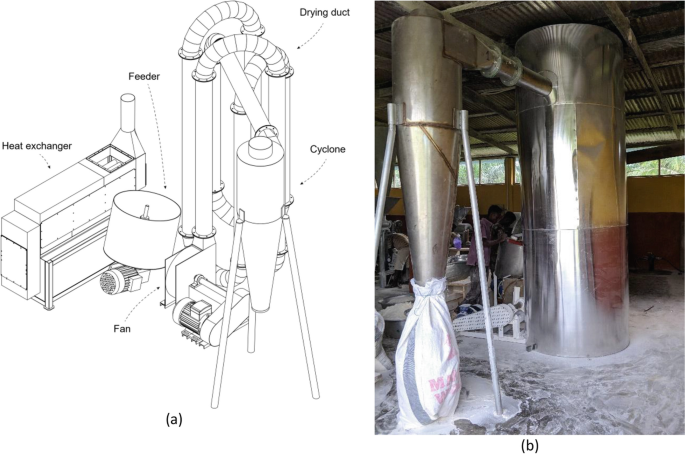

4.3 Prototype Flash Dryer Confirmed That High Energy Efficiency at Small Scale Is Achievable

Numerical simulations indicated that energy-efficient flash drying at small scale was achievable. To validate these results through actual experiments, a prototype flash dryer (100 kg/h capacity) was designed and built at CIAT (Cali, Colombia) in 2017 (Fig. 4.4 ). In addition to integrating the key design components (Sect. 4.4.2 ), the following elements were also essential for operating the dryer:

Regulated feed system : Wet cassava flour or starch is a semi-sticky powder with a tendency to form clumps during handling. Accordingly, the feed system was composed of a cylindrical hopper equipped with stirring paddles to prevent caking and powder bridging and discharging into an endless screw conveyor leading to the drying pipe. A pin mill located between the screw and the drying pipe disaggregated clumps, to minimize particle size and maximize the exchange surface. The speed of the endless screw was regulated by a feedback loop maintaining the temperature of the air stable after drying (setpoint 55 °C). This regulation maintained a stable moisture of the end product, maximized energy efficiency, and reduced fuel consumption and costs. This control strategy can be implemented by manually reading the air temperature after drying and by manually adjusting the feeding rate; however, an automatic temperature controller (PID) is more effective.

Conveying system and collection system of the dry product: Inside the drying pipe, air and product are kept in movement with a blower, which can be located at the beginning or at the end (positive or negative pressure, respectively). Negative pressure is recommended because the blower is located after the cyclone that collects the dry product, which requires less power as the air is cooler (55 °C). Moreover, after the cyclone, the air is free of solid particles, which reduces wear and breakdowns and allows using a blower with more efficient curved blades (as opposed to straight blades). On the other hand, negative pressure requires that the bottom output of the cyclone be closed with a rotary airlock valve to prevent the product from being re-entrained into the cyclone.

In a positive-pressure system, the blower is located at the beginning of the pipe after the feed system and needs to be bigger to move the same quantity of air as an equivalent negative-pressure system due to the higher temperature (150–180 °C) and lower air density. The power consumption of a positive-pressure blower is thus 50–100% higher. Another drawback of positive pressure is that the product passes through the blower, which requires more maintenance and allows only less efficient straight blades to avoid accumulation of product on the blades. On the other hand, in positive-pressure dryers, a single flap valve at the bottom of the cyclone is sufficient instead of a rotary airlock valve.

Hot air generator (burner and heat exchanger): Common fuels such as diesel or biomass generate fumes and particles, which must be kept separated from the product that is being dried. For small-scale dryers, this is achieved through an air-air heat exchanger installed with the burner. Current models are mostly single pass concentric pipe type, with sub-optimum efficiency. The RTB team developed an improved heat exchanger integrating the following:

Counter-current flow of the combustion fumes and fresh air

Increased heat exchange surface through a bundle of thin smoke pipes for the combustion fumes, around which fresh air circulates in a series of chambers with chicanes

Increased turbulence of the flow of fresh air forced to pass through the chicanes (Fig. 4.5 ). This design increased air outlet temperature while reducing fuel consumption

Flash-dryer prototype installed at CIAT

( a ) Cut view of the counter-current improved air-air heat exchanger developed by RTB; ( b ) one of the six heat exchangers built during the scaling-out phase of the project. (Source: Authors and Agrimac Ltd, DR Congo)

Alternatively, if a distribution network of LPG is available, the heat exchanger system can be replaced with a direct-combustion LPG gas burner, which reduces fuel consumption (by 10–15%) and investment costs compared to a system with a heat exchanger.

The performance of the prototype flash dryer was assessed under diverse operating conditions (Table 4.2 ). High energy efficiency was achieved with a pipe longer than 17 m, with specific energy consumption in the range 3300–4000 kJ/kg of water evaporated (Table 4.2 ). These figures are slightly higher than for large-scale dryers due to higher surface-to-volume ratio and consequently higher heat losses in smaller equipment (Kemp 2012 ). The best energy efficiency was obtained with a 20-m-long pipe (3268 kJ/kg water) and high air velocity (24 m/s).

The numerical model predicted that high air velocity would increase specific energy use due to shorter residence time and consequently incomplete drying. On the contrary, actual performance tests indicated that increasing air velocity is not necessarily detrimental (Table 4.2 ). A possible explanation is that higher air velocity also reduces particle size (a factor not included in the numerical model) through increased collisions, thus intensifying the drying. Consequently, when the drying pipe is long enough (>20 m), increasing air velocity may substantially increase drying capacity, without affecting energy efficiency.

Design guidelines and tools resulting from this RTB initiative are available from the authors upon request.

5 From Prototype to Technology Transfer: Optimization of Feeding Rate for Energy Efficiency of a Small-Scale Flash Dryer in Ghana

5.1 introduction.

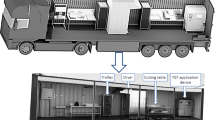

After demonstrating the energy efficiency of the small-scale flash-dryer prototype, the RTB research team moved to transfer these findings to the private sector. Processors from several countries expressed interest (DR Congo, Nigeria, Ghana, Cameroon, Uganda, Tanzania, Colombia, Brazil, and the Dominican Republic) to reduce operating costs and/or increase production of HQCF or starch. Reasons cited included growing demand for HQCF for industry or to replace sun-dried cassava flour, which consumers increasingly see as lower quality due to contamination during drying. Underpinning these trends was ongoing economic development with the emergence of a larger middle-class and more urban consumers with higher incomes. In 2018, a small-scale energy-efficient flash dryer was developed and put into commercial use in the Central Region of Ghana. This provided an opportunity to further evaluate the effect of feeding rate on energy efficiency, following previous findings by Precoppe et al. ( 2016 ).

5.2 Materials and Methods

Drying procedure and processing equipment.

At the partner processing center in Ghana (Tropical Starch Company Ltd.), cassava roots are peeled and washed manually and mashed using a mechanical grater. The mash is dewatered with a screw-operated press. The resulting press cake is pulverized into wet grits using another mechanical grater. The wet grits are fed into a pneumatic dryer, and the resulting dried grits are milled into flour. The pneumatic dryer was developed with joint funding from RTB and the Cassava: Adding Value for Africa project (CAVA II). CAVA-II partners (equipment manufacturers and Tropical Starch Company Ltd.) were given training on the design and construction of small-scale pneumatic dryers, including the key design components described in Sect. 4.4.2 . The equipment was constructed with stainless steel and thermally insulated with 50-mm-thick mineral wool, shielded with aluminum sheeting (Fig. 4.6b ). The drying duct had a diameter of 0.18 m and a length of 24.84 m. To reduce the height of the equipment, the drying duct was divided into seven vertical meandering sections (Fig. 4.6a ). Air flow was forced by a centrifugal 7.5-kW blower located at the start of the drying duct, just after the feeding point (positive-pressure system). The design point used for the blower construction was an air mass flow rate (dry basis, db) of 550 kg/h and a static pressure of 10.2 hPa. Air was heated by a 70-kW diesel burner (model B14; Bairan, Wenling, China) and the improved RTB heat exchanger (Fig. 4.5 ). Drying air temperature was thermostatically controlled with the sensor placed at the dryer inlet, between the heat exchanger and the feeding point.

( a ) Isometric view and ( b ) the pneumatic dryer in Ghana

Experimental design

The energy performance of the dryer was first evaluated following the processing center’s drying procedure, with no interventions other than sampling material and recording drying conditions. Based on the data collected, the feeding rate was adjusted to optimum value, and the data collection was repeated. Data were collected over six consecutive days (recording 5 hours/day), the first 3 days with the original feeding rate and the subsequent 3 days with the optimum feeding rate. Data collection started after the dryer had been in operation for 1 hour to ensure steady-state conditions.

Statistical analyses

Statistical analyses were performed with SAS 9.4 (SAS Institute Inc., Cary, NC, USA) software, following a comparative experimental design (Precoppe et al. 2016 ) with three replicates and two treatments: before and after the adjustment on the feeding rate. One-way analysis of variance (ANOVA) was performed, and to determine whether the pairwise difference comparisons were significantly different, Fisher’s Least Significant Difference (LSD) was used at a 5% level of significance.

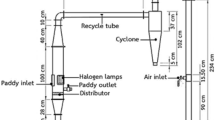

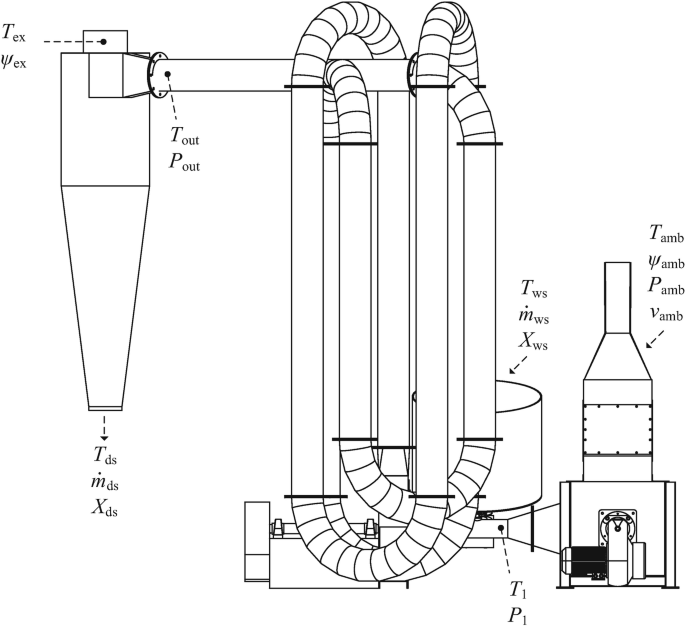

Data collection

Temperatures, relative humidity, pressures, and air velocities were measured at various points on the dryer (Fig. 4.7 ) with suitable sensors connected to a wireless data logger (LOG-HC2-RC, Rotronic) recording values at 1-minute intervals. Mass flow rates of wet and dry cassava grits were measured using a digital balance (AWB120; Avery Weigh-Tronix, Smethwick, UK) and a chronometer. Samples of wet and dried cassava grits were collected at 1-hour intervals for moisture content analysis (3 h at 103 ± 1 °C in a convection oven) according to AOAC 935.29 (AOAC 1998 ).

Measurements on the pneumatic dryer in Ghana. T , temperature; ψ, relative humidity; P , pressure; v , air velocity; ṁ , mass flow rate; X , moisture content; ws, wet cassava grits; ds, dry cassava grits; amb, 1, out, and ex refer to air characteristics at various points of the dryer

5.3 Calculations

Energy performance.

Psychrometric calculations used the formulas provided by British Standard ( 2004 ). Energy performance was calculated as described by Precoppe et al. ( 2016 ). The solid mass flow rate ( ṁ dm , db) was calculated based on ṁ ws and the moisture content of the wet cassava grit. Heat input rate to the dryer ( Q̇ in ) was calculated based on air temperature, relative humidity, and air flow rate ( ṁ air ) at the dryer inlet. Water evaporation rate ( ṁ w ) was calculated using ṁ ws and the difference in moisture content between the wet and dried cassava grits. Specific heat consumption ( q s ) was calculated dividing Q̇ in by ṁ w , and energy efficiency ( η ) was calculated dividing the heat used for moisture evaporation ( Q̇ w) by Q̇ in . Finally, specific heat utilization ( q u ), i.e., energy consumption per kg of dried product, was calculated dividing Q̇ in by ṁ dm .

Optimum feeding rate

The dryer’s original feeding rate was 65.7 ± 11.4 kg.h −1 . This rate was adopted by trial and error by the operators of the flash dryer over a period of 1 year of use. With this feeding rate, T out was 67.3 ± 4.9 °C, and ψ out , calculated using T ex and ψ ex , was 37.6 ± 8.7%. At this temperature and relative humidity, the enthalpy at the dryer outlet ( h out ) was 249.9 ± 15.5 kJ.kg −1 . Based on these values, the lowest allowable air temperature at the dryer outlet was \( {T}_{\mathrm{out}}^{\ast } \) = 60 °C (Precoppe et al. 2016 ). Keeping h out unchanged \( \left({h}_{\mathrm{out}}={h}_{\mathrm{out}}^{\ast}\right) \) and reducing \( {T}_{\mathrm{out}}^{\ast } \) to 60 °C, the highest allowable relative humidity at the dryer outlet \( \left({\psi}_{\mathrm{out}}^{\ast}\right) \) can be raised to \( {\psi}_{\mathrm{out}}^{\ast } \) = 53%. Keeping the other settings unchanged and monitoring the air at the dryer outlet, the feeding rate was gradually increased until T out approached \( {T}_{\mathrm{out}}^{\ast } \) and ψ out approached \( {\psi}_{\mathrm{out}}^{\ast } \) . At this point, the optimum feeding rate was determined to be 98.6 kg.h −1 , a 50% increase compared to the original configuration.

5.4 Results and Discussion Regarding the Small-Scale Flash Dryer in Ghana

Dryer operating conditions.

Adjusting the dryer to optimum feeding rate increased the output of dried cassava grits from 42.2 ± 7.3 kg.h −1 to 65.0 ± 5.5 kg.h −1 , a 54% increase in productivity without increasing energy consumption (Table 4.3 ). Input parameters independent from the feeding rate, i.e., air temperature at inlet and moisture content of wet cassava grits, were unchanged between the treatments. The moisture content of the dried cassava grits (0.14 kg.kg −1 ) was unchanged as well, confirming that it is possible to increase the feeding rate to its optimum without altering the quality of the end product.

The T 1 values seemed high for food drying (Kudra 2009 ); nevertheless, short residence times in pneumatic dryers allow the use of high temperatures without jeopardizing product quality (Pakowski and Mujumdar 2014 ). When drying cassava, the temperature of the product (T ds ) must remain below 56 °C to avoid starch gelatinization (Breuninger et al. 2009 ), which was realized both before and after adjusting the feeding rate.

The water evaporation rate is driven by heat input to the dryer and by the amount of material (Kudra 2009 ). Increasing the feeding rate to optimum value increased the evaporation rate, which significantly improved the energy performance of the dryer (Table 4.3 ). Heat input rate is independent from the feeding rate and hence remained unchanged.

Energy efficiency at optimum feeding rate (72.1%) was close to the top of the range reported for pneumatic dryers (50–75%, Strumiłło et al. 2014 ) but still lower than the values reported by Sriroth et al. ( 2000 ) for large-scale pneumatic dryers. Small-scale dryers inevitably have an unfavorable surface-to-volume ratio that results in higher heat losses (Kemp 2012 ). The higher feeding rate increased the solid loading ratio of the drying air; nevertheless, the conveying mode remained in the dilute phase, and pneumatic transport was not jeopardized.

5.5 Conclusions: The Small-Scale Flash Dryer in Ghana

This case study in a commercial setting confirmed that small-scale flash dryers for HQCF can achieve high energy efficiency similar to large-scale dryers. Adjusting the feeding rate to its optimum value also improved energy performance significantly and is easier to implement than adjusting the air flow rate as it does not require hardware changes.

6 Applying Scaling Readiness to Scale Out Flash-Drying Innovations to DR Congo and Nigeria: Successes and Lessons Learned

6.1 scaling readiness framework.

Scaling Readiness is a stepwise approach for analyzing the characteristics of innovations from a scaling-out perspective, diagnosing the issues (bottlenecks) that hinder scaling out, developing optimum scaling strategies, building common agreements with the key stakeholders on the strategy, monitoring and learning from the implementation of the agreed strategies, and finally updating the strategies accordingly (Sartas et al. 2020a ). Scaling Readiness analyzes the core innovation by breaking it down into complementary innovation components. “Innovation Readiness” refers to the demonstrated capacity of the innovation to fulfill its contribution to development outcomes in specific locations. This is presented in nine stages showing progress from an untested idea to a fully mature, proven innovation. “Innovation Use” indicates the level of use of the innovation or innovation package by the project members, partners, and society. This shows progressively broader levels of use beginning with the intervention team who develops the innovation to its widespread use by users who are completely unconnected with the team or their partners. “Scaling Readiness” of an innovation is a function of innovation readiness and innovation use. Table 4.4 provides summary definitions for each level of readiness and use, adapted from Sartas et al. ( 2020a ).

Readiness and use levels are evaluated using conceptual, applied, and experimental evidence. Scaling Readiness helps to identify the gaps in the design of the innovations and to prioritize the research and engineering work to address these gaps (Sartas et al. 2020b ). The Scaling Readiness framework is discussed in more detail in Chap. 3 .

Building on previous steps (Sects. 4.4 and 4.5 ), the RTB research team applied Scaling Readiness to support the scaling out of the flash-dryer innovation in the private sector in DR Congo and Nigeria, as a first case example of applying Scaling Readiness to a postharvest processing industry (Table 4.5 ).

6.2 Identification of the Innovation Package and Determination of the Innovation Readiness and Innovation Use of Each Innovation Component

In the RTB flash-dryer case, the complementary innovations were identified collaboratively with stakeholders. Small-scale processors of cassava flour (1–3 tons of flour/day) and equipment manufacturers from Nigeria and DR Congo were interviewed to generate a baseline of the technical and socioeconomic conditions of potential scaling project partners. In Nigeria, the cassava processors were selected based on being active in the cassava processing business or continuous processing operations in their factories. Equipment manufacturers were pre-selected based on experience in the commercial manufacture and sale of flash dryers. For sustainability of the flash-dryer innovation, the final selection gave priority to relatively younger manufacturers willing to learn new technology innovations. In DR Congo, flash-dryer manufacturing and use are new but with high potential to improve the quality and food safety of conventional sun-dried cassava flour. Only two local equipment manufacturers had exposure to flash dryers, and three processors were using flash dryers. All three processors and one equipment manufacturer were selected. The scaling partners explained the constraints of the current flash-dryer models (in particular high fuel consumption) and the expected performance improvements.

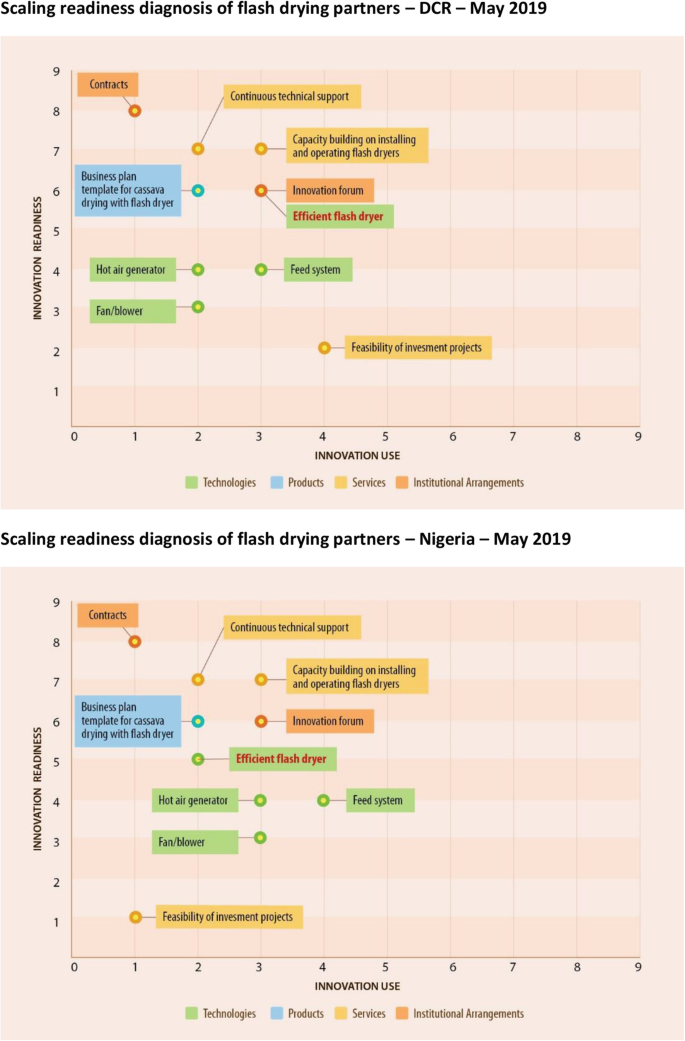

Based on on-site visits and interviews with stakeholders of the cassava value chains, scaling partners, and researchers, 16 innovation components were identified, of which ten were essential for the scaling process: four core technical innovations and six complementary innovations related to capacity building and the socioeconomic context of scaling out. The Scaling Readiness assessment showed varying levels of innovation readiness and use depending on the country (Fig. 4.8 ).

Innovation Readiness and Innovation Use of the cassava flash-dryer innovation package in DR Congo and Nigeria after the Scaling Readiness assessment (May 2019). Core innovation components (technologies) are presented in green and complementary innovations in blue (products), yellow (services), and orange (institutional arrangements)

In both Nigeria and DR Congo, the levels of use and readiness of the technical components were relatively low (2–4 and 3–6, respectively). Nigeria had slightly higher levels of use of the feed system, hot air generator, and blower components. On the other hand, the readiness of the core innovation, i.e., efficient flash dryer, was higher in DR Congo. The main reason for this disparity was because at the beginning of the project, Nigeria had markedly more first-generation flash dryers in operation (higher use), albeit less efficient (lower readiness) than DR Congo. The levels of use and readiness of the complementary innovations were similar in both countries, except the feasibility of investment projects: in DR Congo, processors evaluated feasibility frequently (although with informal tools) due to the perceived market potential of producing HQCF, whereas in Nigeria, investment was seldom considered due to perceived adverse market conditions.

Based on this analysis, bottlenecks, i.e., innovation components with low use and readiness levels, were technical in DR Congo (hot air generator, blower) and economical in Nigeria (feasibility of investment). The strategy of the RTB research team then consisted of identifying and implementing targeted interventions to improve the innovation components and move the innovation package as a whole toward higher levels of readiness and use.

6.3 Scaling Strategy and Key Partnerships to Scale Out Flash-Drying Innovations to DR Congo and Nigeria

Project partners were all small-scale processors but with differences among them, in terms of:

Investment capacity.

Factory setup, i.e., different models of machines and management of operations.

Quality of the final product expected by customers, which requires different processing techniques prior to drying. For example, lactic fermentation is a key step for fufu in DR Congo, which is not required for HQCF in Nigeria.

Administrative and labor management: eight of the ten project partner operations are managed by the owners and two by hired managers. Most managers and workers are men, and only two out of ten project partners were managed by women. Female labor is used for specific, low-paid operations such as root peeling.

On the other hand, most processors shared common concerns, such as the need to decrease fuel consumption (DR Congo and Nigeria) or finding a stable, consistent market for small-scale HQCF production (Nigeria).

After identifying the innovation bottlenecks, the scaling strategy developed and agreed upon with the scaling partners followed four key steps:

Planning and delivering a training workshop to share and address the bottlenecks with scaling partners (equipment manufacturers and HQCF/starch processors). This included a presentation of the findings of the Scaling Readiness assessment and training on technical and socioeconomic aspects of flash drying, such as tools to calculate optimum dimensions and operating conditions and business plans to estimate investments costs, operating costs, and return on investment.

Implementation of the business plans by the scaling partners willing and able to do so. The process involved back-and-forth exchanges between cassava processors and the project team to develop business plans adapted to each partner’s circumstances. Realistic investment costs were provided by the equipment manufacturers who participated in the workshop. Some of the processors then used the resulting business plans to present their investment projects to banks or private investors. For those who invested their own money, the business plan contributed to accurate evaluation and of planning of the investment.

Design, construction, and commissioning of flash dryers by the scaling partners with continuous support from project scientists, through on-line technical consultations and regular on-site visits.

End-of-project debriefing workshop and evaluation of outcomes and lessons learned.

6.4 Results and Outcomes of Scaling Out Flash-Drying Innovations to DR Congo and Nigeria

By its completion in December 2020, the RTB Scaling project on flash-drying innovations fostered investment in energy-efficient, small-scale flash dryers by seven cassava processors: five in DR Congo and two in Nigeria. In addition, two demonstration flash dryers were built for promotion and training at two R&D institutions: the Federal Institute of Industrial Research Oshodi (FIIRO) in Nigeria and the International Institute of Tropical Agriculture (IITA) in Eastern Congo. Five equipment manufacturers were involved in constructing these improved flash dryers and are now well positioned with practical experience to build further dryers as new investors come forward in the future.

In terms of efficiency gains, performance evaluation of the improved flash dryers that have reached commercial operation indicated a 23 to 50% increase in production capacity (from 10 to 12–15 tons of flour/month) and at the same time a 30 to 33% reduction in fuel (diesel) consumption per kg of product, compared to the situation before the project. Feedback from the flash-dryer operators in DR Congo after incorporating the RTB innovations resulted in much improvement in drying efficiency: A processor reported that re-setting the heat exchanger burner and air inlet decreased the fuel consumption by 30% while other adjustments suggested by the project team resulted in an increase in the flour output from 150 to 250 kg/h. As a result, cassava processors reported an increase in net profitability of 8% to 10%.

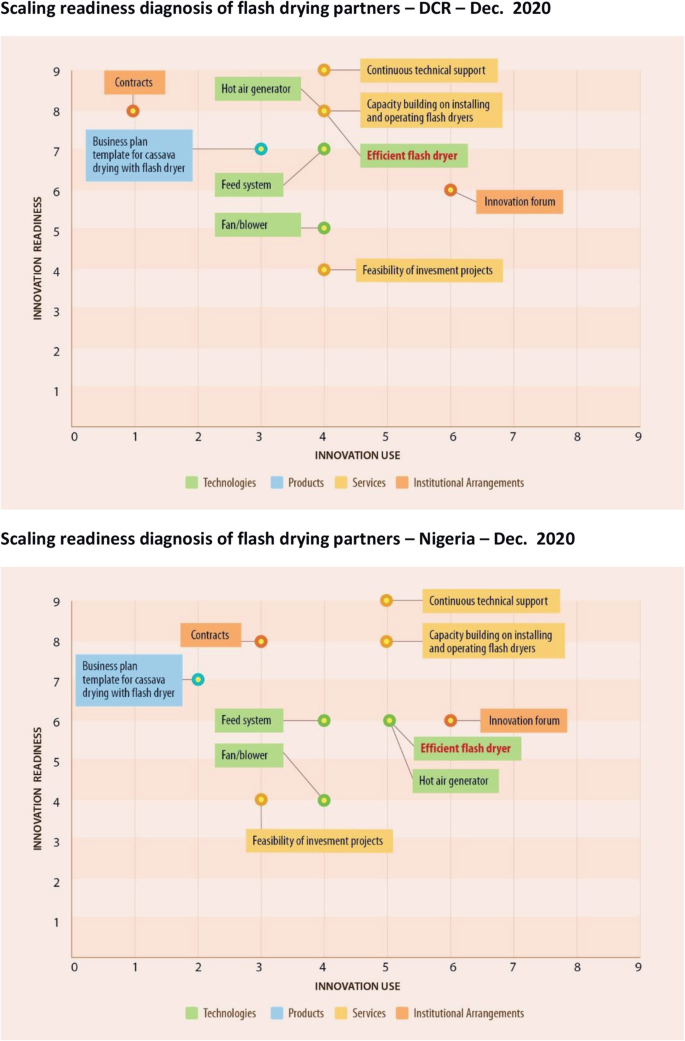

Through end-of-project evaluation and learning events, the innovation package was evaluated a second time, showing the changes achieved during the project (Fig. 4.9 ). As intended initially, technical components moved toward higher levels of use and readiness, which reflects the focus of the research team and scaling partners to construct more energy-efficient flash dryers and prioritize the success of the investments. Complementary innovations also progressed toward higher levels of use and readiness, reflecting the positive contribution of the various events organized during the project and the continuous engagement with manufacturers and processors. Some components did not move, either because they were already at sufficiently high levels of use and readiness or because of logistical delays in implementing activities, in part compounded by Covid restrictions.

Innovation Readiness and Innovation Use of the cassava flash-dryer innovation package in DR Congo and Nigeria at the end of the RTB Scaling flash-drying project (December 2020). Core innovation components (technologies) are presented in green and complementary innovations in blue (products), yellow (services), and orange (institutional arrangements)

Technical components reached higher levels of readiness in DR Congo compared to Nigeria. In DR Congo, the expanding market demand for HQCF to replace conventional sun-dried cassava flour boosted the determination of scaling partners to invest and to rapidly move energy-efficient flash dryers into commercial use. In contrast, in Nigeria, investment was impeded by the following:

Mismatch between production capacity of HQCF factories (~1 t HQCF/day) and the purchase needs of large food companies (30 or 60 t per order, i.e., one or two trailer trucks).

Projected production costs of HQCF after adoption in flash-drying innovations may still be too high to compete easily with flour from imported wheat.

Cassava flour is not a major staple food in Nigeria, so there is limited preexisting market where HQCF could replace a traditional cassava flour by offering better quality or food safety.

During project implementation, several constraints to the development of cassava processing were identified. These included access to investment capital, stable access to cassava roots at cost-effective prices, and availability of engineering skills to conduct maintenance and repairs in a timely manner.

Over several years, RTB has made significant investments in cassava postharvest processing, first in R&D and then scaling-out activities. The outcomes of the scaling project for efficient small-scale flash drying confirm that this initiative has started to bear fruits, with flash-dryer innovations now reaching the stage of independent adoption and dissemination by the private sector in several countries.

Postharvest processing is an important part of sustainable cassava value chains to reduce losses of perishable cassava roots through transformation into food products with a long shelf life. The successful approach presented above for the efficiency of small-scale flash drying can be extended and replicated to optimize other unit operations and reduce processing costs. At the same time, more efficient processing can reduce the environmental footprint of cassava agro-industries through lower fuel and water consumption and lower product losses during processing.

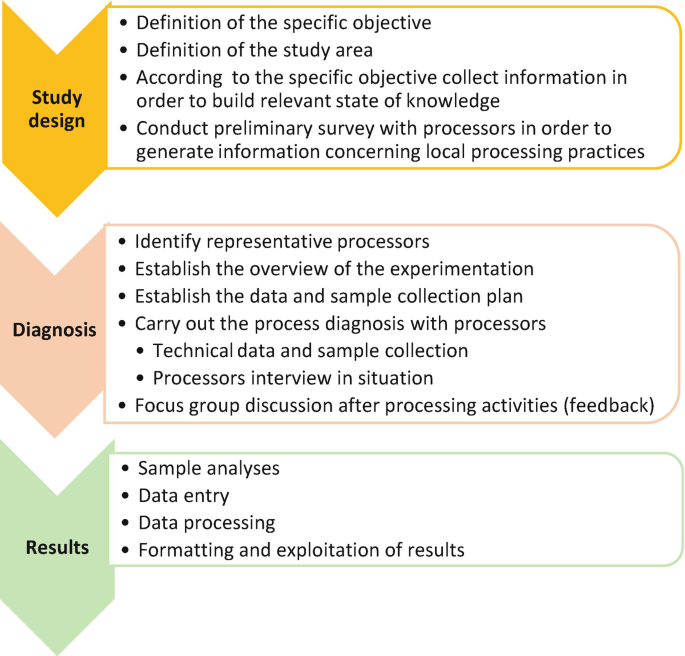

7 Performance Diagnosis of Small-Scale Processes to Support Scaling Out of Innovations for Cassava-Based Products

Many of the activities for scaling-out innovations in cassava processing must start with an accurate comprehensive diagnosis including processing parameters, socioeconomic feasibility, and environmental impacts as a basis for decision-making for all subsequent actions. Comprehensive diagnosis is also useful at the end of scaling-out projects, as part of Monitoring, Evaluation, and Learning (MEL) to document and measure outcomes and impacts. The diagnosis contributes to improvements in product quality through the optimization of existing processes and the introduction of new operations or equipment. In this section, we lay out a versatile diagnosis method (Fig. 4.10 ) developed from several case studies (Adinsi et al. 2019 ; Escobar et al. 2018 ; Bouniol et al. 2017a , b , 2018 , 2019 , 2020 ) for processing of cassava into gari, fufu, and other products in West Africa, with support from RTB.

Steps of the method for diagnosis of small-scale cassava processing units

7.1 Design of the Diagnosis Study: Specific Objective, Study Area, and State of Knowledge

The diagnosis of small-scale processes can focus on various aspects, such as the following:

Influence of cassava variety and processing on product quality.

Resource efficiency (energy, water, raw materials) in relation to production costs and environmental impacts.

Comparing different technologies for processing the same product. The first step is therefore to clearly define the specific objective(s) (Fig. 4.10 ), which in turn will guide the diagnosis methods to be selected.

Traditional, small-scale processing of cassava follows diverse processing pathways linked to different technologies and know-how. In turn, this variability results in different end-product quality, usually matching different consumer preferences. To collect representative data about a given process, it is therefore necessary to define where to carry out the diagnosis. These can be the areas where the target product is most frequently processed (usually areas with high cassava production), or the project’s region of intervention. The diagnosis may target user segments to explicitly be socially inclusive or to take gender into account, besides other criteria: size of towns or cities, production capacity, distances to markets, etc.

The diagnosis design may be based on a review literature about the product, process, and value chain and preliminary interviews with experts, extension officers, and processors to gather information on supply, availability, and quality criteria of raw materials. The design should include a description of each of the process steps and their importance for the quality of the product, as well as gender aspects, business environment (access to infrastructures such as energy, water, road network), and market aspects.

7.2 Diagnosis

Conducting a process diagnosis requires time, qualified people, and funding, so pre-planning is important (Sect. 3.1 ) to coordinate the collection of samples and data and to ensure the quality of the results.

Identify representative processors

The first step of the diagnosis is to identify in the study area a panel of processors representative of current practices, according to the following criteria:

Main economic activity based on the studied product.

Recognized know-how and ability to produce a specific quality of finished products matching the expectations of consumers.

Gender division of labor among the selected processors that is representative of actual gender labor distribution.

Technological level among the selected processors that is representative of the local most common technology. If most processors are small scale, the focus should be on them to mitigate negative social consequences of scaling technologies and to ensure more users of the technology from a social inclusive perspective.

Evaluate the volumes processed (by month/week/year) and the type of market targeted (retail, wholesale, town, village, etc.).

Overview of the experimentation

A schematic overview of the experimentation is necessary to clearly delimit the scope of the diagnosis according to the specific objective, to let the experimenters understand where they intervene in the overall process, and to refine the diagnosis by ensuring that the workflow and experimental design are suitable to collect scientifically valid data (representativeness of the sampling, number of repetitions). Several approaches are possible:

Replicate the entire transformation process from the same batch of raw cassava several times. Tens or hundreds of kilograms are often necessary.

Repeat the experimentation over several years. As much as possible, use the same cassava varieties harvested at the same age and processed under the same conditions.

If appropriate, repeat only specific unit operations, for example, in the case of a series of complex unit operations where all variables may be difficult to control at the same time.

Data and sample collection plan

The collection plan (e.g., Table 4.6 ) maps all the data and samples to collect at each step of the process, which may include temperature, weight, flow rate, dry matter, relative humidity, time, pH, and pressure. This helps to manage the complexity of the diagnosis by checking in advance with the processors the feasibility of the planned measurements and by keeping track of data and sample collection during the diagnosis.

Carry out the process diagnosis with processors

Technical data collection The same batch of raw materials (e.g., cassava roots) should be used for all the replications and in all the locations of the diagnosis to facilitate comparisons between technologies. This may not always be possible, however, due to the short shelf life of fresh roots and transportation distances. In this case, raw materials are sourced locally in each location, and the raw material is considered as one variable of the experimentation. Raw materials then need to be described in detail, including photos of the fresh roots (before peeling), size measurements, and any appropriate laboratory analyses.

All equipment, instruments, and data collection sheet necessary to carry out the experiments, to collect samples, and to record data are prepared in advance, based on the collection plan. The following characterization protocol is then applied: Before the first unit operation, the research team records the weight of the raw materials that will be processed into the product under study. Then after each unit operation (peeling, washing, etc.), the duration is recorded and the intermediate product (e.g., peeled product) and residues (e.g., peels, stems, soil) are weighed for later calculations of yields and mass balance. Samples can also be collected for further laboratory analyses (dry matter, starch content, fibers, pH, etc.). The following diagnosis parameters are then calculated for each unit operation and the process as a whole:

Yield , defined as the quantity of product recovered after each unit operation and expressed as percentage (wet basis) of the quantity of raw material.

Material balance evaluated by checking that the weights of all the inputs (raw materials, water, etc.) and outputs (final product, peels, fibers, wastewater, etc.) are equal.

Productivity , defined as the quantity of raw material (in kg) processed per hour and per processor. This is an important indicator of efficiency and also of drudgery.

Interview of processors and participative approach

To capture processors’ expertise, at each step of the process, interviews can elicit the details that processors use to recognize that the raw materials or intermediate products will give a good final product and how they may adjust their process to ensure the best possible final product. In the case of experiments comparing the processing potential of several varieties, processors can be asked to rank them from good to poor. This ranking can be repeated with intermediate products during processing.

7.3 Exploitation of Results

In addition to regular reporting of results collected for each unit operation, the process as a whole can also be analyzed with the following:

The process flowsheet (e.g., Fig. 4.11 ) describes the sequence of the unit operations, their duration (productivity), inputs and outputs (raw materials, water, electricity, thermal energy, etc.), and material balance based on the yields of the intermediate products.

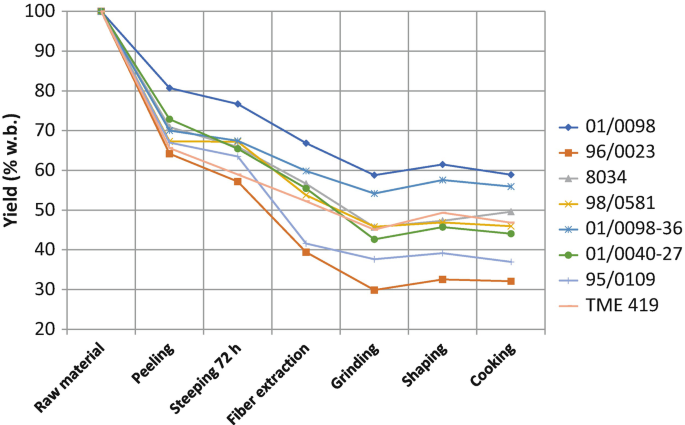

Yields and productivity of intermediate products : The yields of intermediate products reveal which unit operations most impact the overall yield of the process (e.g., Fig. 4.12 ). Productivity of each unit operation reveals bottlenecks, i.e., which operations slow down the overall process. Yields and productivity can also depend on the processing ability of different cassava varieties, as some varieties can be harder to process, e.g., more difficult to peel, thicker peels, lower dry matter, or containing fibers that need to be manually removed. Yield and productivity are important acceptability criteria that influence the adoption of improved technologies and/or new varieties, in addition to acceptability criteria of the end product such as visual appearance, texture, and taste.

Example of a process diagram for gari processing in four locations (shown in blue, italics) (study from Benin in 2015)

Example of the yields of the unit operations for processing gari. Eight cassava varieties revealed the effect of variety on process yields (study from Cameroon in 2015)

7.4 Conclusions

Process diagnosis is most effective when implemented with a formal methodological framework such as the one presented above. Combined with socioeconomic and environmental surveys, process diagnosis is a prerequisite to scaling-out innovations for several purposes: to provide a baseline to monitor the progress and outcomes of scaling-out activities; to reveal local constraints and expectations for the innovations with respect to local traditions and gender, employment, and environmental and economic criteria; and to identify the innovation components package and establish the scaling readiness diagram when applying the Scaling Readiness framework. A well-executed diagnosis provides not only reliable information on the process and product under study but also builds dialog with processors on the benefits and constraints of processing technologies and improved cassava varieties to facilitate the adoption of innovations.

8 Conclusions and Perspectives: Ongoing Research and Strategic Areas for Future Research on Cassava Processing

Since 2013, RTB has fostered several initiatives to improve cassava processing and federated a team of multidisciplinary researchers and engineers from IITA, CIAT, CIRAD, NRI, academic partners, and private partners in several countries. One notable outcome has been the reengineering of small-scale flash dryers for better energy efficiency and lower production costs. The flash-drying results presented in this chapter are useful to illustrate in a practical, step-by-step way the overall approach to reengineering postharvest technologies, from the initial state-of-the-art surveys to the stages of design, proof of concept, pilot testing, and scaling out with private partners. This work also provided a relevant case study for the application of Scaling Readiness, showing the progression of the project through the levels of innovation readiness and use (Table 4.5 ).

This experience shows that R&D interventions at postharvest processing level have an important part to play in advancing sustainable value chains of RTB crops, especially when combined with scaling-out activities in partnership with private small-scale processors and equipment manufacturers. In addition to flash dryers, several cassava products and unit operations have been investigated by RTB: cabinet drying (Precoppe et al. 2017 ), attiéké (Alamu et al. 2020 ), gari (Escobar et al. 2018 , 2021 ; Dahdouh et al. 2021 ), as well as links between processing and human health (Parmar et al. 2019 ; Bede-Ojimadu and Orisakwe 2020 ). Applying the same reengineering approach to other unit operations such as peeling, grating, dewatering, and milling will improve the overall efficiency of small-scale cassava industries and over time should increase incomes and employment along the whole cassava value chain (Escobar et al. 2021 ; Ezeocha et al. 2019 ; Dahdouh et al. 2021 ; Dou et al. 2020 ). Apart from interventions on postharvest processing, RTB researchers are currently also working on mobile cassava processing units to reduce the time and distance from the field to final products, so as to address the barrier of poor transportation infrastructure in West Africa.

The perspectives for cassava value chains over the next 10–20 years are an overall expansion to meet the food security and nutritional needs of growing populations. In this context, gains in processing efficiency will be crucial to improving both product quality and production capacity, which in turn are a prerequisite to connect rural small-scale cassava processors with higher-value and more distant markets, in particular large cities and international exports. Integrating processing innovations with the current scale of processing is important to provide a comparative advantage from the bottom up, as focusing on larger-scale processing can result in scale advantages and also put smaller-scale processors out of business with the risk of increasing inequality, social instability, and adverse gender effects as women are often highly represented in small-scale processing.

Abass AB, Mlingi N, Ranaivoson R, Zulu M, Mukuka I, Abele S, Bachwenkizi B, Cromme N (2013) Potential for commercial production and marketing of cassava: experiences from the small-scale cassava processing project in East and Southern Africa. IITA, Ibadan

Google Scholar

Abass AB, Amaza P, Bachwenkizi B, Alenkhe B, Mukuka I, Cromme N (2017) Adding value through the mechanization of postharvest cassava processing, and its impact on household poverty in north-eastern Zambia. Appl Econ Lett 24(9):579–583

Article Google Scholar

Abass AB, Awoyale W, Alenkhe B, Ndavi M, Asiru BW, Manyong V, Sanginga N (2018) Can food technology innovation change the status of a food security crop? A review of cassava transformation into “bread” in Africa. Food Rev Intl 34(1):87–102

Article CAS Google Scholar

Adegbite SA, Abass AB, Olukunle OJ, Olalusi AP, Asiru WB, Awoyale W (2019) Mass and energy balance analysis of pneumatic dryers for cassava and development of optimization models to increase competitiveness in Nigeria. Curr J Appl Sci Technol 32(3):1–11. https://doi.org/10.9734/CJAST/2019/46215

Adenle AA, Manning L, Azadi H (2017) Agribusiness innovation: a pathway to sustainable economic growth in Africa. Trends Food Sci Technol 59:88–104. https://doi.org/10.1016/j.tifs.2016.11.008

Adinsi L, Akissoé N, Escobar A, Prin L, Kougblenou N, Dufour D, Hounhouigan DJ, Fliedel G (2019) Sensory and physicochemical profiling of traditional and enriched gari in Benin. Food Sci Nutr 7(10):3338–3348

Aichayawanich S, Nopharatana M, Nopharatana A, Songkasiri W (2011) Agglomeration mechanisms of cassava starch during pneumatic conveying drying. Carbohydr Polym 84:292–298

Alamu EO, Ntawuruhunga P, Chibwe T, Mukuka I, Chiona M (2019) Evaluation of cassava processing and utilization at household level in Zambia. Food Secur 11:141–150

Alamu EO, Abass A, Maziya-Dixon B, Diallo TA, Sangodoyin MA, Kolawole P, Tran T, Awoyale W, Kulakow P, Parkes E, Kouame KA, Amani K, Appi A, Dixon A (2020) Report on the status of Attiéké production in Côte d’Ivoire. International Institute of Tropical Agriculture (IITA), Ibadan, p 42

Alonso L, Viera MA, Best R, Gallego S, García JA (2012) Artificial cassava drying systems. In: Ospina Patiño B, Ceballos H (eds) Cassava in the third millennium: modern production, processing, use, and marketing systems. Centro Internacional de Agricultura Tropical (CIAT); Latin American and Caribbean Consortium to support Cassava Research and Development (CLAYUCA); Technical Center for Agricultural and Rural Cooperation (CTA), Cali, pp 427–441

AOAC (1998) Moisture in malt (method 935.29). In: Official methods of analysis. Association of Official Analytical Chemists (AOAC), Gaithersburg

Awoyale W, Abass AB, Ndavi M, Maziya-Dixon B, Sulyok M (2017) Assessment of the potential industrial applications of commercial dried cassava products in Nigeria. J Food Meas Charact 11:598–609

Bede-Ojimadu O, Orisakwe OE (2020) Exposure to wood smoke and associated health effects in Sub-Saharan Africa: a systematic review. Ann Glob Health 86(1):32

Bouniol A, Prin L, Hanna R, Fotso A, Fliedel G (2017a) Assessment of the processability of improved cassava varieties into a traditional food product (“baton” or “chikwangue”) in Cameroon. CGIAR Research Program on Roots, Tubers and Bananas (RTB), Lima, Peru. RTB working paper, p 28