- Online Text to STL

- 3D Printed Soldering Helper

- 3D Printed Coin Vault

- 3D Printed FLARE GUN (PROP/REPLICA) MULTI PART

- 3D Printed Mini Container with PET Bottle Cap Size

TEST 3D PRINTS

Easy & Fun Things to 3D Print

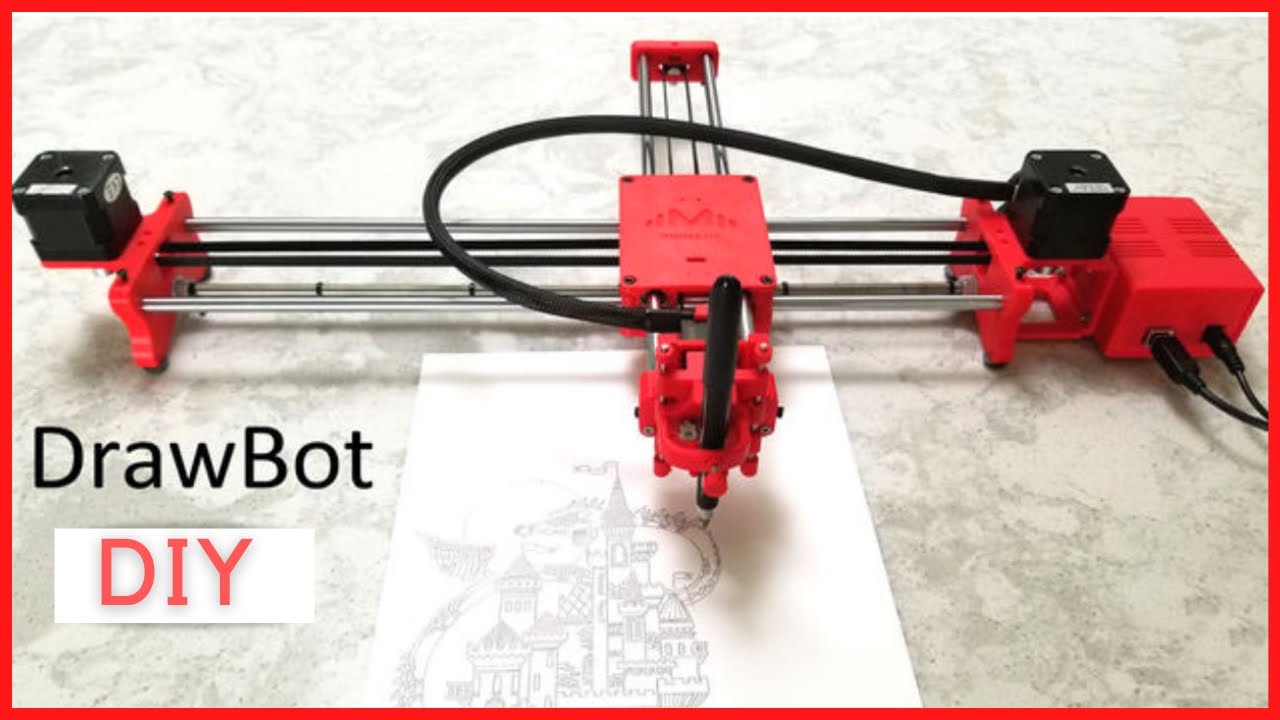

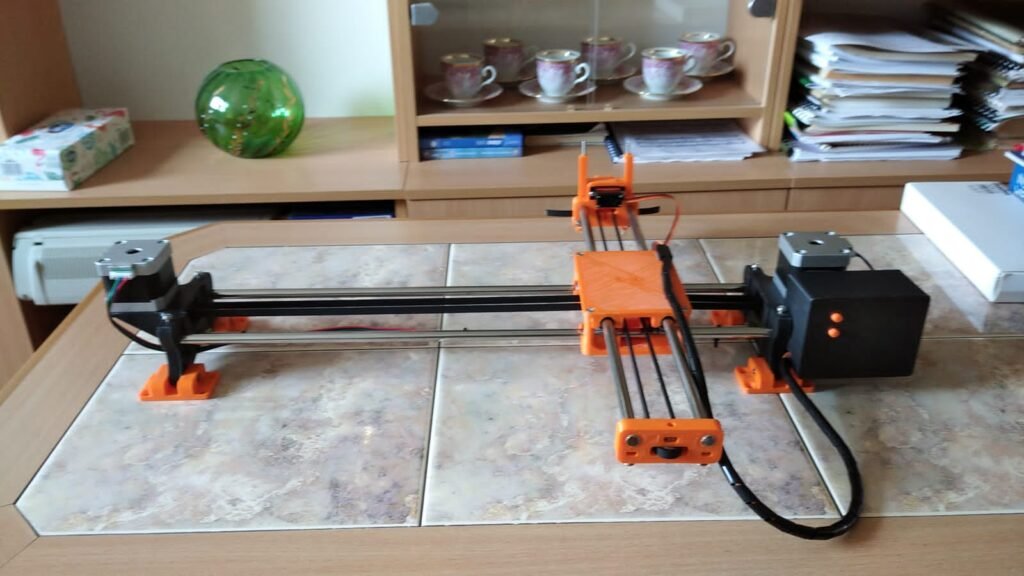

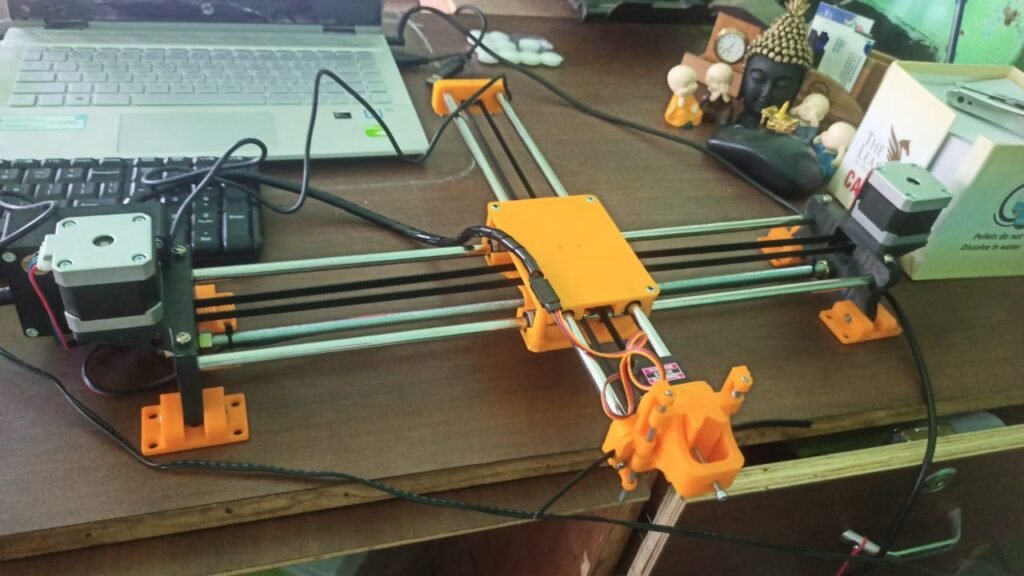

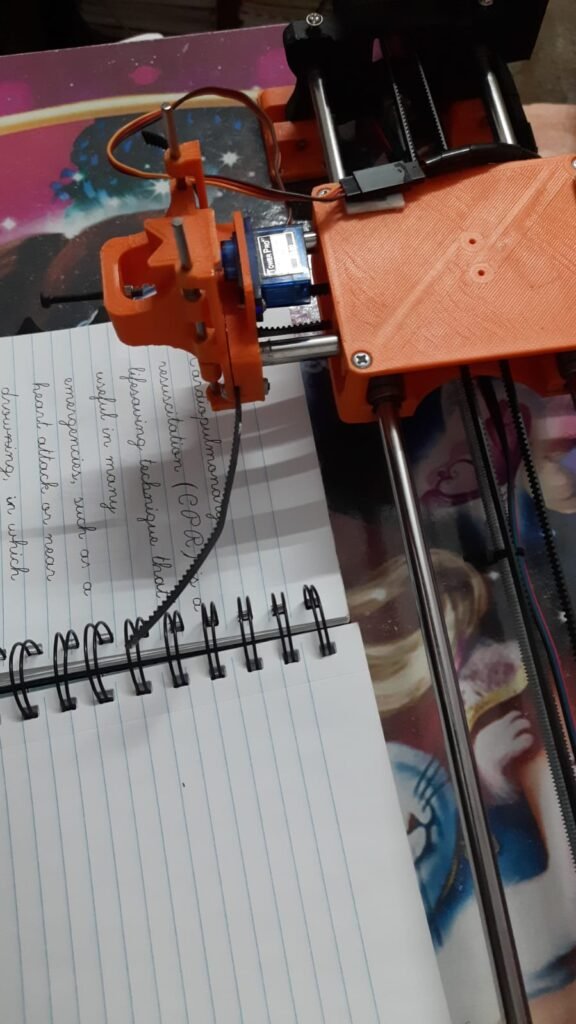

How To Make DIY Pen Plotter / Homework Writing Machine at Home

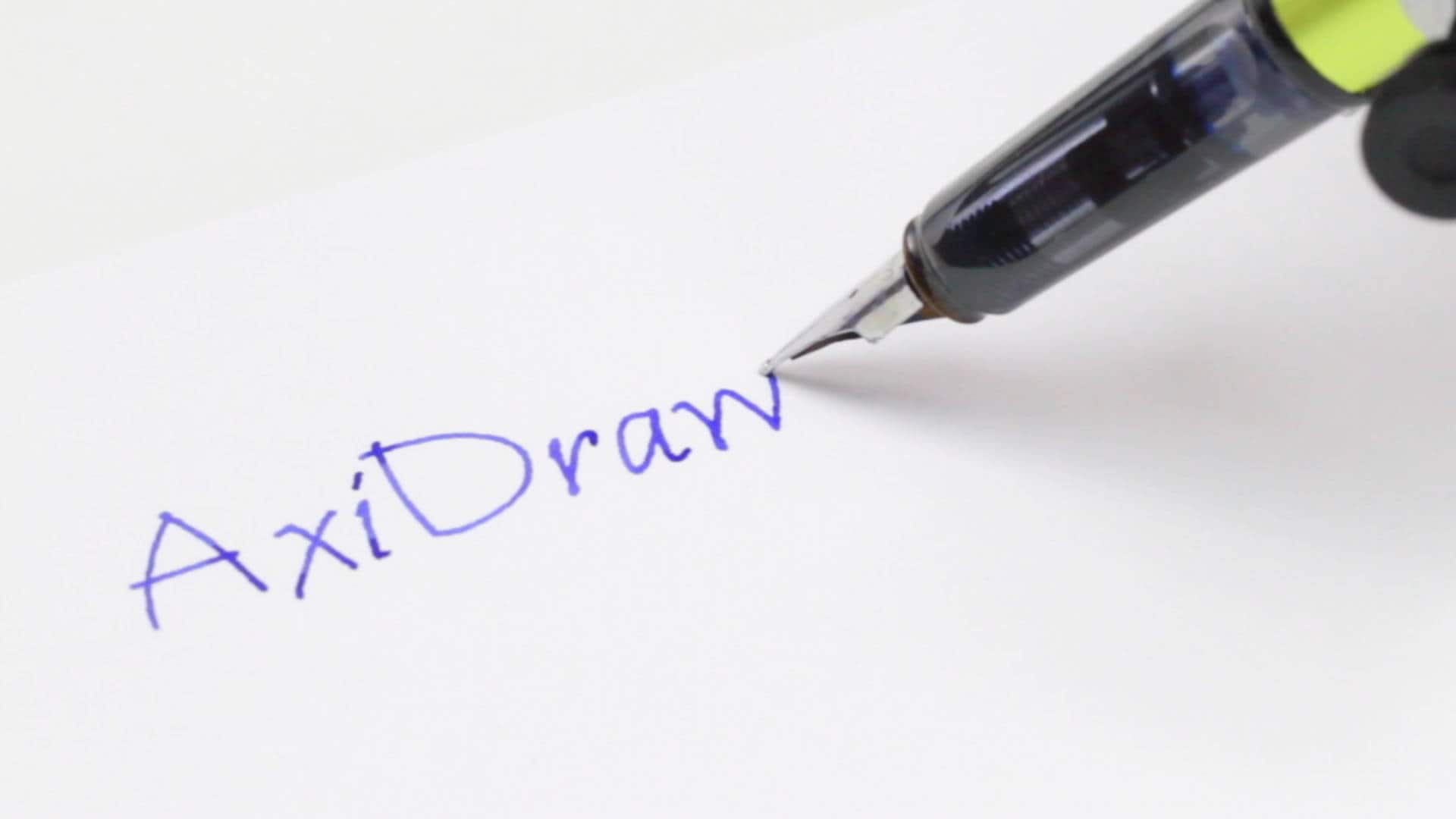

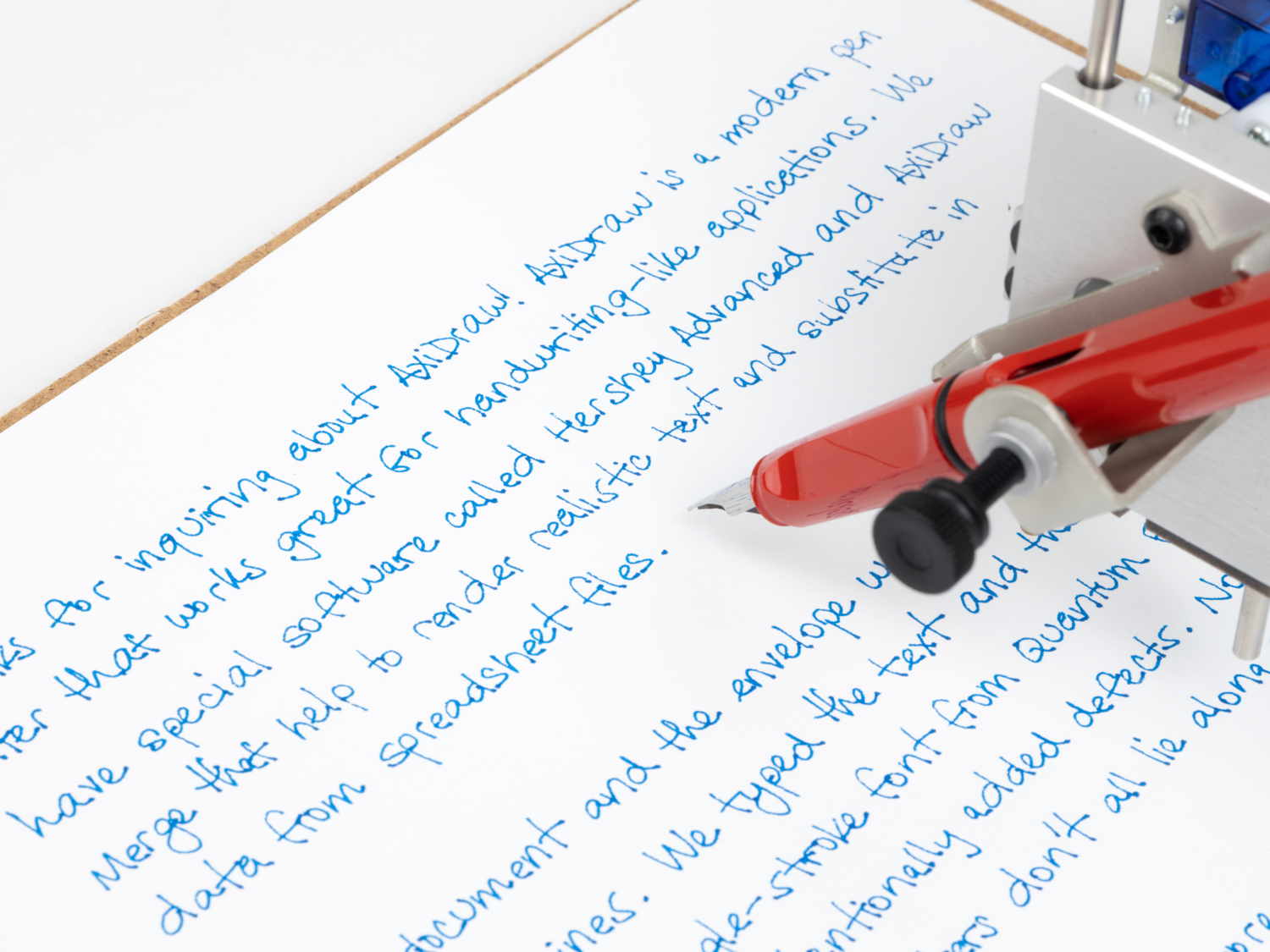

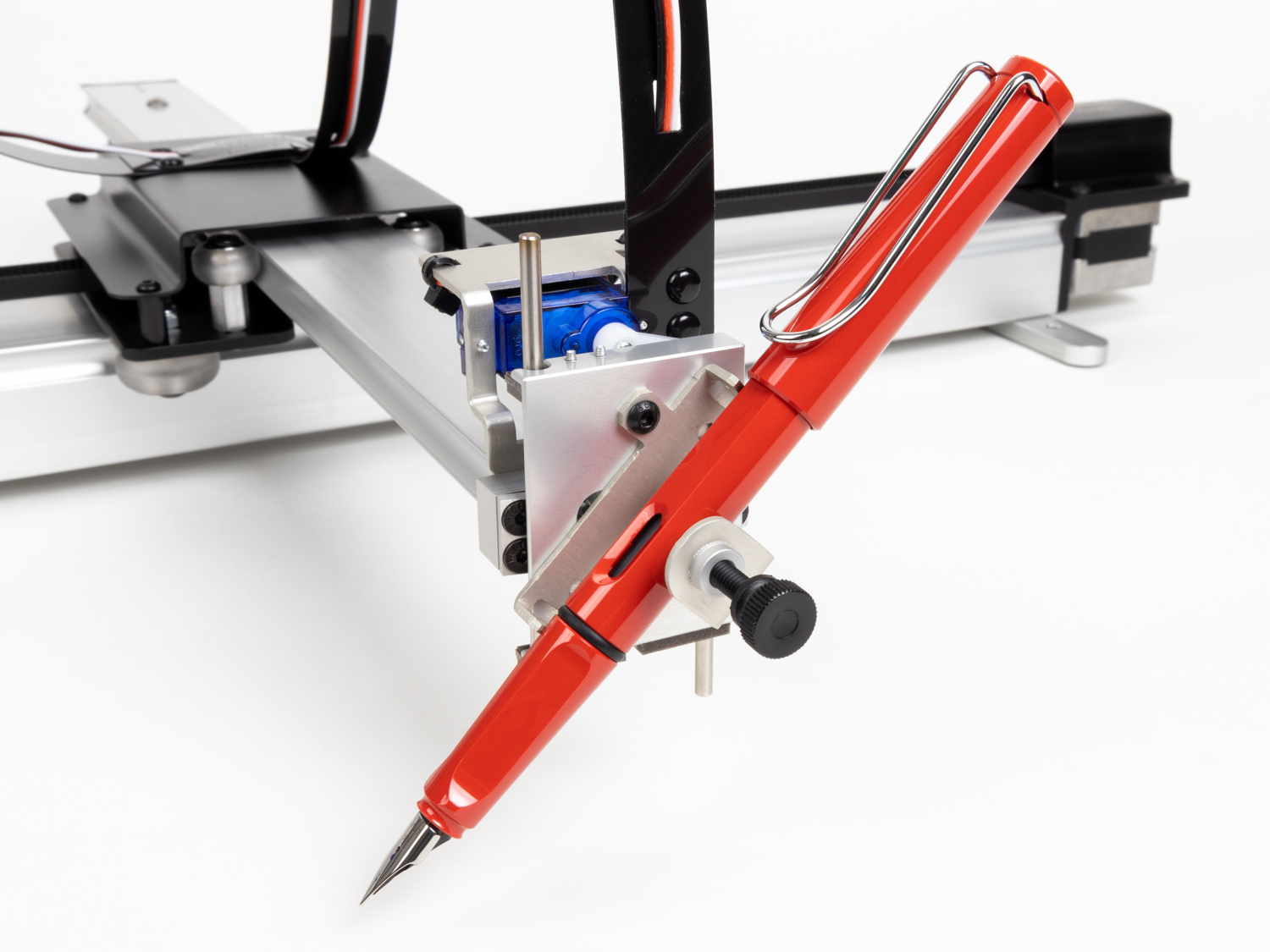

This Drawing Robot/Pen Plotter/Drawing Machine is similar to the commercially available AxiDraw. It is powered by an Arduino Uno controller, uses a CNC Shield, and GRBL firmware.

The cost to build the Drawing Robot is between $75 and $100 depending on where you buy your parts and whether you already own some of the parts such as the Arduino.

Parts and Materials Required

- 2 x Nema 17 Stepper Motors

- 2 x Linear Rod M8 x 450mm for X Axis

- 2 x Linear Rod M8 x 350mm for Y Axis

- 2 x Linear Rod 3mm for Z Axis (you can get it from old CDROM)

- 1 x Threaded Rod M8 x 480mm

- 8 x LM8UU Bearings

- 1 x Servo Sg90

- 1 x Spring 5m (from ball point pen)

- 2 x GT2 Pulley, 16 teeth

- 5 x Bearing 624zz

- 1 x 2000mm GT2 belt

- 1 x Arduino Uno

- 1 x CNC Shield

- 2 x A4988 Stepper driver with heatsink

- 6 x Jumpers

- 1 x 12V 2A Power Supply

- 4 x 5/16in-18

- 13 x Phillips M3-0.5 x 16mm

- 4 x Phillips M3-0.5 x 6mm

- 5 x Phillips M4-0.7x 35mm

- 1 x Hex M3-0.5 x 20mm

- 4 x 5/16in washer

- 4 x M3 washers

3D Printing

- Download the files from Thingiverse

- Open the 3D models in Cura or any other slicer(Sli3er, Simplify 3D, etc.)

- Use 75% infill on all the parts (An infill of 70 – 100% will work as well)

- Printed all the parts with 0.10 – 0.20 mm layer height

- Printed with Hatchbox Red PLA

- Use supports on the Penholder, Slider, X_Support_L and the X_Support_R

Note: The longest part took around 9hrs and the shortest took 30 minutes to print

3D Printed Parts

Cut your Linear Rods

Use a measuring tape and sharpie to mark the spots where the rods need to be cut

- Use a vise to hold the rods in place when you cut them

- Remember that you need (2) 350mm and (2) 450mm long linear rods

- On the threaded rod, mark your cutting point at 470mm

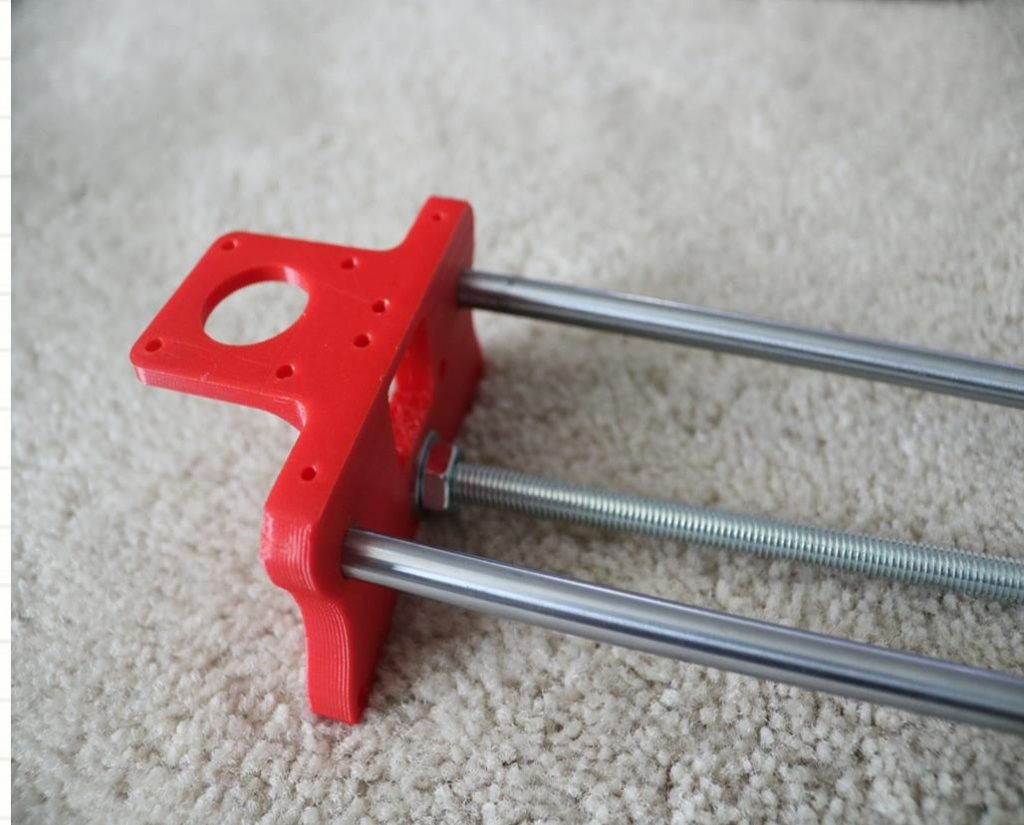

Assemble the X-Axis (Linear/Threaded Rods)

Take the (2) 450mm linear rods and insert them into either x-support part

- Use may need to use a round file to smooth out the holes that you insert them in

- Also, you can use a rubber mallet to help insert the rods

Now take the threaded rod and insert it in the hole below. Feed a 5/16in washer and 5/16in nut on both sides of the x-support part

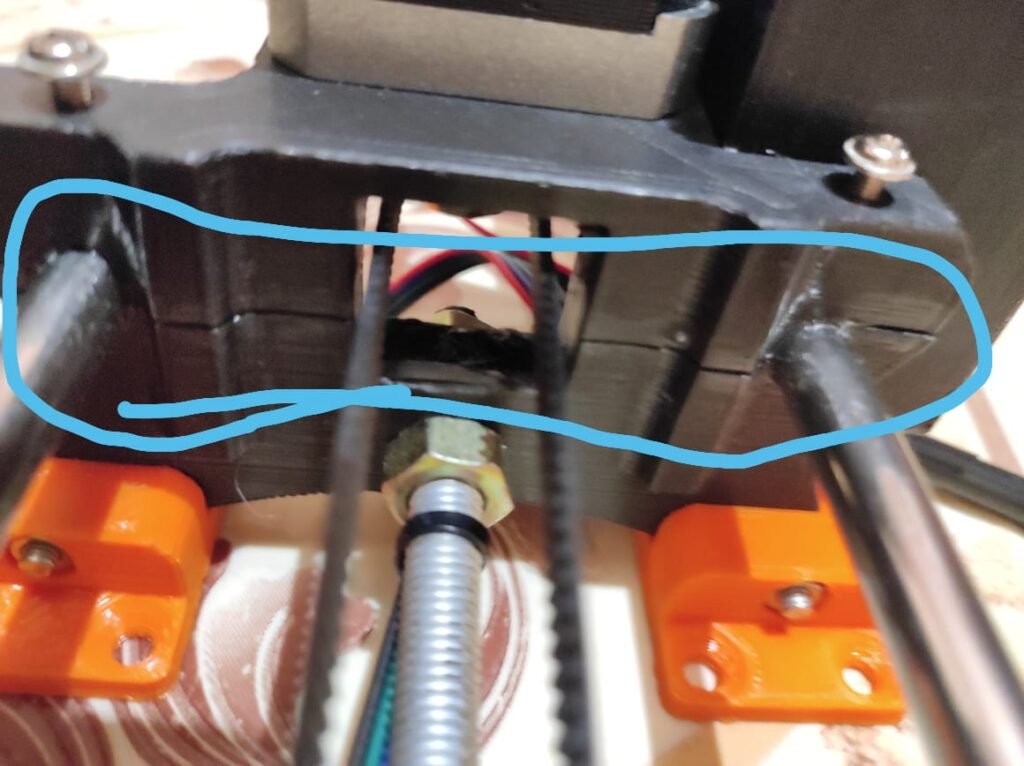

Assemble the X-Axis (Bearings)

Now you want to push the LM8UU bearings into their place on the top and bottom clamshell (The top and bottom clamshell take (4) bearings each)

Take (4) 624zz bearings and push them through the 3D-printed idler pulleys. Leave the 5th bearing for later when you assemble the Y-axis

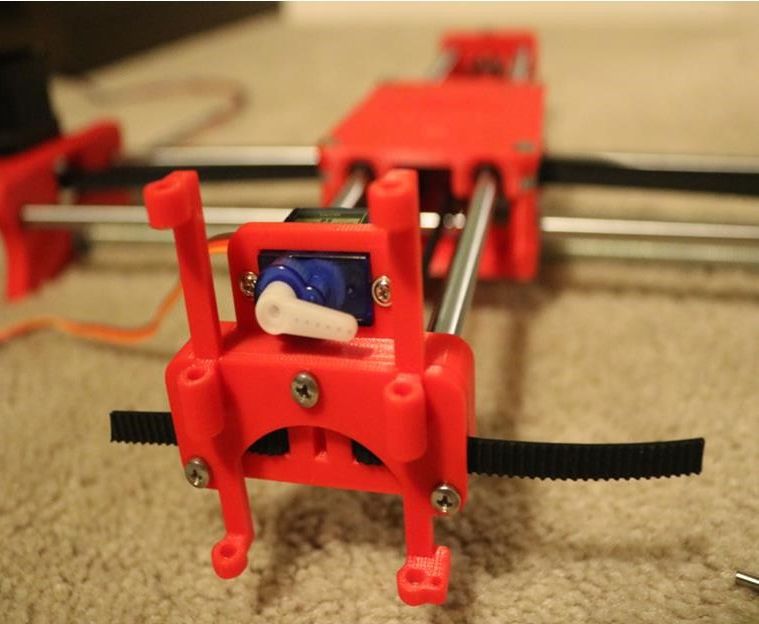

Assemble the X-Axis (Carriage)

- Get (4) M3-0.5 x 20mm screws, (4) M3 nuts, (4) M3 washers and (4) 624zz bearings with the idler pulleys installed

- Take one screw and feed a washer through it, the washer will rest on the bearing. The nut will be at the bottom of the carriage, which will secure the bearing in place

Assemble the X-Axis (X-Support)

- Slide the clamshell through the 450mm (X-axis) linear rods

- Use a rubber mallet again to attach the last X-support on the linear rods

- Make sure that the rods stick out equally on both sides

- Slide the other end of the threaded rod through the hole on the X-support

- Put on the last set of nuts and washers to hold the X-support in place

- Now that the X-axis is complete, you can use (2) Phillips M3-0.5 x 16mm screws per X-support to help keep the linear rods from sliding

Assemble the X-Axis (Stepper Motors)

- Use an appropriate sized allen wrench to attach the 16 teeth pulleys on the stepper motor shafts

- Flipping the entire chassis around will make it easier to attach the stepper motors

- Use (8) M3-0.5 x 6mm screws and a Phillips screwdriver to attach the (2) stepper motors

Assemble the Y-Axis (Clamshell)

(Optional if you have problems keeping belt on bearings)

- Grab (4) M4-0.5 x 35mm screws and (4) M4 nuts

- Make sure that you have the (4) idler pulleys ( Download from Thingiversa ) and the (4) washers printed

- Insert the washers in between the two clamshells, with a screw in between

- Screw the top and bottom clamshells together

Assemble the Y-Axis (Y- Back/Front)

- Take the (2) 350mm linear rods and insert them the Y-back piece by using a rubber mallet

- Get (1) M4-0.5 x 35 screw, (1) M4 nut and the 5th 624zz bearing

- Get (2) M3-0.5 x 16 screws to secure the linear rods

- Slide in the bearing when inserting the screw through the Y-back piece

- Slide the the linear rods/Y-back piece through the LM8UU bearings and attach the Y-front piece using a rubber mallet

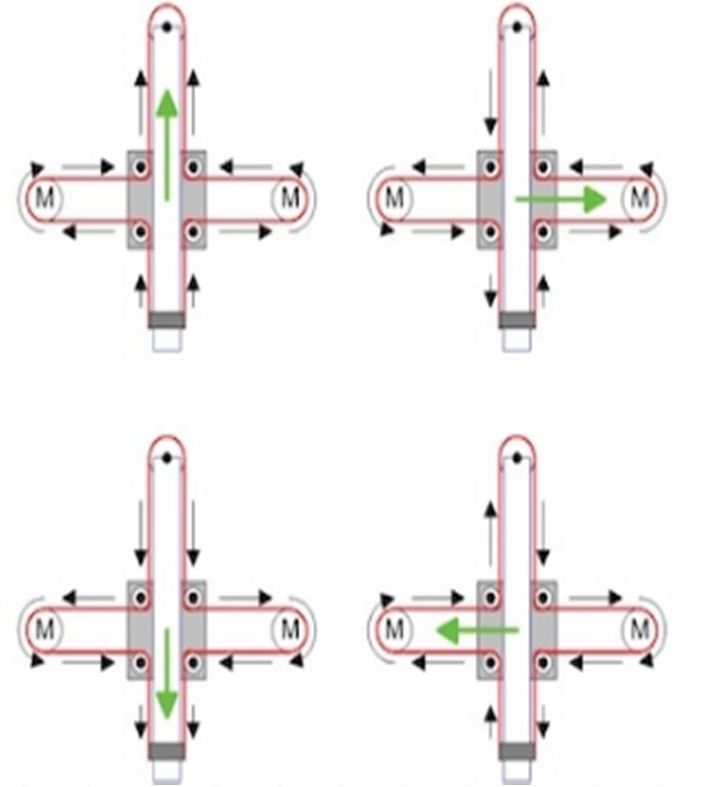

Assemble the X-Y Axis (Belt)

- Use a pair of needle nose pliers to help guide the GT2 belt more easily through the clamshell

- Take the two ends of the belt and slide them through the “teeth” on the Base Slider

- The belt should be tight and not loose

- Note that once the GT2 belt is on, it is normal for the clamshell not to move easily

Belt Diagram

Assemble the Z-Axis

- Get (2) 3mm linear rods and the following 3D printed parts (Slider, Pen Holder, Base Slide, 3MM Metric Thumb Screw)

- Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together.

- Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part. You may need to use (3) M3-0.5 nuts in order to hold it in place

- Push the Slider and Pen Holder together to make one piece

- Now take that new part and the (2) 3mm linear rods and slide the rods through the holes. Place a small spring in between the two parts so there is a little bit of pressure to lift the Slider. You may need to cut the spring a bit until there is an adequate amount of pressure on the slider.

Step By Step Video

The Original Instructions by Henry Arnold Jonathan K

- 3D Printed Hairy Lion →

12 thoughts on “ How To Make DIY Pen Plotter / Homework Writing Machine at Home ”

i constructed all the machine but when i press X+ the both X and Y axis are moving what is the problem

double check the steppers wiring

Have you solved it? I have the same problem with my machine, when I press X+, it’s necessary both motors move at same time, but, only one of them move…

Did you solve this problem?

Same problem how to solve ,?

Is it true that you didn’t use the microswitches in the final design?

Hello how to co figurę this machine to RUN on GRBL. What I mean is that GRBL interprets commands for x axis and y axis independently and if I look on your belt diagram it looks like both Motors have to run at the same time in order to move the carriage along y axis… How did you do that?

Have you solved it?

Thank you, thank you. It’s a very good built.

Is it possible to modify it to draw using brush ang oil based paint ?

Could you please tell what software/plug in and which version do you use to generate g-code for this machine?

Hello, what is the width of your belt? 6mm or 10mm? Thanks!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

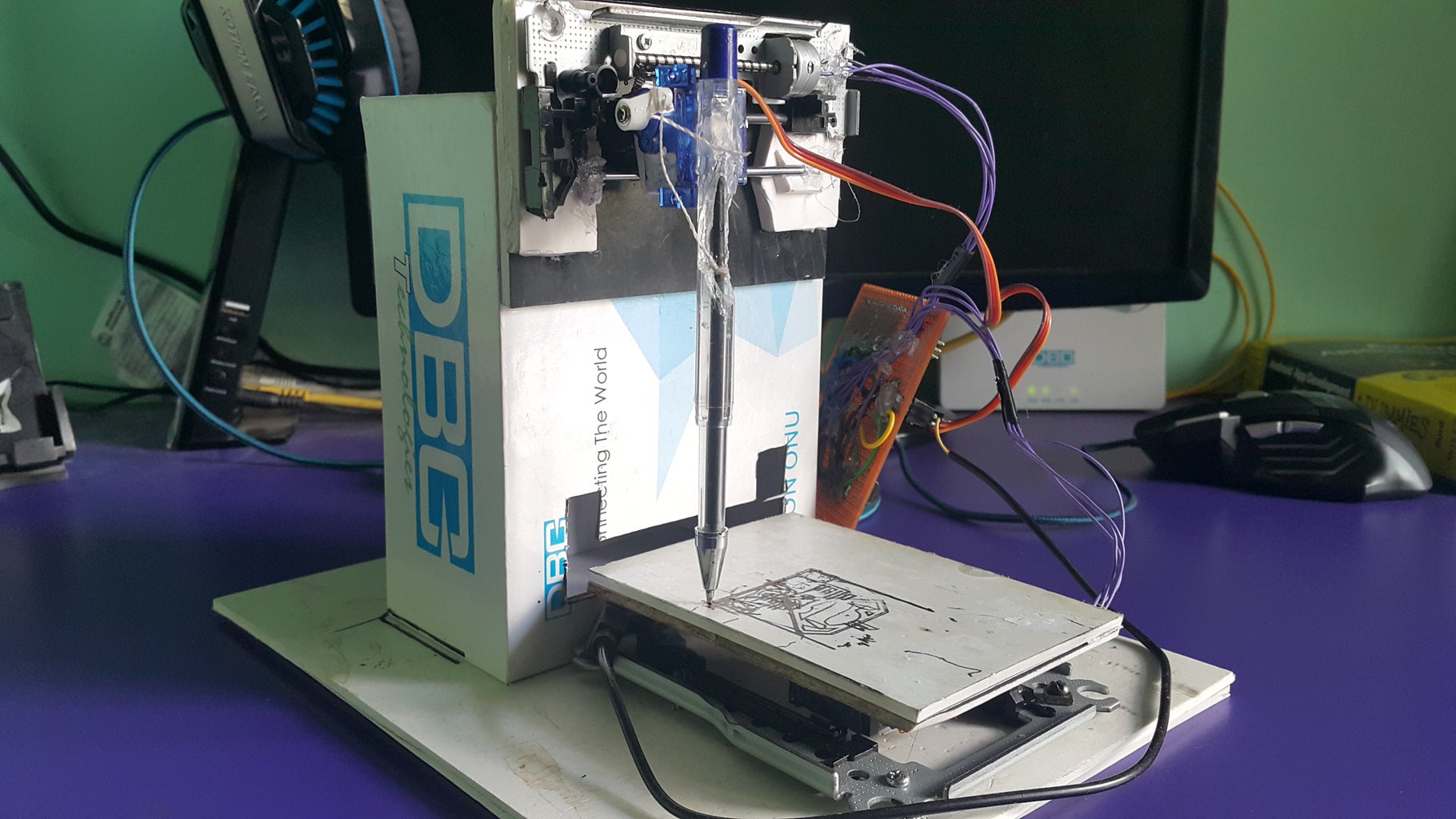

Homework Writing Machine with Arduino and Servo Motor

Homework writing machine is an auto writing machine through which you can make your your work easy by programing your project. As per the title this is a simple project using Arduino to make Homework writing machine at your home.This machine can draw any design and write any type of fonts.You can see sharpness and perfection of writing in photos. The machine uses a gantry to move the writing tip along the X and Y axes. The flexible-nib pen is mounted on a servo motor which rotates the tip onto the writing surface, taking care of the third axis.

Mechanical Kit will be shipped to you and you can learn and build using tutorials. You can start for free today!

1. 3D Printer

2. Automobile Prototyping

3. CNC Machine using Arduino

4. Project Management with Primavera

Homework writing machine project description:

- Servo Motor: A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration.It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors. 1 threaded rod

- Wood: Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic material, a natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression.

Latest projects on Mechanical

Want to develop practical skills on Mechanical? Checkout our latest projects and start learning for free

- Arduno uno: Arduino is an open source computer hardware and software company, project, and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices and interactive objects that can sense and control objects in the physical and digital world. The project's products are distributed as open-source hardware and software, which are licensed under the GNU Lesser General Public License (LGPL) or the GNU General Public License (GPL),permitting the manufacture of Arduino boards and software distribution by anyone. Arduino boards are available commercially in preassembled form, or as do-it-yourself (DIY) kits.

- Grbl shield: =The Arduino grblShield is a complete hardware solution for Dank's CNC motion control system called grbl. Compatible with the Uno and other 328p versions of the Arduino development platform. (Note: grbl 0.6 is not compatible with 168-based Arduinos (nor will it ever be), and currently grbl does not support the Arduino Megas).

- Driver motors : = motor driver is a little current amplifier; the function of motor drivers is to take a low-current control signal and then turn it into a higher-current signal that can drive a motor.

- 9 gram servo : = A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration.[1] It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors. Benbox software

Skyfi Labs helps students learn practical skills by building real-world projects.

You can enrol with friends and receive kits at your doorstep

You can learn from experts, build working projects, showcase skills to the world and grab the best jobs. Get started today!

- Arduino uno

- Servo Motor

- Grbl shield

- Driver motors

- Benbox software

Homework Writing Machine

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

More Project Ideas on Mechanical

Subscribe to receive more project ideas.

Stay up-to-date and build projects on latest technologies

☎ Have a Query?

News the global electronics community can trust

The trusted news source for power-conscious design engineers

Supply chain news for the electronics industry

The can't-miss forum engineers and hobbyists

The electronic components resource for engineers and purchasers

Design engineer' search engine for electronic components

Product news that empowers design decisions

The educational resource for the global engineering community

The learning center for future and novice engineers

The design site for electronics engineers and engineering managers

Where makers and hobbyists share projects

The design site for hardware software, and firmware engineers

Where electronics engineers discover the latest tools

Hardware design made easy

Brings you all the tools to tackle projects big and small - combining real-world components with online collaboration

Circuit simulation made easy

A free online environment where users can create, edit, and share electrical schematics, or convert between popular file formats like Eagle, Altium, and OrCAD.

Transform your product pages with embeddable schematic, simulation, and 3D content modules while providing interactive user experiences for your customers.

Find the IoT board you’ve been searching for using this interactive solution space to help you visualize the product selection process and showcase important trade-off decisions.

A worldwide innovation hub servicing component manufacturers and distributors with unique marketing solutions

SiliconExpert provides engineers with the data and insight they need to remove risk from the supply chain.

Transim powers many of the tools engineers use every day on manufacturers' websites and can develop solutions for any company.

Search EEWeb

- Newsletters

- Internal/External

- Embedded Microstrip

- Symmetric Stripline

- Asymmetric Stripline

- Wire Microstrip

- Wire Stripline

- Edge-Coupled Microstrip

- Edge-Coupled Stripline

- Broadside Coupled Stripline

- Twisted Pair

- RF Unit Converter

- Online SPICE Simulator

- Schematic Converter/Viewer

- Schematic Capture Tool

- Standard Values

- Magnetic Field Calculator

- Wire Self Inductance

- Parallel Wires

- Wire over Plane

- Rectangle Loop

- Broadside-Coupled Traces

- Edge-Coupled Traces

- Engineering Paper (Printable PDF)

- Log-Log Graph Paper (PDF Download)

- Semi-Log Graph Paper (PDF Download)

- Smith Chart Graph Paper (PDF Download)

- Math Reference Sheets Overview

- Algebra Reference Sheet

- Geometry Reference Sheet

- Trigonometry Definitions and Functions

- Trigonometry Rules, Laws, and Identities

- Calculus Derivatives, Rules, and Limits

- Calculus Integrals Reference Sheet

- Online Basic Calculator

- Scientific Calculator

- Tech Communities

- Analog Design

- Power Design

- Digital Design

- Embedded Systems

- Test & Measurement

- Electromechanical

- Passive Components

- Design Library

- Extreme Circuits

- Magazines Archive

- Design Contest

- Homework Writing Machine

This homework writing machine project features a DIY writing machine that uses a typical pen. It can do outline writing and digital signature or even a real text. The main system uses a 2 axis stepper motor driver board with Nema stepper motors and Mg90S Metal Gear Servo control.

The 2 axis stepper motor driver board serves as the main controller. It organizes the motor drivers connection that best fit for the writing machine operation. This writing machine uses threaded rod rotated by nema 17 stepper motors for X-axis and Y-axis movements on the surface, while a Mg90S metal gear servo is used in the pen stand that moves the pen perpendicular to the writing surface. The movements of the motor are synchronized and quite accurate provided that it is assisted by a well-made writing machine frame structure with mixed of wood and acrylic materials.

This project is suitable for embedded development hence it can accomplished digital writing activity. It is also a good reference for DIY text and figure printing provided that it can draw specific figures.

Sources: How to Make Homework Writing Machine at home

Other Related Topics

- Building an Audio-Reactive Music Box

- Go Kart / Electric Car using PVC Pipe

Join the Conversation!

One reply to “homework writing machine”.

sir I am a student of MS electrical power engineering and my thesis are just close to starting but I am confused about topic selection. my area of interest is RENEWABLE ENERGY TECHNOLOGY. please sir help me in topic selection

Add Comment Cancel reply

You must be logged in to post a comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- FarhnSh1d 2024-04-03 02:40:00 1. Energy Source Availability: Identify available energy sources such as solar, wind, vibration, thermal gradients, or ambient RF signals. Choose a technology capable of effectively capturing and converting this energy into usable electrical power. 2. Energy Density and Power Output: Assess the energy density and power output of each potential source to determine if it can meet the application's power requirements, considering factors like sensor power consumption and duty cycle. 3. Environmental Conditions: Evaluate the environmental conditions of the remote location, including temperature extremes, humidity, and exposure to elements. Choose a technology that can withstand these conditions and operate reliably...

- FarhnSh1d 2024-04-03 02:39:02 Reducing the output power of an ultrasonic Piezo Ceramic disc from 35 watts to 10 watts by adjusting the control board is possible but entails several considerations: Effectiveness and Performance Lowering power may compromise the effectiveness of the ultrasonic device, potentially reducing its ability to achieve desired results like cleaning or atomization. Reduced power might lead to weaker vibrations, impacting performance, especially if the device operates away from its optimal resonance frequency. Durability and Lifespan Lowering power could potentially increase the device's lifespan by reducing stress on the piezo ceramic disc. However, extreme power reductions may lead to inadequate vibrations...

- forlinxembedded 2024-03-21 04:05:55 Hello Erdem, It's interesting to learn about the differences in electric pole usage between countries. In many countries, wooden poles are commonly used due to their availability, cost-effectiveness, and ease of installation. However, in regions with higher load requirements like Turkey, stronger poles are necessary to support the infrastructure. In the USA and some European countries, wooden poles are reinforced and treated to withstand the required loads. Additionally, alternative materials like steel and concrete are also used for electric poles in various applications. If you're interested in learning more about electric pole types and standards in different countries, I recommend...

- Lumispot 2024-03-04 11:00:10 Microcontroller For a project like yours, the choice of a microcontroller (MCU) largely depends on the complexity of the device, the number of input/output peripherals you need (like GPIOs for the sensor, speaker, LED lights, and the green light indicator), and any additional features you might require (such as PWM outputs for LED dimming or speaker volume control). Arduino Uno is a robust choice for beginners and prototypes. It's based on the ATmega328P and offers a good balance of GPIO pins, is easy to program, and has extensive community support. Arduino Nano or Arduino Micro could be more suitable for...

- richard-gabric 2024-03-04 11:00:01 You are setting yourself up to kill yourself, or at least to take an eye out. You don't say what DC voltage you need, the voltage you would get from directly applying the mains to a bridge rectifier were typically used, for example, to supply the input to a flyback switch mode power supply, where the switching transformer provides mains isolation. The voltage would typically be around 300V DC, and the rectifier and capacitors have to be rated for that voltage plus a safety factor. I assume that you are needing a low voltage DC, since you have 25Vdc capacitors...

- suvsystemltd 2024-03-01 09:15:42 one suitable device is the LTC4371 from Analog Devices. The LTC4371 is an automotive-grade ideal diode controller designed to operate in harsh environments, making it compliant with the AEC-Q100 standard. Key features of the LTC4371 include: Input Voltage Range: The LTC4371 typically operates with an input voltage range that covers your specified 2.5V requirement. AEC-Q100 Qualification: The LTC4371 is qualified for automotive applications, meeting the AEC-Q100 standard. This ensures reliability and performance under automotive operating conditions. Ideal Diode Functionality: The LTC4371 is specifically designed as an ideal diode/OR-ing controller. It allows for seamless power source transition and provides a low-loss...

- AdeZep 2024-02-23 07:14:54 74AC14 willl do the job ? Thanks!...

- ViasionTech 2024-02-13 09:30:44 In the USA and parts of the EU, wooden electric transmission poles are commonly used due to their cost-effectiveness, widespread availability, and environmental friendliness. The decision is influenced by regional engineering standards, emphasizing factors like renewable resources and biodegradability. While wooden poles may have lower load-bearing capacity than those used in Turkey, they meet safety requirements for specific voltage and environmental conditions. To obtain detailed information about electric pole types and standards in a specific country, it is advisable to contact local electric utilities, government agencies, or industry associations for relevant documentation or standards....

Browse by Categories

- Digital Design (1)

- Electromechanical (15)

- Embedded Systems (51)

- Featured (117)

- General (15)

- Power Design (13)

- RF Design (5)

- Sensors (12)

- Standard (4)

- Test & Measurement (3)

Browse by Topics

- Arduino (28)

- Electronics (9)

- Microcontrollers (10)

- Raspberry Pi (9)

- Robotics (15)

- Wireless (9)

- List of Topics

Embed the widget on your own site

Drawing Robot/Pen Plotter/Drawing Machine is an Open Hardware version of the famous machine AxiDraw which it is a pen plotter, capable of wr

Make DIY Homework Writing Machine at Home

Step 1: parts and materials required, step 2: 3d printing, step 3: assemble the x-axis, step 4: assemble the x-axis bearing, step 5: assemble the y-axis.

- Step 6: Assemble the X-Y Axis (Belt

Step 7: Assemble the Z-Axis

Step 8: electronics, step 9: software, step 10: drawing machine at work.

- Comments (8)

Things used in this project

- Buy from Newark

- Buy from store.arduino.cc

- Buy from Adafruit

- Buy from Arduino Store

- Buy from CPC

Software apps and online services

Hand tools and fabrication machines

Drawing Robot/Pen Plotter/Drawing Machine is an Open Hardware version of the famous machine AxiDraw which it is a pen plotter, capable of writing or drawing on almost any flat surface. It can write with pens, permanent markers, pencils, and other writing implements to handle an endless variety of applications.

Its unique design features a writing head that extends beyond the machine, making it possible to draw on objects bigger than the machine itself. The biggest advantage of the machine is that it can be placed over the book because of the core XY extending design of the machine.

This Drawing Robot/Pen Plotter/Drawing Machine is similar to the commercially available AxiDraw. It is powered by an Arduino Uno controller, uses a CNC Shield, and GRBL firmware

The cost to build the Drawing Robot is between $75 depending on where you buy your parts and whether you already own some of the parts such as the Arduino.

You can find all of my projects on https://www.diyprojectslab.com/

Maximum drawing area 24 * 30 CM.

Thank You NextPCB

This project is successfully completed because of the help and support from NextPCB. Guys if you have a PCB project, please visit their website and get exciting discounts and coupons.

Free shipping 0$ PCB Prototype: https://www.nextpcb.com/pcb-quote?act=2&code=Romeo...

Thanksgiving Christmas lucky draw 100% win: https://www.nextpcb.com/christmas-lucky-draw?code...

2 x Nema 17 Stepper Motors Amazon.com

2 x Linear Rod M8 x 450mm for X Axis Amazon.com

2 x Linear Rod M8 x 350mm for Y Axis Amazon.com

2 x Linear Rod 3mm for Z Axis (you can get it from old CDROM)

1 x Threaded Rod M8 x 480mm8 x LM8UU Bearings Amazon.com

1 x Servo Sg901 x Spring 5m (from ball point pen) Amazon.com

2 x GT2 Pulley, 16 teeth Amazon.com

5 x Bearing 624zz Amazon.com

1 x 2000mm GT2 belt Amazon.com

1 x Arduino Uno Amazon.com

1 x CNC Shield Amazon.com

2 x A4988 Stepper driver with heatsink Amazon.com

6 x Jumpers Amazon.com

1 x 12V 2A Power Supply Amazon.com

- 4 x 5/16in-18

- 13 x Phillips M3-0.5 x 16mm

- 4 x Phillips M3-0.5 x 6mm

- 5 x Phillips M4-0.7x 35mm

- 1 x Hex M3-0.5 x 20mm

- 4 x 5/16in washer

- 4 x M3 washers

Download the files from Thingiverse

Open the 3D models in Cura or any other slicer.

Use 75% infill on all the parts (An infill of 70 – 100% will work as well)

Printed all the parts with 0.10 – 0.20 mm layer height

Printed with PLA

Use supports on the Penholder, Slider, X_Support_L and the X_Support_R

Note: The longest part took around 10hrs and the shortest took 30 minutes to print

PLA is fine for this design. I print at 200C on BuildTak. None of the parts require rafts or brims. I suggest supports only for the pen holder and the Z axis end plate which is standing up.

Remember that you need (2) 350mm and (2) 450mm long linear rods

Take the (2) 450mm linear rods and insert them into either x-support part

- Use may need to use a round file to smooth out the holes that you insert them in

- Also, you can use a rubber mallet to help insert the rods

Now take the threaded rod and insert it in the hole below. Feed a 5/16in washer and 5/16in nut on both sides of the x-support part

Now you want to push the LM8UU bearings into their place on the top and bottom clamshell (The top and bottom clamshell take (4) bearings each)

Take (4) 624zz bearings and push them through the 3D-printed idler pulleys. Leave the 5th bearing for later when you assemble the Y-axis

Assemble the X-Axis (Carriage)

- Get (4) M3-0.5 x 20mm screws, (4) M3 nuts, (4) M3 washers and (4) 624zz bearings with the idler pulleys installed

- Take one screw and feed a washer through it, the washer will rest on the bearing. The nut will be at the bottom of the carriage, which will secure the bearing in place

Assemble the X-Axis (X-Support)

- Slide the clamshell through the 450mm (X-axis) linear rods

- Use a rubber mallet again to attach the last X-support on the linear rods

- Make sure that the rods stick out equally on both sides

- Slide the other end of the threaded rod through the hole on the X-support

- Put on the last set of nuts and washers to hold the X-support in place

- Now that the X-axis is complete, you can use (2) Phillips M3-0.5 x 16mm screws per X-support to help keep the linear rods from sliding

- Take the (2) 350mm linear rods and insert them the Y-back piece by using a rubber mallet

- Get (1) M4-0.5 x 35 screw, (1) M4 nut and the 5th 624zz bearing

- Get (2) M3-0.5 x 16 screws to secure the linear rods

- Slide in the bearing when inserting the screw through the Y-back piece

- Slide the the linear rods/Y-back piece through the LM8UU bearings and attach the Y-front piece using a rubber mallet

Step 6: Assemble the X-Y Axis (Belt)

- Use a pair of needle nose pliers to help guide the GT2 belt more easily through the clamshell

- Take the two ends of the belt and slide them through the “teeth” on the Base Slider

- The belt should be tight and not loose

- Note that once the GT2 belt is on, it is normal for the clamshell not to move easily

- Get (2) 3mm linear rods and the following 3D printed parts (Slider, Pen Holder, Base Slide, 3MM Metric Thumb Screw)

- Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together.

- Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part. You may need to use (3) M3-0.5 nuts in order to hold it in place

- Push the Slider and Pen Holder together to make one piece

- Now take that new part and the (2) 3mm linear rods and slide the rods through the holes. Place a small spring in between the two parts so there is a little bit of pressure to lift the Slider. You may need to cut the spring a bit until there is an adequate amount of pressure on the slider.

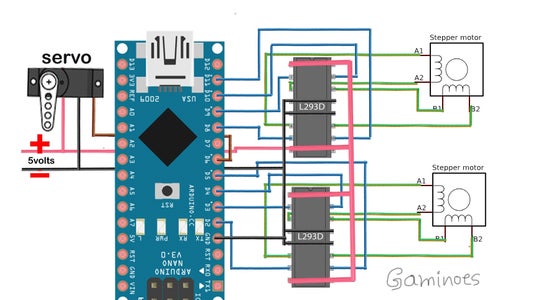

ELECTRONICS

I prefer you can use Arduino uno CNC Shield

Ready to your all circuit

1) 4pcs A4988 Stepper Motor Driver

2) Expansion Board A4988 Driver

3)Arduino UNO First of all take hit sink and stick on A4988 motor Driver.

4pcs A4988 Stepper motor driver connect on expansion board A4988 driver module, then connect the arduino with expansion board and connect all wiring The shield also has a built-in micro stepping control - meaning that instead of using full steps or half steps like a large CNC would do, we can make the motors move by 1/16 or 1/32 of a step to make the laser move with the maximal precision possible. However, the motors will consume more electricity: they will get hot quicker.

To use the micro stepping modes, short some of the mode pins together. Different combinations give different resolutions. Take a look at the chart for the different configurations possible. When the shield is programmed, add the A4988 drivers to it and wire up the rest of the electronics.

To find the coils of the stepper motors, use a multimeter. If there's resistance between the two wires, you have a coil. On the schematic, the coils are represented by two wires of the same color.

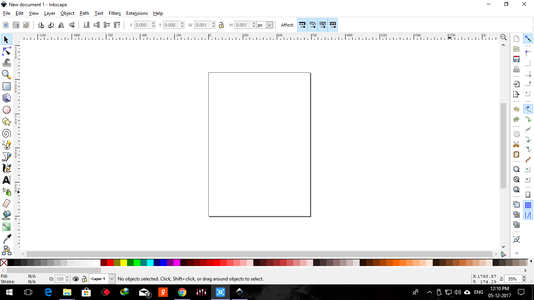

Inkscape which is the graphics design software (draw or import graphics)

Inkscape MI GRBL Extension (convert graphics to G-Code)Universal G Code Sender (sends the G-Code to the robot causing drawing motion)GRBL which is the Arduino firmware (programmed into the Arduino Uno)

Arduino: https://www.arduino.cc/en/software

Universal G-code sender: https://winder.github.io/ugs_website/...

Inkscape: https://inkscape.org/release/inkscape..

4xiDraw & km laser: https://drive.google.com/file/d/1YO8-...

Processing: https://processing.org/download/

drawing to G-code processing: https://drive.google.com/file/d/1PIFx...

watch video for full setup

hookup_QLVR1z3Ob1.jpg

DIY Projects Lab

Related channels and tags.

- home automation

Simple, modern, and precise pen plotters

Axidraw machines work with a variety of writing instruments, including permanent markers and fountain pens. the unique writing head extends beyond the base of the machine, making it possible to write or draw on almost any flat surface. axidraw is the real deal: designed, manufactured, and supported in usa, and backed by exclusive software for realistic handwriting and automation..

Watch the video >

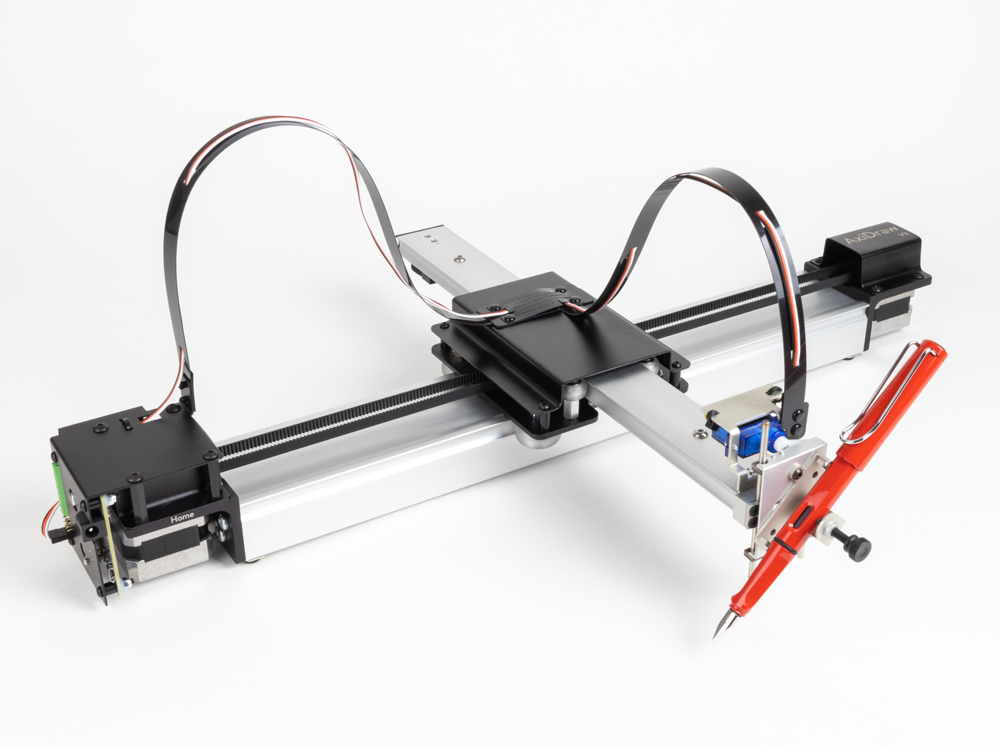

AxiDraw Models

Compact and popular

- 8½ × 11” / A4 Plot Area

- Sturdy aluminum construction

- Our most popular model

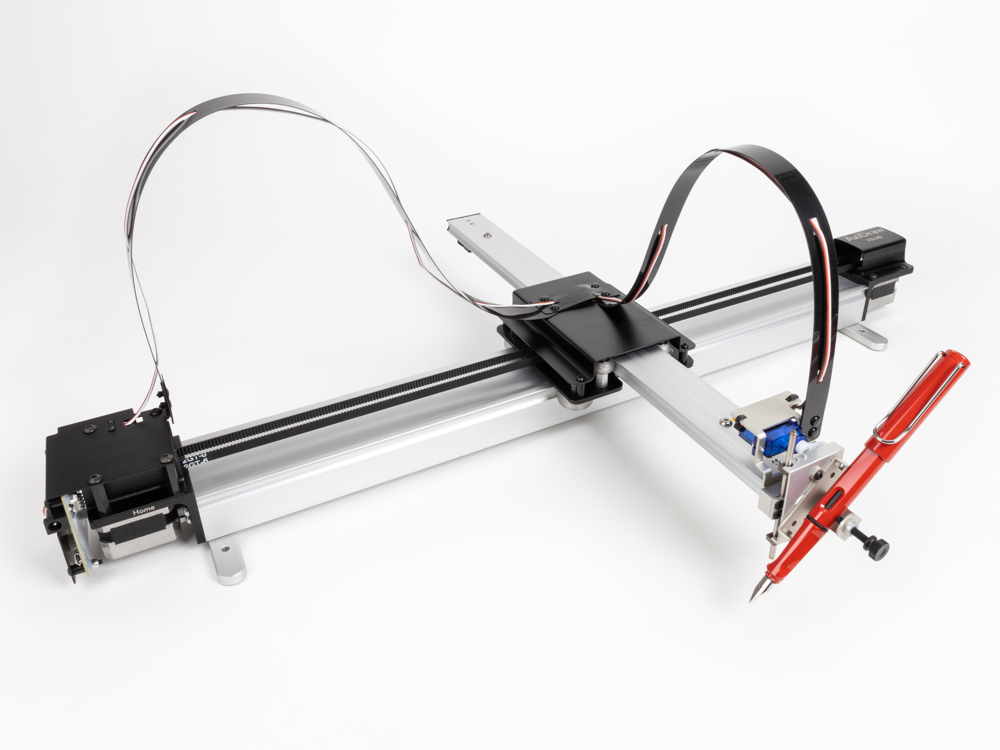

AxiDraw V3/A3

Larger plot area.

- 11 × 17” / A3 Plot Area

- Extended feet for stability

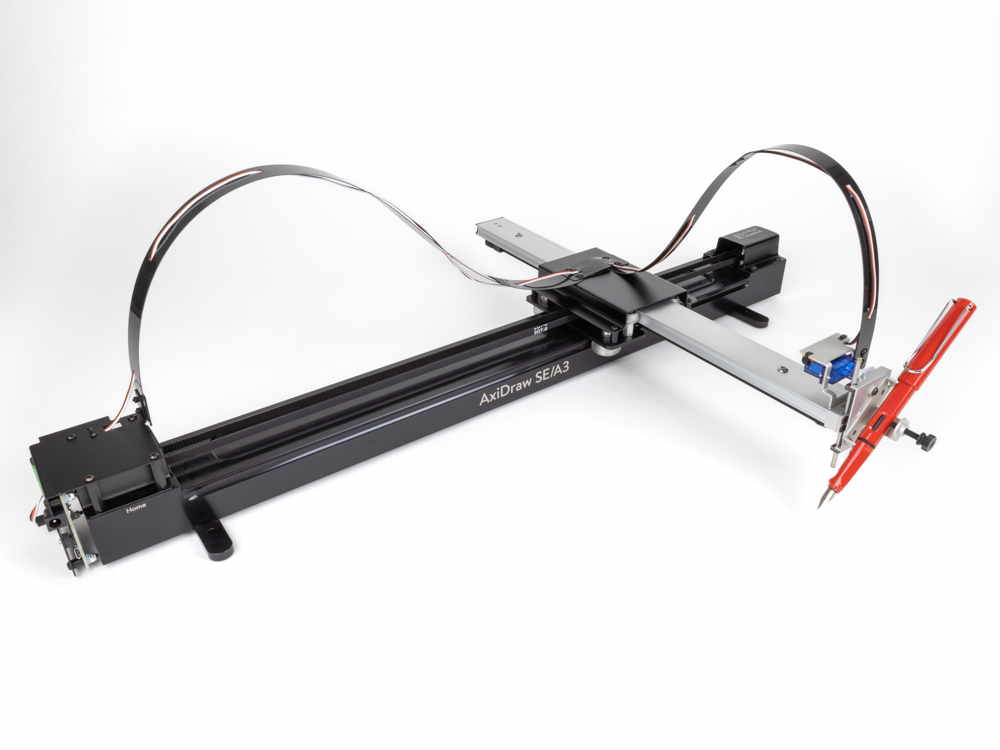

AxiDraw SE/A3

Special edition.

- CNC milled solid aluminum base

- Additional accessories included

Additional AxiDraw models and accessories are available at Evil Mad Scientist

Where to buy AxiDraw

AxiDraw machines are available for purchase directly from Evil Mad Scientist as well as from select distributors:

Frequently Asked Questions

The AxiDraw is a pen plotter, which is a type of simple robot. Its sole function is to guide a pen (or other implement mounted in the pen holder) along the set of vector lines, curves, and paths that you ask it to follow. Everything that the machine is ultimately capable of, such as drawing graphics, writing text, or signing documents, are expressions of this basic function. It is capable of drawing essentially anything that can be composed from a set of lines.

In practice, this is much like using a traditional printer, except that you need to take care that your documents are made of paths, rather than pixels.

The AxiDraw is an extremely versatile machine, designed to serve a wide variety of everyday and specialized drawing and writing needs. You can use it for almost almost any task that might normally be carried out with a handheld pen.

AxiDraw does not require proprietary pens or ink: you can use your own pens, chosen within certain guidelines.

AxiDraw can hold most types of pens and similar instruments up to 5/8" (16 mm) diameter. (A larger XL Pen Clip is available as well to fit larger pens.)

Good choices for pens to use include fountain pens, permanent markers, liquid-ink rollerball pens, technical pens, small-bodied whiteboard markers and other writing and drawing instruments that do not require significant downward pressure. While we refer to writing and drawing instruments as “pens” to be concise, other instruments such as automatic pencils (particularly with soft lead), chalk, charcoal, and brushes can also work well in many cases.

You can read more about pen choices in our documentation here .

AxiDraw does not require special paper; you can use almost any kind and size of paper. (You can even use all kinds of things that are not paper.)

The XY travel (printable area) of the AxiDraw V3 is just over that of both US letter (8½ × 11”) and A4 paper sizes. The larger size models have about twice this travel.

You can work with any size of paper up to the size of the travel area. You can write directly onto small pieces like business cards (or a whole array of them), medium size pieces envelopes and note cards, or sheets of paper.

You can also work with paper larger than the travel area. The unique design of the AxiDraw features a drawing head that extends beyond the body of the machine, making it possible to also draw on flat objects bigger than the machine itself. For example, you can set it right on top of a box to write an address. You can even set it on top of a poster board, chalkboard, or whiteboard to draw graphics in place.

For most applications, the standard-size AxiDraw V3 is the best choice. It's compact so that it fits on your desk more easily, and has enough plotting area to cover any size up to 8½ × 11” / A4.

The larger AxiDraw V3/A3 has twice the plotting area and is perfect for people who need to plot larger items, or to fit two smaller items — like two US Letter or A4 pages side by side, or a sheet of paper plus an envelope.

The Special Edition AxiDraw SE/A3 has the same plotting area as the V3/A3, but features a heavy, rigid base CNC machined from a solid block of Aluminum. It's our top-of-the-line machine, and includes a few nice accessories as well.

Available AxiDraw accessories include alternate pen holders, a tripod mount, a rigid mount that can be used instead of the pen slide, extended feet, extra clip easels, and magnetic workholding easels. You can find them listed here at Evil Mad Scientist.

AxiDraw requires a reasonably modern computer (Mac, Windows, or Linux) with an available USB port and internet access to download software.

Mac requirements: MacOS 10.7 or newer

Windows requirements: Windows 7 or newer

Linux requirements: Recent versions of Ubuntu and similar widely-supported distributions work well. If you are using an obscure or "challenging" distribution, we'll still do our best to help you out.

No. All standard AxiDraw models (V3, V3/A3, SE/A3) come complete, assembled, tested, and ready to use.

If you get a head start by reading the user guide and installing the software, you can be up and plotting five minutes after opening the box.

If you prefer a model that requires assembly, there is now also AxiDraw MiniKit 2 which comes as a kit.

Internet access is required only for downloading software and for access to online documentation.

Internet access is not required while preparing files or using AxiDraw.

A universal-input plug-in power supply is included with the AxiDraw. It accepts worldwide 100 V - 240 V input, and has a US/Canada style plug. For other regions, an inexpensive plug shape adapter will be needed.

No. Most users just make a file or drawing and plot it.

(That said, programming interfaces are available for those who are interested in them.)

You do not need to purchase any additional software to use AxiDraw.

AxiDraw is normally controlled through a set of extensions to Inkscape, the excellent, popular and free vector graphics program. Basic operation is much like that of a printer driver: you import or make a drawing in Inkscape, and use the extensions to plot your text or artwork. It's all handled through a straightforward graphical user interface, and works cleanly on Mac, Windows and Linux.

Yes, and we highly encourage you to do so. Reading the manual is a great way to determine if AxiDraw is a good fit for you.

The AxiDraw V3 family user guide is available for download here .

Unlike a (raster-based) inkjet or laser printer, the time that it takes a plotter to print a page is not fixed. Rather, it depends on the length of distance that the pen has to travel. The AxiDraw typically moves at about the speed of a human hand, depending on your settings, and the plotting time varies accordingly.

This question is much like asking how long a human takes to write or draw on a piece of paper: Addressing an envelope might typically take a minute or two, but complex artwork can potentially be a matter of hours. Such is the case as well for AxiDraw.

Yes. The speed of the AxiDraw is adjustable, depending on your tradeoff between faster completion and higher precision. AxiDraw can move quite quickly (faster than a human normally can) when making large strokes with a wide-tipped marker, but even a (human) calligrapher will slow down for higher neatness. The wedding invitation text in our video should give you a decent idea of typical writing speed when going for higher neatness; that example is a little slower than people normally write.

Yes! The best way to do that is by directly capturing your signature as you sign it, for example on a phone or tablet screen. That way, the AxiDraw can replay it just in the same way that you wrote it. Capturing a signature is covered in our documentation on handwriting, here .

We also have exclusive utilities, available to AxiDraw owners, that can add handwriting-like "defects" to your text. Text laid out in perfectly even rows (like what you get with a handwriting font in MS word) always looks a little too "robotic" to be handwriting.

No, not in the way that you might hope.

Yes, you can scan handwritten text, trace it with a bitmap tracing tool, and plot it. This is straightforward, and your AxiDraw will be more than happy to comply. (AxiDraw will plot the paths that you provide to it.)

However, and with only rare exceptions, automatic tracing of scanned handwriting creates a somewhat unpleasant imitation of handwriting, and we do not recommend this approach as part of any workflow.

You can read more about tracing scans in our documentation, here . (In brief: there are excellent ways to use the AxiDraw to reproduce handwriting, but starting with a scan is not one of them.)

Not at present, but it is something that we are looking into.

Some AxiDraw users do use various types of paper handling machines — sometimes printers with built-in paper feeders and sometimes commercial solutions. Professional print shops and companies that make equipment for them have many different ways of moving pieces of paper from point A to point B.

More commonly, for small scale use, AxiDraw users manually swap out paper clipped to small clipboard easels or use larger-size AxiDraw units that allow multiple pages to fit within the print area.

Yes; you can see a few examples here .

The key issues that you need to be aware of is that the fabric generally needs to be held taut, and you need to choose markers that don't easily catch on the fabric. It is likely that with care and experimentation you will be able to make it work.

Calligraphy is not the same in any sense as (for example) simply using computer fonts or plotting a drawing. Calligraphy generally involves individually sculpted letter shapes, and in many cases pen movements that are far more complex than AxiDraw can provide.

That said, some calligraphers do use AxiDraw for low-end busywork (say, addressing hundreds of place cards), saving some wear on their wrists and presumably passing along some of the cost savings.

The AxiDraw is designed for moving a pen, not a carving or cutting tool. It does not have the type of rigidity that you need for carving, nor the ability to apply significant downward force.

That said, a number of people have experimented with it. Here is one notable project, using the AxiDraw for cutting cardstock and vinyl.

AxiDraw can be used with whatever fonts are on your computer, so long as the text is converted to paths before plotting.

We have developed a special-purpose software application called AxiDraw Merge , which is a mail merge solution for AxiDraw.

Once you are set up with it, AxiDraw Merge can automatically (1) populate a template with data sourced from a CSV file, (2) render the text into handwriting-like stroke-based fonts, (3) add intentionally variations so that text does not lie upon straight lines, and (4) plot the document. It can also merge and plot subsequent pages upon a button press or after a time delay.

AxiDraw Merge is available to AxiDraw owners at no additional cost.

The AxiDraw is designed to work on flat surfaces, and we do not test them in the vertical orientation. That said, quite a few AxiDraw users have mounted theirs to the wall without apparent difficulty.

One issue to consider is that the AxiDraw's pen holder normally rests the pen on the writing surface by its weight alone. On the wall, you'll need an alternative to gravity for lowering the pen. The typical solution is a rubber band.

(1) We maintain a large and growing library at the AxiDraw Wiki Page , our central documentation site for all things AxiDraw. Our documentation is clear and comprehensive, with special sections to help you get up and running quickly.

(2) We have support forums for the AxiDraw, here .

(3) Most importantly: We're the designers and manufacturers of the AxiDraw, and we're here to help! Please don't hesitate to contact us directly.

AxiDraw does not have a duty cycle limit. You can run it all day long if you like.

The AxiDraw is designed to be serviceable for a long life. Components such as the drive belt, rolling wheels, ball bearings, and stepper motors can all be replaced in the unlikely event that it should become necessary. (And, those parts are actually available if you need them.)

One component on the AxiDraw is considered expendable and may need regular replacement in heavy duty (e.g., industrial) settings. The small pen-lift servo motor does wear out over time but is inexpensive and straightforward to replace. For heavy duty applications, you may wish to keep a spare on hand. We do also offer a performance upgrade option to a long-lasting brushless pen-lift servo motor , which also gives the AxiDraw a major speed boost.

No. While AxiDraw is most commonly controlled through a set of extensions to Inkscape, there are other methods of plotting including the command-line interface (CLI).

Many AxiDraw users do their design work in other programs, and use Inkscape as their "page setup" screen for plotting.

For real-time plotting in response to user input and for certain other generative applications, you can plot directly within Processing .

AxiDraw machines are designed, manufactured, and tested right at our facility in Sunnyvale, California.

Demos are available by appointment at our shop in Sunnyvale, CA. Please contact us to request an appointment.

We're open M-F, 12-6, and closed on US postal holidays.

The AxiDraw has two precision stepper motors in its base. Together, they drive a single looped belt that moves the carriage around in the XY plane. The high-performance linear stages feature custom-designed wheels that roll smoothly on custom aluminum extrusions, specially designed for high stiffness and light weight.

The pen-lift stage uses a separate mechanism: a smaller third motor, combined with a precise low-friction linear stage, serves to lift the pen off of the page.

In addition to the popular AxiDraw models listed above we do make a few other standard sizes, as well as custom-sized and custom-configured AxiDraw machines.

One notable version is the compact AxiDraw MiniKit 2 which comes as a kit.

If you need a compact AxiDraw that is not a kit, we do make an AxiDraw V3/B6 (with plot area of 190 × 140 mm, or 7.48 × 5.51 inches) that is available by special order.

We also make larger format and customized AxiDraw machines to order, including the AxiDraw SE/A2 and SE/A1 with plot area of 594 × 432 mm (23.4 × 17 inches) and 864 × 594 mm (34 × 23.4 inches), respectively. These larger machines typically require a custom shipping quote.

No; we do not offer any printing services.

Please contact us and ask; we're here to help.

Support Resources

Our AxiDraw documentation wiki is a continually growing library of resources for getting started with the AxiDraw, including a thoroughly detailed PDF user guide , support forum, a number of tutorials on specialty topics, and links to additional resources.

Personal support: We're here to help!

Having an issue? Need to know where to find something in the manual, or how to do something that isn't in the manual? Want to ask us about your application before deciding to purchase?

If so, please don't hesitate to contact us directly. Our goal is to provide personal, competent service both as you get set up and running, and for as long as you have your AxiDraw.

- Search for:

No products in the cart.

Return to shop

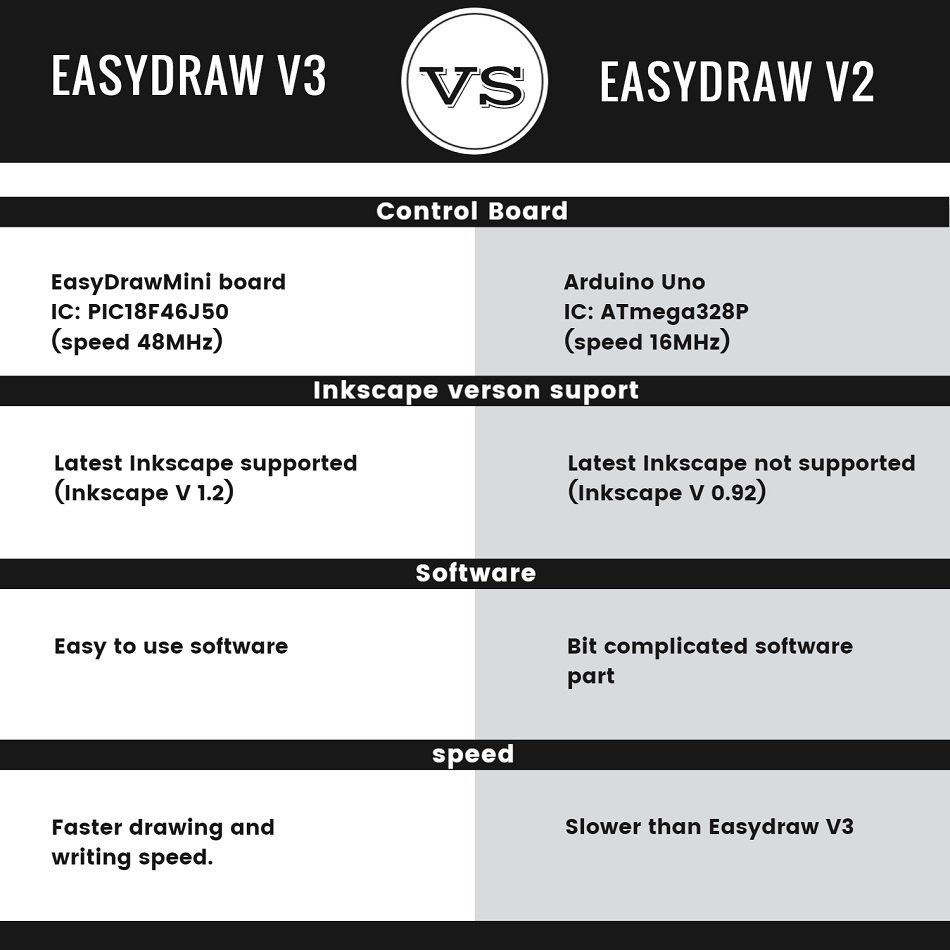

EasyDraw V2 Writing and Drawing Machine (FULLY ASSEMBLED)

₹ 8,590.00 (inc GST)

- Description

- Additional information

- Reviews (43)

buy easyDraw V3 with more FEATURES and very easy to use software.

software tutorial english

software tutorial hindi

DRAWINGBOT is an Open Hardware version of the famous machine AxiDraw which it is a pen plotter, capable of writing or drawing on almost any flat surface. It can write with pens, permanent markers, pencils, and other writing implements to handle an endless variety of applications. Its unique design features a writing head that extends beyond the machine, making it possible to draw on objects bigger than the machine itself. The biggest advantage of the machine is that it can be placed over the book because of the core XY extending design of the machine.

All parts are printed in ABS plastic in 70 °C heated chamber which makes the 3d printed layer very strong.

PLA parts are bad its brittle and break easily and lose strength after few months and the glass transition temperature of PLA is very low so if we place the parts under the sun or inside a parked car under the sun. the parts will slowly melt and deform and become unusable.

All of the above problems are solved by using ABS plastic. ABS is tricky to print its printed in a special water-cooled actively heated 3dprinter.

The Arduino will be programmed by us. so you dont have to upload any code to Arduino.

it’s just plugged and play, just connect the USB cable to the PC or laptop and power adaptor to the machine. and install the software and start drawing or writing

MAX DRAWING ARE : 24 X 30 CM

The machine comes with 3 month’s warranty. In case any parts get damaged contact us via WhatsApp / PH: 8590094244 we will send replacement parts without any cost and guide you to fix it.

After the warranty, you have to pay for the parts. ( all parts will be available )

Delivery will take 5-8 woriking days

43 reviews for EasyDraw V2 Writing and Drawing Machine (FULLY ASSEMBLED)

Safeer Khan – 03/03/2021

I found this product after researching some marketing options for handwritten style letters for my business, and I am SO GLAD I did. This machine allows me to work on other aspects of my business while it writes out my direct mail pieces. You do have to be around to put the next page and hit go, but it is so much less time-consuming than doing it myself, and miles cheaper than hiring it out. I had not used Inkscape before, or any kind of machine like this, so it took me some time to learn to use it.

Tinu Balaji – 05/03/2021

The quality of the product is excellent, but the software is not beginner-friendly

Ankit Mhatre – 10/03/2021

karthik Deekonda – 11/03/2021

The hardware works well. The provided software didn’t work on macOS out of the box, you have to install windows

Veer Gurjar – 20/03/2021

binod kumar – 20/04/2021

The product worked great. I hit a couple of bumps and WhatsApp for help. The help came immediately and all is working great. I REALLY recommend this product.

Ritik Shah – 13/05/2021

nice packing

Mutheswar Rao – 18/05/2021

Excellent product! I love what I buy, I recommend 100% makes perfect drawings and incredible accuracy.

salim M – 14/07/2021

I ordered this product expecting nothing and got a really nice surprise. Works great. Minor software issues were resolved quickly.

Sudhir Bharti – 23/08/2021

The plotter came 100% assembled, and the files were easy to download and install. One happy customer here.

Logeshwaran Shankar – 02/09/2021

Good product, great service

Veer Gurjar – 24/09/2021

slow shipping, it took 8 days to deliver. product is good

Jaya prakash Reddy – 29/09/2021

received, thanks

Selvarajan Natarajan – 29/11/2021

Very nice quality and repeatability on prints.

Indrajith Vs – 02/12/2021

i received my box but without any instruction book or CD inside it 💔 the good thing is that there is a detailed video in the website product description which explains everything in detail. now the machine is working fine. and also the packaging is very good.

Arjun Nambiar – 04/12/2021

The product works great. I have a disability that makes writing difficult and got this to write thank you notes. Like other reviews, the software was a challenge but customer support was top draw and we were up and running in minutes

T Anandhakrishnan – 15/12/2021

The pen up and down servo motor stopped working after 4 months of use, and when I contacted maker q they told me that there is only 3 months warranty for the machine, so I paid for the servo motor (250 rs). After replacing the servo motor the machine is working fine.

Adeel Khan – 30/12/2021

Sureddy Narendra – 08/01/2022

This innovation is amazing!! I was able to “write” all 100 of my wedding thank you notes while working!

Noor Mohammed – 08/01/2022

Software is crap and it won’t work on Mac

ANIK DAS – 19/01/2022

This thing is perfect! i does what it say it will do. I wanted it for drawings and it does it perfectly its just trying to figure out the software. Trail and error is all i have to say and plenty of YouTube videos hahaha it pretty much can draw anything.

rakesh kumar – 28/01/2022

thank you very much

Parikshit Saha – 11/02/2022

The parcel came unharmed and satisfied with the order

Shinto John – 12/02/2022

1st time having a calligraphy machine and I love it. Took me a while to figure out how things work, but seller provides prompt support. Plus, I recommend watching tutorials on Inks-cape on you-tube if you are not already familiar.

gaurav biswas – 25/02/2022

Takes a second to figure out but once you do its gold. I use it for marketing

Prince Kumar – 26/02/2022

Beautiful and amazing product it help me in my project work i am very happy with this budget segment product thank you maker q for this 2d cnc plotter

Rajesh K – 27/02/2022

when I opened the box one of the motor sides is broken and I contacted customer support they shipped a replacement part and refunded 400 RS. but it took a total of 12 days from the day of ordering the machine and finally being able to use the machine. Response for the maker q side is good and fast, that’s the only reason am giving 3 star

Alwin KJ – 21/04/2022

Gaurav Jain – 02/05/2022

So.e parts are broken and the wooden board is missing

Yadamani Venkateswarlu, Retired SI – 09/07/2022

Chiranjeevi P. – 13/07/2022

Anonymous – 25/07/2022

Nice product, fully assembled

I. Fiaz Ahmed – 08/08/2022

A Product without Software Installation Instructions or a Product Instruction manual and no Warranty card.

Joseph F. – 21/09/2022

Good product, helpful support by supplier. Price is also reasonable.

Anonymous – 29/09/2022

Exceeded my expectations! The tutorial was very helpful and within few trials were able to use the device. Highly recommended for engineers.

Aditya Mahajan – 17/12/2022

Good quality. VERY AWESOME, EASY TO UNDERSTAND AND EASY TO USE.

Ravikumar Kr – 15/01/2023

Software not provide bad problem

Prasad Mandelkar – 19/02/2023

your CNC plotter is very good but facing problem for softwares

Dudekula Basheer – 09/03/2023

It’s good tqs for u and u are team members

Arun – 15/03/2023

Working as expected..

Vispi – 29/05/2023

Your Tech Support, in setting up my plotter was really out of the way Tech Support … you really went the one step extra for a customer … THANK YOU 🙏

Yathish K. – 18/06/2023

Very good but the ugs is very headache

Karan – 31/01/2024

Bit difficult to operating

Only logged in customers who have purchased this product may leave a review.

Related products

EasyDraw V2 2D Plotter 3d printed parts (ABS plastic) kit

EasyDraw V2

EasyDraw V2 Writing and Drawing Machine kit (NOT ASSEMBLED)

Username or email address *

Password *

Remember me Log in

Lost your password?

Email address *

Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy .

Simple Easy Homework Machine

Introduction: Simple Easy Homework Machine

This machine is built using cheap materials and doesn't cross 7$ to build. To build this you need some patience and 2hours of time. And you must be familiar with soldering and wiring since this involves a small circuit. Once it is built just plug in this device to your computer and run the required content to be written and it will start the job in no time. This I have called writing machine since it uses a pen to write the things. So let's build your own writing machine.

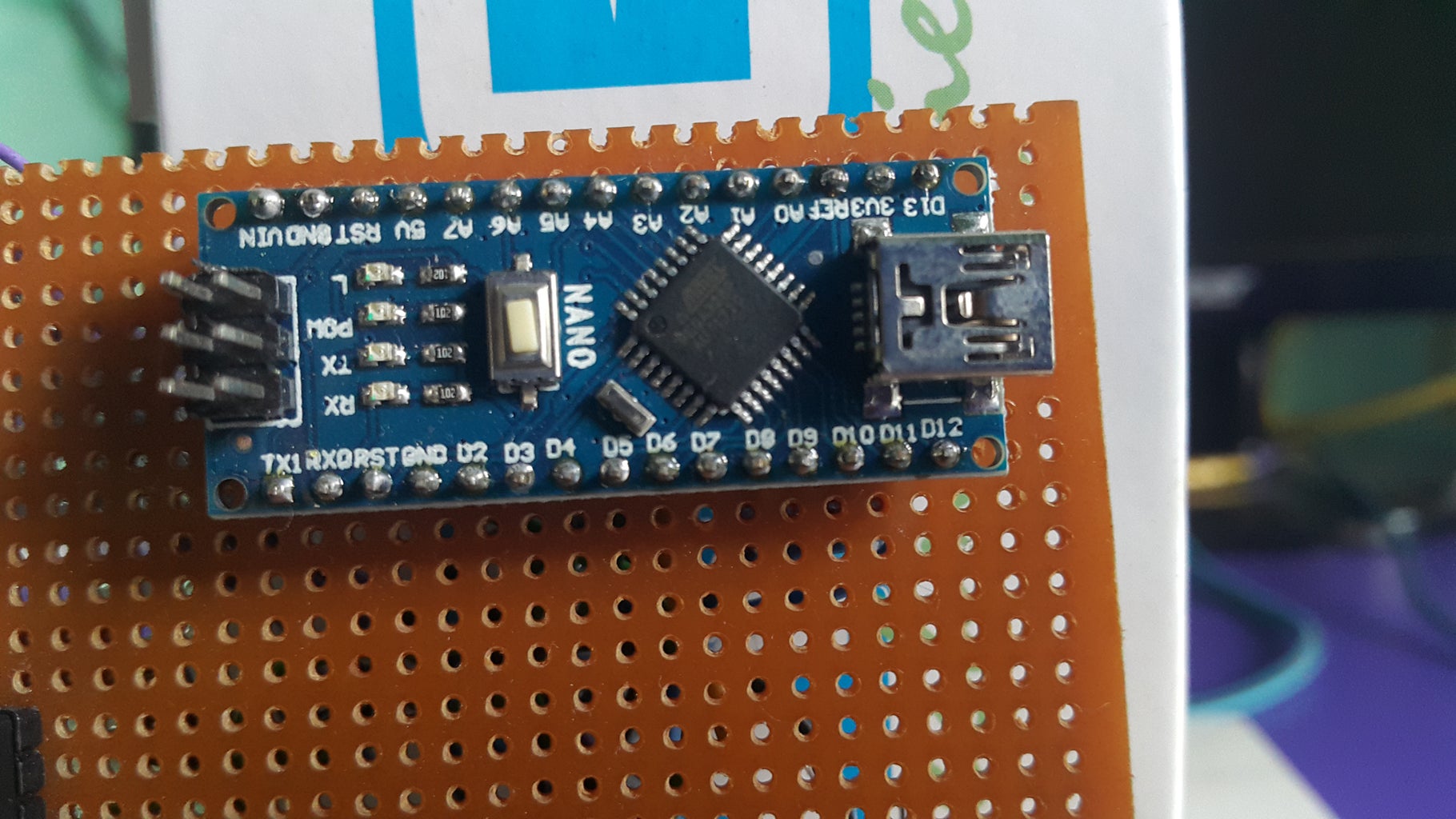

Step 1: Things Gathering

You need following things. 1. arduino nano. x1 2. L293D IC with Base connectors. x2 3. PCB board. x1 4. Computer DVD writers. x2 5. Some hard cardboard boxes. 6. 1ft.X1ft. plastic or wooden or metallic board. 7. Some wires. 8. soldering iron and wire. 9. Some male and female headers. 10. USB cable for arduino. 11. A pen with a strong string or thread which is flexible. 12. A micro 9g tower pro servo motor.

Step 2: Building X and Y Axis Carriages

Take out the stepper Motor from dvd writer as in the picture. You need to open 2 dvd writers carefully without damaging anything inside it. Screw one carriage which contained the stepper motor to the 1ft.x1ft. board, this is the X-axis motor carriage. Keep some gap for Y axis motor carriage to be placed . Left most side of the X-axis carriage stick a cardboard box as in picture and make a long slot at the bottom of the box so that x axis carriage plate can go inside the box. stick a plastic rectangular board to x axis carriage as in image which supports the paper to be placed on it.

Step 3: Circuit Building Process

Place the female headers on PCB board according to the number of pins on either sides of arduino and trim excess and solder that female headers to the one side of the PCB board. and also solder the IC bases to the same board. And solder the wires wherever required by looking into the above circuit image. and solder 3 pins of male header to the same board to facilitate the servo connection to be plugged and unplugged easily.

Step 4: Finalizing and Start Writing the Things

You can make this device write the things of your choice only after writing the gcode. Don't worry about gcode much,. since we are going to use a software to convert the required image or text into .gcode file, and then streaming the .gcode file using another software called Processing. I will give the direct links to download the Processing and Ink-space software so that you can crete your own .gcode files and stream whenever you wish. And the arduino code which you need to upload to your arduino board once and for all. DOWNLOAD EVERYTHING IN A .rar FORMAT

Participated in the Arduino Contest 2017

Recommendations

Puzzles and Games Contest

Build-A-Tool Contest

For the Home Contest

IMAGES

VIDEO

COMMENTS

Step 2: Make Y Axis Slider. Take two 42 cm long 8 mm threaded rods, 8 mm nuts, and the stepper motor holder after all the 3D-printed parts have been completed printing. Then, as shown in the picture, passing this threaded road from the bottom holes in the stepper motor holder.

Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together. Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part. You may need to use (3) M3-0.5 nuts in order to hold it in place.

Step 1: Assembly - Y Axis. Take the 2040mm profile and attach the base plates to both the ends. Use the sliding nuts and m4 bolts to attach the base plates to the profiles. Now turn the profile and attach rubber feet to the bottom slots of the base plates. These rubber feet will hold the machine in place on smooth surfaces.

Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together. Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part. You may need to use (3) M3-0.5 nuts in order to hold it in place.

In this video we make homework writing machine using Arduino uno and stepper motors.This writing machine can be used for writing and drawing in science proje...

This is the Version 2.0 of the Arduino Homework Writing Machine - 2D CNC Plotter. this version comes with a lot of upgrades from the previous one, which incl...

How to Make Homework Writing Machine at homeLearn How to make homework writing and drawing machine at home using Stepper motor.You can make this type of auto...

Get (2) 3mm linear rods and the following 3D printed parts (Slider, Pen Holder, Base Slide, 3MM Metric Thumb Screw) Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together. Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part.

Homework writing machine project description: Servo Motor: A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration.It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with ...

Hi guys , As per the title this is a simple project using Arduino to make Homework writing machine at your home.This machine can draw any design and write any type of fonts.You can see sharpness and perfection of writing in photos. If you are looking for more Arduino Projects ideas than writing machine is the best projects for Arduino projects.

How to make Homework Writing Machine at homeFiles: https://goo.gl/uCwzvRUNO R3 Arduino: https://goo.gl/bpbfJiArduino CNC Shield V3: https://goo.gl/VzsXqh3D P...

This homework writing machine project features a DIY writing machine that uses a typical pen. It can do outline writing and digital signature or even a real text. The main system uses a 2 axis stepper motor driver board with Nema stepper motors and Mg90S Metal Gear Servo control. The 2 axis stepper motor driver board serves as the main controller.

Take the (2) 350mm linear rods and insert them the Y-back piece by using a rubber mallet. Get (1) M4-0.5 x 35 screw, (1) M4 nut and the 5th 624zz bearing. Get (2) M3-0.5 x 16 screws to secure the linear rods. Slide in the bearing when inserting the screw through the Y-back piece. Y-Front.

The document describes how to build a DIY homework writing machine at home. It can be used to write or draw on surfaces larger than the machine itself using pens, pencils or other writing implements. The machine uses an Arduino Uno controller and CNC shield to control two Nema 17 stepper motors that move a writing head along an X-Y axis. It can be built for around $75 and has a maximum drawing ...

Simple, modern, and precise pen plotters. AxiDraw machines work with a variety of writing instruments, including permanent markers and fountain pens. The unique writing head extends beyond the base of the machine, making it possible to write or draw on almost any flat surface. AxiDraw is the real deal: Designed, manufactured, and supported in ...

1. Download and run the AxiDraw software installer for Windows: Download link (21 MB ZIP archive) The installer is an executable, named "AxiDraw_391.exe"; Unzip, open, and run it. 2. Download and install Inkscape version 1.2 from the download page at Inkscape.org. (Most users will want the 64-bit version and the "MSI" installer.)

Learn- How to Make a CNC Writing Machine at HomeThis time I am uploading this video with full details and Programming alsomust follow the procedure step by s...

DRAWINGBOT is an Open Hardware version of the famous machine AxiDraw which it is a pen plotter, capable of writing or drawing on almost any flat surface. It can write with pens, permanent markers, pencils, and other writing implements to handle an endless variety of applications. Its unique design features a writing head that extends beyond the machine, making it possible to draw on objects ...

Step 16: Creating the GCODE FILE. Open Inkscape. Import the desired image and convert it to path. In Extensions, Use the MI GRBL EXTENSION. Press apply and create the GCODE FILE. Open File mode in GCODE Sender. choose the file. hit send. SIT BACK AND LET THE MACHINE DRAW.

Step 2: Building X and Y Axis Carriages. 3 More Images. Take out the stepper Motor from dvd writer as in the picture. You need to open 2 dvd writers carefully without damaging anything inside it. Screw one carriage which contained the stepper motor to the 1ft.x1ft. board, this is the X-axis motor carriage.

1-48 of 73 results for "homework writing machine robot" Results. Avishkaar MEX Robotic ARM 3-in-1 DIY Robotics & AI Science Kit, Robot Toys for Aged 8,9,10,11,12, Building and Construction Set with 150+ Parts, DIY STEM Learning Gift for Boys & Girls, Made in India. 5.0 out of 5 stars 13.

A new tool called Writable, which uses ChatGPT to help grade student writing assignments, is being offered widely to teachers in grades 3-12. Why it matters: Teachers have quietly used ChatGPT to grade papers since it first came out — but now schools are sanctioning and encouraging its use. Driving the news: Writable, which is billed as a ...

How to Make Homework Machine at homeLearn How to make homework writing and drawing machine at home using DVD writer of your computer.You can make this type o...

How to Make Homework Machine at homeLearn How to make homework writing and drawing machine at home using Stepper motor.You can make this type of automatic wr...