Welding and Fabrication Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Construction & Engineering Industry » Welding and Fabrication

Are you about starting a welding and fabrication business ? If YES, here is a complete sample welding and fabrication business plan template & feasibility report you can use for FREE .

When we look around where we work or reside, we will sure note items that you that was produced by a wielder or has been through a welding process. This is why the services of skilled wielder will always be needed and the craft will keep getting attractive.

It is believed that the wielding industry is one industry that shows a substantial return in your investment at every turn and moment. When starting a wielding business, you go need to go for welding training. You also need to be certified, and to get certified, you need to undergo certain trainings in welding.

A Sample Welding and Fabrication Business Plan Template

1. industry overview.

This ever blooming industry seems to be growing the fastest with recent years showing maximum growth. The welding industry has been approximately stated to grow at the very least 6% per year. Conventional electric arc welding equipment and filler metals represent over two-thirds of this total.

This industry has many segments and each segment of the industry and each welding process have its own growth patterns noted after accurate research. It’s important to note that Welding is now the universally accepted method of permanently joining all metals.

The welding industry is considered a mature industry but it is still a growing industry from different perspectives. The true impact of welding on the metalworking industry should be measured in the value of the parts produced by welding, the amount of money saved by the use of welding over other metal fabrication processes, and in the value of products made possible by welding.

Facts on ground has gone a long way to show the growth of the welding equipment and materials industry, which also serves as an indication of the projected growth for the future.

2. Executive Summary

Sonic Welders (SW) is an established wielding and fabrication business that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. We at SW are very much dedicated to providing the highest quality workmanship, reaching the agreed delivery dates, and actualizing the custom work exactly in accordance with the customer’s concept a d astonishing designs.

Our focus at SW is to find out who our future target clients are and understand our marketing strategy, and to expand our operations and marketing so it can substantially increase profitability while also serving the united states of America. Sonic Welder will be established in Thunder Bay, Wisconsin.

Marquette is the county seat of Marquette County and it’s in the upper peninsula of Lake Superior. SW is a business built or established as a sole proprietorship and is owned by Nathan Cardozo who has over 27 years of experience in the wielding and fabrication industry and has built a reputation of excellence and quality work that is very important in the industry.

We at SW plan to manufacture and sell aluminium boat docks and also perform other welding and fabrication services for truck bodies and commercial equipment. We at SW plan to gain our market share in the following target markets: Marinas in Marquette, Lake Superior Upper Peninsula (boat owners), Commercial Customers, Agricultural Entities, and Local Municipalities.

3. Our Products and Services

We at SW primarily wield, fabricate and sell aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to fabricate and repair truck bodies, and perform aluminium repair jobs. All unused scrap metals will also be recycled by Sonic Welders.

The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy. We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

We at SW also plan to raise revenues through the distribution of welding supplies, gasses, and related items that will be bought primarily by local contractors (and also individuals that do their own welding). We at SW expect gross margins of 50% on all welding products sold in our company.

4. Our Mission and Vision Statement

- Our vision at SW is to become the recognized local leader in our targeted market for all wielding and fabrication activities.

- Our mission at SW is to build the best quality product, supply over the top service at installation, and provide exceptional customer service after the sale of the product.

Our Business Structure

It is very important to note that the backbone and founder of SW is Nathan Cardozo. Nathan Cardozo got a dual degree from UC Berkeley, one in business, the second in mechanical engineering . We believe that Nathan Cardozo chose these fields because of his interest in parts construction and general engineering theories and application.

Nathan also believed that it would be very crucial for him to have a business background for possible future application. Sonic Welders will be run solely for now by Nathan Cardozo. He will be in charge of product procurement, order taking, customer service, and assorted other activities.

But as he moves to grow the business, by travelling to the trade shows, doing all necessary things as well as ramping up sales to accommodate the distributor sales, Nathan Cardozo will employ workers that will cover a wide range of services for the company. These workers include;

Chief Executive Officer

Service and Production Supervisor

Operations Manager

- Sales and Marketing Executive

- Welding and Fabrication Engineers / Technicians

Client Service Executive

5. Job Roles and Responsibilities

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counselling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- In charge of providing direction for the business

- Creating, communicating, and implementing the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- In charge of signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Serve as project manager of the organization; works directly with employees

- Develops strategic plan by studying new automobile technological, and financial opportunities; presenting assumptions; recommending objectives.

- Accomplishes subsidiary objectives by establishing plans, budgets, and results measurements; allocating resources; reviewing progress; making mid-course corrections.

- Coordinates efforts by establishing procurement, production, marketing, field, and technical services policies and practices; coordinating actions with corporate staff.

- Builds company image by collaborating with customers, government, community organizations, and employees; enforcing ethical business practices.

- Maintains quality service by establishing and enforcing organization standards.

- Maintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; benchmarking state-of-the-art practices; participating in professional societies.

- Make certain that the service and production department perform efficiently, coordinate employee efforts, and facilitate communications between management and computer repairs and maintenance engineers and technicians

- Make sure s that the organization works in line with international best practices.

- In charge of overseeing the smooth running of HR and administrative tasks for the organization

- Defining job positions for recruitment and managing interviewing process

- Carrying out staff induction for new team members

- In charge of training, evaluation and assessment of employees

- In charge of arranging travel, meetings and appointments

- Oversee the smooth running of the daily office and factory activities.

Sales and Marketing Manage r

- Manage external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Model demographic information and analyse the volumes of transactional data generated by customer

- Identifies development opportunities; follows up on development leads and contacts; participates in the structuring and financing of projects; assures the completion of development projects.

- Writing winning proposal documents, negotiate fees and rates in line with organizations’ policy

- In charge of handling business research, market surveys and feasibility studies for clients

- In charge of supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develop, execute and evaluate new plans for expanding increase sales

- Create new markets cum businesses for the organization

- Empower and motivates the sales team to meet and surpass agreed targets

Accountant / Cashier

- In charge of preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyses financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- In charge of financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting for one or more properties.

- In charge of developing and managing financial systems and policies

- In charge of administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the business

- Serves as internal auditor for the business

Welding and Fabrication Engineers and Technicians

- In charge of developing welding and fabrication techniques, procedures, and application of welding equipment to problems involving fabrication of metals, utilizing knowledge of production specifications, properties and characteristics of metals and metal alloys, and engineering principles: Conducts research and development investigations to develop and test new fabrication processes and procedures, improve existing or develop new welding equipment, develop new or modify current welding methods, techniques, and procedures, discover new patterns of welding phenomena, or to correlate and substantiate hypotheses.

- Tasked with preparing technical reports as result of research and development and preventive maintenance investigations.

- Builds welding procedures to guide production and welding personnel relating to specification restrictions, material processes, pre- and post-heating requirements which involve use of complex alloys, unusual fabrication methods, welding of critical joints, and complex post heating requirements.

- In charge of evaluating new developments in welding field for possible application to current welding problems or production processes.

- Responsible for directing and coordinating technical personnel in performing inspections to ensure workers’ compliance with established welding procedures, restrictions, and standards; in testing welds for conformance with national code requirements; or testing welding personnel for certification.

- In charge of contacting personnel of other agencies, engineering personnel or clients to exchange ideas, information, or offer technical advice concerning welding matters.

- May perform experimental welding to evaluate new equipment, techniques, and materials.

- Welcomes clients and potential clients by greeting them in person or on the telephone; answering or directing inquiries.

- Make sure s that all contacts with clients (e-mail, walk-In centre, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Serves as a auto parts sell attendant

- Manages administrative duties assigned by the creative director in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to Make sure accurate and helpful information is supplied to clients when they make enquiries

6. SWOT Analysis

We at SW believe will have the plan and capabilities to take over the welding industry. We hope to build and maintain an extensive shop which can handle all welding and fabrication issues. We have adequate plans to make our business the best in the industry, which is why we contacted Mandolin Business Consultants to do our SWOT Analysis for us.

Mandolin Business Consultants are known for the experience and agility they posses in terms of business consulting and analysis.

They were very thorough with their dealings and outlined below is a summary of the SWOT Analysis they conducted for us. The following SWOT analysis captures the key strengths and weaknesses within our company, and describes the opportunities and threats facing us at SW.

- Outstanding reputation.

- Quality – we at SW will guarantee all of our work, using the highest quality materials available and the most experienced fabricator available.

- Customer Care – we at SW will go extra time to make sure the customer is satisfied with the service provided.

- Experience – Over 27 years in the construction business, Nathan Cardozo is a talented, experienced fabricator, with a strong work ethic.

- Our weaknesses at SW come from the lack of funding to grow the business. Grant money will be used to purchase equipment, company expansion, create website, advertise, and hire an employee.

Opportunities

- Growing market with a significant percentage of our target market still not knowing we exist.

- Strategic alliances offering sources for referrals and joint marketing activities to extend our reach.

- Increasing sales opportunities beyond our “lake area” to include the many other lakes in the [STATE] area.

- The only obstacle to our success at SW would be further downswings in the economy of the world

7. MARKET ANALYSIS

- Market Trend

After due research, it is believed that semiautomatic welding will greatly increase, machine and automatic welding will increase modestly, but manual welding is decreasing at least as a percentage of the total. Furthermore, it is now evident that the following must be considered with regard to the future of welding:

- There will be continuing need to reduce manufacturing costs and to improve productivity, since wage rates for the people in manufacturing industries will keep on increasing, the cost of metals for producing weld metals and filler metals will also continue to be more expensive, and energy and fuel costs will increase and shortages may occur.

- Also there will be a continuing trend towards the use of higher-strength materials, particularly in the steels and lighter-weight materials.

- There will be more use of welding by manufacturing industries, probably decreasing the use of castings.

- There will be a trend towards higher levels of reliability and higher-quality requirements.

- The trend towards automatic welding and automation in welding will accelerate.

Productivity in this very industry is considered the amount of welding that can be done by a welder in a day. Productivity can be determined by several factors, the most important of which is the operator factor or duty cycle. Operator factor for a welder is the number of minutes per eight-hour period that is spent actually welding.

The different methods of welding have different average duty cycles. Manual welding has the lowest operator factor with semiautomatic welding approximately double and machine welding the next highest, with automatic welding approaching 100%.

Efforts will be made to utilize those processes that have the highest-duty cycles. The expected trend will be away from manual welding towards semiautomatic welding and to machine or automatic welding when possible.

Another factor affecting productivity of welders relates to the deposition rate of the welding process. The higher current processes have the highest deposition rates, thus the submerged arc welding process and the electro slag welding process will remain important as costs must be reduced.

8. Our Target Market

We at SW hope to focus on our ability to complete any project with the required equipment by having all the necessary tools.

Sonic Welders market segmentation scheme is fairly straightforward, and focuses on the target markets of the lake marinas within the banks of Lake Superior, local municipality contracts , agricultural entities, and commercial and residential customers.

We also understand that our prospective customers will prefer a certain quality of work and timeliness and it is our duty at SW to deliver on their expectations. We at SW know that there will always be a need for fabrication companies.

We understand that the customers within the fabrication industry want exceptional workmanship and affordable rates. We believe that our prospective customers will appreciate the quality service that we are hoping to offer, as well as the knowledgeable and experience of our owner.

We believe that these customers have the option to go elsewhere, but they understand that giving their business to SW will be of more advantage to them because we at SW deliver the dedication that they desire. We know Boat dock fabrication is seasonal but with aggressive marketing efforts could expand company operations and reach many more markets along the lakes. Our target market may include;

- Marinas around the mighty Lake

- Agricultural entities in Marquette

- Local Municipalities

Our competitive advantage

It is a known fact that Welding will continue to be a highly efficient and economical method for maintaining structural integrity when joining metals and non-metals, including plastics and composites. We also believe that the welding industry will continue to maintain a strong reputation for producing reliable and cost-effective welded components in the global market.

We have also noted after extensive research that the industry due to a growing need for welded components and a decline in skilled workforce is focused on continual design advancements in welding machines (particularly welding automation) to further enhance efficiency.

The competition in this industry is becoming heavy and unbelievable, which is why we are making all plans efficiently to make sure we take over the market.

We at SW have a strong competitive edge in the industry due to the many fabrication services we hope to offer. We hope that by building a business based on satisfying clients, SW simultaneously build defences against competition. We at SW plan to continue helping clients understand what we offer them and why they need it.

We at SW also plan to become a leading provider of fabrication services in the local area. We believe that to achieve this, we have to invest in many ways that will pay off in competitive advantages for our customers, by pre-job conferencing upon request and assisting in the technical or conceptual design.

9. SALES AND MARKETING STRATEGY

- Sources of Income

It is very important to note that the US fabricated metal parts manufacturing industry includes about 55,000 companies with about 0 billion in combined annual revenue. Major companies in specialty segments include Ball Corporation, Flowserve, Mueller Industries, Snap-On, and The Timken Company.

We believe that because of the special manufacturing processes involved for individual parts, most companies make a limited range of products.

We also have noted after extensive research that the industry as a whole is fragmented: the largest 50 companies account for about 20 percent of revenue. But concentration can be high in industry segments such as boiler, cutlery, metal can, and spring manufacturing.

We at SW plan to get revenues by wielding, fabricating and selling aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to get funds by fabricating and repairing truck bodies, and performing aluminium repair jobs.

All unused scrap metals will also be recycled by us. The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy.

We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

10. Sales Forecast

Our primary ethics at SW is to maintain an excellent customer relation skills and work ethic; these skills we believe will be useful in making customers comfortable in believing us to provide their construction services. We believe that maintaining our customer’s satisfaction is an implicit part of building a relationship that will encourage repeat business.

Our sales projections at SW are based on our promising foundation, our planned increase investment in advertising for our business and future expansion will make us even more appealing to prospective customers. Our Sales forecast for the coming three years in as follows;

- First Year-: $650,000

- Second Year-: $1,100,000

- Third Year-: $2,452,000

- Marketing Strategy and Sales strategy

We at SW totally understand that satisfied customers will aid our business by referring our company to other clients who need our services. We at SW plan to serve the metal fabrication market segment. Our specific choice of target markets at SW is based on an in-depth understanding of our prospective customer’s needs.

We believe that our skills and capabilities will allow us to very well compete and develop our reputation within our business area. This is the reason why we believe that obtaining grant funding and developing a marketing strategy will improve our profitability levels and help us in building a strong customer base.

We at SW plan to use a direct sales force and relationship selling to reach its target markets. These channels are most appropriate because of time to market, reduced capital requirements, and fast access to established distribution channels.

We also plan to advertise in Yellow Pages and local newspapers, and create a website with information, construction background, and contact information will be available online. References to the website will be mentioned in all other forms of advertising once the website is in effect.

SW is a member of the Marquette Lake Association and will obtain a mailing list for potential customers. But we believe that our marketing budget will allow our employed marketing firm the leverage to push us to the top.

11. Publicity and Advertising Strategy

We at SW plan to use email marketing campaigns as an outreach to our prospective customers. We all know that technology that incorporates video with email and offers very powerful, robust and dynamic features. Another advantage is in communicating through the use of streaming video embedded within the email.

We at SW believe that the use of this technology will give us a strong competitive edge and outreach to the community. We at SW are also planning to incorporate an email drip campaign with video into our marketing efforts.

We believe that this technology will more effectively market to our customer and potential customer base. We understand that it is cost effective (averaging about $99 per month), especially when compared to the $1,000’s spent on print advertising, mailing and postage.

We believe that the built-in analytics provide immediate feedback as to the campaigns effectiveness and who actually viewed the message. We also hope that the Auto responders with a specific message can be utilized as an immediate follow-up tool.

It is important to note that we at SW hope that this new email marketing campaign technology will serve to position us to achieve and sustain name recognition in front of our current market within the local community.

We believe that this type of marketing is cost effective and efficient. The first thing most of us do every day is check our email in-box. It is also worthwhile to state that we at SW are currently unaware of any of our competitors incorporating the use of this technology within their operation.

12. Our Pricing Strategy

We at SW know that we are in a purely competitive industry where each business must be a price taker. Meaning that a business that has no ability to affect the market price of its services, regardless of how much work it does is destined for a meltdown.

Therefore, putting it, that marginal revenue (the revenue incurred by producing or servicing one more unit) is equal to the price charged. Furthermore, because the demand curve is essentially horizontal, we at SW plan to at total capacity without affecting the price in the market.

This means that we at SW must strive or look to charge our clients at the market price (or lower). We believe that the price we charge will depend on the workload and duration of the said work, and we understand that as long as marginal costs do not surpass revenues, the method to increase short-run profits is to service automobiles at maximum capacity.

- Payment Options

We at SW after extensive research understand that payment options are the forces that bring any business closer to the heart of the people, and we hope to make use of that extensively. We will be bringing payment options that are unique and will make the payment for the service we offer very easy for our customers.

- Payment by via bank transfer

- Payment via POS machine

- Payment via online bank transfer

- Payment via mobile money

- Payment with cash

To provide all these outstanding services, we have partnered with a renowned bank in the country and we hope to make use of that relationship. Our bank account numbers will be made available on our website and promotional materials so that it will be easier for clients to make payments when necessary.

13. Startup Expenditure (Budget)

It is very important to note that no matter how breath taking your ideas and goals might be or how attractive your business plan might be, without proper and enough financing your ideas are just like water poured on a rock.

It is a known fact that in every business enterprise fund is a big ingredient that can move a business to the limelight and without a detailed business plan; a business won’t be able to land substantial funds from prospective investors. We have analysed the market and have decided on how we plan to spend our start up fund.

These are the key areas where we will spend our start – up capital on;

- Business incorporation fees in the United States of America will cost – $750.

- The budget for Liability insurance, permits and license will cost – $3,500

- Acquiring a work facility that can accommodate a good number of cars per time for at least 6 months (Re – Construction of the facility inclusive) will cost – $100,000.

- The amount required to purchase the needed tool box and repair equipment – $25,000

- Equipping the office (computers, printers, projectors, markers, servers / internet facility, furniture, telephones, filing cabinets, and electronics) will cost – $30,000

- Amount required to purchase the needed software applications to run our business – $3,500

- Launching an official Website will cost – $500

- Amount need to pay bills and staff members for at least 2 to 3 months – $70,000

- Additional Expenditure such as Business cards, Signage, Adverts and Promotions will cost – $5,000

From our detailed cost analysis above, we will be needing approximately two hundred and fifty dollars ( $250,000 ) to start SW. Everything has been put in place and every fact made sure of, that is to enable us achieve our goal and objectives.

Generating Funding / Start up Capital for Sonic Welders

Sonic Welders (SW) is an established wielding and fabrication business owned by Nathan Cardozo that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. The business will be funded by him until we decide to accept investors or partners. Ways we hope to raise our start up capital may include;

- Generate part of the start – up capital from personal savings

- Generate part of the start – up capital from friends and other extended family members

- Generate part of the capital from the bank (loan facility).

Note: Nathan Cardozo has been able to raise $100,000 ( $70,000 from personal savings and $30,000 as soft loans from family and friends ) and we are at the final stages of obtaining a loan facility of $100,000. We have verified all the necessary procedures to actualize or get our start up cost.

14. Sustainability and Expansion Strategy

We at SW understand that our business being medium in nature requires a simple organizational structure. We believe that the implementation of this organizational form calls for Nathan Cardozo to make all of the major management decisions in addition to monitoring all other business activities.

Nathan Cardozo started working in the metal fabrication industry after working in the salt mines for several years and now brings over 27 years of experience to the success of the Company. Our management philosophy at SW is based on responsibility and mutual respect.

We believe that SW will maintain an environment and structure that will bring about productivity and respect for customers and fellow employees. At Sonic Welders, everybody is considered as an individual and we strive to the very last point to respect their dignity and recognize their merit.

We believe that our employees will be encouraged to have a sense of security and pride in their jobs. We will also afford equal opportunity for employment, development, and advancement for those qualified. Our employees at SW will be committed to:

- Afford a safe work environment to protect employees, the employees of customers and subcontractors, and the public.

- We will also supply safe products for customers.

- We will also without setbacks keep on improving the company’s safety program to reduce the risk of accidents and occupational illness in a changing work environment.

- We will advice our employees to participate in accident prevention programs and take personal responsibility for their own and their co-workers’ health and safety.

- Regulatory compliance and contribution to high safety standards for our industry.

- Monitoring workplaces, enforcing safe work practices, and communicating the company’s safety performance to employees and other stakeholders.

Checklist/Milestone

- Business Name Availability Check: Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts various banks in the United States: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of All form of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Leasing, renovating and equipping our facility: Completed

- Generating part of the start – up capital from the founder: Completed

- Applications for Loan from our Bankers: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of the Needed software applications, furniture, office equipment, electronic appliances and facility facelift: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business (Business PR): In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

- Establishing business relationship with banks, financial lending institutions, vendors and key players in the industry: In Progress

Related Posts:

- Dump Truck Business Plan [Sample Template]

- Home Remodeling Business Plan [Sample Template]

- Excavation Company Business Plan [Sample Template]

- Mobile Manufactured Home Business Plan [Sample Template]

- Engineering Consulting Business Plan [Sample Template]

👉 Relocate to Canada Today!

Live, study and work in canada. no payment is required hurry now click here to apply >> immigrate to canada.

7 Steps to Start Welding Business in Nigeria and Succeed

Read the step-by-step guide on how to start welding business in Nigeria – One profitable venture an entrepreneur in Nigeria can invest in is the welding business.

A close look around our immediate environment will reveal one or more items that have undergone a welding process. Welding is a skill that stays high in demand. It’s a business that promises a high return on investment.

The Nigerian government needs to pay close attention to the business of welding because it has huge potentials to contribute massively to our economic growth. The negligence of the government to the business has made it difficult for young people to be attracted to the craft; welding is believed to be a dirty job as many are ignorant of huge potentials of the craft.

In this article, skilled welders working under people and are willing to run their own business will find relevant information on how to go about starting their welding business and how to build a good customer base. Potential investors will also find this article useful.

What is Welding Business ?

Welding is a fabrication process that joins metallic or thermoplastic materials together by heating to their melting temperature, with or without the use filler metal and pressure. It is a process used to join two metal or thermoplastic pieces together to produce a permanent, strong and durable single piece.

Types of Welding

There are different welding processes that are classified according to the source of energy used for heating the metals.We have the Chemical welding, chemico- mechanical welding, Electro- chemical welding, Electro-mechanical welding and Electric- arc welding.

Below are a some types of welding:

1. Hot plastic welding: is utilized for manufacturing plumbers fittings, chemical tanks, heat exchangers etc

2. Contact plastic welding: this is similar to spot welding process, here electric conduction is replaced together with puncher tips to perform tasks.

3. Hot plate welding: this type employs a great platen to melt the parts to get welded.

4. High frequency welding: this employs high frequency electro magnet waves in the welding process and it has very specific applications.

5. Ultrasonic welding: this method employs high frequency sound waves to melt the parts to become welded. Friction welding also known as vibration welding: parts are made to produce friction with the effect of vibration between clamping along with parts to the plastic causing materials to melt resulting in a weld.

Others are:

6. Spin welding 7. Laser welding and 8. Solvent welding

The processes mentioned above will be well taught and better explained when welders undergo mandatory professional training. To set up your own welding business you will need to

How to Start Welding Business in Nigeria

1. get professional welding training.

To start welding business, find a good welding school and enrol yourself, this is where the foundation of the business would be laid. Get extensive training and acquaint yourself with everything you need to succeed from fabrications, repairs and welding processing.

You cannot start welding business in Nigeria without being certified and you can only be certified after you have been professionally trained. Before contracting welders,contractors always request for their licences. You will need to get your certificates and licences to operate.

2. COME UP WITH A BUSINESS PLAN

Before you start welding business, make sure you have a detailed business plan will serve as a guide and aid to setting up your business without foregoing important details. Plan carefully to avoid huge gaffes that may cost you heavily. Include your company name, business goals, mission, funding and modus operandi, create a unique brand.

3. REGISTER YOUR BUSINESS

Before you start welding business, make sure you register your business with the corporate affairs commission. Find out the cost and process of registering your business then find potential investors or lenders to and convince them to finance your business , this is applicable where you do not have your own start up fund.

Hire the services of a lawyer to assist with the legal processes involved to make your business legitimate and free from government harassment. Meet the tax obligations of the state where you will be operating from.

Read Now: New Steps to Register and Incorporate Your Business in Nigeria to PLC or LTD

4. FIND A SUITABLE LOCATION FOR YOUR WELDING BUSINESS

You will need enough space for your business because welding deals with lots of metals and equipment such as welding table, gases, tig rods, mig wires, millermatic 2500 or 251, oxygen and acetylene cylinders, electric welding machines, workshop tools like bench vice, spanners and pliers, angle grinder machines, welding consumables like steel chalk, electrodes and safety equipment like boots, gloves, safety goggle, helmet for welders, welding tongs to mention a few.

Create space for other departments like the accounts, customer care and reception and other necessities. When this is done, you can purchase your equipment mentioned earlier in readiness for business.

5. HIRE LABOUR

You will need the services of other certified welders to aid in contracts or jobs with a huge work load. Find and employ professional and experienced welders to help you start easy and to ensure prompt delivery of excellent services that boosts the reputation of your business.

6. GET INSURANCE

Welding is a risky venture; the probability of accidents occurring during the execution of jobs is high. You need to insure your business against disaster to cover your employees and equipment from loss and liability.

It is essential that you create a safe environment for your employees by ensuring they comply with safety rules and taking precautions against disaster.

See: 5 Importance of Insurance in Nigeria and Why You Need it Now

7. MARKET YOUR BUSINESS

Do whatever it takes to make your business known. Print and distribute complimentary cards, use social media and the internet, use traditional media and keeping spreading the word about your business. Once your publicity becomes effective, it will be relatively easier to find and get contracts that will help you grow.

Welding is incredibly important in the world we live in, it is an essential part of life. It wouldn’t be possible to have cars, ships, planes, pipelines, roads, offices, homes, schools without welding.

Nigeria needs to attract younger generations to this craft by educating them to get involved with training that can teach them about welding. There is currently a shortage for welders in Nigeria, it is therefore not a bad idea for one to invest in this craft as we can’t get enough of them.

Before you start welding business, think thoroughly about the impacts of welding on everyday life and you will b e convinced there’s no better industry to invest in.

📢 We are hiring writers!

Copyright warning.

How To Produce Disinfectants and Germicides like Izal

How to plant water leaf to get good yields anytime of the season, related articles.

10 Ways to Invoice Like a Pro

9 steps to start keke (tricycle) business in nigeria.

14 steps to start Knitting business in Nigeria

How to start nanny service business in nigeria, leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

It looks like you're using an ad blocker!

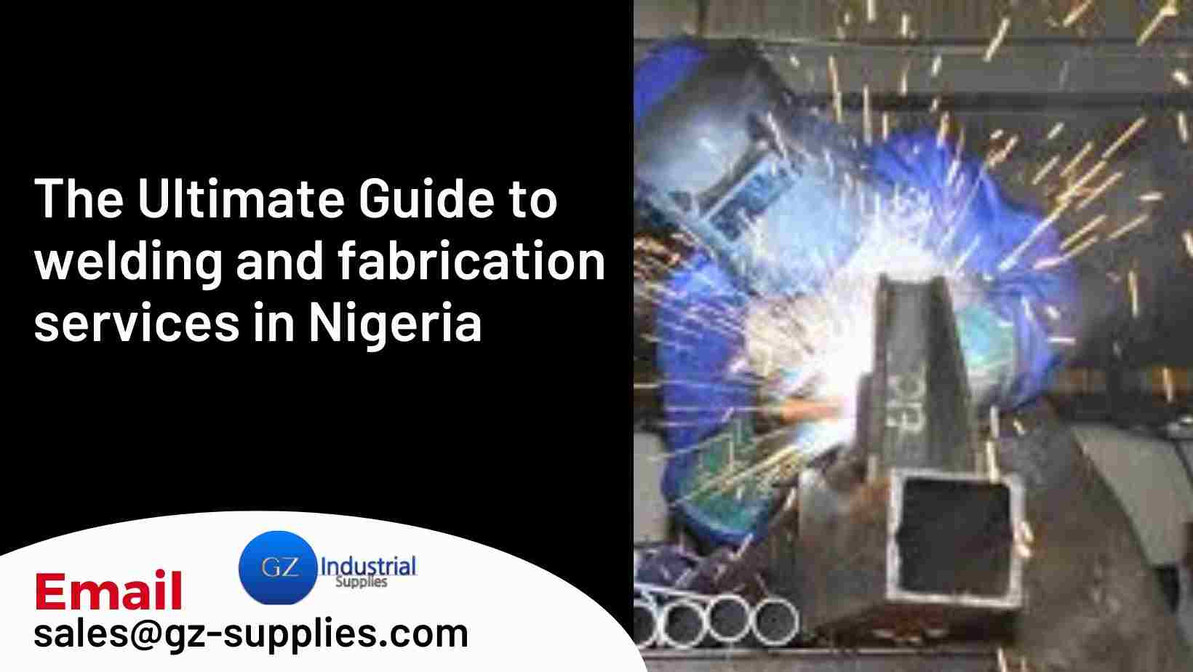

The Ultimate Guide to welding and fabrication services in Nigeria

Welding and fabrication plays a vital role in Nigeria's economic development. These services are fundamental to various sectors, including construction, automotive, oil and gas, and infrastructure projects. The ability to join and shape metal materials is crucial for building the frameworks of buildings, bridges, pipelines, and manufacturing essential machinery and vehicles.

we offer a comprehensive range of welding and fabrication services designed to meet the diverse needs of various industries. Our expertise encompasses MIG, TIG, and Stick welding techniques , allowing us to work effectively with a variety of materials, including steel, aluminum, and titanium. We specialize in custom metal fabrication projects that require precise, high-quality welds, such as structural components for buildings, custom automotive parts, and furniture. Additionally, our services include metal repair and maintenance, ensuring that all fabrications are not only created to the highest standards but are also durable and long-lasting. With reliable equipment and a team of certified professionals, we are equipped to handle both large-scale industrial projects and smaller, more intricate designs, ensuring that every job is executed with the utmost precision and quality.

This guide will provide a comprehensive overview of the welding and fabrication services in Nigeria, covering everything from the basic techniques and tools used to the legal and business aspects of setting up a welding workshop . Whether you're a seasoned welder, a newcomer to the field, or an investor, this guide aims to equip you with the knowledge needed to succeed in the Nigerian welding industry.

Overview of Welding and Fabrication Services

Welding involves fusing materials, typically metals, using high heat to melt the parts together and allowing them to cool, causing fusion. Fabrication is the process of creating metal structures by cutting, bending, and assembling processes. Together, these services form the backbone of metalworking industries, enabling the creation of everything from simple tools to complex structures.

Types of Welding Techniques

- MIG Welding (Metal Inert Gas): Uses a continuously feeding wire, is easy to learn, and is efficient for joining thin or thick metals.

- TIG Welding (Tungsten Inert Gas): Known for its precision, it allows for stronger and higher quality welds in more delicate metal.

- Stick Welding: Uses an electrode that doubles as the filler material, suitable for outdoor conditions and thicker materials.

Metal Polishing

Offering rough to fine polishing with up to a #4 brush finish, our metal polishing services can create the perfect surface for your components. GZ Custom Fabrication team regularly develops specialized finishes for assemblies, decorations, recreational products, threads, and more.

We also partner with trusted companies to offer plating, anodizing, electropolishing, and painting services to meet projects’ particular needs.

Custom Welding

Offering six different welding processes, GZ Industrial Supplies is a premier welding service provider. Our team specializes in SMA Welding GMAW (MIG welding), GTAW (TIG welding), soldering, and automated seam welding, along with cylindrical welding for tubing and pressure applications, as well as aerospace metal fabrication welding. Our custom industrial fabrication services include resistance spot welding for automotive and electronics industry applications, fencing and more. We fabricate all our products We proudly comply with AWS (American Welding Society) and ASME (American Society of Mechanical Engineers) standards.

Setting Up a Welding and Fabrication Business in Nigeria

Business registration and legal requirements.

To start a welding and fabrication business in Nigeria, you must first register your business with the Corporate Affairs Commission (CAC). This registration provides legal recognition and allows you to operate within the law. Additionally, obtaining necessary permits and licenses, such as from local government authorities and the Standards Organization of Nigeria (SON), is crucial to ensure compliance with industry regulations.

Investment and Financing Options

Starting a welding and fabrication business can require significant capital investment. Costs include purchasing equipment, renting or buying workspace, and hiring skilled labor. Prospective business owners can look into various financing options such as bank loans, private investors, or government grants specifically aimed at supporting small and medium-sized enterprises (SMEs).

Tools and Equipment Used in Welding and Fabrication

1. essential tools and equipment.

The primary tools for a welding and fabrication shop include welding machines, cutting torches, grinders, and safety gear like helmets and gloves. Advanced equipment may include CNC (Computer Numerical Control) machines for precise cutting and shaping, and plasma cutters for efficient metal slicing.

2. Recommendations for Suppliers and Brands

It's important to purchase high-quality tools from reputable suppliers to ensure reliability and efficiency. Brands such as Lincoln Electric, Miller, and Hobart are renowned for their welding equipment. In Nigeria, suppliers like GZ Industrial Supplies offer a range of quality products and support services.

Skills and Training

. necessary skills for welders.

Welders need a solid understanding of different metals and their properties, as well as proficiency in various welding techniques. Critical thinking and problem-solving are also essential to address the challenges that may arise during welding processes.

.Training and Certification

Formal training can be acquired through technical colleges or vocational schools in Nigeria that offer courses in metalwork and welding. Additionally, obtaining certification from recognized bodies such as the American Welding Society (AWS) can greatly enhance a welder's credentials and opportunities for advancement.

Challenges in the Welding and Fabrication Industry

Local challenges.

The Nigerian welding and fabrication sector faces several unique challenges, including:

- Infrastructure Deficiencies: Inconsistent power supply and inadequate transportation infrastructure can significantly hinder operational efficiency.

- Skill Shortages: There is often a gap between the industry's demand for skilled labor and the available workforce, which can affect the quality of work and project timelines.

- Material Availability: Fluctuations in the availability and cost of raw materials can impact project budgets and completion schedules.

Solutions and Innovations

To address these challenges, businesses can:

- Adopt Technology: Leveraging modern technology such as automated and robotic welding can improve precision and reduce reliance on manual labor.

- Training and Development: Investing in continuous training for staff can help bridge the skills gap.

- Local Sourcing: Building relationships with local suppliers for materials can reduce costs and increase supply chain reliability.

Health and Safety Regulations

Safety standards and best practices.

Welding and fabrication work involves inherent risks that can be mitigated by adhering to strict safety standards. Businesses must comply with Nigerian safety regulations and international best practices, including proper use of personal protective equipment (PPE), regular safety audits, and ensuring that all equipment is up to code.

Implementing Safety Measures

Effective safety measures include:

- Regular Training: Ensuring all employees are trained in safety protocols.

- Equipment Maintenance: Keeping all welding equipment well-maintained and up-to-date.

- Emergency Preparedness: Establishing clear procedures for handling accidents and emergencies.

Future Trends and Opportunities

Emerging trends.

The Nigerian welding and fabrication industry is expected to evolve with trends such as:

- Increased Automation: As technology advances, there is a growing trend towards automation, which can help tackle the issue of skilled labor shortages.

- Greener Practices: With global movements towards sustainability, there is a push for more environmentally friendly fabrication processes.

Opportunities for Growth

The ongoing development in sectors like construction and oil and gas presents continuous growth opportunities for the welding and fabrication industry. Additionally, initiatives to improve infrastructure and promote industrialization in Nigeria will likely increase demand for these services.

A. Further Reading

For those interested in deeper insights, recommended readings include industry publications and online resources that focus on advanced welding techniques and market analyses. checkout Tikweld blog posts

B. Industry Associations and Networks

Joining associations like the Nigerian Institute of Welding (NIW) can provide networking opportunities, industry updates, and professional development resources.

For more information on quality tools and materials for your welding and fabrication needs, visit GZ Industrial Supplies at https://gz-supplies.com . Explore our extensive range of products and benefit from our expert advice to enhance your projects and business operations.

frequently asked questions (FAQs) about welding and fabrication services

1. what is the difference between welding and fabrication.

Welding is a specific process that involves joining two pieces of metal together by melting the parts with heat and allowing them to fuse upon cooling. Fabrication, on the other hand, is a broader term that encompasses multiple processes including welding, cutting, bending, and assembling to create machines and structures from raw materials.

2. What are the most common types of welding used in industrial applications?

The most common types of welding used in industrial applications include:

MIG Welding (Metal Inert Gas): Versatile and fast, ideal for both thick and thin materials.

TIG Welding (Tungsten Inert Gas): Provides high-quality, precise welds for materials like stainless steel and aluminum.

Stick Welding: Effective for outdoor conditions and on rusty or dirty materials.

3. Can welding be done on all types of metals?

Most metals are weldable, but the approach and technique might vary significantly depending on the type of metal. For instance, metals like aluminum require specific techniques like TIG welding and special handling due to their properties like high thermal conductivity and oxidation tendency. Other metals, like cast iron, pose challenges but can be welded with the proper preheating and cooling techniques.

4. What safety measures should be taken during welding?

Safety measures in welding include:

Wearing appropriate personal protective equipment (PPE) such as helmets, gloves, and protective eyewear.

Ensuring good ventilation to avoid inhalation of harmful fumes.

Keeping flammable materials away from welding sites.

Regularly inspecting welding equipment for any signs of wear or damage.

5. How do I choose the right welding service provider?

Choosing the right welding service provider involves several considerations:

Experience and Expertise: Look for providers with extensive experience and knowledge in the specific type of welding you need.

Certification: Ensure the welders are certified and have undergone proper training.

Equipment Quality: Check if the provider uses high-quality, modern equipment that can handle your specific requirements.

Customer Reviews and References: Assess feedback from previous clients to gauge reliability and quality of service.

Contact Us Now to Discuss Your Fabrication Needs. We offer custom solutions for all your metalwork requirements .

Additional Resources

Understanding Metal Properties and Their Impact on Welding Success

Welding and fabrication price list in Nigeria..

Welding and fabrication work in Lagos, Welders near me

Welding and fabrication services in Abuja

This guide has provided a comprehensive overview of the welding and fabrication services in Nigeria, covering essential aspects from setting up a business to navigating industry challenges and looking ahead to future trends.With the right approach, tools, and training, there is significant potential for successful and profitable welding and fabrication businesses in Nigeria. Stakeholders are encouraged to leverage emerging trends and government initiatives to capitalize on these opportunities.

Contact us for all welding and fabrication services

- #welding and fabrication services

- #welding services

- #welding techniques

Recent Posts

Preventive vs. Reactive Surface Maintenance: Which Approach Is Right for You

The Science of Floor Paint: How it Works and What to Expect

The Definitive Guide to Protective Coatings: Types, Applications, and Benefits

Business Plan For Welding And Fabrication

Congratulations on taking the first step in creating a business plan for welding and fabrication. This is an essential step towards entrepreneurial success and a well-crafted business plan will provide a solid foundation for your business venture!

Whether you're a budding entrepreneur with a brilliant idea or a seasoned business owner looking to expand, a thoughtfully constructed business plan will help you plan and navigate towards business prosperity.

In this comprehensive guide, we will walk you through the essential elements of creating a business plan for welding and fabrication that captures your vision as well as attracting investors, partners, and customers alike. From defining your mission and identifying your target market to formulating financial projections and developing a robust marketing strategy, our aim is to empower you with the knowledge and tools needed to turn your aspirations into a reality.

So whether you're just starting out or you're looking to revamp your existing business plan, read on for everything you need to know.

Why is a business plan important?

A business plan will help you think about your welding and fabrication business like you’ve never done before. This thinking will help you clarify important elements like your long-term goals and objectives. You can then work backwards from your goals to develop strategies and marketing campaigns to help make these objectives a reality.

A business plan will also help you think about your customers in great detail. You will be able to understand their wants and needs, where they hang out, and exactly how you will target them. This clarity will enable you to focus on developing the products or services they want.

Finally, if you are seeking outside capital such as investment or a bank loan, a well-thought-out business plan will show them you are serious about your business and you have developed a clear and thorough plan of action to achieve success.

A Business Plan For Welding And Fabrication - The Key Parts

The executive summary, your company description, market analysis, products and services.

- Marketing Strategy

- Operational Plan

- Financial Projections

Risk Analysis

- Funding Request and Use of Funds (if applicable)

- Additional Information

An executive summary of your business plan for welding and fabrication is a brief overview of your business plan.

This is the first thing that potential investors or lenders will see, so it is crucial that you make a good impression. Keep this section short and highlight the key points of your plan.

What should an executive summary include?

- Overview of the Business

- Mission Statement

- Key Objectives

- Summary of Products/Services

- Financial Highlights and Funding Requirements (if applicable)

Remember potential investors don’t always have huge amounts of time to read your document so make sure that you condense the critical information, enabling the reader to make quick and well-informed judgments. Tips for the Executive Summary

Wait until you’ve written the whole business plan and then come back and complete the executive summary. This way you will know your business plan for welding and fabrication inside and out so you can highlight the key elements of the document. Remember the Executive Summary will shape the reader's initial perception of the business and whether they continue reading the document.

If you are looking for any tips on how to improve any section of your business plan, check out our Learning Zone , which has several in-depth guides on each section of the business plan.

The Company Description section of your welding and fabrication business plan is crucial as it offers a comprehensive overview of your business. This section provides essential information about your company's history, mission, vision, legal structure, location, and key milestones. It allows readers to gain a clear understanding of your company's fundamental characteristics and the context in which it operates.

When crafting your company description, make sure to include the following key elements:

- Business Name and Legal Structure: Clearly state the legal name of the company and its legal structure.

- Business History: Provide a brief overview of how the business came into existence. Highlight key milestones or events that shaped the company's growth and development.

- Mission and Vision Statements: Present the company's mission statement, which outlines its purpose and primary goals. Additionally, share the vision statement, which describes the long-term vision and objectives for your business.

- Products and Services: Briefly explain the products or services your business offers, emphasising their unique selling points and how they address customer needs.

- Competitive Advantages: Clearly state the competitive advantages that differentiate your business from others in the market. This could include unique features, patents, proprietary technology, or a strong brand presence.

- Location and Facilities: Provide details about the physical location of your business and any facilities required to operate successfully.

Tips for writing the company description section:

- Interweave storytelling into the company's history, tell the reader about your passion for the business and the journey you’ve been on to get to this point.

- Include strong visuals and infographics.

- Avoid jargon and keep the writing style clear and concise.

- Focus on your company's unique selling point (USP) and how that makes you stand out in the marketplace.

- Back up this information with customer testimonials if possible.

The market analysis section of your welding and fabrication business plan is essential for understanding the competitive landscape and the overall business environment. It is crucial to execute this section effectively as it demonstrates your in-depth knowledge of the market dynamics. This process will enable you, as an entrepreneur, to identify opportunities, mitigate risks, and develop strategies for success.

To conduct a good market analysis, it is important to have a deep understanding of the industry you are operating in. This information will help you make informed decisions about your product or service offerings, marketing strategies, and pricing.

Key elements to include in your market analysis section:

- Industry Overview: Provide a general overview of your industry. Describe the industry's size, growth rate, major players, and key trends. Include relevant statistics and data to support your claims.

- Target Market and Customer Segmentation: Clearly define your target market and outline the specific customer segments you aim to serve. Identify the needs, preferences, and behaviours of each segment.

- Competitor Analysis: Identify direct and indirect competitors in the market. Analyse their strengths, weaknesses, market share, and strategies. Highlight areas where your business differentiates itself from competitors.

- Market Trends and Opportunities: Explore current and future trends in the industry and market. Assess how these trends can impact your business positively and identify potential opportunities for growth.

- SWOT Analysis (optional): Consider including a SWOT analysis specific to your market. This can help you understand your business's strengths, weaknesses, opportunities, and threats in the context of the market.

How to nail the market analysis section?

- Differentiation: Focus on highlighting how your business differentiates itself from competitors, really try to drum home this point.

- Market Surveys or Interviews: Adding surveys or interviews and adding the key findings and quotes in the Market Analysis to support your claims will help reinforce the plans in your document.

- Competitive Matrix: a competitive matrix visually comparing your business against key competitors based on factors such as price, features, and customer service. This matrix is a great visual method highlighting your competitive advantages.

- Emerging Technologies or Trends: Identifying potential disruptions and how your company is prepared for them shows a great understanding of market dynamics and trends.

Looking for more inspiration on how to make your market analysis section even better, then check out our in-depth business market analysis guide.

In this section, we will highlight the core products and services that make your welding and fabrication business unique and valuable. It is essential to showcase what sets you apart from the competition and why your offerings are exceptional. This information is especially important for potential investors, partners, and customers who are keen to understand what sets your business apart in the market.

When describing your products and services ensure you include the following information:

- Description of Products/Services: Provide a clear and concise description of each product or service your business offers. Explain their primary function and how they address customer needs.

- Unique Selling Proposition (USP): Highlight the unique features or benefits that make your products or services stand out from competitors. Clearly state why customers should choose your offerings over alternatives.

- Product/Service Life Cycle: Describe where each product or service stands in its life cycle (e.g., introduction, growth, maturity, decline) and outline plans for updates or new offerings in the future.

- Intellectual Property (if applicable): If your business has any intellectual property (e.g., patents, trademarks, copyrights) related to your products or services, mention them in this section.

Extra elements to make this section stand out:

- Customer Use Cases: Present real-life customer use cases or success stories that illustrate how your products or services have solved specific problems for customers. Use compelling narratives to engage readers.

- Product Roadmap: If applicable, include a product roadmap that outlines future updates, enhancements, or new offerings. This showcases your business's commitment to innovation and continuous improvement.

- Quality and Testing Standards: Discuss the quality standards your business adheres to and any testing processes you conduct to ensure the reliability and performance of your offerings.

- Pricing Strategy: Integrate your pricing strategy into this section. Explain how you've determined the pricing of your products or services, considering factors like production costs, competition, and value to customers.

- Environmental and Social Impact: If your products or services have positive environmental or social implications, highlight them in this section. Increasingly, customers appreciate businesses that contribute positively to society.

The Marketing Strategy Section

Key Information to Include Within the Marketing Strategy Section:

- Marketing Goals and Objectives: Clearly state the marketing goals you aim to achieve. Focus on how you will increase brand awareness and drive customer conversions or leads.

- Target Market Strategy: Describe the specific strategies you will use to reach and engage with your target customers. This could involve digital marketing, traditional advertising, or other channels.

- Pricing Strategy: Explain how your pricing will attract the target market and how it compares to competitors' pricing.

- Promotion and Advertising Plan: Outline the promotional activities and advertising campaigns you plan to execute. Include details about social media marketing, content marketing, email campaigns, and other promotional tactics.

- Sales Strategy: Describe your sales process and how you plan to convert leads into paying customers. Mention any sales team structure and their responsibilities if applicable.

- Customer Relationship Management (CRM) Approach: Discuss how you intend to build and maintain strong relationships with your customers to encourage repeat business and loyalty.

Getting Creative with the Market Strategy Section

- Create a visual marketing timeline.

- Outline influencer or brand ambassador partnerships if applicable.

- Detail key metrics and KPIs.

By infusing creativity and innovative marketing ideas with sound fundamental marketing, you can really make this section stand out and impress potential investors and partners.

The Operation Plan Section

While marketing activities may seem more exciting, operational planning is essential for the success of your welding and fabrication business. This section focuses on the day-to-day operations and internal processes that drive your business forward. By providing a comprehensive roadmap of your resources, workflows, and procedures, you can instill confidence in potential investors that your business is well-equipped for growth.

Here are some key items to include in your operational plan:

- Organisational Structure: Describe the organisational structure of the company, including key roles and responsibilities.

- Key Personnel and Team: Introduce key team members and their qualifications. Highlight how their expertise contributes to the success of the business.

- Operational Workflow and Processes: Provide a high-level step-by-step overview of delivering your product or service, from production to delivery or distribution.

- Resource Requirements: Outline the key resources required to run the business, such as equipment, technology, facilities, and human resources.

- Quality Control and Assurance: Explain how the company ensures the quality and consistency of its products or services, and how it addresses any potential issues.

- Supply Chain Management (if applicable): If the business involves sourcing materials or products from suppliers, describe the supply chain management process.

- Legal and Regulatory Compliance: Discuss any legal or regulatory requirements specific to the industry and how the company ensures compliance.

How to add value to the Operation Plan section:

- Use visuals to outline organisation structures and workflows.

- Outline contingency plans, for example how the company is prepared for supply chain shortages or price shocks.

- Efficiency, efficiency, efficiency. Describe how you have driven efficiency gains for the business.

- Have you considered your business's environmental impact? If so, mention within this section.

The operational section of a business plan does have the potential to be dryer than more exciting elements such as marketing, however, by incorporating creative elements and forward-thinking workflows you can help keep reader engagement high.

The Financial Projections

The Financial Projections section can make or break a business plan. Always include well-researched and accurate projections to avoid undermining your business plan and losing out on potential investment. What to include in the financial projections section:

- Sales Forecast: Provide a detailed projection of the company's sales revenues for each product or service category over the forecast period.

- Expense Projections: Outline the expected operating expenses, including costs related to production, marketing, salaries, rent, utilities, and any other significant expenses.

- Profit and Loss (P&L) Statement: Present a comprehensive Profit and Loss statement that summarizes the business's revenue, cost of goods sold (COGS), gross profit, operating expenses, and net profit or loss for each year of the forecast.

- Cash Flow Projection: Include a cash flow statement that outlines the inflows and outflows of cash over the forecast period. This will help identify potential cash flow gaps.

- Break-Even Analysis: Perform a break-even analysis to determine the point at which the business's total revenue equals total costs, indicating when it becomes profitable.

How to add value to your financial projections section:

- Be prepared to defend your assumptions with data. If you are planning for a high-growth % make sure you can justify this assumption. If in doubt the more conservative the better.

- Include visuals that help readers quickly grasp the trends and patterns in revenue, expenses, and profits.

- Offer different scenarios based on varying assumptions. For example, present a conservative, moderate, and aggressive growth scenario.

- Include key financial ratios like gross margin, net profit margin, and return on investment (ROI).

The Funding Request and Use of Funds Section

This section outlines the financial requirements of the company and how the requested funds will be utilised to support its growth and operations. Providing potential investors or lenders with a clear picture of how their money will be used will improve the business case for the funds and provide further confidence to investors. What to include in this section?

- Funding Request Amount: State the specific amount of funding you are seeking to obtain from investors, lenders, or other sources.

- Use of Funds: Provide a detailed breakdown of how the requested funds will be allocated across different aspects of the business. Common categories include product development, marketing, operational expenses, hiring, equipment, and working capital.

- Timeline of Funds Utilisation: Outline the timeline for utilising the funds. Specify when and how the funds will be disbursed and the expected milestones or deliverables associated with each funding phase.

- Expected Return on Investment (ROI): If applicable, include information on the expected ROI for investors. Highlight the potential for financial gains or equity appreciation over time.

- Repayment Plan (if applicable): If seeking a loan, provide a clear repayment plan that outlines the repayment period, interest rate, and the proposed schedule for repayment.

How to maximise this section?

- Create a visual timeline for key milestones such as the initial investment and key payback periods.

- Outline risk mitigation plans to instil confidence.

- Reiterate the company's long-term vision and how the funds can help achieve these goals.

As you near the end of your welding and fabrication business plan, it is crucial to dedicate a section to outlining potential risks. This section holds immense significance as it can greatly influence the confidence of potential investors. By demonstrating your market awareness and addressing challenges head-on, you can instill trust and credibility.

When conducting a risk analysis for your welding and fabrication car rental business plan, consider including the following:

- Identification of Business Risks: Enumerate the key risks and uncertainties that could affect the business. These risks can be internal (e.g., operational, financial) or external (e.g. market changes, regulatory changes, economic downturns).

- Impact Assessment: Analyse the potential impact of each identified risk on the business's operations, finances, and reputation. Rank the risks based on their severity and likelihood of occurrence.

- Risk Mitigation Strategies: Present specific strategies and action plans to mitigate each identified risk. Explain how you will proactively address challenges and reduce the negative impact of potential risks.

- Contingency Plans: Describe contingency plans for worst-case scenarios, outlining how the business will respond and recover from significant risks if they materialise.

How to make your risk analysis stand out?

- Add context with real-life examples. Are there similar businesses that have dealt with risks successfully in a similar manner to your strategy? This will add credibility to this section.

- Create adaptive strategies that demonstrate your business’s flexibility and adaptability.

- Outlining the responsible person for each risk and how they own it, giving further confidence in your risk management strategies.

Some additional information you may want to include in your business plan for welding and fabrication:

- Customer Surveys and Feedback

- Letters of Support or Intent

- Legal Documents (e.g., licenses, permits)

- Resumes of Key Team Members

A Business Plan For Welding And Fabrication Wrapping It All Up

A business plan is one of the most important documents that you will create about your business. It can literally be the difference between securing additional finance or missing out. Developing your business is not an easy task, however, the opportunity to think about your business in such detail will no doubt help you develop new and important insights along with new ideas and strategies. With all sections of your business plan and especially the financial plan, be prepared to defend your position to potential investors or lenders. This means that you should never publish anything that you can’t back up with additional data or rationale. Business Plans are not created overnight so take the time to research and think about each section properly, always try to support your claims and strategies with market insight and data. We hope you’ve enjoyed reading this guide, if you are looking for more tips on creating a business plan check out our learning centre .Good luck with your next business endeavour! Action Planr

Thank you! You’ll receive an email shortly.

Oops! Something went wrong while submitting the form :(

Learning ZoNe

How To Start A Welding Business In Nigeria(2022)

Table of Contents

Understand How To Start A Welding Business In Nigeria

Having a welding workshop now is one way of ensuring that your source of income is not under anyone’s control, like the case of those employed in industries.

Due to the increase in the import tariff which had made many imported goods to be costly, many Nigerians now prefer domestic and locally made products. The evidence of such is the increased rate of demand for iron doors and gates from the welders and the reduced rate in the selling of imported doors.

One of the requirements for opening a welding workshop is to know how to weld metals because that is where most people find it difficult and may see reasons not to venture into the business .

A good entrepreneur should develop the mind to learn skills of the trade he or she wants to venture into which welding is one of them.

The best way to learn welding skills is by working with a welder or going for a short time of welding training, some welding training centers can charge as high as N100, 000 or as low as N50, 000 for the duration of three to four months of training.

How To Start A Welding Business In Nigeria

To set up a welding workshop the following are the things needed;

WELDING MACHINE

A welding machine is a major tool if you are planning to know how to start a Welding Business in Nigeria because that is the place the two electrodes actually used for the welding are fixed.

One way to identify a good welding machine is to check for its voltage output rating not the size of the welding machine but this criterion is only for the imported welding machines since there will be no way to easily access the coil inside.

Meanwhile, to get a locally made welding machine of good quality, the type popularly made by the electrical technicians located at Onitsha and other places you must pay more attention to the type of coil they were made with.

The two popular wires used for the making of the local welding machines are copper wire and aluminum wire.

The coil of a welding machine made with copper wire has higher quality in terms of voltage output, durability, and smaller size but its disadvantage is that it costs more than the aluminum type of the same rating.