Devikrupa Group

Leading PVC Pipe Machine, HDPE Pipe Machine, PVC Profile Plant & Screw Barrel manufacturer In India.

Inquiry Now

07573-037402

PVC Pipes Manufacturing Project Business Plan

First Polyvinyl-Chloride is known as PVC. You can easily start a PVC pipe manufacturing business in small and medium scale basis. The PVC pipes are widely used in electrical, irrigation and construction industries. The materials like wood, paper and metal are replaced by PVC in many applications. PVC pipes are widely used as electrical conduits in both domestic as well as industrial use.

PVC pipes are widely used for water supply. It has many characteristics which are suitable for water supply. It is lightweight, low cost, easy installation, non-corrosiveness, high tensile strength to bear the high fluid pressure. PVC pipes are resistant to most of the chemicals and also have maximum electrical and heat insulation properties.

PVC Pipe Manufacturing – Indian Market

In India, the PVC pipe market is on the peak as the infrastructure growing high and high. PVC pipes are mainly used in construction and agriculture sector and the demand is become increasing in the nearest future. It is used for various purposes like water supply, spray irrigation, deep tube well schemes and also in land drainage.

The PVC slotted and corrugated pipes are widely used for drainage of water from the land where waterlogging is necessary. As the demand in rural water suppliers, for irrigation facilities, development in the construction industry and the expansion of electricity network in rural areas. Over 60% of the demand for PVC pipe is in up to 110 mm outer diameter.

How to register PVC pipe manufacturing Business and Licence?

To start PVC pipe manufacturing business, register first with the ROC. Obtain Trade Licence from Municipality. After that apply for Factory Licence according to your current state rules. Apply for Udyog Aadhar MSME online registration. Apply for VAT registration. Also, apply for ‘No Objection Certificate’ from the state’s Pollution Control Board. Obtain the BIS certification for Quality Control. Open a current bank account in a nationalized bank. Secure your brand by Trademark Registration. Apply for ISO certification.

PVC Pipe Manufacturing Machinery & Required Equipment

- High-speed mixer, nonshell type capacity of 50 kg. per batch/hr. and having full controls and also cooling setup.

- 65 mm/ 18 V PVC rigid pipe extrusion plant consisting of twin-screw extruder, vacuum sizing unit, cooling tank, haul-off unit and cutting machine.

- Dies sizes like 20, 25, 45, 63, 75, 90, 110 mm and mandrel size 2.5 kg/cm 2 , 4 kg/cm 2 , 6 kg/cm 2 , 10 kg/cm 2 .

- Require the scraper, grinder, heavy-duty fitted with Electric Motor.

- Overhead water tank and recycling pump units.

- Weighing balance, heavy type industrial model with moderate accuracy.

- Pipe storage, racks, maintenance of small hand tools, greasing, oiling equipment etc.

- Chemical testing laboratory equipment like chemical balance, oven and other testing equipment. Apparatus for testing bulk density, specific gravity lead and tin estimation (in ppm).

What are the raw materials used for PVC Pipe Manufacturing?

For PVC Pipe manufacturing required raw materials are PVC resin, DOP, Stabilizers, Processing acids, Lubricants, Colours, Fillers. The electricity and water are also required.

PVC Pipe Manufacturing Process

For manufacturing of PVC pipe, like other thermoplastics the PVC uncompounded resin, is not suitable for direct processing. For process and stability require to mix additives with PVC resin. These are some additives are used in the manufacturing process for rigid PVC pipes: DOP, DIOP, DBP, DOA, DEP.

Plasticizers – common plasticizer are DOP, DIOP, DBP, DOA, DEP, Reoplast, Paraplex etc.

Stabilizers – The common stabilizers are lead, barium, cadmium, tin, stearate etc.

Lubricants – Lubricants used are Buty-Stearate, Glycerol Moni-Stearate, Epoxidised Monoester of oleic acid, stearic acid etc.

Fillers – Fillers are used for producing a special quality product like calcined clay.

Before starting the process, the PVC resin is compounded with plasticizers, stabilizers, lubricants and fillers for improving the process and stability of the product. The ingredients and PVC resin are mixed in a high-speed mixer.

In the process, the compound resin is fed to the double screw extruder and there are the inserts and die are fitted for required diameter. After that, the PVC compounds are passed through a heated chamber and melted under the compression of screw and heat of the barrel. In the last, the marking is done at the time of extrusion.

The pipes come from extruder are cooled in the sizing operation. There are two types of sizing are used. Pressure Sizing and Vacuum Sizing.

The next process after sizing is traction. The tube traction unit is required for continuous haulage of pipes being extruded by the extruder.

The last process is cutting. There are two types of cutting techniques for PVC pipes are Manual and Automatic. Then the pipes are tested for ISI marks and ready for dispatch.

Now arrange the suitable vehicle for transport the PVC pipes to the distributors.

Leave a Reply Cancel reply

Your email address will not be published.

Over 17 years experience and knowledge of international industrial systems, dedicated to provide the best economical PVC Pipe Machine & Screw Barrel to our valued customers. We Won Many Factory Awards and Ceritificates Since 2001-2018.

Our Products

- PVC Pipe Machine

- HDPE Pipe Machine

- PVC Profile Plant

- Screw Barrel

About Company

- Manufacturing Facilities

- Quality Policies

- Area of Application

Download Now

- High Speed Heater Cooler Mixer

- Vacuum Tank

- Traction Machine

- Tilting Machine

- Pipe Cutting Machine

Alchem Learning

How to Start a Pvc Pipe Manufacturing Business

🛠️ Looking to build a sturdy foundation for success? Uncover the secrets of initiating a PVC Pipe Manufacturing Business and learn how to pipe up your entrepreneurial journey! 🔧🏭 #PVCProduction #BusinessBlueprint

Here’s a step-by-step guide to help you get started:

Research and Planning

Do thorough market research to understand the demand for PVC pipes in your target region. Identify your target audience and potential competitors. Create a solid business plan outlining your goals, budget, production capacity, and marketing strategies.

Legal Formalities and Permits

Register your business and obtain all the necessary licenses and permits required to operate a manufacturing business in your area. This might include business registration, environmental clearances, and industry-specific permits.

Location and Infrastructure

Choose an appropriate location for your manufacturing unit. Set up a well-organized and efficient workspace with proper infrastructure, including machinery, raw material storage, production area, and quality control measures.

Procure Equipment and Raw Materials

Purchase the necessary machinery and equipment for PVC pipe manufacturing. Ensure you have a reliable supply chain for raw materials like PVC resin, stabilizers, plasticizers, and colorants.

Production Process and Quality Control

Develop a streamlined production process that ensures consistent quality. Implement rigorous quality control measures to maintain product standards and reliability.

Skilled Workforce

Hire skilled personnel with experience in PVC pipe manufacturing, including machine operators, technicians, and quality control experts. Provide appropriate training to ensure efficient and safe operations.

Marketing and Distribution

Create a strong marketing strategy to promote your PVC pipes. Build relationships with distributors, retailers, and construction companies. Utilize both traditional advertising and digital platforms to reach your target audience.

Compliance and Sustainability

Ensure your manufacturing process aligns with environmental regulations and sustainable practices. Consider recycling and waste management initiatives to minimize your ecological footprint.

Financial Management

Maintain proper financial records and manage your budget effectively. Monitor expenses, revenue, and profit margins closely to ensure a sustainable and profitable business.

Expand and Innovate

As your business grows, explore opportunities for innovation and product diversification. Stay updated with industry trends and continuously seek ways to improve your products and processes.

Best of luck with your PVC pipe manufacturing journey! 🛠🏭

Frequently asked questions (FAQs) about starting the business:

FAQ 1: What is PVC and why is it commonly used for pipes? Answer: PVC stands for Polyvinyl Chloride, a synthetic plastic polymer known for its durability, affordability, and corrosion resistance. It’s commonly used for pipes due to its excellent properties, making it suitable for various applications, including plumbing, irrigation, and construction.

FAQ 2: How much capital do I need to start a PVC pipe manufacturing business? Answer: The capital required depends on factors like the scale of production, machinery, location, and raw material costs. A rough estimate could range from a few hundred thousand to several million dollars.

FAQ 3: What machinery is essential for PVC pipe manufacturing? Answer: Essential machinery includes extrusion lines, cooling tanks, cutters, printers, and socketing machines. The specific equipment needed may vary based on the types and sizes of pipes you plan to produce.

FAQ 4: How do I ensure the quality of PVC pipes produced? Answer: Quality control measures include regular testing of raw materials, monitoring the extrusion process, conducting pressure and leak tests, and adhering to industry standards and certifications.

FAQ 5: What are the potential markets for PVC pipes? Answer: PVC pipes have a wide range of applications, including water supply, drainage, agriculture, irrigation, and sewage systems. Your target market will depend on your product specialization.

FAQ 6: How can I market my PVC pipes effectively? Answer: Implement a combination of strategies, such as attending trade shows, building a strong online presence, forming partnerships with construction companies, offering competitive pricing, and showcasing the durability and advantages of your pipes.

FAQ 7: Are there environmental considerations when manufacturing PVC pipes? Answer: Yes, consider sustainable practices, such as recycling PVC waste, minimizing energy consumption during production, and exploring eco-friendly additives. Compliance with environmental regulations is crucial.

FAQ 8: What are the challenges in PVC pipe manufacturing? Answer: Challenges can include fluctuating raw material prices, competition from other materials, meeting quality standards, and adapting to changing market demands.

FAQ 9: Can I start a PVC pipe manufacturing business on a small scale? Answer: Yes, starting on a small scale is possible. You can begin with a limited range of pipe sizes and gradually expand your product offerings as your business grows.

FAQ 10: How long does it take to establish a profitable PVC pipe manufacturing business? Answer: The timeline varies based on factors such as market demand, business strategy, location, and investment. With effective planning and execution, it could take a few years to establish a profitable venture.

😊🛠🏭 #PVCManufacturing #BusinessFAQs #Entrepreneurship

Top Businesses in the World

Explore our handpicked selection of the world’s top 20 businesses and their website links. These sites can provide valuable insights for building your own website.

- 1. Apple Inc.

- 2. Amazon.com Inc.

- 3. Microsoft Corporation

- 4. Alphabet Inc. (Google)

- 5. Tesla, Inc.

- 6. Facebook, Inc.

- 7. Berkshire Hathaway Inc.

- 8. Visa Inc.

- 9. JPMorgan Chase & Co.

- 10. Walmart Inc.

- 11. Alibaba Group Holding Limited

- 12. Tencent Holdings Limited

- 13. Samsung Electronics Co., Ltd.

- 14. Procter & Gamble Co.

- 15. Johnson & Johnson

- 16. Nestle S.A.

- 17. The Coca-Cola Company

- 18. Toyota Motor Corporation

- 19. Intel Corporation

- 20. Pfizer Inc.

References:

- How to Start a Small Business: A Step by Step Guide | Amazon Business

- How to Start Your Own Business (with Pictures) – wikiHow

- 9 Things Needed to Start a Business in 2023

- How to start and fund your own business | USAGov Lock

- How to (Realistically) Start an Online Business That (Actually) Grows | BigCommerce

- How to start a business: Step by Step

- The complete guide to starting a business | Legalzoom

- How to Start a Business – Ramsey

- 10 Steps to Starting a Business | Coursera List

- How to Start a Business in 6 Steps | Mailchimp

- How to Start a Business in 2023: A 10-Step Guide

- 70 Small Business Ideas for Anyone Who Wants to Run Their Own Business

- 5 Steps to Start Your First Business – YouTube

- How to Grow a Successful Business

- How to Start a Small Business (Step-by-Step Guide) | ADP

- How to Start a Small Business at Home: 5 Tips for Success

- 10 Key Steps to Creating a Business (2023 Guide) | Wolters Kluwer

- How to Start a Business: Steps to Start Up a Business | Square

- 10 steps to start your business | U.S. Small Business Administration Lock

- How To Start A Business: A Step by Step Guide For 2023

- How To Start A Business In 11 Easy Steps (2023 Guide) – Forbes

- How to Start a Business From Scratch in 7 Steps | The Hartford

- How to Start a Business: 13 Steps to Launch – Shopify

- How to Start a Business in 15 Steps – NerdWallet

- How to Start a Business: A Startup Guide for Entrepreneurs

- How to Start a Business in India – The Complete Guide

Share this:

Leave a reply cancel reply, discover more from alchem learning.

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

Business Ideas

Investment Ideas

Make Money at Home

- Bitcoin and Xcoins

- Earn On Social Networking

- Freelancing

- Make a Website

- Money Making Apps

- Affiliate Marketing

- Online Surveys

- Start a Blog

- Web Hosting

Startup Ideas

- Your Passion Your Money

Make Money Online

How To Start A PVC Pipe Manufacturing Business

Table of contents, market research for the business plan, business plan to setup pvc pipe manufacturing unit, investment for starting pvc pipe manufacturing business, license, permissions, and registration required for starting pvc pipe manufacturing unit, noc from the state pollution control board, suitable location for establishing pvc pipe manufacturing company, safety and quality measures for starting pvc pipe manufacturing company, marketing strategies for promoting your pvc pipes.

Introduction on how to start a PVC pipe manufacturing

Are you willing to start a PVC pipe manufacturing company from scratch? Or you require a PVC pipe production business plan guide? If your answer is yes, then I request you to follow this article carefully for a successful business in this segment.

The revolution of PVC pipes has downgraded the use of metal pipes when it is used for conveying water, sewer, and even for safeguarding underground cables. Plumbing works have become easier because of the advent of PVC pipes on the market.

A step by step guide on how to start a PVC pipe manufacturing business

Polyvinyl Chloride (PVC) pipes are known to be highly durable and safer, and difficult to damage and are strong as such because of its composition; it is made by plastic and vinyl materials. With PVC pipes you need not bother about rust and bacteria formation inside the pipes mainly when it is used for water distribution.

Therefore, if you are planning to start a manufacturing company that would manufacture products that can be contentedly and effectively used for sewer lines, underground wiring, and water system in buildings, then you must start your own Polyvinyl Chloride (PVC) pipe manufacturing company to feel the difference.

Starting your own PVC pipe manufacturing company would open you up to various options in the construction industry because there is no construction job that is done without the use of PVC pipes. No doubt establishing a PVC pipe manufacturing company will demand huge capital but the truth is that it is a high-income generating especially if you know how to place yourself in the marketplace.

If you have decided to start your own PVC pipes manufacturing company, then the following main tips should help you.

PVC pipe manufacturing company is not only any kind of company that you can begin without basic preparation. The fact that it needs huge capital to establish a PVC pipe manufacturing company means that you should perform a thorough research and feasibility studies before moving forward into this type capital intensive business if you worry about the risks associated with your investment.

Handicraft Making at Home: A Small Profitable Business Idea

Pet-tech startups: innovations for animal lovers, tech repair services: meeting the demand for gadget maintenance, maximizing rewards: smart credit card habits for cashback and points, ultimate guide to making money from goat milk business, how to start an agricultural value added product business.

One cannot expect to initiate or own a PVC pipe manufacturing company without a proper and well-designed comprehensive business plan that will stand to be a blueprint for your business. It is nice to get your business plan handy and modify it from time to time when needed by checking it over and over again before you begin the process of building your PVC pipe manufacturing company.

Even if you have started your PVC pipe manufacturing company, you may continue to review your business plan. That is why you should make your business plan in a way that you will be able to make alterations when there is a need.

If you have completed your feasibility studies and have gathered the required capital to build your PVC pipes manufacturing company; then it is perfect. On the other hand, if are not having the required capital, then you must explore all the available options to raise the required capital.

You may avail of a loan from the bank, or you can sell your business idea to financers, and you can as well collect capital from your friends and family members. Your business plan is the main aspect you would need when you will be trying to convince people to spend in your business; if your business plan is well designed, then the process of raising funds will be easy.

The registrations and licenses which are important to begin a PVC pipe manufacturing industry are stated below:-

The initial step is to get the company registered. It can be done as LLP registration, Partnership firm or if you are planning for a more corporate structure, opt for Company Registration.

Obtaining a Trade License from the local municipal body. This is obligatory to have the approval by the local body to optimize the trade and ensure compliance with government guidelines and regulations.

Factory license – under the Factory Act 1948[1], the Chief Inspectorate of Factories in the region specified for the set-up of the new unit approves this license. Before setting the factory the occupational certificate or plot allotment letter from the Industries Department is needed to begin the construction.

GST registration is needed for businesses so that the taxes can be claimed from the customers and pass on the credit of the taxes; the business can claim the input tax credit and there is easy processing of input tax credit from suppliers and vendors.

Udyog Aadhaar MSME : Udyog Aadhaar is needed to register the business as an MSME. There are several benefits to possessing the Udyog Aadhaar. Starting from subsidies and low-interest rates, the business associated disputes will be resolved faster, collateral-free loans from the financial institutions; reimbursement of a payment made for ISO certification, qualify for IPS subsidy, 50% subsidy for patent registration, and many more.

BIS certification – for all domestic manufacturers of PVC pipes, mainly that is related to household electrical goods, it is important to apply for BIS Certification from the Bureau of Indian Standards. The applicant must be submitted along with the fees at the nearest BIS office. In the following step, an inspection of the factory is done by a BIS officer. The product samples are verified in the factory and if the provided the samples pass the test, the license is approved within a specific period of time.

Trademark Registration for the company logo is allotted by the Controller General of Patents Designs and Trademarks, under the Ministry of Commerce and this allows the business owner or the trademark owner the power to sue other parties when there is any occurrence is seen.

Furthermore, the authority monitoring the industry should inspect your factory before the license is issued and permission is given to start your own PVC pipe manufacturing company.

The location you select to build your PVC pipe manufacturing company is not much vital as such, so you shouldn’t spend your investment trying to obtain an expensive facility or location. You can establish your PVC pipe manufacturing company far away from the city since it is reasonable to do so. But this will increase the transportation expenses that are needed to deliver goods and procure raw materials. The only risk and disadvantage with starting your PVC pipe manufacturing factory on the outskirts of your city is the cost associated with transporting your goods and raw materials.

People who work in PVC pipe manufacturing factories are mainly exposed to risks that are why you must ensure to carry out best practices when it is associated with safety measures. In case, the necessary safety measures are proper, your factory will be at the risk of being shut down by local authorities.

Another important aspect that is essential to guarantee your PVC pipes manufacturing company to become significant is when you are dedicated to producing only high standard PVC pipes. If the PVC pipes you manufacture are heard to get damaged easily under little pressure, people may not approach you. High-quality PVC pipes are known to bear pressure caused by minor earth tremors to even some earthquakes.

You should not miss this: How To Start A Gardening Business In India .

If you are assured about the quality of PVC pipes your factory delivers, then you will feel confident in the market place. The market for the PVC pipes is extensive and the profit you stand to make is great as well. Your target market must be focused on people who are involved in any form of construction and plumbing works, and those who are into placing underground wires and cables. So try to reach their sites or any region where you can meet them and thereby market your products to them.

In marketing your PVC pipes, you could enter a deal where you should design and produce PVC pipes based on your clients’ requirements. Another aspect that will give you command in the market place is when you select to deliver the purchased PVC pipes free of charge to your client instead of allowing them to carry on their own expenses will earn some goodwill as well.

To conclude, all the major tips that can aid you to build your own PVC pipe manufacturing company from the primary stage to great success.

In case if you are interested in this: Low-cost Agriculture Business Ideas For Beginners .

LEAVE A REPLY Cancel reply

Save my name and email in this browser for the next time I comment.

Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with...

How to make profits with organic country chicken: best strategies for beginners, 10 value-added business ideas for millets: low-investment and highly profitable, why cleaning service business becoming more profitable in metro cities in india, 10 best businesses to start in ayodhya for profits, top drone business ideas in india: unlocking aerial innovation & opportunities, top 10 service businesses you can start with no money, ultimate guide to starting a home-based advertising agency business, starting a nail salon near your location: check list, business plan, licensing,..., construction company name ideas: guide to create new construction company names, 8 best small businesses to start in hyderabad: low-cost and profitable, 10 best small businesses to start in massachusetts: low-cost and profitable, 10 best small businesses to start in maryland: low-investment and profitable, 10 best small businesses to start in delaware: low-investment and profitable, ideas to make money in india – a full guide, mudra yojana loan scheme, eligibility, how to apply, profit in dry fruit business (cost to start), how to make money from rice mill business in india, profitable agriculture business ideas in india, government loans for women entrepreneurs in india.

- Best Products

How to Start PVC Pipe Manufacturing Business – Complete Guide

- March 31, 2024

- by Next What Business Research Team

India’s rapid industrialization and urbanization have led to a surge in demand for essential infrastructure components, including PVC pipes. These types of pipes are widely used in construction, irrigation, plumbing, and other applications. If you’re considering venturing into the PVC pipe manufacturing business in India, you’re poised to tap into a lucrative market with significant growth potential. In this comprehensive guide, we’ll walk you through the essential steps to start your PVC pipe manufacturing venture.

What are PVC Pipes?

PVC pipes, or Polyvinyl Chloride pipes, are a type of plastic piping commonly used in various applications. It includes plumbing, irrigation, construction, and industrial processes. These pipes are made from a synthetic polymer called polyvinyl chloride, which is derived from natural gas or petroleum. PVC pipes are also known for their durability, versatility, and affordability. As a result, PVC pipes are a popular choice for transporting fluids, gases, and solids in a wide range of industries.

Related: Best Small Manufacturing Business Ideas

Is PVC Pipe Manufacturing Business Profitable?

The Indian PVC pipes market is growing at a healthy rate due to tremendous government spending on infrastructure. The construction sector and the agricultural sector are expected to boost demand for PVC pipes in the future. PVC pipes are used for a variety of purposes e.g. water supply schemes, spray irrigation, deep tube well schemes, and land drainage schemes.

PVC slotted and corrugated pipes are ideal systems for drainages of water from the land where waterlogging is inevitable. Given the priorities for rural water suppliers, irrigation facilities in the national planning, immense growth in the construction industry and rapid rural electrification, the demand for rigid PVC pipe is growing regularly. The 60% of the total demand for PVC pipe that exists today is up to 110 mm outer diameter.

Types of PVC Pipes

PVC pipes, or Polyvinyl Chloride pipes, come in several types, each designed for specific applications and usage scenarios. Here are the main types of PVC pipes:

⇒ Rigid PVC Pipes

Rigid PVC pipes are the most common type of PVC pipes and are widely used in pressurized applications such as water supply, drainage, and plumbing. These pipes are strong, durable, and resistant to corrosion, making them ideal for underground and above-ground installations.

⇒ Flexible PVC Pipes

Flexible PVC pipes, also known as PVC hoses or tubing, are designed for non-pressure applications such as irrigation, gardening, and electrical conduits. These pipes are highly flexible and can bend without breaking, making them suitable for areas with limited space or tight bends.

⇒ CPVC Pipes

CPVC pipes, or Chlorinated Polyvinyl Chloride pipes, are a variation of PVC pipes that are chlorinated to enhance their temperature resistance. CPVC pipes can withstand higher temperatures than standard PVC pipes and are commonly used in hot water distribution systems, industrial processes, and chemical transportation.

⇒ UPVC Pipes

UPVC pipes, or Unplasticized Polyvinyl Chloride pipes, are rigid PVC pipes that do not contain plasticizers, making them more rigid and durable than standard PVC pipes. UPVC pipes are commonly used in underground drainage systems, sewage lines, and industrial applications where strength and durability are paramount.

⇒ PVC Pressure Pipes

PVC pressure pipes are designed to handle high-pressure applications such as water supply networks, firefighting systems, and industrial processes. These pipes are manufactured to withstand internal pressures and are available in various pressure ratings to suit specific requirements.

⇒ PVC Drainage Pipes

PVC drainage pipes are used for wastewater disposal and drainage systems in residential, commercial, and industrial buildings. These pipes have smooth interiors to facilitate the flow of liquids and prevent clogging, making them ideal for sewage and stormwater drainage.

⇒ PVC Electrical Conduits

PVC electrical conduits are used to protect and route electrical wiring in buildings and construction projects. These pipes are lightweight, durable, and resistant to moisture, chemicals, and corrosion, providing safe and reliable electrical installations.

⇒ PVC Pipe Fittings

In addition to pipes, PVC fittings such as couplings, elbows, tees, and reducers are available to facilitate pipe connections, transitions, and installations. These fittings are designed to provide leak-proof joints and connections in PVC piping systems.

Steps to Start a PVC Pipe Manufacturing Business

1. market research and feasibility analysis.

Before diving into PVC pipe manufacturing, conduct thorough market research . It is needed to assess the demand, competition, pricing dynamics, and regulatory landscape in your target market segments. Evaluate the feasibility of your venture by analyzing factors such as raw material availability, infrastructure requirements, distribution channels, and potential challenges.

2. Develop a Business Plan

Draft a detailed business plan outlining your PVC pipe manufacturing venture’s objectives, target market segments, product portfolio, production capacity, marketing strategy, financial projections, and operational requirements. A well-defined business plan serves as a roadmap for your venture and helps attract investors, secure funding, and guide decision-making.

3. Obtain Necessary Licenses and Permits

In starting PVC pipe manufacturing, first, register your business with ROC. Obtain a Trade License from the Municipal authority. Apply for a Factory License according to your state rules. Obtain GST registration number. Apply for Udyog Aadhaar MSME online registration.

Apply for a ‘No Objection Certificate’ from the state’s Pollution Control Board. Obtain BIS certification for Quality Control. Open a Current Bank Account. Preferred the nationalized bank. Protect your brand by having a Trademark Registration . You can also apply for ISO Certification. At present, GST Registration is mandatory to run any manufacturing business in India.

4. Set Up Manufacturing Facilities

Select a suitable location for your PVC pipe manufacturing plant with access to essential infrastructure such as transportation, utilities, and raw material suppliers. Set up modern manufacturing facilities equipped with state-of-the-art extrusion lines, mixing units, cooling tanks, cutting machines, and quality control equipment to ensure efficient production processes and product quality.

5. PVC Pipe Manufacturing Machine & Equipment

To manufacture PVC pipes efficiently, manufacturers rely on specialized equipment and machinery designed to handle various stages of the production process. Here’s an overview of the key equipment and machinery used in PVC pipe manufacturing:

⇒ Mixing Unit

The mixing unit is used to blend PVC resin with additives such as stabilizers, plasticizers, and pigments. This unit ensures uniform distribution of additives throughout the PVC compound, which is essential for achieving consistent quality and performance in the final product.

⇒ Extrusion Machine

The extrusion machine is the heart of the PVC pipe manufacturing process. It heats the PVC compound and forces it through a die to form the desired shape of the PVC pipe. The extrusion machine consists of an extruder, barrel, screw, heating elements, and die assembly.

⇒ Cooling Tank/Water Bath

After extrusion, PVC pipes pass through a cooling tank or water bath, where they are rapidly cooled to solidify the material and maintain its shape. The cooling tank ensures uniform cooling of the pipes and prevents warping or distortion.

⇒ Sizing Equipment

Sizing equipment is used to control the dimensions and accuracy of the PVC pipes. Sizing sleeves or moulds are installed on the production line to shape the pipes to the desired diameter and wall thickness. This equipment ensures uniformity and consistency in pipe dimensions.

⇒ Cutting Machine/Saw

Once the PVC pipes are sized, they are cut to the desired length using a cutting machine or saw. Automatic cutting machines can accurately cut pipes to the required length, increasing efficiency and reducing waste.

⇒ Printing/Marking Equipment

Printing or marking equipment is used to apply markings such as brand names, specifications, and manufacturing dates on the surface of the PVC pipes. This equipment ensures proper identification and traceability of the pipes throughout their lifecycle.

⇒ Quality Control Instruments

Various quality control instruments are used to monitor and assess the quality of PVC pipes at different stages of production. These instruments may include dimensional measurement tools, visual inspection systems, and testing equipment for mechanical properties, durability, and chemical resistance.

⇒ Packaging Equipment

Packaging equipment is used to bundle, package, and label the finished PVC pipes for shipment. Automatic packaging machines can efficiently handle large volumes of pipes, ensuring proper packaging and protection during transportation and storage.

⇒ Material Handling Equipment

Material handling equipment such as conveyors, lifts, and racks are used to transport raw materials, semi-finished products, and finished goods within the manufacturing facility. This equipment ensures smooth workflow and efficient production operations.

⇒ Maintenance Tools

Maintenance tools and equipment are essential for maintaining and servicing the machinery used in PVC pipe manufacturing. Regular maintenance helps prevent downtime, optimize equipment performance, and extend the lifespan of production machinery.

6. Source Raw Materials

Establish reliable supply chains for sourcing high-quality raw materials such as PVC resin, additives, stabilizers, and pigments from reputable suppliers and manufacturers. Negotiate favourable contracts, bulk discounts, and delivery schedules to optimize raw material procurement and minimize production costs.

7. PVC Pipe Production Process

The manufacturing process of PVC pipes involves several steps. Each step is carefully executed to produce high-quality pipes suitable for a wide range of applications. Here is an overview of the PVC pipe manufacturing process:

a) Raw Material Preparation

The process begins with the preparation of raw materials, primarily PVC resin, which is the main component of PVC pipes. PVC resin is combined with additives such as stabilizers, plasticizers, and pigments to enhance properties such as strength, flexibility, and colour.

b) Mixing and Compounding

The blended PVC resin and additives are fed into a mixing machine where they undergo compounding to ensure uniform distribution and homogeneity of the materials. This step is crucial for achieving consistent quality and performance in the final product.

c) Extrusion

Once the PVC compound is properly mixed, it is fed into an extrusion machine, which heats the material and forces it through a die to form the desired shape of the PVC pipe. The extrusion process involves melting the PVC compound and shaping it into a continuous profile with the desired diameter and wall thickness.

d) Cooling and Sizing

As the PVC pipe emerges from the extrusion machine, it passes through a cooling tank or water bath, where it is rapidly cooled to solidify the material and maintain its shape. The pipe is then passed through sizing sleeves or moulds to ensure uniform dimensions and accurate sizing.

e) Cutting and Marking

After sizing, the PVC pipe is cut to the desired length using a cutting machine or saw. Additionally, markings such as brand names, specifications, and manufacturing dates may be printed or embossed on the surface of the pipe for identification and traceability purposes.

f) Quality Control

Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the PVC pipes meet industry standards and specifications. Quality checks may include dimensional measurements, visual inspections, and testing for mechanical properties, durability, and chemical resistance.

g) Packaging and Storage

Once the PVC pipes pass quality control inspections, they are bundled, packaged, and labelled for shipment to customers. Proper packaging helps protect the pipes from damage during transportation and storage until they are ready for installation.

8. Distribution and Marketing Strategies

You must develop effective distribution and marketing strategies to promote your PVC pipes and reach target customers across residential, commercial, agricultural, and industrial sectors. In addition, build relationships with wholesalers, retailers, contractors, builders, and government agencies to expand your market reach and secure bulk orders.

Cost of Starting a PVC Pipe Manufacturing Business

Starting a PVC pipe manufacturing business in India requires careful financial planning to cover various expenses associated with setting up the manufacturing facility, procuring equipment and machinery, sourcing raw materials, obtaining licenses and permits, hiring staff, and marketing the business. Here’s an overview of the cost factors involved in starting a PVC pipe manufacturing business:

- Infrastructure and Land

- Machinery and Equipment

- Raw Materials

- Licensing and Permits

- Labour and Staffing

- Marketing and Branding

- Miscellaneous Expenses

In summary, the total cost of starting a PVC pipe manufacturing business in India can vary widely depending on factors such as the scale of the operation, location, market conditions, regulatory requirements, and business objectives. A rough estimate for the initial investment required to start a medium-sized PVC pipe manufacturing plant in India could range from INR 50 lakhs to INR 5 crores or more.

Frequently Asked Questions

What is the market potential for pvc pipe manufacturing.

The market potential for PVC pipe manufacturing in India is significant. This is due to increasing urbanization, infrastructure development, and demand for reliable plumbing, irrigation, and construction materials. The growth of industries such as agriculture, real estate, and water supply further fuels the demand for PVC pipes.

What are the different types of PVC pipes that can be manufactured?

PVC pipes come in various types. It includes rigid PVC pipes for pressurized applications like water supply and drainage, flexible PVC pipes for non-pressure applications such as irrigation and electrical conduits, CPVC pipes for hot water distribution, and UPVC pipes for underground drainage systems.

What are the key factors to consider when selecting a location for the manufacturing plant?

Some of the key factors to consider when selecting a location for a PVC pipe manufacturing plant are as follows:

- Proximity to raw material suppliers

- Access to transportation networks

- Availability of skilled labour

- Proximity to target markets

- Access to infrastructure facilities like water and power supply

- Compliance with environmental regulations.

What are the challenges and risks associated with PVC pipe manufacturing?

There are some challenges and risks associated with PVC pipe manufacturing. It includes volatility in raw material prices, competition from alternative materials, fluctuations in demand due to economic factors, regulatory compliance issues, environmental concerns related to PVC production and disposal, and supply chain disruptions.

- X (Twitter)

Related posts:

- How to Start a Profitable Plastic Toothpick Manufacturing Business

- How to Start Ceramic Glazed Tiles Manufacturing Business

- How to Start a Stone Crusher Plant Project Business

- How To Start A Cement Distribution Business – Complete Guide

- Chemical & Materials

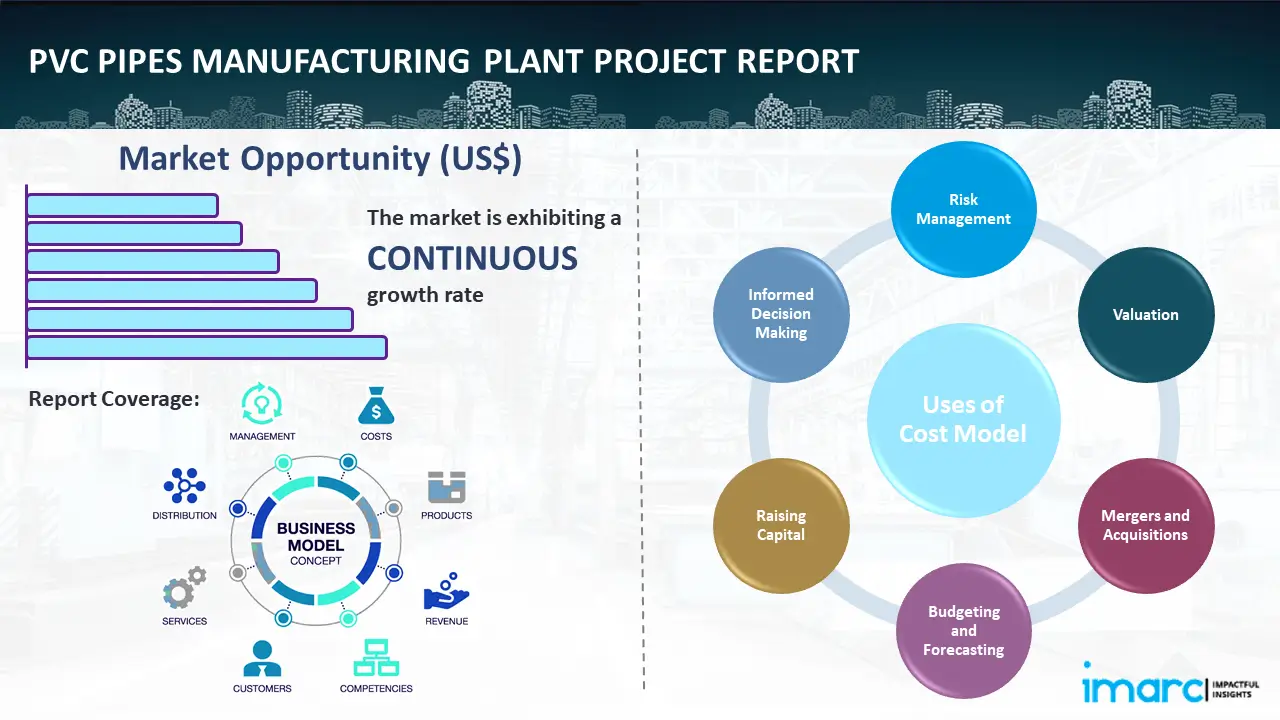

PVC Pipes Manufacturing Plant Project Report

Pvc pipes manufacturing plant project report 2024: industry trends, plant setup, machinery, raw materials, investment opportunities, cost and revenue.

- Report Description

- Table of Contents

- Methodology

- Request Sample

Report Overview:

IMARC Group’s report, titled “PVC Pipes Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a PVC pipes manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The PVC pipes project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

PVC Pipes Market Analysis:

According to IMARC Group’s report, the global modular construction market size reached US$ 86.2 Billion in 2023 and it is expected to reach US$ 137.2 Billion by 2032. Modular construction involves gathering building components off-site in administered factory environments before transporting them to the construction site and final assembly. PVC pipes are integral components for drainage, plumbing, and heating, ventilation, and air conditioning (HVAC) systems in modular buildings. The efficacy and ease of installation of PVC pipes make them well-suited for these buildings.

Moreover, modular construction is observed as a more sustainable building method compared to traditional construction owing to decreased waste, energy efficiency, and enhanced environmental performance. PVC pipes range with substantial goals as they are recyclable, have a low carbon footprint, and contribute to resource efficiency in modular construction buildings.

PVC Pipes Market Trends:

Thriving Smart Agriculture Industry

As per IMARC Group’s report, the global smart agriculture industry is expected to reach US$ 35.7 Billion by 2032. The thriving smart agriculture industry is increasing the emphases on efficient water usage to optimize crop yield while conserving resources, which is catalyzing the demand PVC pipes in drip irrigation systems, where water is delivered directly to the roots of plants, thereby minimizing water wastage. Furthermore, PVC pipes are crucial components in hydroponic and vertical farming systems, where crops are growing without soil in controlled environments.

PVC pipes are adopted for nutrient delivery, irrigation, and drainage in these systems, which contributes to the efficient cultivation of crops in restricted spaces and urban environments. Besides this, PVC pipes facilitate the insertion of sensor-based irrigation systems by providing a reliable infrastructure for dispersing water to crops.

Rapid Urbanization

The World Bank’s report 2023 claims that around 50% of the population lives in urban areas, which is expected to increase by 1.5 times to 6 billion by 2045. Urbanization is enabling the growing demand for infrastructure development, such as water supply, sewage systems, and drainage networks in which PVC pipes are essential components due to their durability, corrosion resistance, and cost-effectiveness.

In addition, urban areas necessitate the expansion and modernization of municipal services to meet the growing needs of urban populations. PVC pipes play a vital role in the expansion of municipal water supply networks and wastewater treatment plants.

Latest Industry News:

The market is also being driven by increasing investments and capacity expansions:

- January 2024: Advanced Drainage Systems, Inc., announced a partnership with Rainwater Management Solutions to drive advancement in sustainable stormwater solutions.

Key Insights for PVC Pipes Manufacturing Plant Setup

The following aspects have been covered in the PVC pipes manufacturing plant report:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Forecast

The report provides insights into the landscape of the PVC pipes industry at the global level. The report also provides a segment-wise and region-wise breakup of the global PVC pipes industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of PVC pipes, along with the industry profit margins.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the PVC pipes manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other PVC pipes manufacturing plant costs. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

.webp)

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a PVC pipes manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a PVC pipes manufacturing plant.

Profitability Analysis:

Report Coverage:

Key questions answered in this report:.

- How has the PVC pipes market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global PVC pipes market?

- What is the regional breakup of the global PVC pipes market?

- What are the price trends of various feedstocks in the PVC pipes industry?

- What is the structure of the PVC pipes industry and who are the key players?

- What are the various unit operations involved in a PVC pipes manufacturing plant?

- What is the total size of land required for setting up a PVC pipes manufacturing plant?

- What is the layout of a PVC pipes manufacturing plant?

- What are the machinery requirements for setting up a PVC pipes manufacturing plant?

- What are the raw material requirements for setting up a PVC pipes manufacturing plant?

- What are the packaging requirements for setting up a PVC pipes manufacturing plant?

- What are the transportation requirements for setting up a PVC pipes manufacturing plant?

- What are the utility requirements for setting up a PVC pipes manufacturing plant?

- What are the human resource requirements for setting up a PVC pipes manufacturing plant?

- What are the infrastructure costs for setting up a PVC pipes manufacturing plant?

- What are the capital costs for setting up a PVC pipes manufacturing plant?

- What are the operating costs for setting up a PVC pipes manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for a PVC pipes manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up a PVC pipes manufacturing plant?

- What are the key success and risk factors in the PVC pipes industry?

- What are the key regulatory procedures and requirements for setting up a PVC pipes manufacturing plant?

- What are the key certifications required for setting up a PVC pipes manufacturing plant?

Report Customization:

While we have aimed to create an all-encompassing PVC pipes plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. has played a crucial role in constructing, expanding, and optimizing sustainable manufacturing plants worldwide.

India Dairy Market Report Snapshots Source:

Statistics for the 2022 India Dairy market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports.

- India Dairy Market Size Source

- --> India Dairy Market Share Source

- India Dairy Market Trends Source

- India Dairy Companies Source

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Purchase options

Benefits of Customization

Personalize this research

Triangulate with your data

Get data as per your format and definition

Gain a deeper dive into a specific application, geography, customer, or competitor

Any level of personalization

Get in Touch With Us

UNITED STATES

Phone: +1-631-791-1145

Phone: +91-120-433-0800

UNITED KINGDOM

Phone: +44-753-713-2163

Email: [email protected]

Client Testimonials

IMARC made the whole process easy. Everyone I spoke with via email was polite, easy to deal with, kept their promises regarding delivery timelines and were solutions focused. From my first contact, I was grateful for the professionalism shown by the whole IMARC team. I recommend IMARC to all that need timely, affordable information and advice. My experience with IMARC was excellent and I can not fault it.

The IMARC team was very reactive and flexible with regard to our requests. A very good overall experience. We are happy with the work that IMARC has provided, very complete and detailed. It has contributed to our business needs and provided the market visibility that we required

We were very happy with the collaboration between IMARC and Colruyt. Not only were your prices competitive, IMARC was also pretty fast in understanding the scope and our needs for this project. Even though it was not an easy task, performing a market research during the COVID-19 pandemic, you were able to get us the necessary information we needed. The IMARC team was very easy to work with and they showed us that it would go the extra mile if we needed anything extra

Last project executed by your team was as per our expectations. We also would like to associate for more assignments this year. Kudos to your team.

.webp)

We would be happy to reach out to IMARC again, if we need Market Research/Consulting/Consumer Research or any associated service. Overall experience was good, and the data points were quite helpful.

The figures of market study were very close to our assumed figures. The presentation of the study was neat and easy to analyse. The requested details of the study were fulfilled. My overall experience with the IMARC Team was satisfactory.

The overall cost of the services were within our expectations. I was happy to have good communications in a timely manner. It was a great and quick way to have the information I needed.

My questions and concerns were answered in a satisfied way. The costs of the services were within our expectations. My overall experience with the IMARC Team was very good.

I agree the report was timely delivered, meeting the key objectives of the engagement. We had some discussion on the contents, adjustments were made fast and accurate. The response time was minimum in each case. Very good. You have a satisfied customer.

.webp)

We would be happy to reach out to IMARC for more market reports in the future. The response from the account sales manager was very good. I appreciate the timely follow ups and post purchase support from the team. My overall experience with IMARC was good.

IMARC was a good solution for the data points that we really needed and couldn't find elsewhere. The team was easy to work, quick to respond, and flexible to our customization requests.

- Competitive Intelligence and Benchmarking

- Consumer Surveys and Feedback Reports

- Market Entry and Opportunity Assessment

- Pricing and Cost Research

- Procurement Research

- Report Store

- Aerospace and Defense

- Agriculture

- Chemicals and Materials

- Construction and Manufacturing

- Electronics and Semiconductors

- Energy and Mining

- Food and Beverages

- Technology and Media

- Transportation and Logistics

Quick Links

- Press Releases

- Case Studies

- Our Customers

- Become a Publisher

United States

134 N 4th St. Brooklyn, NY 11249, USA

+1-631-791-1145

Level II & III, B-70, Sector 2, Noida, Uttar Pradesh 201301, India

+91-120-433-0800

United Kingdom

30 Churchill Place London E14 5EU, UK

+44-753-713-2163

Level II & III, B-70 , Sector 2, Noida, Uttar Pradesh 201301, India

We use cookies, including third-party, for better services. See our Privacy Policy for more. I ACCEPT X

- Business Ideas

- Dealership Ideas

- Franchise Ideas

How to Start PVC Pipe Manufacturing Business

- by SBH Team

- April 26, 2022

If you are thinking of starting a business, thinking of starting the best business, which will not drown you, in which there is a lot of money, then at this time that business is PVC pipe manufacturing business.

The full form of PVC is Polyvinyl chloride. PVC pipes are commonly used in the construction industry, electrical activities, and irrigation fields. PVC pipes come in different sizes, colors, quality and they have a huge demand in the market.

PVC pipes are more durable than traditional G.I pipes and they avoid electrical earthling issues in the construction industry.

If you also want to start a PVC pipe manufacturing unit, then in this article we will discuss the area required to start the unit, raw materials used, machinery required, and much more.

In this Post

PVC Pipe Manufacturing Business Plan

Like any other business, proper planning is necessary in starting a PVC pipe manufacturing Business. So we have listed some steps, which you can implement in your project.

- Proper Market Research

- Type of Products to manufacture

- Deciding your plant size & Budget

- Choosing the location

- Machinery Purchase

- Raw Material Purchase

- Getting required licenses and Registrations

- Manpower selection & capacity

- Sales and Marketing

Machinery Required

• High-speed mixture machine • Rigid Extruder machine • Grinder • Granulate Extruder machine • different types of die • Raw material

You can get the contact details of these machine dealers from websites like indiamart.com . You can get quotations from multiple dealers and can choose the best one.

Raw Materials Required

- P-Wax (Polyethylene/Paraffin Wax)

- One pack stabilizer

- Cpe (Chlorinated PVC Resin)

- Calcium chloride

- DOP (Dioctyl Polyethylene)

- Optical Brightener

Licenses and Registrations Required

- MSME Registration

- Company Registration

- GST certificate

- Pollution Certificate: You can get it from the local pollution Board office

- ISI Certificate from Bureau of Indian Standards

- Business Insurance

- N.O.C (No objection Certificate) from the municipality or Gram Panchayat: This is important because you need to have an independent commercial bore well for your plant.

- Registration of Trademark: This is not required by law, it is a good idea to register the name of your business as a trademark. If another business tries to use the same or similar name, you will have legal recourse to stop it.

Investment required for Tiles business

If you are running a large scale plant then you need to get in touch with good distributors. They usually have a good network all over the region. This would help you to reach your products to the entire region you are targetting.

I hope this article has resolved many of your doubts related to starting a tiles business in India. If you have any suggestions feel free to mention them in the comment box below. If you like this article kindly share it with your friends.

You may also like:

- How to start a Cement Business in India

- How to start a Paint shop in India ?

- How to start a Stationery Shop ?

- How to get Royal Enfield Dealership?

1 thought on “How to Start PVC Pipe Manufacturing Business”

How much investment required?

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Questions? +1 (202) 335-3939

- Pricing & Comparison Chart

There were 157 press releases posted in the last 24 hours and 391,265 in the last 365 days.

PVC Pipes Manufacturing Plant Project Report 2024: Business Plan, Manufacturing Process, Cost and Revenue

PVC Pipes Manufacturing Plant

PVC are a type of plastic piping commonly used in a variety of applications, particularly in plumbing, irrigation, and drainage systems.

BROOKLYN, NY, UNITED STATES, February 28, 2024 / EINPresswire.com / -- Syndicated Analytics’s new report titled “ PVC Pipes Manufacturing Plant Project Report 2024: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities” offers a comprehensive overview of the process involved in establishing a manufacturing facility for PVC pipes. It methodically examines various aspects, including manufacturing requirements, project costs and economics, success and risk factors, returns on investment, and profit margins. The study provides an in-depth analysis of the performance of the PVC pipes market, encompassing major regions, key market segments, and future prospects. As such, this report is an essential read for business strategists, investors, researchers, consultants, and entrepreneurs who are interested in venturing into the PVC pipes industry. The report draws upon both desk research and multiple levels of primary research to ensure accuracy and reliability.

What are PVC pipes?

PVC or polyvinyl chloride pipes are a type of plastic piping commonly used in a variety of applications, particularly in plumbing, irrigation, and drainage systems. These pipes are made from a synthetic polymer known as polyvinyl chloride, which is derived from natural resources like salt and hydrocarbons. Besides this, PVC pipes are known for their durability, lightweight nature, and resistance to corrosion, chemicals, and abrasion, making them suitable for both above-ground and underground installations. Additionally, they offer excellent thermal insulation properties, maintaining consistent water temperatures and reducing energy loss in heating and cooling systems. These pipes are also relatively low-cost compared to alternative piping materials such as metal or concrete, making them a cost-effective choice for large-scale infrastructure projects. Furthermore, PVC pipes are easy to install and require minimal maintenance, contributing to their widespread use in residential, commercial, and industrial construction projects worldwide.

Request for a Sample Report: https://bit.ly/3T0FRf9

What are the growth prospects and trends in the PVC pipes industry?

The rapid urbanization and industrialization leading to an increased demand for reliable and efficient infrastructure, including water supply, sewage systems, and drainage networks represents the key factor driving the demand for PVC pipes. Besides this, the growing construction activities, coupled with government initiatives for infrastructure development, are strengthening the market growth. Moreover, the superior properties of PVC pipes, such as corrosion resistance, lightweight, and low cost compared to traditional materials like metal or concrete, have made them a preferred choice for various applications, including plumbing, irrigation, and industrial piping systems, creating a positive outlook for market expansion. In addition to this, stringent regulations and standards mandating the use of environmentally friendly materials in construction projects spurring the adoption of PVC pipes due to their recyclability and low environmental impact are impelling the market growth. Furthermore, ongoing technological advancements in PVC pipe manufacturing processes, including extrusion and injection molding, have enhanced product quality and reduced production costs, propelling the market forward. Apart from this, the increasing awareness about the benefits of PVC pipes, such as their long lifespan, ease of installation, and low maintenance requirements, is aiding in market expansion.

Which aspects are covered in our report on setting up a PVC pipes manufacturing plant?

Market Overview:

• Market Performance • Regional Insights • Key Market Segmentation • Price Trend Analysis • COVID-19 Impact • Market Outlook • Market Key Players Analysis

Manufacturing Operations:

• Product Description and Insights • Detailed Process Flow • Identification of Unit Operations Involved • Mass Balance Analysis and Raw Material Requirements • Quality Control

Project Requirements, Details, and Costs:

• Site Development, Location, and Land Requirements • Plant Layout • Machinery Requirements and Associated Costs • Raw Material Requirements and Associated Costs • Packaging Requirements and Associated Costs • Transportation Requirements and Associated Costs • Utility Requirements and Associated Costs • Manpower Requirements and Associated Costs

Project Financial Analysis:

• Capital Investments Analysis • Operating Costs Analysis • Expenditure Projections Analysis • Revenue Projections Analysis • Taxation and Depreciation Analysis • Profit Projections Analysis • Comprehensive Financial Analysis

Ask Analyst for Customization: https://www.syndicatedanalytics.com/request?type=report&id=1150&flag=C

Need Customized Project Report?

You can share any particular business requirements that you have, and we will adjust the scope of the report to your needs. The following are some typical customizations that our clients ask for:

• The report may be customized based on the region/country in which you intend to locate your business. • The production capacity of the facility can be customized in accordance with your needs. • Suppliers of machinery and prices can be tailored to your requirements. • Depending on your needs, we may also modify the current scope.

Key Questions Addressed in the Report on the PVC Pipes Manufacturing Project:

• How has the performance of the PVC pipes market been thus far, and what can be expected in the upcoming years? • What is the market segmentation of the global PVC pipes market? • What is the regional distribution of the global PVC pipes market? • What are the price trends of various feedstocks in the PVC pipes industry? • What is the structure of the PVC pipes industry, and who are the major players? • What are the different unit operations involved in the manufacturing of PVC pipes? • What is the total land area required for the establishment of a PVC pipes manufacturing plant? • What is the layout of a PVC pipes manufacturing plant? • What are the machinery requirements for establishing a PVC pipes manufacturing plant? • What are the raw material requirements for setting up a PVC pipes manufacturing plant? • What are the packaging requirements for establishing a PVC pipes manufacturing plant? • What are the transportation requirements for establishing a PVC pipes manufacturing plant? • What are the utility requirements for establishing a PVC pipes manufacturing plant? • What are the human resource requirements for establishing a PVC pipes manufacturing plant? • What are the infrastructure costs associated with establishing a PVC pipes manufacturing plant? • What are the capital costs involved in setting up a PVC pipes manufacturing plant? • What are the operating costs associated with establishing a PVC pipes manufacturing plant? • What should be the pricing mechanism for the final product? • What will be the income and expenditures for a PVC pipes manufacturing plant? • What is the timeframe required to achieve the break-even point? • What are the profit projections for establishing a PVC pipes manufacturing plant? • What are the key factors for success and risks in the PVC pipes industry? • What are the essential regulatory procedures and requirements for establishing a PVC pipes manufacturing plant? • What are the necessary certifications required for establishing a PVC pipes manufacturing plant?

Browse Other Reports:

• Pea Protein Powder Manufacturing Plant Project Report: https://bit.ly/3uQAC8j • Binding Wire Manufacturing Plant Project Report: https://bit.ly/3OYObcA • Electric Vehicle Manufacturing Plant Project Report: https://bit.ly/3Knn6OW • Electric Scooter Manufacturing Plant Project Report: https://bit.ly/3C5q3ia

Why Choose Syndicated Analytics Reports:

• Our reports offer valuable insights for stakeholders to make informed business decisions and determine the feasibility of a business venture. • With a vast network of consultants and domain experts in over 100 countries spanning North America, Europe, Asia Pacific, South America, Africa, and the Middle East, we provide in-depth market analysis and competitive intelligence. • Our extensive database of equipment and raw material suppliers across major continents, combined with our ongoing tracking and updates of costs of land, construction, utilities, and labor across 100+ countries, provide valuable information for decision-making. • As a trusted business partner to leading corporations, governments, and institutions worldwide, our client list ranges from small and start-up businesses to Fortune 500 companies. • Our dedicated in-house team of experts, including engineers, statisticians, modeling experts, charted accountants, architects, and more, have a proven track record of building, expanding, and optimizing sustainable manufacturing plants globally.

Syndicated Analytics, a subsidiary of IMARC Group, offers consulting services and provides comprehensive market intelligence in the form of research reports, production cost reports, and feasibility studies. Our team, consisting of experienced researchers and analysts from diverse industries, is deeply committed to the quality of the information and insights delivered to the clients, which range from small and medium enterprises to Fortune 1000 companies. These firms are able to achieve this by studying the qualitative and quantitative aspects of the market as well as staying up to date with the current and evolving trends of the industry.

Katherine Shields Syndicated Analytics +1 213-316-7435 email us here Visit us on social media: Facebook Twitter

You just read:

EIN Presswire's priority is source transparency. We do not allow opaque clients, and our editors try to be careful about weeding out false and misleading content. As a user, if you see something we have missed, please do bring it to our attention. Your help is welcome. EIN Presswire, Everyone's Internet News Presswire™, tries to define some of the boundaries that are reasonable in today's world. Please see our Editorial Guidelines for more information.

Project Report Bank

PVC Pipe Manufacturing Plant Project Report

₹ 500

Description

You will have to do a deep study of the PVC Pipe Manufacturing Plant Project Report If you want to set up a PVC pipe manufacturing plant in India. You can get the PVC Plant project report pdf with much ease.

PVC or Polyvinyl-Chloride pipes are a segment in which you can start a small or medium-scale PVC pipe manufacturing business. The electrical, irrigation, and construction industries all employ PVC pipes. PVC is used to substitute wood, paper, and metal materials in various applications. Electrical conduits made of PVC pipes are commonly employed in household and industrial settings. PVC pipes are commonly used for water distribution. It has some properties that make it excellent for water delivery. It is lightweight, inexpensive, simple to install, non-corrosive, and has high tensile strength to withstand high fluid pressure. PVC pipes are chemically resistant and have excellent electrical and thermal insulation qualities.

Polyvinyl chloride, or PVC, has become a popular alternative to metal piping. PVC is one of the most extensively used plastics globally due to its strength, durability, ease of installation, and low cost. PVC is a thermoplastic that can be moulded into a wide range of shapes to make pipes, fittings, valves, and other liquid handling equipment. For drainage and plumbing, white pipes are mostly used. PVC pipes are made by extruding PVC as raw material. They generally follow the same procedures as standard pipe extrusion operations: Feeding the PVC twin-screw extruder with raw material pellets or powder. Multiple extruder zones are melting and heating.

Table of Contents

- 1 PVC Pipe Manufacturing Plant Project Report

- 2 Why should I buy PVC Pipe Manufacturing Plant Project Report

- 3 PVC Pipe Manufacturing Plant Business Plan

- 4 Indian Market Potential Of PVC Pipe

- 5 India Market Outlook For PVC Pipe

- 6 Types Of PVC Pipes In Demand In India

- 7 Application Of PVC Pipes

- 8 Advantages Of PVC Pipes

- 9 PVC Pipes Manufacturing Machine

- 10 PVC Pipes Manufacturing Process

- 11 Contents Of PVC Pipe Manufacturing Plant Project Report

The most often used plastic piping material is polyvinyl chloride (PVC). Extruded PVC pipe comes in a range of diameters and dimensions and is usually available in 10′ and 20′ lengths. PVC pipe is offered in two types of construction: solid wall and cellular core. The simultaneous extrusion of at least three layers of material into the pipe wall is required for cellular core construction: a solid outer layer, a cellular core intermediate layer, and a solid inner layer. Along with starting the PVC Pipe manufacturing business you can also buy one more equipment to manufacture PVC Tape as it also has great demand in the market. Thus exploring PVC Tape Project Report is really a great idea!

PVC (polyvinyl chloride) pipe is a plastic-vinyl chloride composite material. The pipes are long-lasting, sturdy, and difficult to damage. They are resistant to rust, rot, and wear. At room temperature, PVC is rigid because it is a polar polymer with strong intermolecular forces. However, flexible PVC goods are obtained when a plasticiser is introduced during the fabrication process. PVC’s adaptability is one of its main advantages.

Why should I buy PVC Pipe Manufacturing Plant Project Report

A project report of PVC pipe manufacturing plant is necessary for the following reasons.

- Helps the investor to make an investment decision in the PVC pipes manufacturing business.

- Makes the entrepreneur aware of the various aspects of the PVC pipes business.

- Helps in understanding the pvc pipe manufacturing process.

- Serves as a sample report to prepare project reports for other purposes.

PVC Pipe Manufacturing Plant Business Plan

Before setting up a PVC pipe manufacturing plant, it is necessary to research the market and prepare a detailed business plan. Project report plays an essential role in the preparation of a business plan.

In 2020, the worldwide PVC pipe market was expected to reach 21.32 million tonnes. The market is expected to increase at a CAGR of 5.32 per cent between 2021 and 2026, according to IMARC Group. PVC pipes are made by extruding a polyvinyl chloride (PVC) mixture plus several additives. Compared to concrete pipes, the production of PVC pipes uses around four times less energy and results in lower raw material losses.

Furthermore, PVC pipes have a much less environmental imprint than alternative piping materials due to their complete recyclability. PVC pipes are used in water systems, underground wiring, and sewer lines because of these characteristics. The market has been divided into irrigation, water supply, sewerage, plumbing, HVAC, and oil and gas applications. Currently, the irrigation segment dominates the market, accounting for most sales. As PVC helps to manufacture a number of bath items so you can get some tips to start bathroom fittings business by reading our bathroom fittings project report and earning extra income.

India’s PVC pipe export industry has risen significantly over the years due to the country’s expertise in low-cost production and technically qualified labour. The global PVC pipe market was worth $54,246 million in 2015, and it is expected to reach $85,565 million by 2022, growing at a CAGR of 6.7 percent. Polyvinyl chloride (PVC) is the third most prevalent polymer after polyethylene and polypropylene. It has many advantages over other materials, including chemical resistance, durability, low cost, and recyclability; as a result, it can be used to replace wood, metal, concrete, and clay in various applications.

Indian Market Potential Of PVC Pipe