Trends and new practical applications for warehouse allocation and layout design: a literature review

- Open access

- Published: 30 November 2023

- Volume 5 , article number 378 , ( 2023 )

Cite this article

You have full access to this open access article

- Pierre-William Albert 1 ,

- Mikael Rönnqvist 1 &

- Nadia Lehoux 1

2016 Accesses

Explore all metrics

Companies’ productivity is critical in contemporary warehouse environment to maintain efficiency and competitiveness within their supply chain. Warehousing operations are well known for their impact on the overall supply chain and need to be wisely managed. Among those activities, allocation planning and layout design are some of the most important concepts in practice. Current research tends to emphasize homogeneous environment, which leaves heterogeneous and non-standard cases with less attention, even today. This paper aims to review the literature regarding warehouse allocation planning and layout design methods that could suit practical industry problems, with a focus on heterogeneous and non-standard spare parts. It also aims to describe the current trends in these fields. Following a literature review methodology, a total of fifty-seven articles were reviewed to identify the methods developed and used. The reviewed papers were also investigated in order to identify research gaps and future directions. The analysis concluded that more research is needed to better understand and optimize heterogeneous and non-standard spare parts environments in terms of allocation and layout design. More practical case applications also remain a gap to address.

Article highlights

This article evaluates 8 concepts/parameters related to warehouse allocation operation. This is to ensure a deep analysis of heterogeneous and non-standard parts presence in literature.

A research gap is identified regarding heterogeneous and non-standard parts in warehouse allocation and layout design methods in the scientific literature.

This article evaluates 3798 scientific papers over a 20-year timeframe. From this, we present 57 methods and 8 gaps in scientific literature.

Similar content being viewed by others

Special Optimization Process for Warehouse Layout Design

Warship spare parts configuration optimization for stock control: Investigating the gap between qualitative and quantitative constraints

Warehouse Design and Order Picking Algorithms for Apparel Industry

Avoid common mistakes on your manuscript.

1 Introduction

Faced with stiff economic and international competition, companies need to become truly efficient in warehouse operation planning to fulfill their mission and remain productive [ 59 ]. Nevertheless, in real-life situations, optimizing warehousing layout design and allocation is often a challenge to achieve a feasible solution [ 88 ], as different factors may be difficult to overcome [ 85 ]. Moreover, 90% of warehouses in the world are still managed manually or with low-level automation [ 50 ]. The recent changes in global uncertainty and risk on the supply chain that Covid-19 imposed is a good example of a factor which had a real impact on warehousing systems [ 76 ]. Furthermore, customer behavior and preferences can change at any moment and logistics should be able to keep pace [ 46 ]. Thus, a robust warehouse layout design and an efficient internal product allocation process enhance the probability of success [ 24 ]. [ 31 ] highlighted three priorities for optimal management systems, involving reduction of the use of sheets to keep track of the operations performed, to manage real-time inventory needs, and to maintain high productivity levels.

In this article, we perform a literature review that focuses on warehouse layout design and allocation planning methods. We focus on heterogeneous spare parts which suits practical industry problems. [ 6 , 44 , 75 , 88 ] all deplored the lack of literature on the practical effect of real-life features on warehousing operational planning activities. Many challenges arise with heterogeneous parts and real industrial constraints. [ 13 ] suggested an increase in the complexity of warehouse handling activities. [ 75 ] highlighted the difference in complexity for heterogeneous parts characteristics and their impact on warehousing and maintenance inventory. Specific interest in evaluating spare parts in such industrial realities is clear. In fact, the aftermarket business model and operational realities are completely different than in industrial production in relation to the uncertainty factor [ 75 ]. Thus, a focus on these aftermarket spare parts becomes evident to increase the understanding on this subject and determine storage needs and capacity. [ 110 ] From an economic perspective, spare parts play a critical role in the value for the customer and enterprise. This increases the need for further research on this matter since this subject still seems to best in its infancy.

The objective of this study is therefore to highlight the most promising methodologies and approaches that could suit such environment. To achieve this goal, concepts related to warehouse operations planning from the last 20 years (2000 to 2022) were analyzed to answer the following four research questions in relation to specific keyword sets. For each keyword iteration, one or more of those elements such as non-standard/heterogeneous, trends, practical case studies, and upcoming technologies were analyzed in the initial screening:

RQ1 Which methods were developed to improve productivity in warehouse allocation planning?

RQ2 Which methods were developed to improve productivity in warehouse layout design?

RQ3 Which methods were proposed to improve productivity in warehouse regarding allocation and layout design simultaneously?

RQ4 Which methods were used to increase productivity for practical case studies, especially for heterogeneous non-standard parts environment?

To answer these questions, we used a set of specific keywords. For each keyword iteration, one or more of those elements such as non-standard/heterogeneous, trends, practical case studies, and upcoming technologies were analyzed in the initial screening.

Trends and emerging practices were also examined during the analysis. The investigations showed that smaller and more frequent transactions occur in warehouses [ 31 ]. Also, product allocation planning regarding handling constraints for workforce security management seems to be on the rise [ 86 ]. Another concept in self-storage warehousing with customer choice appears as a contemporary issue [ 113 ].

The remainder of this paper is as follows. Section 2 summarizes the main concepts of warehousing and operational planning. Section 3 describes the methodology used in this paper. Section 4 presents the answers to the research questions and some recommendations. Section 5 concludes the paper.

2 Preliminary concepts

This section presents some preliminary concepts about warehouse layout design and allocation planning.

2.1 Layout desing

Warehouse layout design typically focuses on the positioning of docks, reception, racking location, racking height, and slots dimensioning. [ 46 ] described warehouse design activities as the physical layout, the storage equipment, the handling equipment, automation solutions, information systems, labor, and activities to determine. Physical layout can be described as the aisle and lane configuration, the stacking height, while storage, and handling equipment, including racking, forklift, and carousel. [ 93 ] tries to solve a warehouse design for a block stacked warehouse. They determined the lane depth, stages, and temporary additional capacity which is of dynamic nature. Thus, a lack of flexibility and capacity which evolve dynamically can have a major impact on the system [ 21 ]. [ 36 ] proposed a review of warehouse layout design methods and identified five decisions as follows: overall structure, department layout, operation strategy, equipment selection, sizing, and dimensioning. They also introduced the importance of benchmarking and analytical operations for a better performance evaluation. [ 96 ] investigated the warehouse layout problems and concluded on the utility of the cube-per-order index (COI). [ 63 ] presented a literature review that looks at designing warehousing systems with a focus on order picking. [ 107 ] presented a review for optimal warehouse designs with case study applications. They focused on average order picking and total traveled distance for determining the design.

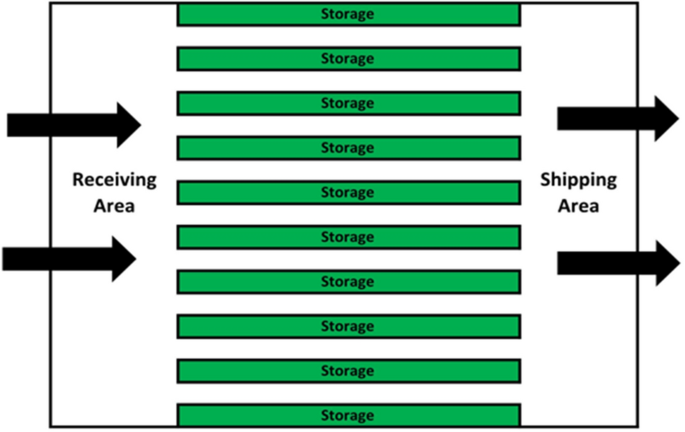

Sometimes layout design needs to be reviewed to be more efficient, as redesigning might be more suitable and less expensive than building a new warehouse. [ 26 ] suggested how to redesign production layout for real case scenarios with a dedicated storage method. [ 5 ] followed the redesign layout planning for a systematic layout planning usable on real case studies. Another approach for real cases is considered by [ 81 ]. They evaluated different warehouse layouts by comparing a classic layout design with other general layout concepts like fishbone, class-based, shared storage, dedicated, and random. [ 43 ] utilized the warehouse design dedicated policy for a real case study. [ 67 ] followed the redesign by proposing layout changes and handling methods for a real case raw material storing process. [ 69 ] presented a case study with limited space situation and for warehouse layout design in a specific automobile material supplier. Their main objective was to design two warehouse layouts to fulfill the company storage assignment. They followed a class-based approach. [ 40 ] presented a design methodology for converting regular warehouses into different zones. [ 84 ] resolved a warehouse layout design for a real case problem while mixing allocation techniques such as ABC class-based storage. [ 51 ] worked on the design of a multi warehouse inventory model with the rain optimization algorithm. They also presented the concept of optimal replenishment policy (ORP). Figure 1 presents a dynamic cross-docking layout design for easy picking.

An illustration of a dynamic picking zone model

2.2 Storage, product allocation, and slotting

Storage, product allocation, and slotting all refer to the capacity and ability to put items correctly in a specific place. [ 37 ] specified that one of the most important things in warehouse operations planning relates to the storage and allocation of products to the right storage positions. [ 31 ] explained that SKU and storage zones, including strong correlation together, should be the closest possible to each other. [ 48 ] described slotting as the operation to find the best location to keep an SKU inside the storage zone. Thus, many problem-solving algorithms or methods related to allocation were developed over the years. Here is a non-exhaustive list of allocation problems or methods one can find in the literature: the multi-layer allocation problem (MLAP), the storage location allocation problem (SLAP), the class-based storage location allocation problem (CBSLAP), dedicated storage, random, closest, farthest, ABC class, forward reserve, and zoning. SLAP is derived from the more general location allocation problem (LAP). [ 14 ] studied storage and stacking in the marine transportation industry. The objective was to stack sea cans in a fixed stack with limited height while the stacks had to be at a workable distance from the cranes. [ 57 ] focused on stacking goods for a real case study in container stacking in ports which they defined as the stack loading problem (SLP). [ 64 ] described the MLAP problem as a variation of the SLAP problem, including multiple floor levels for bins in the warehouse. In other words, the MLAP differs from the general SLAP by adding another dimension in the storage with floors and height. [ 104 ] followed the class-based storage location but used a constrained clustering method as well. To achieve their results, the COI index was used. [ 33 ] also followed the class-based storage method for a real case study. [ 19 ] worked on order picking in a multi-level rack warehouse with a class-based storage policy. In their paper, they pointed out important factors to take into consideration like the material handling system, product characteristics, demand trends, and the turnover rate. They also regrouped the storage assignment policies in three main groups which are random storage, dedicated storage, and class-based storage. [ 3 ] wanted to optimize storage classes via a minimum travel cost. They ranked location with frequencies, arrivals, and demand. [ 108 ] also presented a class-based storage with a finite number of items. They concluded that using more classes is not always better. [ 11 ] investigated the CBSLAP in more depth with a class-based storage location assignment overview of policies and classification. Their classification for storage policies separated the SLAP problem between dedicated and shared storage, dedicated storage being linked to parts number, turnover rates, COI, and correlated items while shared policy being separated between class-based and haphazard. [ 32 ] tried to solve the general assignment problem by including worker capabilities. [ 45 ] used a genetic algorithm to solve a multi-objective storage allocation. [ 98 ] interacted with the intelligent storage allocation with multiple objectives. They used class-based with fixed location and worked with flood management. Forward reserve is another option for storage and allocation. [ 100 ] presented a forward reserve storage strategy for customer order mixed with class-based criteria. The objective was to measure customers’ order response time and the overall system capacity in an AS/RS situation. A forward pick area can be described as a warehouse within a warehouse. It can help to stock the most popular items in small amounts to reduce the main picking zone [ 9 ]. It can then be replenished with bigger reserve storage.

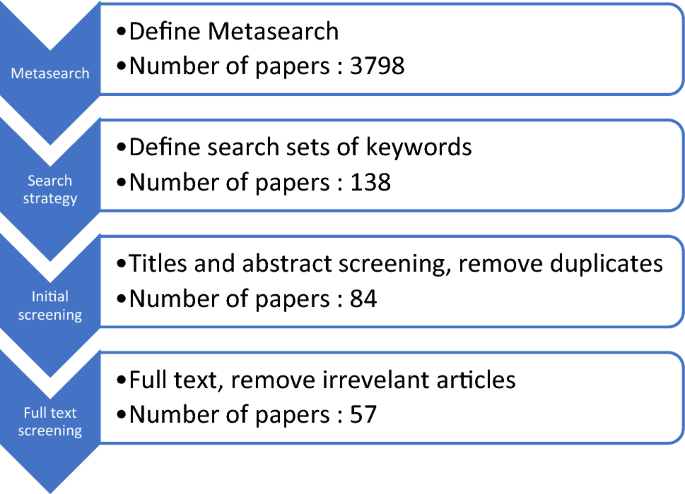

3 Research methodology

To find the most promising methods that could suit practical industry problems related to allocation planning and layout design, especially for heterogeneous spare parts, a literature review approach called a conservative search and screening methodology. This approach is a reliable methodology that could be easily repeated by any reader. In fact, the methodology is used in other papers. [ 23 , 36 , 90 ] Also, to the best of our knowledge, no other papers were evaluating heterogenous environment even at a low importance concept which represent a large gap between the literature and the practical world. Thus, a conservative and screening approach was more adequate to clearly address the research question. The process together with the number of articles identified in the steps is illustrated in Fig. 2 .

Conservative search and screening methodology

3.1 General Methodology

The first step of the method involved defining the research questions. To identify promising methods that would be useful in the real world, especially when dealing with non-standard space parts, the questions to investigate were defined. The objective was to find papers related to allocation planning, layout design or both concepts simultaneously. The last question is concerned about practical case studies and heterogeneous/non-standard environment.

The second step involved determining the keywords, the research databases, the source types, the language considered, and the years of publication. We investigated different combinations of keywords related to the variability of warehouse operations concepts. Thus, we first separated those concepts as follows: “warehouse allocation planning”, “warehouse layout planning”, “non-standard shelf layout or warehouse variable layout or warehouse adaptable layout”, “warehouse operational planning”, “warehouse limited storage capacity”, “non-standard or heterogeneous or diversified spare parts”, “warehouse capacity utilization”, “warehouse total storage capacity or warehouse storage capacity”, “warehouse storage management”. Then, a mix of keywords to identify previous literature reviews was searched: “literature review and warehouse allocation”, “literature review and warehouse layout design”, “literature review and warehouse operational planning”. All keywords set iterations evaluated the best articles related to the main concepts of this research which are non-standard/heterogeneous, trends, practical case studies, and upcoming technologies.

The research database “Compendex” and “Inspec” were the ones selected as being recognized as useful tools in the field of engineering and operations management. To limit the number of papers to examine, a focus on scientific journal papers was determined and English was the only language considered. Only papers published from 2000 to 2022 were considered from an evolutionary perspective of how the current subjects evolved through time while detecting the new trends emerging from such subjects. The reason for the diminution in the number of papers between the metasearch and the search strategy is related to the keywords sets which involved a focus on allocation or layout design concepts. All the papers with a focus on other main concepts such as picking, routing, automation technology or shipping were eliminated from the search. This reduced the number of papers from 3798 to 138.

The third step involved conducting an initial screening by looking at the titles and abstract to determine whether the articles were relevant for this study or not. Once again, articles focusing on concepts other than allocation and layout design were excluded, as well as purely theoretical studies considering a perfect homogeneous environment. This decreases the number of papers to be reviewed in the next step to 84.

The following step encompassed a full-text screening. A total of 57 papers were finally kept for the literature review.

4 Results and discussion

4.1 descriptive results.

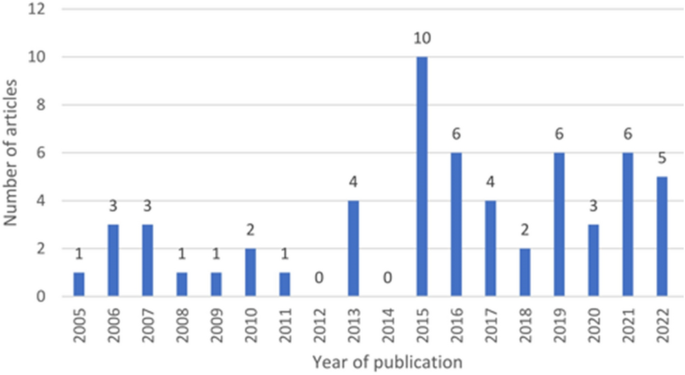

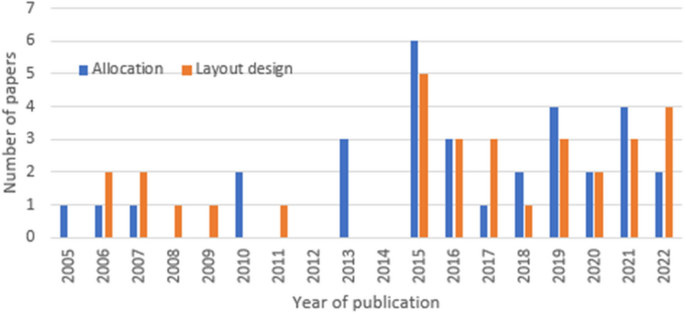

Figure 3 presents the number of reviewed papers per year. We can see that research on warehouse allocation and layout design concepts has increased in recent decades and that 85% of the literature reviewed has become available since 2010.

Statistics concerning the papers reviewed per year

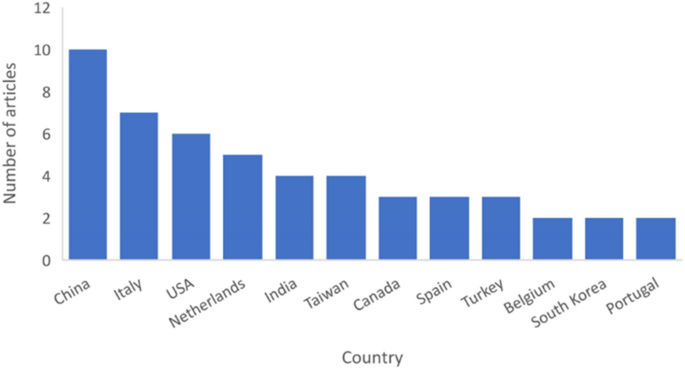

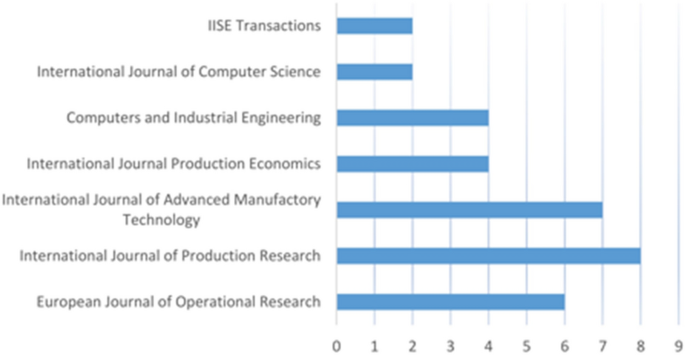

Figure 4 shows the total number of papers based on the country of affiliation of the first author. All the countries with at least 3 papers reviewed are shown within this figure. Figure 5 describes the number of articles by journals in ascending order when at least 2 articles were published in them. The International Journal of Production Research, the International Journal of Advanced Manufacturing Technology, and the European Journal of Operational Research are the most frequent journals in the field. Figure 6 describes the number of papers looking at the two main concepts together (allocation and layout design) per year. Table 1 is related to the number of papers per methodology. Simulation methodology refers to research including a simulation model and/or the use of simulation software. A literature review methodology refers to a paper in which the research core is concerned with presenting the literature and papers related to the specific concepts of a scientific field. Analytical methodology refers to research papers including a mathematical model or a heuristic. Analytical represents mathematical models including algorithmic models that normally look for an exact solution and optimization model. Heuristics models are also included. A qualitative methodology refers to research papers describing conceptual frameworks, questionnaires, or factual data. Most of the reviewed papers used mathematical models to identify an optimal solution. Only a few articles exploiting heuristics were found. Table 2 presents the concepts studied in this research according to degree of popularity (number of papers and their overall percentage on the total numbers evaluated).

Papers distribution of publications based on first author’s country

Papers reviewed according to the name of journals

Papers reviewed per year based on the main concepts (allocation and layout design) considered in this study

4.2 Research questions

This part presents all relevant findings in relation to the research questions investigated.

4.2.1 Question #1

4.2.1.1 which methods were developed to improve productivity in warehouse allocation planning.

The first research question was related to warehouse allocation planning and the current approaches and methods available in the literature to solve this problem, especially regarding non-standard, heterogeneous environments. In [ 85 ] an architecture for product allocation planning with compatibility and safety constraints and with an IoT-based warehouse. A proposed multi-agent architecture for PAP with compatibility constraint was described. [ 86 ] focused on a product allocation planning (PAP) problem with handling constraints within a case study. The constraints evaluated were the weight and the shape. The model followed a zero–one quadratic assignment. They brought something new as the Covid-19 handling constraints which add additional challenges to operational planning. Their modeling led to 24% reduction in picking distance by implementing ABC clusters and odd shaped constraints. [ 98 ] described a dynamic programming approach for the SLAP problem. The main objective was to enhance order-picking with good storage location in a dynamic perspective. [ 111 ] mixed IoT, integrated production planning, and warehouse storage assignment for a practical case. A linear programming model minimizing the total production cost and warehouse operations was presented. [ 80 ] followed the same thinking with an integrated model for warehouse and inventory planning. They also evaluated the capacity restrictions in inventory planning. [ 61 ] proceeded in a separate direction with a class-based storage assignment over life cycle picking patterns. The model was based on a mixed-integer linear programming (MILP) pattern. They introduced product popularity (consumption level) as the main characteristic for an SKU storage level. The more popular it was, the closer to floor level it had to be. [ 55 ] focused on the optimization of warehouse storage capacity with a dedicated storage policy. Moreover, this paper aimed to determine the space requirements under a dedicated storage policy. Thus, they used a non-linear programming model to minimize the cost of space used in the warehouse. [ 58 ] evaluated beyond static scenarios with a dynamic storage assignment with product affinity and ABC classification. They proposed a case study to show the usefulness of such a scenario. Their method used a product affinity-based heuristic with a quadratic assignment problem. [ 41 ] created a model for storage arrangement and reallocation in storage operations. The model proposed a heuristic algorithm for storage reallocation. [ 70 ] aimed to maximize the storage space availability inside a chaotic warehouse via a heuristic for the SLAP problem in a multi-level case. Their method was also usable for determining the right timing for relocation. [ 3 ] checked the allocation problem for the unit-load warehouse and tried to optimize it via storage classes. The focus of the paper was on describing a potential solution for practical cases. The method was solved with linear programming. [ 38 ] evaluated the impact of storage space on storage policy performance in a unit-load warehouse. The study also found that class-based storage performs better than turnover-based policy. [ 99 ] pointed out that literature normally evaluates single-period instead of multiple-period for orders in warehouse. Thus, warehouses should rather be seen as a dynamic place which needs to evolve over time. The proposed innovative way for warehouse storage allocation evaluated the entry-item-quantity and then sorted all SKU. [ 104 ] followed a constrained clustering method for class-based SLAP in a warehouse. The originality of such method lies on the constrained cluster and in the practical storage constraints evaluated. They used the COI index for grouping and sub-grouping and then found results with a heuristic assignment model. Multiproduct slot allocation heuristic was the main object in [ 10 ]. The objective was to minimize storage space with such a heuristic. The model linked to a real industry case and showed good results with a dedicated storage policy. [ 108 ] discovered an interesting correlation that more classes in a class-based allocation strategy are not always better. Their research evaluated the class-based storage with a finite number of items in a SLAP problem. They found that 3 to 8 classes were normally sufficient to obtain near optimal solutions. [ 102 ] also evaluated class-based storage policies for the allocation problem. This time, the focus was on optimal dimensions for multi-deep storage systems instead of standard warehouse. This is related to AS/RS automated storage systems. Once again, the utilization of class-based strategies was relevant. [ 47 ] looked at large distribution centers for their storage location assignment heuristic based on slot selection and frequent itemset grouping. They evaluated a new dimension of SKU by integrating itemset grouping, which led to better agglomeration of parts in a smaller slot. [ 29 ] worked on the SLAP problem with order picking optimization in the automobile industry. They solved it with a class-based policy and batching and routing problems via an integer programming model. In [ 59 ] a linear programming and decision-making model was presented to improve warehouse utilization. The objectives were to find the best decision for storage racks with box placement.

4.2.2 Question #2

4.2.2.1 which methods were developed to improve productivity in warehouse layout design.

The second question focused on the warehouse layout design concept, with a focus on non-standard, heterogeneous environments. Layout design modeling for a real world just-in-time warehouse was presented in [ 42 ]. They proposed another perspective for layout design related to just-in-time warehouse instead of a traditional one. [ 66 ] used a particle swarm optimization algorithm for the multiple-level warehouse layout design problem. The paper proposed solutions such as orientation of storage racks and the overall configuration. For non-conventional warehouse design, [ 30 ] discussed a heuristic comparative assessment for unit-load warehouse. They used the FlexSim software to present a simulation of different designs. [ 16 ] proposed solutions to determine slot sizes in a unit-load warehouse. The purpose of this paper was to go beyond the equal height slot generally found in the literature and to present different slot size possibilities in one solution. [ 78 ] tried to enhance manual order picking areas via the design of the layout structure. Their model minimized the travel distances in the picking area with parallel structure. Another possibility with warehouse models is self-storage warehouses. Thus, [ 113 ] described a design for self-storage warehouse with customer choice. They used a customer choice model to evaluate the probability of purchase. This model was a mixed-integer model solved with the branch-and-price algorithm. A guideline was proposed by [ 83 ] for developing a design in a case-picking warehouse. The main objective was to determine guidelines for good design in manual case-picking warehouses. [ 79 ] explained how to estimate optimal ABC zone sizes in manual warehouses. They presented the benefits of ABC class-based storage policy for SLAP problems. The zoning experiments were compared between one to three zones (20/30/50) patterns. [ 103 ] investigated a fuzzy multi-level warehouse layout problem. A tabu search was utilized and presented a good steppingstone for the layout problem. [ 73 ] mixed the determination of warehouse layout and control policies in their paper. [ 39 ] studied the uncertainty theory method in relation to the multi-level warehouse layout problem. Uncertainty factors were included, and two different models’ scenarios were evaluated. [ 94 ] followed a different path with the imperfect staggering in product inflow with queuing theory. The paper explored the block stacking layout problem with a model of the imperfect staggering effects. [ 6 ] discussed a structured approach for warehouse design. The paper of [ 15 ] related to economic and ergonomic performance measures helped to understand the rack design for the warehouse layout design problem. [ 17 ] focused on the fishbone warehouse design with vertical travel. The paper presented a three-dimensional design with a fishbone layout. Another point in layout design is to manage the deep lane storage system layout. [ 1 ] proposed an iterative decision-support model for this problem with block stacking storage environment. A simulation and the analytic hierarchy process for decision support systems were presented in [ 76 ]. The focus was on air cargo warehouse capacity design. Thus, they tried to integrate a practical case study with a complex simulation. The question between automated or manual storage systems was the subject of [ 110 ]. The authors proposed insights for managers to select the most appropriate storage systems. [ 91 ] wanted to optimize layout for a three-dimensional order picking warehouse. Their work helped to determine layout warehouse while determining the depth and number of levels of such a warehouse. On a more global note, [ 23 ] presented the major changes in the last years in terms of warehousing. This paper encompassed the new trends and technologies and gave insights concerning what is happening nowadays. [ 92 ] evaluated the design of an order-picking warehouse with vertical travel and space sharing. The warehouse was a single block rack-based and the model integrated practical case data.

4.2.3 Question #3

4.2.3.1 which methods were proposed to improve productivity in warehouse regarding allocation and layout design simultaneously.

Regarding the study of both concepts simultaneously (allocation and layout design), only a few publications were found. Those articles mainly focused on reviews or general models. In [ 13 ], assembly kits were an important variable to determine warehouse layout design and assignment procedure. The main difference with previous research was based on the physical attributes of the parts evaluated and their occurrence in assembly kits. In [ 24 ], an overview of the problems found in layout design, storage assignment, and order concepts of warehouse operational planning such as zoning was proposed. They described many advantages of good practices in warehouse operational planning, such as transportation/production economies, reduced lead time uncertainty, increased customer service, and satisfied changing market conditions. Another review was found in [ 35 ]. The review based on warehouse operations enhanced the reader’s knowledge on various operations planning problems, including the layout design and allocation problem. [ 105 ] tried to minimize operating costs in a picker-to-part warehousing system. From this, an evaluation on multiple concepts from warehouse operational planning (WOP) was developed, which included allocation and layout design. The paper proposed an algorithm determining the number of zones, bins, and racks. [ 97 ] integrated an optimized fishbone warehouse layout with a SLAP problem and a picker routing. With those 3 concepts from WOP, they proposed a 3D layout design with a turnover-based assignment for allocation. In another spectrum, [ 34 ] incorporated human factors in order picking planning. [ 13 ] designed diagonal cross-aisle warehouses including a class-based storage assignment strategy. They worked on a non-traditional model such as diagonal cross-aisle with unit load and compared their results with a traditional and random one. In [ 90 ], the design of efficient order picking systems with a planning combination was studied. The main objective was to show which combination policies could be used for such problem.

4.2.4 Question #4

4.2.4.1 which methods were used to increase productivity for practical case studies, especially for heterogeneous non-standard parts environment.

For the last question, the literature related to practical case studies and heterogenous non-standard spare parts (SKU) was evaluated. However, a few numbers of articles on non-standard spare parts were found while practical case studies appeared to be a little more frequent. [ 30 ] worked on a heuristic for non-conventional warehouse designs. The fishbone design seemed to be the most effective method in terms of warehouse designs [ 13 ]. worked on assembly kits with variable parts and physical attributes. They looked for solutions to agglomerate the assembly kits parts in corridors and to create such a kit in a single warehouse corridor. Part categorization was the main procedure for such a solution. Then, one could determine the warehouse corridor and structure afterwards. [ 78 ] focused on the limited storage capacity problem found in some warehouses. They proposed an optimal policy for multi-item systems with stochastic demand and backlogged shortages. The solution was an inventory model for multiple products. [ 75 ] worked on maintenance inventory allocation with heterogeneous part characteristics. The paper helped to better understand dynamic demand in non-standard parts systems for specific maintenance with aeroengine. They used an ABC-VED matrix for the classification of distinct categories. [ 12 ] considered a non-traditional warehouse with a diagonal cross-aisle design.

In [ 86 ], the case study analytical model was related to a PAP problem with handling constraints in the retail sector and with manual order-picking operations. The model developed a shape parameter linked with data to distinguish non-conventional parts against standard ones. [ 42 ] evaluated the just-in-time warehouse real-world practical case with the layout design model problem. The case study was in the retail industry. [ 16 ] compared data from different distribution centers in the industry. A key part of their study was the evaluation of slot sizes in warehouses. From this, one could evaluate different slot sizes in a non-standard environment. For the automotive industry cases, [ 29 ] proposed a solution for the SLAP problem and order picking optimization. The solution showed that proximity for storage location is the main factor to minimize the total travel time in assembly warehouses. [ 113 ] evaluated a self-storage in Rotterdam for the design of self-storage warehouses with customer choices. The paper included layout design and a real case study for a specific non-standard warehousing aspect in self-storage. [ 111 ] proposed an IoT assisted case from a food company for warehouse storage assignment and integrated production planning. With the beverage industry, [ 1 ] from a block stacking warehouse presented a way to design and manage deep lane storage system layout. This helped in minimizing the storage space and time inefficiencies.

In their simulation, [ 76 ] worked in the air cargo warehouse capacity design. This case study gave insights concerning how to minimize the cost while enhancing the performance in a highly dynamic environment. [ 58 ] looked at a general case study on dynamic storage assignment including product affinity and ABC classification. [ 3 ] evaluated their method with a third-party logistics provider and a unit-load warehouse. They proposed an approach to optimize storage classes for this kind of environment. The method used the layout information and the product flow. They found that random allocation is the best choice in highly dynamic environment with few allocation bins available at any time. The busier the more random the allocation should be since emergency allocation tends to increase drastically traveling time inside the warehouse. [ 101 ] worked with the steel supply chain in a highly dynamic and look-like SKU environment. Their method was based on a managerial optimization with RFID warehouse. Thus, the allocation and retrieval process could easily enhance its productivity with proper RFID system implementation [ 10 ]. validated their multiproduct slot allocation heuristic with a real industrial case. Even if the main purpose of the paper did not directly involve a practical case implementation, their heuristic aiming at minimizing storage space using a dedicated storage policy meant it seemed to be possible to implement in real life. The constrained clustering method for class-based SLAP by [ 104 ] followed the same reality as in the previous paper. The main purpose of the paper was not directly related to a case study. However, this article tended to obtain satisfactory results for practical issues.

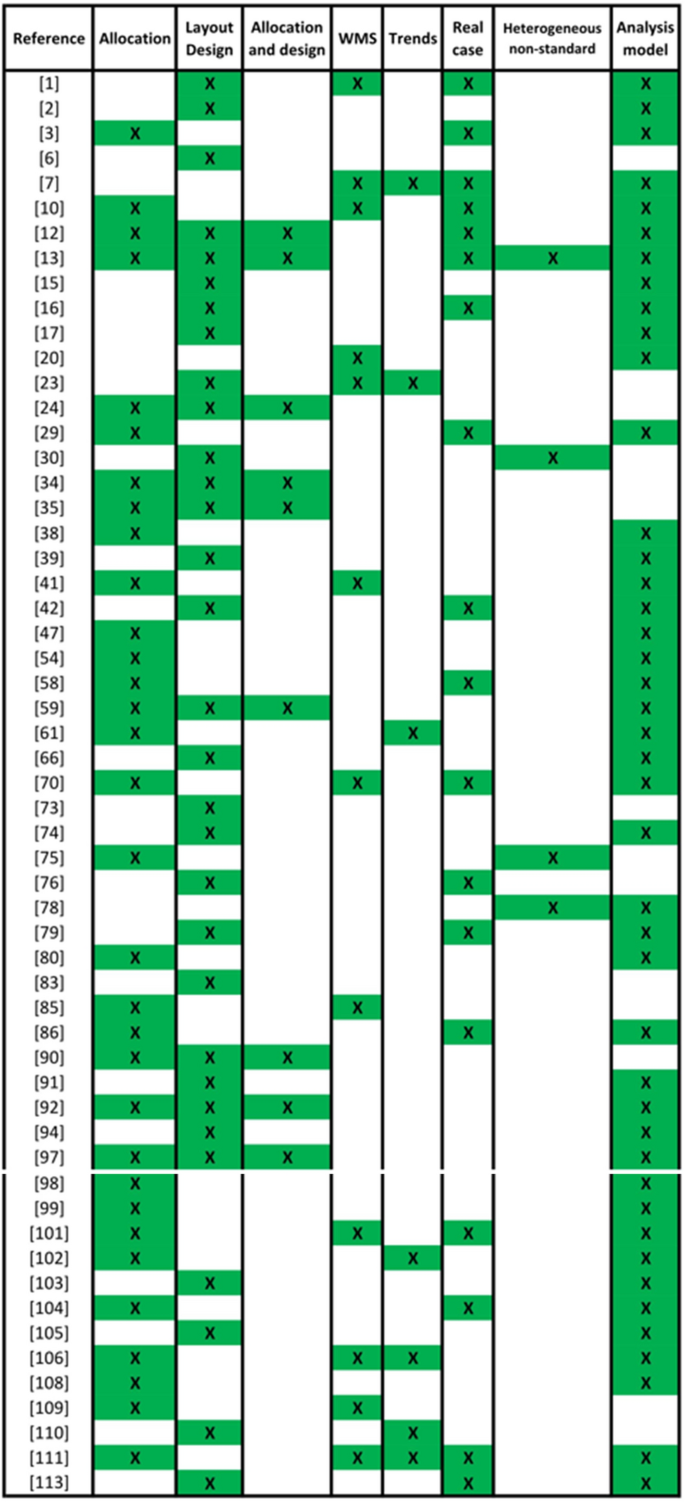

Figure 7 presents a resume of the analyzed paper related to the main criteria of this study.

Summary categorization of the analyzed papers

4.3 Discussion

In this section, we discuss the approaches and methods found when conducting the review and their application to solve practical cases. A discussion focusing on the gaps identified as well as the opportunities and trends observed is also proposed.

4.3.1 Warehouse allocation methods

Based on the allocation methods reviewed in this paper, the most common elements considered by the authors were the following ones:

Determining an SKU classification

Considering ABC class within the SKU classification

Allocating block-unit warehouse (standard location)

Minimizing traveling time for SKU picking/slotting

Using the shortest path algorithm for allocation

One of the interesting methodologies proposed in the literature is the forward area where the warehouse storage location is split between a large warehouse containing all the SKUs and a smaller more convenient zone in the forward area. A main challenge identified when reviewing allocation solutions resides with the homogeneous standard evaluation. Most companies are not always standard in their operations and SKU dimensions. Thus, the literature should focus more on flexible warehouse storage solutions with different widths and sizes. More research should be done with methodologies suitable for unconventional items (heterogeneous) size problems.

4.3.2 Layout design discussion

The literature reviewed highlighted that designing storage zones and rack dimensions were the main elements studied by the authors. Nevertheless, the methods typically involved static solutions. There seems to be a lack of research on flexible layout design. Most of the layout design-oriented research also focused on classic rack layout problems with general, same-size SKUs. However, in practical case situations, SKUs of various sizes and dimensions can be handled. More research could certainly be conducted for evaluating the impact of SKUs characteristics with non-standard or variation in dimensions, evaluating the impact of dynamic factors over time, the impact of e-commerce/mass customization, as well as the impact and productivity of non-conventional layouts (e.g., cross-docking, JIT, heterogeneous parts).

Also, workforce behavior and management cannot be neglected to fully implement new designs, e.g., the impact of heavyweight SKUs on potential injury for a worker. Some possibilities for future research could include evaluating managerial and workforce variables in WOP research, including union or work restriction realities in algorithms and simulation models, and evaluating the impact of unconventional temperature environment on well-being and performance.

The Covid-19 epidemic showed how dramatically such events could impact the overall practice and realities in warehousing. The crisis has shaken the foundation of many concepts such as lead times and security stocks. [ 31 ] reported important changes over the years in warehousing activities. Among them, smaller and more frequent transactions [ 23 , 89 ]. This reality drastically increases the operations planning because of the volume increase of purchase orders and leads to more come and go for the pickers inside the warehouse. Another reality is an increase in item returns. This can be seen with e-commerce [ 23 ]. [ 89 ] dug into the emerging practice due to the recent change in order number and the increasing “just-in-time” demand from customers. In terms of time, [ 82 ] explained that companies should be able to complete customer orders in less than 24 h for more than 98% of overall order. [ 46 ] talked about the increasing complexity for inventory management where workforce seems to need to develop new capacities and understanding of warehousing activities. [ 51 ] made a three-decade literature review about warehouse research. Their results showed that the emerging keywords in terms of warehousing are related to automated & intelligent warehousing such as integrated WMS, application of industry 4.0, and AI sensors. [ 55 ] presented a case study to design and describe an application of Internet of Things (IOT) in the industry 4.0 era. [ 21 ] made a literature review presenting flexible automated warehouses. In terms of emerging technologies, dynamic/flexible automation is an important part of it. In this matter, flexibility can be interpreted as giving more opportunities to adjust to market changes such as e-commerce, customization, and just-in-time. Automation can be defined as the technology that processes tasks without human workforce or assistance. Emerging technologies presented in [ 21 ] are Internet of things (IOT), cyber-physical systems (CPS), Big data, artificial intelligence (AI), and cloud computing. The future of warehousing is slowly converging to fully automated systems and unmanned procedures. One should determine which level of automation is required to be effective and depending on the resources. There is an opportunity for future research to look at automation levels and the impact on productivity and cost, the minimum automation level to adopt in a specific warehouse, cross-automation on multilayer warehouses, including the impact of human workforce on floor levels and automatic picking on floor levels, dynamic and flexibility related to automation, as well as methodologies for automated implantation in practical case studies.

4.3.3 Mixed concepts

As stated in RQ3, some of the papers in this review integrated both concepts of warehouse allocation and layout design. However, most of the papers were literature reviews, explaining the concepts and presenting what has been done so far. Only one paper included an analytical model for a potential solution with a practical case and only one with a non-standard environment. There seems to be a necessity to conduct more research on both concepts supported by practical case studies. The reasons for such low interest in this matter are still unknown.

4.3.4 Practical cases and non-standard

During the analysis, practical case studies were found in the literature. However, most of the time, practical cases meant that some data from a real warehouse were integrated to a mathematical model to generate results. Those results do not necessarily confirm whether the implementation of such a solution is suitable for real-life practical cases. Moreover, some papers proposed high-level algorithms that probably only a few companies could use, and which would necessitate skilled workforce and/or a significant implementation cost. More research could thus look at practical case implementations involving allocation and layout design methods.

4.3.5 Future research directions and gaps

Based on the papers investigated, future research directions and gaps to fill in the literature could be summarized as follows.

Workforce satisfaction and well-being increase overall productivity in warehouses. New or adapted methods could therefore be proposed to consider this key element in heterogeneous environment and make the comparison with the standard one. This could increase the understanding of productivity related to specific environment [ 34 , 86 ].

Non-conventional environment such as cold storage and heated warehouses affects workers’ behavior inside warehouses. New management/human resources research mixed with allocation planning or layout design in those kinds of environments could increase productivity. To the best of our understanding, no research evaluates those impacts while mixing them with new innovative productivity solution [ 85 ].

Implementing solutions to practical real-life case studies increases the value for industry and enhances the research opportunity in the warehouse operations field. New adapted methods should be proposed to limit the gap between theoretical models and real-life applications that, most of the time, are stated in the literature [ 16 , 30 , 39 ].

Combined concepts solutions give a faster and more flexible way of solving problems for managerial teams. Most of the papers propose one concept without evaluating the overall warehouse activities for practical case scenarios. This could lead to improvement in one concept but cause problems for other ones. Thus, evaluating the impact of one warehouse operational concept on another could give a better understanding on operations correlation in real-life cases. As shown in the results, few papers really evaluate more than one concept and even fewer integrate them to practical situations, which presents an important gap in the literature.

Non-conventional or heterogeneous warehouse types such as cross-docking, heterogeneous, and JIT environment are not uncommon in the industry. However, as shown in the results, few studies are related to those. New methods and approaches could be proposed with those elements in further research.

The Covid-19 pandemic created drastic changes in terms of warehousing health and safety concerns regarding workforce protection in recent years. Research should investigate those impacts on real-life industry with new approaches regarding this topic [ 76 ].

Data-driven operations and automated solutions, enabled by Industry 4.0 technology, are an upcoming reality for warehousing systems [ 21 , 27 , 55 ]. They are expected to play a critical role in increasing warehousing efficiency. Thus, future research could study the impact of this evolution in modern warehousing methods using real case studies to facilitate their implementation. Future research could also include the effect of combining such technologies with sustainable practices on resources consumption and long-term warehouses productivity.

As warehouses may play a role in ensuring more resilient supply chains, some research could be conducted to identify the new warehouse allocation and layout design techniques to adopt so as to build resilience and increase the overall effectiveness in warehouse systems.

5 Conclusion

This paper presented a methodological literature review for warehouse allocation and layout design methods in general and for heterogeneous and non-standard spare parts in particular. The main objectives were to find relevant information regarding methodologies and concepts in that field of study and one of which could be implemented in practical cases.

The main findings were related to the lack of non-heterogeneous and non-standard environments concerning warehouse allocation and layout design methods. We find that very few papers integrated those concepts and even fewer with practical applications. At present, the literature is mainly composed of mathematical models looking at one specific concept such as layout design or allocation. A few papers try to integrate both concepts together and most of the time they do it from a literature review perspective.

The limitations of this paper reside in the specific keywords and sets involved. This could lead to different results if any other keywords were to be added or removed in subsequent research. The time frame can also limit the results. Another specification is the possibility that some research papers are not included in the final version due to initial screening keywords elimination.

We believe that future research might and will focus on emerging technologies and automatization in WOP related to allocation and layout design for productivity enhancement. It might be an interesting opportunity to mix emerging technologies and automation with management policies and workforce. More research on the impact of Covid-19 health issues with WOP is another opportunity for future research. As previously stated, the lack of practical case studies remains a challenge for future research. Also, it would be of great interest to include a bibliometric-based scientific approach for a better understanding of the evolution of this research field with spare parts and heterogeneous components. Finally, we also believe that more complex algorithms and mathematical models will evolve with emerging technologies and hopefully evaluate non-standard environments from a practical implementation perspective.

6 Conflict of interest

All of the authors have no relevant financial or non-financial interests to disclose. Also, none of the authors received support from any organization for the submitted work. Thus, no funding, no employment, no financial or non-financial interests have been received by any authors of this paper. The authors declare that they have no competing interests.

Data availability

All data generated or analyzed in this study are included in this published article [and its supplementary information files].

Code availability

All material and/or code generated or analyzed in this study are included in this published article [and its supplementary information files].

Accorsi R, Baruffaldi G, Manzini R (2017) Design and manage deep lane storage system layout. An iterative decision-support model. Int J Adv Manuf Technol 92:57–67. https://doi.org/10.1007/s00170-016-9962-9

Article Google Scholar

Al-Gwaiz M, Chao X, Romeijn HE (2016) Capacity expansion and cost efficiency improvement in the warehouse problem. Naval Res Log. https://doi.org/10.1002/nav.21703

Article MathSciNet MATH Google Scholar

Ang M, Lim YF (2019) How to optimize storage classes in a unit-load warehouse. Eur J Oper Res 278:186–201. https://doi.org/10.1016/j.ejor.2019.03.046

Azadeh K, De Koster R, Roy D (2019) Robotized and automoated warehouse systems: Review and recent developments. Transp Sci 53(4):917–945. https://doi.org/10.1287/trsc.2018.0873

Bagaskara B, Gozali L, Widodo L (2020) Redesign layout planning of raw material area and production are using systematic layout planning (SLP) methods (case study of CV Oto Boga Jaya). In: IOP Conf. Series: Materials science and engineering, 852. https://doi.org/10.1088/1757-899x/852/1/012122

Baker P, Canessa M (2009) Warehouse design: a structured approach. Eur J Oper Res 193:425–436. https://doi.org/10.1016/j.ejor.2007.11.045

Ballestin F, Perez A, Lino P, Quintanilla S, Valls V (2013) Static and dynamic policies with RFID for the scheduling of retrieval and storage warehouse operations. Comput Ind Eng 66:696–709. https://doi.org/10.1016/j.cie.2013.09.020

Bartholdi JJ, Hackman S, T., (2008) Warehouse and distribution science: release 089. Supply Chain Log Inst. https://doi.org/10.1201/9780849305801.ch1

Bartholdi JJ, Hackman S (2008) Allocating space in a forward pick area of a distribution center for small parts. IIE Trans 40(11):1046–1053. https://doi.org/10.1080/07408170802167662

Battista C, Fumi A, Laura L, Schiraldi MM (2014) Multiproduct slot allocation heuristic to minimize storage space. Int J Retail Distrib Manage 42(3):172–186. https://doi.org/10.1108/ijrdm-03-2012-0024

Behnam B, Hemen P, El-Houssaine A (2019) Class-based storage location assignment: an overview of the literature. In: Proceedings of the 16th international conference on informatics in control, automation and robotics, pp 390–397. https://doi.org/10.5220/0007952403900397

Bortolini M, Faccio M, Ferrari E, Gamberi M, Pilati F (2019) Design of diagonal cross-aisle warehouses with class-based storage assignment strategy. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-018-2833-9

Bortolini M, Faccio M, Gamberi M, Pilati F (2020) Assembly kits with variable part physical attributes: warehouse layout design and assignment procedure. Assem Autom 40(6):857–886. https://doi.org/10.1108/aa-10-2019-0173

Bruns F, Knust S, Shakhlevich NV (2016) Complexity results for storage loading problems with stacking constraints. Eur J Oper Res 249:1074–1081. https://doi.org/10.1016/j.ejor.2015.09.036

Calzavara M, Glock CH, Grosse EH, Persona A, Sgarbossa F (2017) Analysis of economic and ergonomic performance measures of different rack layouts in an order picking warehouse. Comput Ind Eng 111:527–536. https://doi.org/10.1016/j.cie.2016.07.001

Cardona LF, Gue KR (2019) How to determine slot sizes in a unit-load warehouse. IISE Transaction 51:355–367. https://doi.org/10.1080/24725854.2018.1509159

Cardona LF, Soto DF, Rivera L, Martinez HJ (2015) Detailed design of fishbone warehouse layouts with vertical travel. Int J Prod Econ 170:825–837. https://doi.org/10.1016/j.ijpe.2015.03.006

Caron F, Marchet G, Perego A (2000) Optimal layout in low-level picker-to-part systems. Int J Prod Res 38(1):101–117. https://doi.org/10.1080/002075400189608

Article MATH Google Scholar

Chan FTS, Chan HK (2011) Improving the productivity of order picking of a manual-pick and multi-level rack distribution warehouse through the implementation of class-based storage. Expert Syst Appl 38:2686–2700. https://doi.org/10.1016/j.eswa.2010.08.058

Chow KH, Choy KL, Lee WB (2006) On the design of a real-time knowledge-based system, for managing logistics operations, intelligent systems in accounting. Finance Manage 14:3–25. https://doi.org/10.1002/isaf.274

Custodio L, Machado R (2020) Flexible automated warehouse: a literature review ans innovative framework. Int J Adv Manuf Technol 160:533–558. https://doi.org/10.1007/s00170-019-04588-z

Davarzani H, Norrman A (2015) Toward a relevant agenda for warehousing research: literature review and practitioner’s input. Logist Res 8:1. https://doi.org/10.1007/s12159-014-0120-1

De Koster RBM, Johnson AL, Roy D (2017) Warehouse design and management. Int J Prod Res 55(21):6327–6330. https://doi.org/10.1080/00207543.2017.1371856

De Koster R, Le-Duc T, Roodbergen KJ (2007) Design and control of warehouse order picking: A literature review. Eur J Oper Res 182(2):481–501. https://doi.org/10.1016/j.ejor.2006.07.009

De Koster MBM, Smidts A (2012) Organizing warehouse management. Int J Oper Prod Manage 33(9):1230–1256. https://doi.org/10.1108/ijopm-12-2011-0471

Dianto C, Widiandoko F, Rahmanasari D, Yuniaristanto, Sutopo W (2020) Redesign production layout using dedicated storage method: case study of PT.Solo Grafika Utama, In: IOP conf. series: materials science and engineering, vol 943. https://doi.org/10.1088/1757-899x/943/1/012042

Duc ND, Huu TT, Nananukul N (2020) A dynamic route-planning system based on industry 4.0 technology. Algorithms 13:308. https://doi.org/10.3390/a13120308

Article MathSciNet Google Scholar

Elbert RM, Franzke T, Glock CH, Grosse EH (2017) The effects of human behavior on the efficiency of routing policies in order picking: the case of route deviations. Comput Ind Eng 111:537–551. https://doi.org/10.1016/j.cie.2016.11.033

Ene S, Öztürk N (2012) Storage location assignment and order picking optimization in the automotive industry. Int J Adv Manuf Technol 60:787–797. https://doi.org/10.1007/s00170-011-3593-y

Esmero A, Branzuela QR, Paypa J, Rojo SM (2021) Heuristic comparative assessment of non-conventional warehouse designs. Eng Manage Prod Serv 13:89–103. https://doi.org/10.2478/emj-2021-0007

Frazelle E (2016) World-class warehousing and material handling. McGraw Hill education, New York. https://doi.org/10.1002/9780470172506

Ganbold O, Kundu K, Li H, Zhang W (2020) A simulation-based optimization method for warehouse worker assignment. Algorithms 13:326. https://doi.org/10.3390/a13120326

Gozali L, Marie IA, Natalia, Kustandi GM, Adisurya E (2020) Suggestion of raw material warehouse layout improvement using class-based storage methode (case study of PT. XYZ). In: IOP conf. series: materials science and engineering, 1007. https://doi.org/10.1088/1757-899x/1007/1/012024

Grosse EH, Glock CH, Jaber MY, Neumann P (2015) Incorporating human factors in order picking planning models: framework and research opportunities. Int J Prod Res 53(3):695–717. https://doi.org/10.1080/00207543.2014.919424

Gu J, Goetschalckx M, McGinnins LF (2007) Research on warehouse operation: a comprehensive review. Eur J Oper Res 177:1–21. https://doi.org/10.1016/j.ejor.2006.02.025

Gu J, Goetschalckx M, McGinnins LF (2010) Research on warehouse design and performance evaluation: a comprenhensive review. Eur J Oper Res 203:539–549. https://doi.org/10.1016/j.ejor.2009.07.031

Guerriero F, Musmanno R, Pisacana O, Rende F (2013) A mathematical model for the multi-levels product allocation problem in a warehouse with compatibility constraints. Appl Math Model 37:4385–4398. https://doi.org/10.1016/j.apm.2012.09.015

Guo X, Yu Y, De Koster RBM (2016) Impact of required storage space on storage policy performance in a unit-load warehouse. Int J Prod Res 54(8):2405–2418. https://doi.org/10.1080/00207543.2015.1083624

He R, Li H, Zhang B, Chen M (2020) The multi-level warehouse layout problem with uncertain information: uncertainty theory method. Int J Gen Syst 49(5):497–520. https://doi.org/10.1080/03081079.2020.1778681

Ho Y-C, Liu C-F (2005) A design methodology for converting a regular warehouse into a zone-picking warehouse. J Chin Inst Indus Eng 22(4):332–345. https://doi.org/10.1080/10170660509509303

Hou J-L, Wu Y-J, Yang Y-J (2010) A model for storage arrangement and reallocation for storage management operations. Int J Comput Integr Manuf 23(4):369–390. https://doi.org/10.1080/09511921003642154

Horta M, Coelho F, Relvas S (2016) Layout design modelling for a real world just-in time warehouse. Comput Ind Eng 101:1–9. https://doi.org/10.1016/j.cie.2016.08.013

Irman A, Muharni Y, Yusuf A (2020) Design of warehouse model with dedicated policy to minimize total travel costs: a case study in a construction workshop. In: IOP conf. series: materials science and engineering. https://doi.org/10.1088/1757-899x/909/1/012088

Isler CA, Righetto GM, Morabito R (2016) Optimizing the order picking of a scholar and office supplies warehouse. Int J Adv Manuf Technol 87:2327–2336. https://doi.org/10.1007/s00170-016-8625-1

Jiao Y-L, Xing X-C, Zhang P, Xu L-C, Liu X-R (2018) Multi-objective storage location allocation optimization and simulation analysis of automated warehouse based on multi-population genetic algorithm. Concurr Eng Res Appl 26:367–377. https://doi.org/10.1177/1063293x18796365

Kembro JH, Norrman A, Eriksson E (2018) Adapting warehouse operations and design to omni-channel logistics a literature review and research agenda. Int J Phys Distrib Logist Manag 48(9):890–912. https://doi.org/10.1108/ijpdlm-01-2017-0052

Kim J, Mendez F, Jimenez J (2020) Storage location assignment heuristic based on slot selection and frequent itemset grouping for large distribution centers. IEEE Access. https://doi.org/10.1109/access.2020.3031585

Kofler M, Beham A, Wagner S, Affenzeller M, Reitinger C (2010) Reassigning storage locations in a warehouse to optimize the order picking process. In: 22 nd European modeling and simulation symposium, Morocco. https://doi.org/10.1109/lindi.2011.6031124

Kofler M, Beham A, Wagner S, Affenzeller M (2014) Affinity based slotting in warehouses with dynamic order patterns. Intell Eng Inf 6:123–143. https://doi.org/10.1007/978-3-319-01436-4_7

Kumar S, Mahapatra RP (2021) Design of multi-warehouse inventory model for an optimal replenishment policy using a rain optimization algorithm. Knowl-Based Syst. https://doi.org/10.1016/j.knosys.2021.107406

Kumar S, Narkhede BE, Jain K (2021) Revisiting the warehouse research through an evolutionary lens: a review from 1990 to 2019. Int J Prod Res 59(11):3470–3492. https://doi.org/10.1080/00207543.2020.1867923

Kusrini E, Asmarawati CI, Sari GM, Nurjanah A, Kisanjani A, Wibowo SA, Prakoso I (2018) Warehousing performance improvement using Frazelle model and per group benchmarking: a case study in retail warehouse in Yogyakarata and central Java, MATEX web of Conferences, . https://doi.org/10.1051/matecconf/201815401091

Larco JA, De Koster R, Roodbergen KJ, Dul J (2017) Managing warehouse efficiency and worker discomfort through enhanced storage assignment decisions. Int J Prod Res 55(21):6407–6422. https://doi.org/10.1080/00207543.2016.1165880

Lee M-K, Elsayed EA (2005) Optimization of warehouse storage capacity under a dedicated storage policy. Int J Prod Res 43(9):1785–1805. https://doi.org/10.1080/13528160412331326496

Lee CKM, Yaqiong L, Ho W, Choy KL (2018) Design and application of internet of things-based warehouse management system for smart logistics. Int J Prod Res 56(8):2753–2768. https://doi.org/10.1080/00207543.2017.1394592

Lenoble N, Frein Y, Hammami R (2018) Order batching in an automated warehouse with several vertical lift modules: optimization and experiments with real data. Eur J Oper Res 267:958–976. https://doi.org/10.1080/09537287.2020.1751326

Lersteau C, Nguyen TT, Le TT, Nguyen HN, Shen W (2021) Solving the problem of stacking goods: mathematical model, heuristics and a case study in container stacking in ports. IEEE Access. https://doi.org/10.1109/access.2021.3052945

Li J, Moghaddam M, Nof SY (2016) Dynamic storage assignment with product affinity and ABC classification- a case study. Int J Adv Manuge Technol 84(21):2179–2194. https://doi.org/10.1007/s00170-015-7806-7

Manoharan S, Stilling D, Kabir G, Sarker S (2022) Implementation of linear programming and decision-making model for the improvement of warehouse utilization. Appl Syst Innov 5:33. https://doi.org/10.3390/asi5020033

Manzini R, Gebennini E (2008) Optimization models for the dynamic facility location and allocation problem. Int J Prod Res 46(8):2061–2086. https://doi.org/10.1080/00207540600847418

Manzini R, Accorsi R, Gamberi M, Penazzi S (2015) Modeling class-based storage assignment over life cycle picking patterns. Int J Prod Econ 170:790–800. https://doi.org/10.1016/j.ijpe.2015.06.026

Mehmood E, Anees T (2020) Challenges and solutions for processing real-time big data stream: a systematic literature review. IEEE Access 8:119123–119143. https://doi.org/10.1109/access.2020.3005268

Melinda T, Nazaruddin, Ginting R (2020) Design of warehousing system in order picking process: literature review. In: IOP Conf. Series: materials science and engineering. https://doi.org/10.1088/1757-899x/801/1/012126

Mirabelli G, Pizzuti T, Macchione C, Lagana D (2013) Warehouse layout optimization: a case study based on the adaptation of the multi-layer allocation problem. XX Summer School “Francesco Turco” – Indust Syst Eng . https://doi.org/10.1109/idaacs.2013.6662663

Neamah AF (2021) Adoption of data warehouse in university management: Wasit University case study. J Conf, Ser Phys. https://doi.org/10.1088/1742-6596/1860/1/012027

Önut S, Tuzkaya U, Dogac B (2008) A particle swarm optimization algorithm for the multiple-level warehouse layout design problem. Comput Ind Eng 54:783–799. https://doi.org/10.1016/j.cie.2007.10.012

Parameswari Z, Pujawan IN (2019) Changes in layout and handling method for raw materials to reduce put away and picking time: a plastic packaging manufacturer case study. In: IOP conf. series: materials science and engineering, vol. 598. https://doi.org/10.1088/1757-899x/598/1/012125

Petersen CG, Siu C, Heiser DR (2005) Improving order picking performance utilizing slotting and golden zone storage. Int J Oper Prod Manage 25(10):997–1012. https://doi.org/10.1108/01443570510619491

Phumchusri N, Kitpipit P (2017) Warehouse layout design for an automotive raw material supplier. Eng J. https://doi.org/10.4186/ej.2017.21.7.361

Quintanilla S, Perez A, Ballestin F, Lino P (2015) Heuristic algorithms for a storage location assignment problem in a chaotic warehouse. Eng Optim 47(10):1405–1422. https://doi.org/10.1080/0305215x.2014.969727

Rogers WP, Kahraman MM, Dessureault S (2019) Exploring the value of using data: a case study of continuous improvement through data warehousing. Int J Min Reclam Environ 33(4):286–296. https://doi.org/10.1080/17480930.2017.1405473

Ronzoni C, Ferrara A, Grassi A (2015) A stochastic methodology for the optimal management of infrequent demand spare parts in the automotive industry. IFAC-PapersOnline 48–3:1405–1410. https://doi.org/10.1016/j.ifacol.2015.06.283

Roodbergen KJ, Vis I, Taylor GD Jr (2015) Simultaneous determination of warehouse layout and control policies. Int J Prod Res 53(11):3306–3326. https://doi.org/10.1080/00207543.2014.978029

Roodbergen KJ, Sharp GP, Vis I (2008) Designing the layout structure of manual order picking areas in warehouses. IIE Trans 40(11):1032–1045. https://doi.org/10.1080/07408170802167639

Samuel MP, Srivastava S (2013) Maintenance inventory allocation in presence of heterogeneous part characteristics. Int J Perform Eng 9(5):505–514. https://doi.org/10.1109/qr2mse.2013.6625815

Sencer A, Karaismailoglu A (2022) A simulation and analytic hierarchy process-based decision support system for air cargo warehouse capacity design. Simul Trans Soc Model Simul Int 98:235–255. https://doi.org/10.1177/00375497211029915

Shi Y, Guo X, Yu Y (2018) Dynamic warehouse size planning with demand forecast and contract flexibility. Int J Prod Res 56(3):1313–1325. https://doi.org/10.1080/00207543.2017.1336680

Sicilia J, San-josé LA, Alcaide D, Abdul-Jalbar B (2022) Optimal policy for multi-item systems with stochastic demands, backlogged shortages and limited storage capacity. Appl Math Model 108:236–257. https://doi.org/10.1016/j.apm.2022.03.025

Silva A, Roodbergen KJ, Coelho LC, Darvish M (2022) Estimating optimal ABC zone sizes in manual warehouses. Int J Prod Econ. https://doi.org/10.1016/j.ijpe.2022.108579

Strack G, Pochet Y (2010) An integrated model for warehouse and inventory planning. Eur J Oper Res 204:35–50. https://doi.org/10.1016/j.ejor.2009.09.006

Sudiarta N, Gozali L, Marie IA, Sukania IW (2020) Comparison study about warehouse layout from some paper case studies. In: IOP conf. series: materials science and engineering, vol. 852. https://doi.org/10.1088/1757-899x/852/1/012112

Suloriva I, Zavodska L (2017) State-of-the-art approaches to material transportation, handling and warehousing. Procedia Eng 192:857–862. https://doi.org/10.1016/j.proeng.2017.06.148

Thomas LM, Melle RD (2015) Developing design guidelines for a case-picking warehouse. Int J Prod Econ 170:741–762. https://doi.org/10.1016/j.ijpe.2015.02.011

Tippayawong KY, Sopadang A, Patitad P (2013) Improving warehouse layout design of a chicken slaughterhouse using combined ABC class based and optimized allocation techniques. In: Proceedings of the world congress on engineering, vol 1. https://doi.org/10.46254/an12.20220374

Trab S, Bajic E, Zouinkhi A, Abdelkrim MN, Chekir H, Ltaief RH (2015) Product allocation planning with safety compatibility constraints in IoT-based warehouse. Procedia Comput Sci 73:290–297. https://doi.org/10.1016/j.procs.2015.12.033

Trindade MAM, Sousa PSA, Moreira MRA (2021) Product allocation planning with handling constraints: a case study analysis. Int J Manag Sci Eng Manage 16(3):175–183. https://doi.org/10.1080/17509653.2021.1907812

Van Dinter R, Tekinerdogana B, Catal C (2021) Automation of systematic literature reviews: a systematic literature review. Inf Softw Technol. https://doi.org/10.1016/j.infsof.2021.106589

Van Gils T, Caris A, Ramaekers K, Braekers K, de Koster RBM (2019) Designing efficient order picking systems: the effect of real-life features on the relationship among planning problems. Transp Res Part E 125:47–73. https://doi.org/10.1016/j.tre.2019.02.010

Van Gils T, Ramaekers K, Braekers K, Depaire B, Caris A (2018) Increasing order picking efficiency by integrating storage, batching, zone picking, and routing policy decisions. Int J Prod Econ 197:243–261. https://doi.org/10.1016/j.ijpe.2017.11.021

Van Gils T, Ramaekers K, Caris A, De Koster RBM (2018) Designing efficient order picking systemns by combining planning problems: state-of-the-art classification and review. Eur J Oper Res 267:1–15. https://doi.org/10.1016/j.ejor.2017.09.002

Venkitasubramony R, Adil GK (2015) Layout optimization of a three-dimensional order picking warehouse. IFAC-PapersOnLine 48–3:1155–1160. https://doi.org/10.1016/j.ifacol.2015.06.240

Venkitasubramony R, Adil GK (2017) Design of an order-picking warehouse factoring vertical travel and space sharing. Int J Adv Manuf Technol 91:1921–1934. https://doi.org/10.1007/s00170-016-9879-3

Venkitasubramony R, Adil GK (2019) Designing a block stacked warehouse for dynamic and stochastic product flow: a scenario-based robust approach. Int J Prod Res 57(5):1345–1365. https://doi.org/10.1080/00207543.2018.1472402

Venkitasubramony R, Adil GK (2021) Modeling the effect of imperfect staggering in product inflow using queuing theory: revisiting block stacking layout. Flex Serv Manuf J 33:689–716. https://doi.org/10.1007/s10696-020-09390-8

Vieira A, Dias LS, Pereira G, Oliveira JA, Carvalho MS, Martins P (2015) Using Simio to automatically create 3D warehouse and compare different storage strategies. FME Trans 43:335–343. https://doi.org/10.5937/fmet1504335v

Vrysagotis V, Kontis PA (2011) warehouse layout problems: types of problems and solution algorithms. J Comput Model 1(1):131–152

Google Scholar

Wan Y, Liu Y (2022) Integrating optimized fishbone warehouse layout, storage location assignment and picker routing. Int J Comput Sci 49:3. https://doi.org/10.1061/9780784413753.154

Wang M, Zhang R-Q (2019) A dynamic programming approach for storage location assignment planning problem. Procedia CIRP 83:513–516. https://doi.org/10.1016/j.procir.2019.04.113

Wei N-C, Chang C-F, Lin S-K (2016) An innovative way for warehouse storage allocation. Int J Org Innov. https://doi.org/10.1109/wsc.2016.7822265

Wu W, de Koster RBM, Yu Y (2020) Forward-reserve storage strategies with order picking: When do they pay off? IISE Trans 52(9):961–976. https://doi.org/10.2139/ssrn.3243879

Xu Z, Ming XG, Zhou J, Song W, He L, Li M (2013) Management optimization based on dynamic SKU for RFID-enabled warehouse management in the steel supply chain. Int J Prod Res 51(10):2981–2996. https://doi.org/10.1080/00207543.2012.751513

Xu X, Zhao X, Zou B, Li M (2019) Optimal dimensions for multi-deep storage systems under class-based storage policies. Cluster Comput. https://doi.org/10.1007/s10586-018-2873-9

Yang L, Feng Y (2006) Fuzzy multi-level warehouse lyout problem: new model and algorithm. J Syst Sci Syst Eng 15(4):493–503. https://doi.org/10.1007/s11518-006-5017-3

Yang C-L, Nguyen TPQ (2015) Constrained clustering method for class-based storage location assignment in warehouse. Ìnd Manage Data Syst 166(4):667–689. https://doi.org/10.1108/imds-09-2015-0361

Yang M-F, Shih P-H, Pan JC-H, Li M-C (2022) The optimal layout design for minimizing operating costs in a picker-to-part warehousing system. Int J Adv Manuf Technol 118:2523–2537. https://doi.org/10.1007/s00170-021-08026-x

Yang D, Wu Y, Ma W (2021) Optimization of storage location assignment in automated warehouse. Microprocess Microsyst. https://doi.org/10.1016/j.micpro.2020.103356

Yener F, Yazgan HR (2019) Optimal warehouse design: literature review and case study application. Comput Ind Eng 129:1–13. https://doi.org/10.1016/j.cie.2019.01.006

Yu Y, de Koster RBM, Guo X (2015) Class-based storage with a finite number of items: using more classes is not always better. Prod Oper Manag 24(8):1235–1247. https://doi.org/10.1111/poms.12334

Yuan R, Cezik T, Graves SC (2018) Stowage decisions in multi-zone storage systems. Int J Prod Res 56:333–343. https://doi.org/10.2139/ssrn.2990432

Zaerpour N, Volbeda R, Gharehgozli A (2019) Automated or manual storage systems: Do throughout and storage capacity matter? INFOR: Inf Syst Oper Res 57(1):99–120. https://doi.org/10.1080/03155986.2018.1532765

Zhang G, Xiaoting S, Fawzat A, Yiqin Y, Tatsushi N (2021) Integrated production planning and warehouse storage assignment problem: An IoT assisted case. Int J Prod Econ. https://doi.org/10.1016/j.ijpe.2021.108058

Zhao Z, Zhang M, Yang C, Fang J, Huang GQ (2018) Distributed and collaborative proactive tandem location tracking of vehicle products for warehouse operations. Comput Ind Eng 125:637–648. https://doi.org/10.1016/j.cie.2018.05.005

Zhou S, Gong Y, De Koster R (2016) Designing self-storage warehouse with customer choice. Int J Prod Res 54(10):3080–3104. https://doi.org/10.1080/00207543.2016.1158880

Download references

All of the authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and affiliations.

Département de Génie Mécanique, Faculté des Sciences et de Génie, Université Laval, Pavillon Adrien-Pouliot 1065, Av. de la Médecine, Local 1504, Québec, Canada

Pierre-William Albert, Mikael Rönnqvist & Nadia Lehoux

You can also search for this author in PubMed Google Scholar

Contributions

PWA contributed to the study conception and design. Material preparation, data collection and analysis were performed by PWA. The first draft of the manuscript was written by PWA. NL and MR commented on previous versions of the manuscript. All authors read and approved the final manuscript (PWA, NL and MR).

Corresponding author

Correspondence to Pierre-William Albert .

Ethics declarations

Conflicts of interest.

No authors have potential conflicts of interest in regard to this paper.

Consent for publication

Not applicable.

Informed consent

Human participants and/or animals, additional information, publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The following tables (Table 3 , 4 , 5 and 6 ) describe the main findings and method in relation to the previous questions. One can find the evaluated articles with their most important information.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Albert, PW., Rönnqvist, M. & Lehoux, N. Trends and new practical applications for warehouse allocation and layout design: a literature review. SN Appl. Sci. 5 , 378 (2023). https://doi.org/10.1007/s42452-023-05608-0

Download citation

Received : 18 June 2023

Accepted : 15 November 2023

Published : 30 November 2023

DOI : https://doi.org/10.1007/s42452-023-05608-0

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Warehouse allocation methods

- Warehouse layout design methods

- Literature review

- Non-standard shelf layout

- Non-standard spare parts

Advertisement

- Find a journal

- Publish with us

- Track your research

warehouse operations Recently Published Documents

Total documents.

- Latest Documents

- Most Cited Documents

- Contributed Authors

- Related Sources

- Related Keywords

A literature review of smart warehouse operations management

AbstractE-commerce, new retail, and other changes have highlighted the requirement of high efficiency and accuracy in the logistics service. As an important section in logistics and supply chain management, warehouses need to respond positively to the increasing requirement. The “smart warehouse” system, which is equipped with emerging warehousing technologies, is increasingly attracting the attention of industry and technology giants as an efficient solution for the future of warehouse development. This study provides a holistic view of operations management problems within the context of smart warehouses. We provide a framework to review smart warehouse operations management based on the characteristics of smart warehouses, including the perspectives of information interconnection, equipment automation, process integration, and environmental sustainability. A comprehensive review of relevant literature is then carried out based on the framework with four perspectives. This study could provide future research directions on smart warehouses for academia and industry practitioners.

Towards an increased understanding of learning: a case study of a collaborative relationship between a retailer and a logistics service provider