- Start Business

- Grow Business

How to Start a Profitable Rice Mill Business

- by Next What Business Research Team

- Agro Based , Business Plans , Food

- August 30, 2024

Starting a rice mill business can be a rewarding and profitable venture. Paddy in its raw form cannot be consumed by human beings. Therefore, it needs to be suitably processed for obtaining rice. It is a staple food product for a large population. Basically, rice milling is the process that helps in the removal of hulls and brans from paddy grains to produce polished rice. If you live in a highly paddy-producing area, you can establish a rice mill business of your own.

However, to be successful in the rice milling business, you need to do careful planning, have knowledge of the industry, and must adhere to various regulations. Below are some of the most important steps you need to follow to start a profitable rice mill company:

Table of Contents

13 Steps to Start a Rice Mill Business

1. market research.

Before setting up a rice mill plant, it is advisable to understand the local demand for rice and the competition in your area. You need to conduct detailed market research and identify your target markets, such as wholesalers, retailers, or direct consumers.

2. Create a Business Plan

Create a detailed business plan outlining your goals, target market, pricing strategy, sourcing of raw materials, production process, and marketing efforts. Some of the chapters that must be included in your rice mill business plan document:

Executive Summary:

- Overview of your rice mill business.

- Mission, vision, and goals.

- Brief description of products and services.

- Summary of financial projections.

Company Description:

- A detailed explanation of your rice mill business.

- Legal structure (proprietorship, partnership, LLP, etc.).

- Location of the business.

- Background of founders and key team members.

Market Analysis:

- Overview of the rice industry in India.

- Analysis of the local and regional rice market.

- Identification of target customer segments.

- Competitive analysis of other rice mills.

Products and Services:

- Types of rice you will produce (Basmati, non-Basmati, parboiled, etc.).

- Processing methods and techniques.

- Packaging options and branding.

Marketing and Sales Strategy:

- How you will promote your rice mill business.

- Pricing strategy based on market research.

- Distribution channels (wholesalers, retailers, online platforms).

- Sales forecast and projections.

Operational Plan:

- Description of the rice milling process.

- Equipment and machinery required.

- Supply chain management (procurement of paddy, processing, packaging).

- Inventory management.

Management and Organization:

- Organizational structure and key roles.

- Profiles of founders and management team.

- Responsibilities of each team member.

Financial Plan:

- Start-up costs and funding requirements.

- Breakdown of expenses (equipment, labor, utilities, etc.).

- Projected revenue and sales forecasts.

- Profit and loss statement, cash flow statement, balance sheet.

Funding and Investment:

- How you plan to secure funding for your rice mill business.

- Details of loans, investments, or personal contributions.

Implementation Timeline:

- A step-by-step plan to launch and operate the rice mill.

- Estimated timeline for each phase, from setting up the infrastructure to full-scale production.

Risks and Mitigation Strategies:

- Identification of potential challenges and risks.

- Strategies to address and mitigate those risks.

Regulatory and Legal Considerations:

- Licenses and permits required to operate a rice mill.

- Compliance with food safety and quality standards.

- Supporting documents such as market research data, industry reports, financial projections, legal documents, etc.

3. Register your Rice Mill Business

Register your rice mill as a legal entity. It can be a sole proprietorship, partnership, or private limited company. You need to choose the business structure as per the size and scale of operation.

Read: How to Register a Company/ Startup in India

4. Obtain Licenses and Permits

In starting the business, you will need to obtain several different licenses from Government authorities.

- Udyog Aadhaar MSME Registration

- Obtain a Factory License.

- Apply for ‘consent to establish and ‘consent to operate’ from Pollution Control Board

- Apply for a license according to the Rice-Milling Industry (Regulation) Act, 1958.

- Obtain GST registration

- You must comply with PFA and ESIC registration for the employees.

- For export, IEC registration is mandatory.

5. Naming Your Rice Mill Business

Choose a name that reflects the essence of your rice mill business. Consider including words related to rice, quality, tradition, or your geographical location. Select a name that is easy to remember and catchy, making it stand out in the minds of your customers.

Read: How to Name a Business

6. Choose a Suitable Location

Select a location with easy access to paddy supply and markets. Ensure it meets zoning requirements and has adequate space for processing and storage.

7. Rice Mill Plant Unit Establishment

First of all, you must figure out the requirement of the area. Generally, it broadly depends on two aspects. Whether the unit will be using a parboiling unit for pre-treatment of paddy before the commencement of milling operation or it will be directly milling raw paddy. Generally, 1.00 to 1.50 acres of land are required for establishing an improved rice milling unit having an installed processing capacity of 2 MT/ hr.

The total power requirement will be to the tune of 75 KW. However, the essential power requirement of the unit is about 90 HP, and accordingly, a suitable standby generator provision is made. Additionally, you have to arrange water for parboiling and domestic consumption purpose. Therefore, you must ensure suitable arrangements for a continuous water supply of desired quality and quantity.

You must build several constructions for different unit activities. Such as raw paddy godown, cleaning unit, drier, and necessary supporting structures such as boiler/blower system, etc., milling section, finished product stores, machine rooms, etc. Additionally, you must maintain Quality Control and Standards as per AGMARK specifications.

8. Buy Machinery

Acquire and install the necessary equipment, including cleaning machines, milling machines, polishers, graders, and packaging machinery.

Some of the basic machinery required for rice mill plant setup is as follows:

- Raw paddy cleaner cum aspirator consisting of large aspiration of desired suction width. It must be fitted with double fans with necessary damper controls.

- One rubber roll paddy sheller

- Paddy Separator to separate unshelled paddy from deshelled paddy.

- Blowers, husk, and barn aspirators for aspiration of light particles. It also separates husks from dehusked kernels and bran from milled rice.

- Cone-type paddy polishers

- Rice grader/ aspirator for purification and grading of polished rice grains

- Bucket elevators for bulk transport and conveyance

- Procurement of Raw Materials

9. Production Process

The rice milling unit operation includes several steps. Those are:

- Pre-Cleaning: Removing all impurities and unfilled grains from paddy

- De-stoning: Separating small stones from paddy

- Parboiling: It helps to improve the nutritional quality by gelatinization of starch inside the rice grain. It improves the milling recovery percent during deshelling and polishing/whitening operation

- Husking: Removing the husk from the paddy

- Husk Aspiration: Separating the husk from brown rice/ unhusked paddy

- Paddy Separation: Separating the unhusked paddy from brown rice

- Whitening: Removing all or part of the bran layer and germ of brown rice

- Polishing: Improving the appearance of milled rice by removing the remaining bran particles and polishing the exterior of the milled kernel

- Length Grading: Separating small and large broken from head rice

- Blending: Mixing head rice with a predetermined amount of broken, as required by the customer

- Packaging: Package the rice in different quantities, such as bags or sacks, and label them appropriately.

10. Quality Control

Establish relationships with paddy farmers, traders, or cooperatives to ensure a consistent supply of good-quality paddy. Implement strict quality control measures to ensure only high-quality paddy is processed.

11. Evaluate the Costs

Calculate the costs involved in production, including raw materials, labor, machinery maintenance, packaging, and marketing. Set competitive yet profitable prices for your rice products. Create a budget and financial projections for the first few years of operation.

12. Arranging Funds

There are several ways of funding your rice mill business. Some of them are listed below:

- Personal Savings: Utilize your personal savings to cover initial expenses such as equipment purchases and setting up the infrastructure.

- Bank Loans: Approach banks or financial institutions for business loans . Prepare a comprehensive business plan to present your venture’s viability and repayment plan.

- Government Schemes: Explore government schemes and subsidies available for agribusiness and food processing industries.

- Investors: Pitch your business idea to potential investors who are interested in the food and agriculture sector.

Also, do apply for a credit card to meet small-time business expenses.

13. Marketing and Distribution

Create an attractive brand and package design that appeals to your target customers. Establish distribution channels to reach wholesalers, retailers, and consumers. Consider online platforms for wider reach.

Frequently Asked Questions

Is a rice mill business profitable.

Yes, a rice mill business can be profitable due to the high demand for rice in India. Furthermore, since India is a major exporter of rice in the world, there is a big export opportunity.

What is the cost to start a rice mill?

The initial investment can vary depending on the scale of your operation, location, and equipment. However, to start a mini rice mill business, you will need an approximate investment of Rs. 50 Lacs.

What is the 1-ton Rice Mill project cost?

On average, the cost of a 1-ton rice mill cost will be around Rs. 70 Lacs to Rs. 1 Cr. in India

Do I need any prior experience to start a rice mill?

While prior experience can be beneficial, it’s not mandatory. You can learn the technical aspects through training and hiring experienced personnel.

Are there any subsidies available for rice mill businesses?

Yes, the government offers subsidies and incentives for rice mill businesses under various schemes.

How do I find reliable suppliers for paddy?

Establish connections with local farmers, rice traders, and agricultural cooperatives to ensure a steady supply of paddy.

What is the shelf life of rice, and how should it be stored?

Properly processed and stored rice can have a shelf life of several months to a year. Store rice in a cool, dry place to prevent moisture and insect infestation.

Can I start a rice mill business on a small scale?

Yes, you can start small and gradually expand your operations as you gain experience and build a customer base.

Discover more from NextWhatBusiness

Subscribe to get the latest posts sent to your email.

Type your email…

Step-by-Step Guide to Crafting a Business Plan for Rice Milling

Get Full Bundle

| $169$99 | $59$39 | $39$29 | $15$9 | $25$15 | $15$9 | $15$9 | $15$9 | $19 |

Total Bundle:

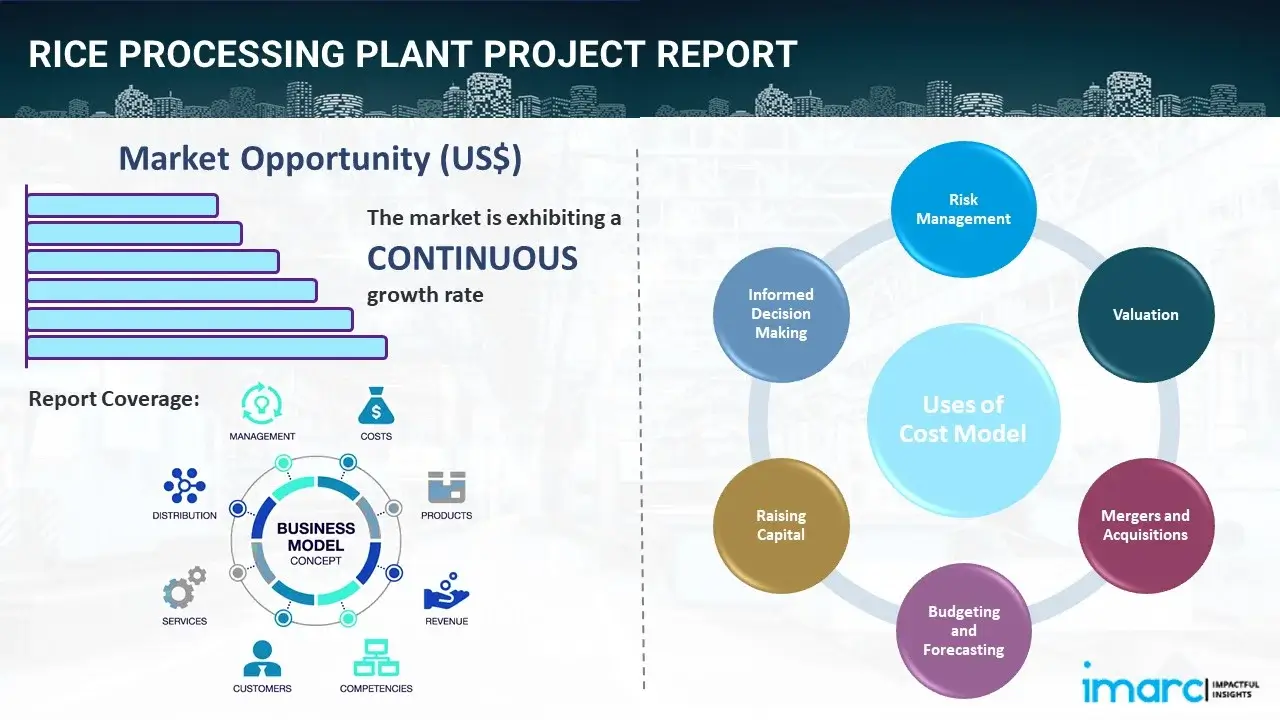

Embarking on a new business venture can be an exhilarating yet daunting journey. Before you dive into crafting a comprehensive business plan, it's crucial to lay the groundwork. In this concise guide, we'll explore the 9 essential steps you must take to ensure your Rice Milling business is poised for success. From market research to securing financing, this checklist will equip you with the insights and strategies needed to transform your entrepreneurial vision into reality.

Steps Prior To Business Plan Writing

| Step | Key Considerations |

|---|---|

| Conduct market research and competitive analysis | Examine the current market trends, demand patterns, and the competitive landscape. Identify the target market's preferences, price points, and potential growth opportunities. Analyze the strengths and weaknesses of existing rice milling operations in the region. |

| Identify target customers and their needs | Clearly define the target customer segments, their specific requirements, and the unique value proposition your rice milling business can offer. Consider factors such as geographic location, purchasing power, and preferred product attributes. |

| Determine product specifications and quality standards | Establish the desired rice varieties, grades, and processing methods to meet customer expectations. Ensure compliance with relevant industry regulations and certifications, such as food safety and environmental standards. |

| Evaluate production costs and profit margins | Conduct a thorough analysis of the anticipated production costs, including raw materials, labor, utilities, and overhead expenses. Determine the optimal pricing strategy and expected profit margins to ensure the business's financial viability. |

| Secure reliable sources for raw materials | Identify and establish partnerships with reputable suppliers of high-quality rice paddy. Assess factors such as supply reliability, pricing, and transportation logistics to ensure a consistent and cost-effective raw material supply. |

| Assess equipment and facility requirements | Evaluate the necessary milling equipment, storage facilities, and infrastructure to support the desired production capacity and quality standards. Determine the optimal location for the rice milling operation, considering factors such as access to transportation, utilities, and labor force. |

| Develop a distribution and sales strategy | Outline the distribution channels, logistics, and sales processes to effectively reach and serve your target customers. Consider factors such as wholesale, retail, and e-commerce opportunities, as well as potential partnerships with distributors or retailers. |

| Explore financing options and funding sources | Evaluate the financial resources required to launch and sustain the rice milling business, including start-up capital, working capital, and potential expansion plans. Investigate various financing options, such as loans, grants, or investor funding, and assess their feasibility and terms. |

| Assemble a skilled team of professionals | Identify the key roles and responsibilities required to operate the rice milling business effectively, such as management, production, quality control, and sales. Recruit a talented and experienced team with the necessary expertise to execute the business plan successfully. |

Conduct Market Research and Competitive Analysis

Launching a successful rice milling business requires a deep understanding of the market landscape and your potential competitors. Before developing your business plan, it's crucial to conduct thorough market research and a comprehensive competitive analysis. This critical first step will provide you with the insights needed to make informed decisions and position your rice milling operation for long-term success.

Begin by exploring the overall rice market, including current trends, consumer preferences, and industry dynamics. Analyze data on rice consumption patterns, pricing, and distribution channels to gain a clear picture of the market's size, growth potential, and key drivers. According to the USDA, the United States produced over 11 million metric tons of rice in 2022, with a per capita consumption of around 26 pounds per year.

Next, identify your target customer segments and their specific needs. Understand their preferences for rice varieties, quality attributes, and packaging preferences. This will help you develop a product offering that aligns with their demands and sets your rice milling business apart from the competition.

- Conduct consumer surveys and focus groups to gather in-depth insights into your target market's buying behavior and pain points.

- Analyze industry reports and trade publications to stay informed about emerging trends and consumer preferences in the rice market.

Equally important is the analysis of your competitors. Identify the key players in the rice milling industry, both locally and regionally. Evaluate their product offerings, pricing strategies, distribution channels, and marketing approaches. Research shows that the top 5 rice milling companies in the US account for over 60% of the market share . Understanding your competitors' strengths and weaknesses will enable you to develop a unique value proposition and gain a competitive edge.

By conducting thorough market research and competitive analysis, you'll be well-equipped to make informed decisions about your rice milling business plan, from product development and pricing to marketing and distribution strategies. This foundational work will be crucial in ensuring the long-term viability and success of your rice milling enterprise.

| Rice Milling Business Plan Get Template |

Identify Target Customers and Their Needs

Identifying your target customers and understanding their specific needs is a critical step in developing a successful business plan for your rice milling operation. By conducting thorough market research, you can gain valuable insights into the preferences, pain points, and purchasing habits of your potential customers, allowing you to tailor your products and services to meet their demands.

In the case of the 'Golden Grain Millers' rice milling business, it's essential to understand the diverse customer base that the company aims to serve. According to the business idea description, the focus is on catering to a market looking for 'better, healthier rice options' with an emphasis on 'local sourcing, freshness, and specific dietary and cultural needs.'

To effectively identify the target customers and their needs, consider the following steps:

- Demographic Analysis: Examine the demographic characteristics of your potential customers, such as age, income level, geographic location, and household size. This information can help you understand the purchasing power and preferences of your target market.

- Dietary and Lifestyle Preferences: Investigate the dietary and lifestyle preferences of your target customers, including their interest in organic, gluten-free, or low-carb options, as well as their cultural or religious dietary requirements.

- Convenience and Packaging Needs: Assess the convenience and packaging needs of your customers, such as their preference for pre-portioned or resealable packaging, or their need for easy-to-prepare rice products.

- Price Sensitivity: Evaluate the price sensitivity of your target customers and their willingness to pay a premium for high-quality, locally-sourced rice products.

- Distribution Channels: Identify the preferred distribution channels and purchasing habits of your target customers, whether they prefer to buy rice from local grocery stores, specialty food shops, or online retailers.

- Conduct in-depth interviews or focus groups with potential customers to gather firsthand insights into their needs and preferences.

- Analyze industry reports and market trends to identify emerging consumer demands and opportunities in the rice milling industry.

- Collaborate with local community groups, health organizations, or cultural associations to better understand the specific needs of diverse customer segments.

By thoroughly understanding your target customers and their needs, you can develop a rice milling business plan that effectively addresses their pain points, offers unique value propositions, and positions your company as a trusted provider of high-quality, locally-sourced rice products.

Determine Product Specifications and Quality Standards

Establishing clear product specifications and quality standards is a critical step in creating a successful rice milling business plan. Golden Grain Millers must meticulously define the characteristics of the rice products they intend to offer, ensuring they meet the evolving needs and preferences of their target customers.

Begin by conducting thorough market research to understand the specific requirements of your target consumers. Factors such as grain size, texture, aroma, and nutritional content may vary depending on cultural preferences and dietary needs. For example, some customers may prefer long-grain, aromatic rice, while others may seek out short-grain, sticky varieties for sushi or risotto dishes.

- Engage with potential customers directly to gather insights on their preferred rice characteristics and quality expectations.

- Analyze industry trends and competitor offerings to identify opportunities for differentiation and innovative product development.

Once you have a clear understanding of your target market's preferences, work closely with your rice suppliers and milling team to establish rigorous quality control measures . This may include implementing strict grading systems, conducting regular testing for contaminants and impurities, and maintaining optimal storage and processing conditions to preserve the rice's freshness and nutritional value.

Consider obtaining relevant certifications, such as organic, non-GMO, or gluten-free, to further differentiate your products and cater to specific dietary requirements. Additionally, explore opportunities to highlight the provenance and sustainability of your rice by emphasizing local sourcing, environmentally-friendly farming practices, and transparent supply chain management.

- Develop detailed product specifications that outline the desired characteristics, including grain size, color, aroma, and nutritional profile.

- Implement a comprehensive quality assurance program to ensure consistent product quality and customer satisfaction.

By meticulously defining your product specifications and quality standards, Golden Grain Millers can differentiate its offerings, build a strong brand reputation, and position itself as a trusted provider of high-quality, sustainable rice products in the marketplace.

Evaluate production costs and profit margins

Evaluating production costs and profit margins is a critical step in developing a comprehensive business plan for your rice milling operation. This analysis will help you determine the feasibility of your venture, identify areas for cost optimization, and ensure that your business model is financially viable.

To evaluate production costs, you'll need to consider the following key factors:

- Raw material costs: The price you'll pay for purchasing paddy rice from local farmers or suppliers. This can vary depending on factors like crop yield, market demand, and transportation costs.

- Processing and milling expenses: The costs associated with operating your rice mill, including electricity, labor, maintenance, and any additional processing steps like parboiling or polishing.

- Packaging and labeling: The expenses for packaging your milled rice products in an appropriate and attractive manner, including the cost of bags, labels, and any branding materials.

- Distribution and logistics: The costs of transporting your rice products to wholesalers, retailers, or directly to consumers, including fuel, vehicle maintenance, and any storage or warehousing fees.

- Overhead costs: General business expenses like rent, insurance, licenses, and administrative staff that contribute to the overall cost of running your rice milling operation.

Once you've identified and quantified these production-related costs, you can then determine your expected profit margins. This involves estimating the wholesale or retail prices you'll be able to charge for your rice products, based on market research, competitor analysis, and an understanding of your target customers' willingness to pay.

- Conduct a thorough cost-benefit analysis to ensure your rice milling business is financially viable. Aim for a profit margin of at least 20-30% to ensure a sustainable and profitable operation.

- Consider ways to optimize production costs, such as negotiating better prices with suppliers, investing in energy-efficient equipment, or streamlining your operations to improve efficiency.

- Stay up-to-date with industry trends and adjust your pricing and cost structure accordingly to maintain a competitive edge and respond to market changes.

By carefully evaluating your production costs and profit margins, you'll be able to create a robust financial plan that accurately reflects the economic realities of running a rice milling business. This information will be crucial in securing financing, attracting investors, and ensuring the long-term sustainability of your enterprise.

| Rice Milling Financial Model Get Template |

Secure Reliable Sources for Raw Materials

Securing reliable sources for raw materials is a critical step in establishing a successful rice milling business. As the core input for your operations, the quality and consistency of the rice you procure will directly impact the final product and your ability to meet customer demands. In the case of 'Golden Grain Millers', this means building strong relationships with local rice farmers to ensure a steady supply of high-quality, sustainably-grown rice varieties.

When evaluating potential suppliers, consider factors such as production capacity, quality control measures, delivery reliability, and pricing . Conduct thorough due diligence to ensure your partners can consistently meet your volume and specification requirements. Diversifying your supplier base can also help mitigate risks and provide flexibility in times of disruption.

- Establish long-term contracts with select suppliers to guarantee access to raw materials and negotiate favorable terms.

- Visit potential supplier facilities to assess their operations, quality standards, and sustainability practices firsthand.

- Implement robust quality assurance protocols, including regular testing and inspections, to maintain the integrity of your raw materials.

In the rice milling industry, the availability and price of raw materials can be subject to seasonal fluctuations and environmental factors. Careful planning and inventory management are essential to ensure a steady flow of rice through your production process. Analyze historical data on rice yields, market prices, and your own consumption patterns to forecast your raw material needs accurately.

By securing reliable sources for your key raw material - rice - you can confidently plan your production, minimize disruptions, and deliver consistent, high-quality products to your customers. This foundation will be crucial in establishing 'Golden Grain Millers' as a trusted and dependable supplier in the growing market for locally-sourced and sustainable food products.

Assess Equipment and Facility Requirements

Establishing a successful rice milling operation requires carefully evaluating the equipment and facility needs to ensure efficient and cost-effective production. As part of the business plan for your rice milling venture , this step is crucial in determining the necessary capital investments and operational costs.

The first consideration is the type and capacity of the rice milling equipment required. This will depend on the anticipated production volume, the variety of rice products you plan to offer, and the desired level of automation. High-quality rice milling equipment can range from $50,000 to $500,000 or more, depending on the scale and features. Factors such as input capacity, milling efficiency, and energy consumption should be carefully evaluated to find the right balance between cost and performance.

- Explore options for used or refurbished equipment to potentially reduce initial capital investments.

- Consider the long-term maintenance and repair costs when selecting rice milling equipment.

- Investigate government or industry grants and subsidies that may be available for upgrading or modernizing rice milling facilities.

In addition to the milling equipment, the facility itself must be designed to accommodate the production workflow, storage, and packaging requirements. The average size of a rice milling facility ranges from 5,000 to 20,000 square feet , depending on the scale of operations. Factors such as access to utilities, proximity to transportation hubs, and compliance with local zoning and environmental regulations must be carefully evaluated when selecting a suitable location.

The facility layout should be optimized to ensure efficient material flow, minimize waste, and provide ample space for storage and packaging. Specialized features such as humidity and temperature control, dust extraction systems, and safety measures should also be incorporated to maintain product quality and comply with industry standards.

- Explore options for leasing or purchasing an existing facility to potentially reduce initial capital investments.

- Consult with industry experts or architects to design an efficient and cost-effective rice milling facility layout.

- Investigate any local or regional incentives or tax credits that may be available for establishing a rice milling operation in a specific location.

By carefully assessing the equipment and facility requirements, you can ensure that your rice milling business plan aligns with the operational needs and financial constraints of your venture. This comprehensive evaluation will help you make informed decisions and lay the foundation for a successful and sustainable rice milling operation.

Develop a Distribution and Sales Strategy

Developing a comprehensive distribution and sales strategy is crucial for the success of your rice milling business. By strategically positioning your products and leveraging effective sales channels, you can ensure that your high-quality rice reaches the right customers and maximizes your profitability.

One of the key considerations in your distribution strategy should be identifying the most suitable sales channels. This may include direct-to-consumer sales through an online platform or a physical retail store, as well as wholesale partnerships with local grocery stores, specialty food shops, and even restaurants. By diversifying your sales channels, you can cater to a wider range of customers and reduce your reliance on a single outlet.

When it comes to pricing, it's important to strike the right balance between maintaining a competitive edge and ensuring a healthy profit margin. According to industry data, the average retail price for a 20-pound bag of premium rice ranges from $15 to $25 , with organic and specialty varieties commanding even higher prices. Carefully analyze your production costs, target market, and competitor pricing to determine the optimal pricing strategy for your rice products.

- Consider offering volume discounts or wholesale pricing to attract larger customers, such as restaurant chains or institutional buyers.

- Explore the possibility of selling directly to consumers through a subscription-based model or a community-supported agriculture (CSA) program.

- Invest in effective marketing and branding to differentiate your rice products and command a premium price in the market.

Effective distribution and sales strategies also involve logistics and supply chain management. Ensure that you have a reliable transportation network, secure storage facilities, and efficient order fulfillment processes to deliver your products to customers promptly and consistently. Industry data shows that the average cost of rice transportation can range from $0.50 to $1.50 per hundredweight, depending on the distance and mode of transportation .

Additionally, stay informed about industry regulations, certifications, and labeling requirements to ensure compliance and build trust with your customers. Continuously monitor market trends, customer feedback, and competitor activities to adapt your distribution and sales strategies as needed, ensuring the long-term success of your rice milling business.

| Rice Milling Pitch Deck |

Explore Financing Options and Funding Sources

Securing the necessary financing is a critical step in establishing a successful rice milling business. Exploring various financing options and funding sources can help you obtain the capital required to invest in equipment, facilities, and working capital. As you develop your rice milling business plan, consider the following strategies to fund your operations:

- Small Business Loans : Investigate loan programs offered by banks, credit unions, and government agencies such as the Small Business Administration (SBA). These lenders may provide competitive interest rates and favorable terms for small businesses in the agricultural sector.

- Angel Investors and Venture Capital : Reach out to angel investors or venture capital firms that have a track record of investing in food processing or agricultural startups. These sources can provide not only funding but also valuable industry insights and mentorship.

- Crowdfunding Platforms : Leverage crowdfunding platforms like Kickstarter or Indiegogo to raise funds from a wide network of individual investors. This can be an effective way to engage with your target market and generate initial capital for your rice milling venture.

- Government Grants and Subsidies : Explore federal, state, or local government programs that offer grants or subsidies for agricultural businesses, particularly those focused on sustainable practices or rural economic development.

- Equipment Financing : Consider leasing or financing the purchase of specialized rice milling equipment to minimize upfront capital expenditures and spread the costs over time.

- Carefully evaluate the terms, interest rates, and repayment schedules of any financing options to ensure they align with your business's cash flow and long-term financial goals.

- Develop a detailed financial plan that includes projected revenue, expenses, and cash flow to demonstrate the viability of your rice milling business to potential investors or lenders.

- Maintain a strong credit profile and be prepared to provide collateral or personal guarantees to increase your chances of securing financing.

By exploring a diverse range of financing options and funding sources, you can increase your chances of securing the necessary capital to launch and grow your rice milling business . Careful planning and a thorough understanding of the various financing alternatives available can help you make informed decisions and position your venture for long-term success.

Assemble a Skilled Team of Professionals

Building a successful rice milling business requires assembling a team of skilled professionals with diverse expertise. From sourcing and processing to marketing and distribution, each member of the team plays a crucial role in the success of the operation. Here's a closer look at the key roles and responsibilities to consider when building your rice milling team:

- Operations Manager: Responsible for overseeing the day-to-day operations of the mill, including production planning, quality control, and equipment maintenance. This role requires a deep understanding of the rice milling process and a strong commitment to efficiency and safety.

- Procurement Specialist: Tasked with sourcing high-quality raw rice from local farmers and suppliers, ensuring a consistent and reliable supply. This role involves negotiating contracts, managing logistics, and maintaining strong relationships with the agricultural community.

- Sales and Marketing Manager: Develops and implements strategies to promote the Golden Grain Millers brand, identify target markets, and secure distribution channels. This role requires excellent communication skills, market insights, and a deep understanding of consumer preferences.

- Financial Analyst: Responsible for developing financial projections, managing budgets, and securing financing for the business. This role is essential for ensuring the long-term viability and profitability of the rice milling operation .

- Quality Assurance Technician: Ensures that the rice products meet strict quality standards, from the initial processing to the final packaging. This role involves testing, inspecting, and implementing quality control measures to maintain the brand's reputation for excellence.

- Consider hiring experienced professionals with a proven track record in the rice milling industry to ensure a smooth startup and operations.

- Invest in continuous training and development for your team to keep them up-to-date with the latest industry trends, technologies, and best practices.

- Encourage collaboration and cross-functional communication to foster a culture of innovation and problem-solving within your rice milling business.

By assembling a skilled and dedicated team, Golden Grain Millers can leverage the expertise and collective knowledge to navigate the complexities of the rice milling industry, optimize operations, and deliver high-quality products to their customers.

Related Blogs

- 7 Mistakes to Avoid When Starting a Rice Milling in the US?

- What Are The Top 9 Business Benefits Of Starting A Rice Milling Business?

- What Are The Nine Best Ways To Boost A Rice Milling Business?

- What Are Nine Methods To Effectively Brand A Rice Milling Business?

- Rice Milling Business Idea Description in 5 W’s and 1 H Format

- Your Essential Checklist to Acquire a Rice Milling Business

- What Are The Reasons For The Failure Of Rice Milling Businesses?

- How To Fund Or Get Money To Start A Rice Milling Business?

- How To Name A Rice Milling Business?

- 9 Ways to Increase Your Rice Milling Business Owner Income

- How to Open a Rice Milling Business: Key Steps for Success

- 7 Vital KPIs to Track in Your Rice Milling Business

- How to Optimize Your Rice Milling Operating Costs

- What Are The Top Nine Pain Points Of Running A Rice Milling Business?

- Unleash Success with Your Rice Milling Dreams! Elevate Your Idea Today!

- How to Increase Revenue in the Rice Milling Business

- What Are Nine Strategies To Effectively Promote And Advertise A Rice Milling Business?

- The Complete Guide To Rice Milling Business Financing And Raising Capital

- Strategies To Increase Your Rice Milling Sales & Profitability

- What Are The Best Nine Strategies For Scaling And Growing A Rice Milling Business?

- How To Sell Rice Milling Business in 9 Steps: Checklist

- Core Startup Expenses For Your New Rice Mill

- What Are The Key Factors For Success In A Rice Milling Business?

- Valuing a Rice Milling Business

- How to Start a Rice Milling Business with Zero Investment

| Expert-built startup financial model templates |

Leave a comment

Your email address will not be published. Required fields are marked *

Please note, comments must be approved before they are published

Project Report Bank

Rice Mill Project Report

₹ 500

Description

If you are planning to set up a rice mill in India, Rice Mill Project Report is very useful for you. Agriculture being an important occupation of India is popular in West Bengal primarily. Among the crops that are a part of agriculture, rice is the main food crop. West Bengal is the state that is the largest producer of this crop.

The rice mills obtain rice after hulling and dehusking the paddy. The rice has 20% rice hull, 11% bran and 695 starchy endosperms. Paddy is the raw form of rice that humans cannot eat. Thus it is processed in rice mill to make it edible. Thus polished rice is produced. Rice milling removes husk and bran from paddy to produce edible rice.

The rice which is obtained is free from impurities and has minimum broken rice. FCI that is food corporation of India takes into hand 20 to 25% of rice for distribution under public distribution system.

The Rice mill business can be done as a small and big industry. You can read the article based on the opportunities available for more information about the large enterprise .

Table of Contents

- 1 Rice Mill Project Report

- 2 Objective

- 3 Market Opportunities

- 4 Product and Uses

- 6 How to get Rice Mill Business Model?

- 7 Rice Mill Manufacturing Process

The Rice Mill Business Plan is available for quick download here. This pre-feasibility report is in respect of Rice Mill. The objective of the Rice Mill Project Report is to provide information that the potential entrepreneurs are willing to get before they invest in a Rice Mill. The project report contains all the information needed for a new startup. This rice mill business plan covers various aspects of startup, marketing, finance and business management.

The main objective of every rice mill is to produce edible rice crop for sale in the market. The rice so obtained should be free from husk and bran. It should not have stones and other pesticide. Minimization of grain breakage should be the goal of the rice mill and it must try to maximize whole rice recovery.

The production of rice in any state of India has shown growth in the production of rice. Rice is being grown in an area of 5 million hectare producing 15 million tons of rice. As per the latest strategy of rice production, high yielding variety program for producing edible rice are run. The rice mills are operating on 3 shifts a day including harvesting and procurement process.

Market Opportunities

When you set up a rice mill, the farmers are engaged in farming and the mill earns good profits. Rice bran that is a by product is obtained during processing of rice. It is a great source of edible oil. Rice has a good demand in house hold and hotels, restaurants and dhabas too. A share of 20 to 25% of rice is taken by FCI to distribute rice in public distribution systems.

People in the south of India consume rice on a daily basis with fish and curries. The consumption of cooked rice per year per person is 164 kg. The country is not able to meet the demand of rice thus the government wants entrepreneurs to set up more rice mills.

Thus the business of rice mill manufacturing has a wide scope in the country. We insist you can get the rice mill project report for bank loan and get financial assistance from the government to start your own mill.

You can set up a rice mill and a plant to manufacture puffed rice and rice bran oil .

Product and Uses

Rice which is the staple food crop in most states of India. The byproduct is rice bran obtained while processing of rice. It has many antioxidants having other benefits for human health. It is utilized to produce oil and animal feed.

Rice bran being the niche product is healthy oil. The husk has good calorific value and is brought to use as source of energy. The husk is served to horses and is demanded for animal food.

The rice mill operates on scale model. The decision about its capacity depends on factors like demand for rice in the market, availability of man power to produce rice etc. The capacity of rice mill business model is 50 quintal. The plant can operate for 16 hours a day in two shifts.

How to get Rice Mill Business Model?

The process to download the Rice Mill project report is simple. First of all, you have to add the project report in the basket. Second, you have to checkout. The third is to pay. You can download the rice mill project report PDF format immediately after making the payment. Later you can change the sample project report pdf into word format using online conversion free tools.

Rice Mill Manufacturing Process

Preparation

Moving to planting, preparation of cultivation requires minimal soil manipulation. If rice will be grown in a hilly area, the area should be kept on roofs. Paddies are dodged and surrounded by dikes or levees with an aide of earth-moving equipment, then plowed fields before planting. Suitable irrigation of the terrace or river delta bed is mandatory and pumping is accomplished by controlling and leveling the water with reservoirs, sutures, and streams.

Rice seeds get wet before sowing. For the level of mechanization and the size of planting, provisional, seeding is done in three ways. In many Asian countries that have not industrialized their agricultural practices, seeds are sown by hand. After 30–50 days of development, transplanting is done from nursery beds into clusters of flooded trees. Seeds can also be sown through a machine called a drill that places the seed into the ground. Large enterprises often sow rice seeds in the United States by airplane. Low-flying aircraft deliver seeds to already flooded fields. An average supply is 90–100 pounds per acre (101–111 kg per hectare), producing about 15–30 plants per square foot.

Harvesting Of RICE IN INDIA

Once the plants have touched full growth (about three months after planting) and the grains begin to ripen – the tops begin to dry and the stem turns yellow – the water drains from the fields. As the fields dry up, the grain ripens more and harvesting begins. It depends on the size of the setup and the amount of mechanization, Rice is also harvested by hand or machine.

Through the hand, the rice stalk is replaced with a sharp knife or sickle. This practice still occurs in many Asian countries. Rice can also be harvested by a mechanized hand harvester or a tractor / horse-drawn machine that cuts and steals rice stalks. If the rice has been harvested by hand or by a semi-automated process, the thrush is terminated by hand or using a mechanized thresher.

First milling, rice grains should be dried between 18-22% to reduce the moisture content. This is done with the help of naturally occurring sunlight, hot air, or more frequently. Rice grains are left on racks in the fields to dehydrate naturally. Once dried, the grain of rice, now called coarse rice, is ready for processing.

PloUGHING oF Rice

The plow can be completed by hand by rolling or grinding rough rice between stones. However, more often it is processed in a mill with the help of automated processes. Rough rice is first cleaned, allowing debris to flow. The blown air extracts the top substance. Once cleaned, the rice is stirred by a machine that mimics the action of hand-made stones. The shelling machine rolls the rice hulls between two sheets of metal and decomposes them. During this process, 80–90% of the kernel hull is removed.

With the shelling machine, the grain and the rudder are transported to a stone reel which aspirates the waste mites and moves the kernels into a machine that separates from the thin grains. After shaking the kernels, the paddy machine services heavy unhealthy grains on one side of the machine, while light-weight rice falls to the other end. Unhealthy grains are then squeezed into additional batches of shelling machines to complete the stirring process. Thin rice grains are known as brown rice.

As it retains the outer bran coating of rice grains, brown rice does not require any other processing. However, with additional vitamins and minerals, bran layers also contain oil that spoils brown rice faster than melted white rice. This is the reason why brown rice is pushed forward to make white rice more visually.

The milling method used to make white rice removes vitamins and minerals mainly found in the outer bran layers. Further handling is often performed to bring nutrients back to the grain. Once complete, the rice is called converted rice.

White rice is converted into one of two methods. Before milling, Rice is immersed under pressure to transfer all the vitamins and minerals from the layers of the bran to the kernel. Once done, the rice is boiled, dried, and then mixed. Rice that has already been mixed can be included in bathing vitamins and minerals that coat the grains. When soaked, they are dried and mixed with uncooked rice. A project report is essential to understand the process of rice manufacturing. So you must download the project report of the rice mill. You can also start flattened rice poha business in the rice Mill as extra product production.

Contents of Rice Mill Project Report

| Sr.No. | Particulars |

| 1 | Confidentiality Note And Disclaimer |

| 2 | Project At Glance |

| 3 | Key Highlights |

| 4 | Introduction |

| 5 | Objective |

| 6 | Mfg. Process & Chart |

| 7 | Project Cost Estimate |

| 8 | Means Of Financing |

| 9 | Assumptions |

| 10 | Planning For Human Resources |

| 11 | Building And Civil Works |

| 12 | List Of Plant & Machinery |

| 13 | Miscellaneous Fixed Assets |

| 14 | Plant And Machineries Supplier |

| 15 | Preliminary & Pre-Operative Expenses |

| 16 | Depreciation Chart |

| 17 | Term Loan Repayment Schedule |

| 18 | Computation Of Working Capital |

| 19 | Administrative Expenses Details |

| 20 | Calculation Of Debt-Service Coverage Ratio |

| 21 | Installed Capacity And Capacity Utilization |

| 22 | Revenue Model |

| 23 | I – Form Proposed Facilities |

| 24 | II – Form Profit & Loss A/c |

| 25 | III – Form Balance Sheet |

| 26 | IV – Form Comparative CA & CL |

| 27 | V – Form MPBF |

| 28 | VI – Form Fund Flow |

| 29 | Ratio Analysis |

| 30 | Conclusion |

In addition to the above, other information which can help in preparing the project report.

License / Registration for rice mill business plan

You should take the following steps for the operation of the rice mill. Before applying for license and permissions, you must have the project report of the rice mill. It is mandatory to attach the project report with the application.

Register Business Structure For Rice Mill

Let us look at and understand the types of business unit structures available in India. Below is a list of some of them:

- One Person Company (OPC): If you want to have complete control over your business with limited liabilities, OPC is the best option to start. But make sure that you change the structure of your business (within six months) to the private company after the cross.

- Register a Company: It is the most well-known legal framework for business. Any default, financial liability of shareholders, In the case of bankruptcy and/or recovery by banks or creditors limited to their shares. It simply means

- Private Limited company

- Public Limited Company (PLC)- A public Limited Company business structure is great for the long run but has more regulatory requirements. Apart from all the advantages of a private limited company, it can be easy to transfer to any number of members.

- Limited Liability Partnership (LLP) If you do not want to take responsibility or liability for the misconduct, incompetence, or negligence of another partner and limit your liabilities for debts and losses. If you want to enjoy tax benefits, LLP can be.

- Partnership Firm If you do not want to take responsibility or liability for the misconduct, incompetence, or negligence of another partner for debts and losses. Therefore, you can create Partnership firm by creating a Partnership Deed.

- Proprietorship You can register your business as a sole proprietorship.

Industry Based UDYAM Registration

Your business must be register for Udyam Registration on MSME portal .

- Micro-Enterprise – Set up a business that investment in plant and machinery and equipment’s does not exceed Rs 1 Crore and Turnover does not exceed Rs.5 Crore in a specific business that comes under Micro Enterprises.

- Small-Enterprise – Set up a business that investment in plant and machinery and equipment’s exceed Rs 1 Crore but does not exceed Rs 10 Crore and Turnover exceed Rs.5 Crore does not exceed Rs.50 Crore in a specific business that comes under Small Enterprises.

Factory License For rice Mill

An individual/group planning to start a new business is required to obtain a factory/trade license. Factory/trade license is t o regulate the specific laws of trade for a particular area or locality.

No Pollution Certificate For Rice Mill

Apply for ‘Consent to operate’ and ‘Consent for establishment’ from Pollution Control Board Act 1958: Apply for the Rice-Milling Industry (Regulation) Act, 1958.

EPF and ESIC Registration

If you have more employees than prescribed in the EPF and ESIC in the rice mill plant, then you will have to get EPF (Employees’ Provident Fund Organisation) and ESIC registration for the employees as per the labor law.

FSSAI License

The rice mill plant is classified in the food industry; Therefore, you need to apply for an FSSAI license (Food Safety and Standard Authority of India) , one of the necessary condition is to get a government license/permit after registering the business unit.

In case you are in the food industry such as hawker, traveling vendor, temporary stakeholder; Food distributors at any religious or social gathering events, except for one caterer, Or in any way related to the manufacture, transportation, storage, or distribution of food products or small food businesses, must obtain an FSSAI registration or FSSAI license before commencing operations.

GST Registration For rice Mill

Obtaining a GST Goods and Services Tax number which is mandatory for every business after the GST rule comes into force. It is very easy to do business in India and do interstate sales without restrictions

- Limited compliance

- High rebate for new businesses under composition scheme

- Low tax liability

- Financial inclusion in the long run

- Boosting the country’s economy is increasing opportunities for startups

SWOT Analysis For Rice Mill Business Model

Strength : The biggest strength of the rice mill plant is it is a high source of nutrition for more than half of the world’s population, rice is by far one of the most essential commercial food crops. The Rice mill plant gives you a high profit because it is the highest consumable food in India.

Weakness: Rice has great demand as a raw material to take out tof he plant. This business required a large number of knowledge of the market. The Rice mill plant also needs a large number of labour capital intensive. The Rice mill plant setup requires so many licenses.

Opportunities: Rice marketing opportunities are available in some guidelines for searching for potential buyers are communicating through exporting your relatives in that country, online portals like Alibaba and Indiamart, social media advertising, promotion of your website, and more.

Threats: Sometimes in this type of agriculture industry, many competitors also try to spread false rumours about the quality of the product that you gave. In starting of rice mill plant you have to face lots of ups and downs you may say only downs in your business.

Frequently Asked Questions On Rice Mill Project Report

What are the essential equipment and machinery required for the rice mill business.

• Grading machine • Grain dryerlighting equipment • Measurement and packing machine • Paddy Bran Making Machine • Paddy separator machine • Cleaning machine • Colored solution • Day-Stoner Machine • Milling Detection Machine • Polishing machine • Rice albumen

Can i download Rice mill project report for bank loan

Yes, you can download the rice mill project repory from our website as we have a team of professionals who help you by writing personalised project reports for bank loan for your new startup.

What is the use of rice mill project report pdf?

You can use the rice mill project report pdf to start your new rice mill business because you need to research about every pros and cons before you start with this venture. You can download rice mill business plan model pdf and get complete detail about this business.

Where can i get rice mill project report msme in India?

If you are planning to start msme rice mill business, you will need bank loan and to avail it you require bank loan. You can henceforth get it from our website.

You may also like…

Poha Manufacturing Project Report

Puffed Rice Manufacturing Project Report

Rice Bran Oil Project Report

Related products.

Wheat Dalia Project Report

Grocery Shop Project Report

Mushroom Cultivation Project Report

Maize Flour Mill Project Report

How to Start a Rice Mill Business Even If You Have No Experience

By: Author Tony Martins Ajaero

Home » Business ideas » Agriculture Industry » Agro Processing & Allied Industry

A rice milling business is a business that involves processing raw rice grains to produce refined rice for consumption. The process typically includes cleaning, husking, milling, polishing, and grading the rice.

After harvesting, the rice is transported to the milling facility where it undergoes these steps to remove impurities and produce polished grains ready for market. The business may also offer value-added services such as packaging and distribution.

Rice milling businesses are prevalent in regions where rice is a staple, such as Asia, Africa, and Latin America. These businesses contribute significantly to the agricultural economy and provide employment opportunities.

Suggested for You

- How to Start a Flour Production Company – Sample Business Plan Template

- How to Start a Scorpion Venom Business Even If You Have No Experience

- How Much Does It Cost to Start an Aquarium Business? (Sales Forecast and Breakeven Analysis Included)

- Feed Store Startup Cost Analysis (Monthly Expenses, Sales and Breakeven Point Included)

- Rice Mill Startup Cost Analysis (Monthly Expenses, Sales and Breakeven Point Included)

Data from the Food and Agriculture Organization (FAO) indicates that Asia accounts for about 90% of global rice production, highlighting the substantial market potential for rice milling businesses in these regions.

Steps on How to Start a Rice Milling Business

Conduct market research.

Conducting market research is an essential step when starting a rice milling business to help identify potential customers and understand their needs and preferences.

First, you are expected to identify who your potential customers are, and then you are expected to determine their demographic characteristics, such as age, income, and location.

Next, you are expected to analyze their pricing, services, and marketing strategies to determine how you can differentiate your business.

Conduct surveys or focus groups to understand what customers are looking for in the rice milling business. Ask about their preferences for products, pricing, and customer service.

You should also determine the cost of goods sold for each product and the overhead costs associated with running the business.

Analyze pricing strategies used by competitors to determine what pricing structure will be most competitive and profitable for your business.

Lastly, based on your research, you should develop a marketing plan that targets your ideal customers and highlights your unique selling points.

a. Who is the Target Market for a Rice Milling Business?

- Farmers: Providing milling services to farmers who grow rice but lack the infrastructure to process it.

- Rice traders: Offering milling services to traders who buy rice in bulk for distribution and sale.

- Food manufacturers: Supplying processed rice to food manufacturers for use in various products like cereals, snacks, and beverages.

- Retailers: Selling packaged rice directly to retailers for sale to consumers.

- Exporters: Providing high-quality processed rice for export to international markets.

- Consumers: Offering polished rice directly to consumers through retail channels or online platforms.

b. Is the Rice Milling Business a Profitable Business?

Yes, rice milling can be profitable due to the steady demand for rice globally. Profit margins vary based on factors like scale, efficiency, and market conditions.

According to industry reports, successful rice milling businesses can achieve healthy returns, with profitability influenced by factors such as technology adoption, value-added services, and cost management. However, profitability may fluctuate based on factors like crop yields, input costs, and competitive pressures.

c. Are There Existing Niches in the Industry?

No, there are no existing niches when it comes to the rice milling business.

d. Who are the Major Competitors?

- Asia Golden Rice Co., Ltd.

- Thai Hua Rubber Public Company Limited

- Jasmine Rice Export Company Limited

- Vietnam Southern Food Corporation

- Ambe Agro Industries Limited

- Kohinoor Rice Mills

- KRBL Limited

- Daawat Rice Limited

- Laxmi Rice Mills

- LT Foods Limited

- Hain Celestial Group

- Far West Rice

- Riviana Foods

- Sun Valley Rice

- Novel Denim Japan Co., Ltd.

e. Are There County or State Regulations or Zoning Laws for Rice Milling Business?

In the United States, regulations and zoning laws for rice milling businesses vary depending on the county and state. These regulations are typically aimed at ensuring public health and safety, environmental protection, and adherence to zoning ordinances.

Each state may have its own set of regulations governing food processing facilities, which rice mills fall under. These regulations often cover aspects such as sanitation, waste management, and employee safety. County and municipal zoning laws also play a significant role in determining where rice milling businesses can operate.

Zoning ordinances designate specific areas for industrial, commercial, and agricultural activities, and rice mills must comply with these regulations to obtain permits for operation. Some areas may have restrictions on noise levels, traffic, and proximity to residential neighborhoods.

Additionally, environmental regulations impact rice milling operations, especially regarding wastewater management and air emissions.

Rice milling can generate organic waste and byproducts that must be disposed of properly to prevent pollution. Compliance with environmental permits and regulations is essential to avoid fines and penalties.

Furthermore, food safety regulations enforced by federal agencies such as the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) apply to rice milling businesses.

f. Is There a Franchise for Rice Milling Business?

No, there are no franchise opportunities for the rice milling business.

g. What Do You Need to Start a Rice Milling Business?

- Rice milling machine

- Raw rice grains

- Cleaning equipment (e.g., sieves, cleaners)

- Husking machine

- Milling equipment (e.g., whitening machines, polishers)

- Packaging materials (e.g., bags, containers)

- Storage facilities (e.g., warehouses)

- Labour (skilled and unskilled workers)

- Utilities (e.g., electricity, water)

- Business licenses and permits

- Marketing and distribution channels.

Memorable Business Name

- Royal Dutch® Rice Milling Company, Inc.

- Green Life® Rice Milling Company, Co.

- Joy McPherson® Rice Milling Company, Inc.

- Nora Spiff® Rice Milling Company, Inc.

- Adah Abraham® Rice Milling Company, Inc.

- Theodora Edison® Rice Milling Company, Inc.

- Ariel Darlington® Rice Milling Company, LLC

- Amos Wycliff® Rice Milling Company, Inc.

- Rowland Norman® Rice Milling Company, LLC

- Chloe Chapman™ Rice Milling Company, Inc.

- Tracie Paulson® Rice Milling Company, Inc.

- Magritte Foods® Rice Milling Company, Inc.

- Gordon Bobson™ Rice Milling Company, Inc.

- Rita Rhodes® Rice Milling Company, Inc.

- Grace Court® Rice Milling Company, LLC

- Golden Plate® Rice Milling Company, Inc.

- Janice Yorke® Rice Milling Company, Inc.

- Georgia Victor™ Rice Milling Company, Inc.

- Shavonne Stallone® Rice Milling Company, Inc.

- Ruth Samson® Rice Milling Company, Inc.

Register Your Business

A. what type of business structure is best for rice milling business.

The ideal business structure for a rice milling company is determined by a variety of factors, including the size of the company, the number of owners, the level of personal liability the owners are ready to accept, and the tax consequences of the various business structures.

However, we normally recommend a limited liability company structure. An LLC is a hybrid corporate form that provides the flexibility of a partnership while also providing its owners with limited liability protection.

An LLC can have one or more owners, and the owners are not personally accountable for the debts or liabilities of the business. This business form is frequently used for small to medium-sized organizations.

b. Steps to Form an LLC

- Choose a Name for Your LLC.

- File Articles of Organization.

- Choose a registered agent.

- Decide on member vs. manager management.

- Create an LLC operating agreement.

- Comply with other tax and regulatory requirements.

- File annual reports.

c. What Type of License is Needed to Open Rice Milling Business?

- Business License

- Food processing license

- Environmental permit

- Health department permit

- Fire safety permit

- Zoning permit

- Water usage permit

- Transportation permits (if applicable)

- Trade license

- Import/export license.

d. What Type of Certification is Needed to Open Rice Milling Business?

You do not need any certifications to open a rice milling business.

e. What Documents are Needed to Open Rice Milling Business?

- Business plan

- Proof of business registration

- Identification documents (e.g., passport, driver’s license)

- Tax identification number (TIN)

- Certificate of incorporation

- Lease agreement or property ownership documents

- Environmental impact assessment (if required)

- Health and safety policy

- Building permits

- Equipment purchase invoices

- Insurance policies (e.g., liability insurance)

- Financial statements

- Employment contracts

- Water usage permits

- Import/export documentation (if applicable).

f. Do You Need a Trademark, Copyright, or Patent?

A trademark is essential for protecting your brand name, logo, or slogan associated with your rice milling business. It helps distinguish your products from those of other businesses in the market.

Registering a trademark with the relevant intellectual property office provides legal protection and exclusive rights to use that mark in connection with your products.

Copyright protection is not typically applied to rice milling products but may be relevant for creative content associated with your business, such as marketing materials, website content, or promotional videos.

Patents are generally not applicable to the production of rice milling products as it is a natural product.

Cost Analysis and Budgeting

A. how much does it cost to start a rice milling business.

The cost to start a rice milling business can vary widely depending on factors such as the size of the business, location, equipment, and supplies needed, staffing costs, marketing expenses, and more. However, a rough estimate could range from $500,000 to over $5 million, depending on the size and scope of the business.

b. Costs Involved in Starting a Rice Milling Business

- Legal and administrative costs (the cost of obtaining business licenses and permits, registering the business, and consulting with attorneys and accountants): $7,500

- Equipment and supplies: $3 million

- Staffing costs: $155,000 (first 2 months)

- Rent/lease: $85,000

- Marketing and advertising costs: $3,000

- Insurance costs: $2,800

- Miscellaneous Expenses: $5,000.

c. What Factors Determine the Cost of Opening a Rice Milling Business?

- The size of the rice milling business

- The choice of location

- The required licenses and permits

- The cost of hiring and paying a business consultant and attorney

- The cost of branding, promotion, and marketing of the rice milling business

- The cost of furnishing and equipping the rice milling products

- The cost of the insurance policy covers

- The cost of registering the business

- Source of your supplies and ongoing expenses

- Cost of recruiting and training your staff

- The cost of the purchase and customizing of uniforms, shoes, and caps for your employees

- The cost for the grand opening of the rice milling business.

d. Do You Need to Build a Facility? If YES, How Much Will It Cost?

It is not necessary to build a new facility for your rice milling business, but, if you have the required finance, it will pay you to build your own facility.

The truth is that building or reconstructing a facility for your rice milling business will allow you to come up with a facility that will perfectly fit into your overall business goals and vision.

e. What are the Ongoing Expenses of Rice Milling Business?

- Supplies costs

- Packaging materials

- Labor wages

- Rent or lease for a production facility

- Utilities (electricity, water, gas)

- Marketing and advertising expenses

- Equipment maintenance and repair

- Insurance (liability, product, property)

- Transportation and shipping costs

- Regulatory compliance fees (health and safety regulations)

- Website maintenance and e-commerce platform fees

- Research and development for new product development and innovation.

f. What is the Average Salary of your Staff?

- General Manager – $75,000 per year

- Quality Control Staff – $60,000 per year

- Administrative Assistant (Cashier) – $55,000 per year

- Processing and Production Staff – $50,000 per year

- Logistics and Shipping Staff – $45,000 per year

- Customer Service Executive -$40,000 per year

g. How Do You Get Funding to Start a Rice Milling Business?

- Raising money from personal savings and sale of personal stocks and properties

- Raising money from investors and business partners

- Sell shares to interested investors

- Applying for a loan from your bank/banks

- Pitching your business idea and applying for business grants and seed funding from the government, donor organizations, and angel investors

- Source for soft loans from your family members and friends.

Write a Business Plan

A. executive summary.

Shavonne Stallone™ Rice Milling Company, Inc. aims to establish a leading rice milling operation in Little Rock, Arkansas, capitalizing on the region’s conducive business environment and proximity to rice-producing areas.

Our company seeks to provide high-quality rice products to meet the growing demand both domestically and internationally. With a focus on state-of-the-art milling technology and efficient production processes, we aim to deliver premium rice products while maintaining competitive pricing.

Our strategic location in Little Rock offers logistical advantages for sourcing raw materials and distributing finished products.

Leveraging the city’s infrastructure and transportation networks, we can streamline operations and ensure timely delivery to customers across the United States and beyond.

Furthermore, our commitment to sustainability and environmental responsibility will guide our operations, ensuring compliance with regulations and minimizing our ecological footprint.

Shavonne Stallone™ Rice Milling Company, Inc. plans to collaborate with local farmers, suppliers, and distributors to foster strong partnerships within the community and create economic opportunities.

Through innovation, quality assurance, and customer satisfaction, we aim to establish ourselves as a trusted leader in the rice milling industry, contributing to the growth and prosperity of both our company and the region as a whole.

b. Products and Service

At Joy McPherson™ Rice Milling Company, we specialize in providing premium rice products and comprehensive milling services.

Our offerings include a diverse range of high-quality rice varieties, meticulously processed to meet the needs and preferences of our discerning customers.

We will also offer custom milling services, utilizing advanced technology and industry expertise to efficiently process raw rice grains into refined, polished products.

Whether sourcing our exceptional rice varieties or utilizing our milling services, clients can trust Joy McPherson™ for excellence, reliability, and unparalleled customer satisfaction.

c. Mission Statement

“At Joy McPherson™ Rice Milling Company, Inc., our mission is to consistently deliver the highest quality rice products and milling services to our customers.

We are dedicated to utilizing advanced technology, sustainable practices, and exceptional customer service to exceed expectations and build lasting relationships within our community and beyond.”

Vision Statement:

Our vision at Joy McPherson™ Rice Milling Company, Inc. is to become a recognized leader in the rice milling industry, known for our commitment to excellence, innovation, and integrity.

We aspire to continuously enhance our operations, expand our product offerings, and contribute positively to the growth and development of the rice industry.

d. Goals and Objectives

At Joy McPherson™ Rice Milling Company, Inc., our goals are to establish ourselves as a premier provider of high-quality rice products and milling services, achieve operational excellence through technological innovation and sustainability practices, expand our market reach domestically and internationally, foster strong relationships with customers and stakeholders, and continually strive for growth and improvement in every aspect of our business operations to maintain our position as a trusted leader in the rice milling industry.

e. Organizational Structure

- Chief Executive Officer

- General Manager

- Quality Control Staff

- Administrative Assistant (Cashier)

- Processing and Production Staff

- Logistics and Shipping Staff

- Customer Service Executive.

Marketing Plan

A. swot analysis.

- Joy McPherson™ Rice Milling Company, Inc. prides itself on producing premium rice varieties using advanced milling technology, ensuring consistent quality and taste.

- Situated in a region with access to rice-producing areas and efficient transportation networks, the company benefits from logistical advantages for sourcing raw materials and distributing finished products.

- With a focus on excellence and customer satisfaction, Joy McPherson™ has built a solid reputation for reliability and integrity in the rice milling industry.

- The company continually invests in state-of-the-art milling equipment and processes, enhancing efficiency, productivity, and product quality.

- Joy McPherson™ is committed to environmental responsibility, implementing sustainable practices to minimize its ecological footprint and comply with regulations.

- Despite its high-quality products, Joy McPherson™ may face challenges in penetrating new markets and increasing market share due to intense competition in the rice industry.

- The company’s reliance on external suppliers for raw materials exposes it to supply chain risks, such as fluctuations in prices and availability.

- Maintaining advanced milling technology and sustainable practices may incur higher operational costs, impacting profit margins and competitiveness.

- While located in a strategic area for rice production, Joy McPherson™ may face limitations in expanding its market reach beyond regional and national borders.

- Over-reliance on rice milling as the primary revenue source may leave the company vulnerable to market fluctuations and industry challenges.

Opportunities

- Joy McPherson™ can explore opportunities to expand its product offerings, diversify into related food products, or target niche markets to capture new customer segments.

- With the increasing global demand for rice products, the company can pursue international market expansion, leveraging its reputation for quality and reliability.

- Collaborating with local farmers, suppliers, or distributors can enhance supply chain efficiency, reduce costs, and strengthen market presence.

- Investing in research and development to introduce new rice varieties or value-added products can differentiate Joy McPherson™ in the market and attract discerning consumers.

- Embracing online sales channels and digital marketing strategies can broaden the company’s reach, attract new customers, and enhance brand visibility in an increasingly digital marketplace.

- Intense competition from established rice milling companies and emerging players in the industry poses a threat to Joy McPherson™’s market position and profitability.

- Price Volatility: Fluctuations in rice prices and input costs, influenced by factors like weather conditions, global market trends, and government policies, can impact the company’s profit margins and financial stability.