100+ Short Workplace Safety Topics from [A-Z] – Free Download

The human attention span has been dwindling since the mass-adoption of the Internet. No wonder it’s becoming more and more difficult to engage your workforce in safety training.

But that’s where short workplace safety topics come into play. With the right resources, they can be conducted several times throughout the week and last about 10-15 minutes. That’s enough to keep safety knowledge fresh on everyone’s mind and build the foundation of a strong health and safety culture. A culture in which your entire workforce is engaged and invested.

All great except… There is one challenge here. Quick safety talks can actually be more work because of the limited time. As Mark Twain famously said,

“I didn’t have time to write a short letter, so I wrote a long one instead.” Mark Twain

So, how do you make a short safety talk count?

The Short Safety Talks Secret: How to Effectively Communicate Workplace Safety Practices In Minutes

Good news! With the abundance of short safety topics that the Internet has to offer, you have just about enough resources to make even a 2-minute safety talk effective.

But before we get to the downloadable toolbox talk templates, here are a few tips on communicating safety best practices:

- Tell a story . According to cognitive psychologist Jerome Bruner, we are 22 times more likely to remember facts when they are presented through a story. Another study suggests that “telling stories when communicating can make the speaker appear more warm and trustworthy, as opposed to speaking some other way, such as providing only statistics and figures”.

- Stay focused on your topic . Yes, there are probably dozens of related things that you want to say. And they all seem important. But, if you want your safety talk to stick, you have to remain laser-focused on one specific topic.

- 5-10 slides max . You’ll probably want to keep a slide for about a minute. Keeping slide count smaller enables you to keep your toolbox talk short, too.

100+ Short Safety Talks For Work [A-Z index]

Ready to transform your workplace’s attitude towards health and safety? It’s easy to stay consistent with your safety talks when you have a reliable backlog of quick safety topics for you to choose from.

We’ve done the homework for you. Here are 100+ short safety talks, ready for when your next safety moment takes place. Hopefully, these will help keep your idea bank full for the foreseeable.

- 5 Examples of Unsafe Bad Habits

- Achieving your Team’s Health and Safety Goals

- Alcohol Awareness

- Allergies and Hayfever

- Attitudes to Workplace

- Health and Safety

- Back Stretches

- Being a Positive Influence for your Colleagues

- Being Proactive

- Bullying in the Workplace

- Burns and Knowing the Different Levels of Severity

- Carbon Monoxide

- Carcinogens

- Cell Phones as Dangerous Distractions

- Close Calls

- Communication

- Concrete

- Construction Sites

- Construction Surveying

- COVID-19 (we’ll cover this topic in more detail later)

- Cutting Down Complacency

- Deadline Pressures

- Defibrillators

- Dropping Heavy Objects

- Dust and its Hazards

- Electrical Safety

- Energy Drinks and Excessive Caffeine Consumption

- Establishing a Safe Working Environment

- Excavation

- Eye Damage and Eye

- Fall Protection

- Fall Prevention

- Feeling Immune – ‘It

- Wouldn’t Happen To Me’

- Fire Extinguishers

- Fire Safety

- First Aid Kit

- First Day Back

- Gasoline

- General Day-To-Day Safety

- Hand and Arm Protection

- Hand Tools

- Handling Chemicals

- Hazardous Substances

- Health and Safety Mentoring

- Heart Attacks

- Heat Stress

- Heavy Lifting

- Improving our Health and

- Safety Communication

- Keeping Everyone

- Accountable for Workplace Health and Safety

- Keeping Hydrated

- Ladder Safety

- Lead-Based Paint

- Learning From an Accident

- Lyme Disease

- Machine Guarding

- Meeting your Safety Goals

- Mental Health

- Mosquitoes

- Neck Stretches

- New Employees

- Noise and Noise-Induced Hearing Loss

- Office Safety

- Personal Hygiene

- Personal Protective Equipment

- Planning a New Task

- Potential Hazards

- Protective Clothing

- Radio Communication

- Reporting an Incident

- Reporting Injuries

- Responding to an Emergency

- Safety Paperwork

- Safety Signs

- Sleep and Fatigue

- Slips and Trips

- Snow and Frost

- Workplace Stress

- Teamwork and Our Health and Safety Culture

- The Common Cold

- Truck Driving

- Using New Equipment

- Water Safety

- Winter Safety

- Working Alone Safely

- Workplace Violence

For more inspiration, check out OSHA’s library of free safety training materials which include:

- Brochures/booklets;

- Fact Sheets;

- Guidance documents that provide detailed examinations of specific safety and health issues;

- Online Safety and Health Topics pages;

- Posters;

- Small, laminated QuickCards™ that provide brief safety and health information; and

- QuickTakes , OSHA’s free, twice-monthly online newsletter with the latest news about OSHA initiatives and products to assist employers and workers in finding and preventing workplace hazards.

Flu and Covid Toolbox Talks and Safety Moments

Given the current situation, it’s important to cover this particular safety topic in a bit more detail. Besides, speaking to your workforce about the risks presented by COVID-19, and how you can mitigate them, is a great topic for a quick, 5-minute safety topic.

Here are some of the points you can cover within this particular topic:

- Social distancing

- The importance of wearing a mask

- The main COVID-19 and flu symptoms

- What to do if you show any COVID-19 symptoms

- How often you should use hand sanitizer

- The best way to wash your hands

- Understanding the risks (including any key risks for your particular type of work)

- The current situation in the USA (legislation, statistics and changes)

- Examples of small changes that you can make to ensure your work practice is as safe as possible

You can pick and choose from any of these topics and adapt your safety discussions accordingly to best suit your workforce. As you can see, short safety talks are ideal for covering a health and safety concern of this kind in a way that is efficient, informative and as useful as possible for your workforce.

How Should You Document Safety Toolbox Topics?

Different document types have their own strengths and weaknesses. So, it’s worth considering what would be the right format to deliver your chosen topic.

In the table below, we’ve listed the document types that you can typically use, alongside their plus points and drawbacks.

How Often Should You Conduct Safety Talks?

In an ideal world, safety talks should take place daily. But this may be an unrealistic goal due to a Safety manager’s ever-increasing responsibilities. So, a good aim would be 3-5 short workplace safety topics a week. If your team is going through a busy period, you can also decide cut down the time that these talks last for. You can always find the time for a super quick 1-minute safety topic.

Where Should Safety Talks Be Conducted?

You should base these safety minutes in a place where everyone feels at-ease, while still firmly focused on what you’re saying. With this in mind, you could choose to have your next safety talk take place in a comfortable meeting room, a break room, or even the work area itself.

You don’t need to have a fixed location for these talks, either. The aim is to make them feel more informal and personal than a typical meeting. You can pick the location with the topic in mind. For example, if you’re talking about food allergies, the break room would make the message of your talk directly applicable to the day-to-day activities of your workers.

What Else Can You Do to Have a Better Safety Meeting?

Getting workers to listen for the entire duration of the talk is a challenge in itself. Not to mention getting them to actively relate to and understand the topic and then being able to apply the message to their own workplace behaviors.

To make your talk more engaging, try to interact with your audience directly. Encourage their participation, questions and feedback. Show them that this is not a lecture; it is a dynamic conversation that is taking place between the team as a whole. This way, you are helping to create a team that places the highest importance on keeping their operations as safe as possible.

Who Should Present a Safety Talk?

Normally, this would be the job of the team’s EHS manager. The presenter should be the individual who reports any incidents to OSHA. This way, it is the team member who is most well-versed in these topics who is delivering the content.

Does OSHA Require Toolbox Talks?

No. These talks are not a legal requirement of OSHA. The agency does not have a fixed standard in which safety training information needs to be communicated to a workforce. However, toolbox talks are a highly recommended way to advance your workplace’s health and safety beyond the bare minimum. Plus, the flexibility of these talks allows you to branch out beyond the topics that OSHA requires you to cover.

By incorporating regular safety talks into your workplace routines, you are putting your workforce in the best position to minimize preventable workplace accidents. Dedicating just a couple of minutes each day to a short safety moment will ensure maximum engagement in the topics being covered.

Also, these short safety topics for work help your team’s attitude towards health and safety and help improve your safety culture overall. This is far more intuitive and considerate than what could be achieved by a long meeting spent reading from a binder.

Additional Safety Moment Resources

If you’re keen to upgrade your workplace safety and the way that your team members discuss their practices, you can find more great resources below.

- Safety tips from eSafety : 8 Workplace Safety Tips Every Employee Should Know

- OSHA, Safe + Sound : Better Safety Conversations

- OSHA’s Safety Training page

- NSC : 2 Minute Safety Videos

- OSHA’s Training Requirements

Related Posts

8 important march 2023 safety topics to cover + spring safety tips, 7 interesting february safety topics to cover in 2023, 8 december safety topics for a safer holiday season at work.

Type above and press Enter to search. Press Esc to cancel.

Your cart is empty

Use this bar to show information about your cookie policy.

Free Safety Training PowerPoints

Here is a directory of free safety training PowerPoints. These are not owned or endorsed by Affordable Safety Training LLC. Use them at your discretion.

Free Safety Training Power Points

Aerial Lift PowerPoints

Asbestos PowerPoints

Bloodborne Pathogens PowerPoints

Confined Spaces PowerPoints

Construction PowerPoints

Crane and Rigging Safety PowerPoints

Driving Safety PowerPoints

Electrical PowerPoints

Excavation and Trenching PowerPoints

Fall Protection PowerPoints

Forklift Operator PowerPoints

Hazard Communication and GHS PowerPoints

Heat Stress PowerPoints

Hydrogen Sulfide PowerPoints

Ladder Safety PowerPoints

Lockout Tagout PowerPoints

Machine Guarding PowerPoints

Mine Safety PowerPoints

Recordkeeping PowerPoints

Respirator Safety PowerPoints

Scaffolding PowerPoints

Scissor Lift PowerPoints

Silica PowerPoints

Tractor Safety PowerPoints

A short sentence describing what someone will receive by subscribing

Downloadable Videos

Compliance Kits Can Be Downloaded

30 Day Money Back Guarantee

Not Satisfied? Let Us Know For A Full Refund

Expert Owned

Certified Safety Experts

Secure payments

Payment Information Not Stored

- Opens in a new window.

Home PowerPoint Templates Safety

Safety Presentations for PowerPoint and Google Slides

Our innovative Safety Slide is key for creating engaging and impactful safety presentations effortlessly. With this powerful template, you can communicate crucial precautions and safety measures to your audience. No more hassle designing or preparing complex slides – we have streamlined the process for you, ensuring clear and concise visuals that leave a lasting impression.

You can use our 100% editable Safety Slide to give your presentations a personal touch. They are easily downloadable, and you can quickly edit the placeholder with your plan to suit your presentation content. It saves time, energy, and resources, making your presentation unique. Download our Safety Slide now and captivate your viewers with a presentation that speaks volumes.

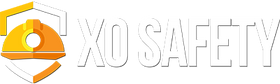

Incident Report PowerPoint Template

HSE PowerPoint Template Diagram

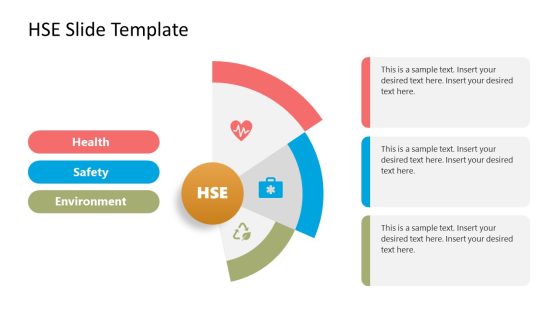

Safety Rules PowerPoint Template

Exit Sign PowerPoint Template

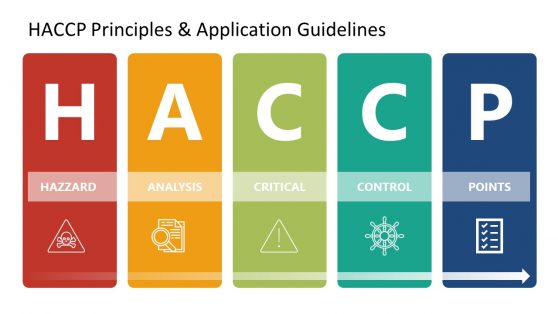

HACCP Principles and Application PowerPoint Template

Coronavirus Safety and Symptoms PowerPoint Template

Safety Equipment PowerPoint Template

Work After COVID-19 PowerPoint Template

Security Agency PowerPoint Template

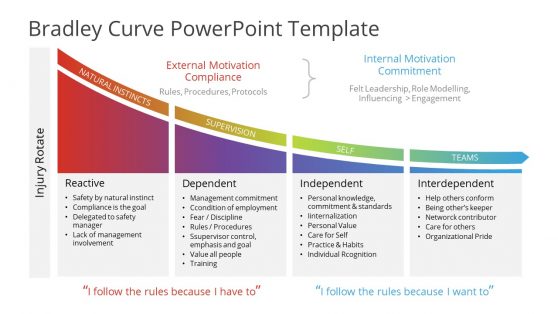

Bradley Curve PowerPoint Template

Animated Safe Shapes Template for PowerPoint

Safety means protection from harm, danger, or injury. It’s about minimizing or eliminating potential risks to keep people, property, and the environment safe. Our templates help educate your audience about hazards and provide guidelines.

Our Safety Slide PowerPoint Template is a creative tool for presenting safety rules. These rules guide risk control and protection for processes, personnel, and equipment. Defining specific rules is crucial before implementing standard protocols. Our templates benefit professionals like doctors, engineers, teachers, and more.

These templates are perfect for training, workshops, and business presentations; this versatile slide enhances safety awareness. Engage your audience with graphics and easy-to-understand content, promoting a culture of safety and security.

These templates come in various colors, fonts, icons, images, and diagrams, suitable for formal and informal settings across industries. They work on Mac and Windows, Keynote, and Google Slides. Download, customize, and captivate your audience, concluding your presentation with applause.

What Is A Safety Slide Template?

A Safety Slide Template is a pre-designed PowerPoint slide created to convey safety-related information or guidelines to your audience. It serves as a visual aid in safety presentations, training sessions, or any context where promoting safety awareness and practices is essential.

What Should A Safety Presentation Include?

A Safety Presentation should include the following key elements:

- Introduction

- Safety Policies

- Hazard Identification

- Safety Tips

- Emergency Procedures

- Safety Equipment

- Case Studies

- Q&A Session

Why is a safety presentation important?

A safety presentation is crucial to raise awareness about potential hazards and best practices in promoting a safe working environment. It helps educate employees or individuals on safety protocols, reducing the risk of accidents, injuries, and property damage. Prioritizing safety fosters a culture of responsibility and care within an organization or community.

How Do You Create A Safety Slide In PowerPoint?

To create a safety slide in PowerPoint, you should follow the below-listed steps:

- Open the PowerPoint software and select a slide layout that is suitable for you.

- Add a clear title that reflects the slide’s purpose, such as “Safety Guidelines” or “Safety Tips.”

- Organize the safety information using bullet points.

- Enhance the slides using relevant images or icons to represent safety concepts while maintaining a consistent color scheme.

- Use icons and limit the text to avoid overcrowding.

- Optionally, add subtle transitions or animations for a smoother presentation.

The goal of using a Safety Slide is to communicate essential safety guidelines and encourage your audience to prioritize safety in their actions and decisions.

Can I Customize the Safety Slide Template to Suit my Organization’s Needs?

Yes, the safety slide template in PowerPoint is 100% editable. You can modify the content, layout, colors, and visuals to align with your organization’s safety policies and branding. Customizing the template allows you to tailor the safety presentation to address unique safety concerns or requirements.

Download Unlimited Content

Our annual unlimited plan let you download unlimited content from slidemodel. save hours of manual work and use awesome slide designs in your next presentation..

An official website of the United States government.

Here’s how you know

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

Occupational Safety and Health Administration

- 中文(简体) (Chinese-Simplified)

- 繁體中文 (Chinese-Traditional)

- Kreyòl ayisyen (Haitian Creole)

- 한국어 (Korean)

- Español (Spanish)

- Filipino/Tagalog

- Tiếng Việt (Vietnamese)

- OSHA Directorate of Training and Education

Training and Reference Materials Library

This library contains training and reference materials as well as links to other related sites developed by various OSHA directorates.

Workplace Safety and Health Topics

Training Materials

- 29 CFR 1926.1101 - OSHA's Asbestos Standard for the Construction Industry . OSHA Slide Presentation, 80 slides.

- Significant Changes in the Asbestos Standard for Construction 29 CFR 1926.1101 . OSHA.

- Significant Changes in the Asbestos Standard for General Industry, 1910.1001 (through June 29, 1995) . OSHA.

Additional Resources

- Asbestos . OSHA Safety and Health Topics Page.

Bloodborne Pathogens

- Bloodborne Pathogens [ ZIP ]. OSHA.

- Bloodborne Infectious Pathogens HIV/AIDS, Hepatitis A, Hepatitis B and Hepatitis C Virus . National Institute of Occupational Safety and Health (NIOSH).

- Bloodborne Pathogens and Needlestick Prevention . OSHA Safety and Health Topics Page.

Construction

- Construction Hazards Prevention Videos . OSHA v-Tools, (2011, September). A series of 12 videos depicting how quickly workers can be injured or killed on the job. These videos are intended to assist those in the industry to identify, reduce, and eliminate construction-related hazards. Most of the videos are 2 to 4 minutes long, presented in clear, easily accessible vocabulary, and show common construction worksite activities. The videos may be used for employer and worker training. Available in English and Spanish.

- Construction Safety: Choice or Chance . OSHA Video, (2000, April), 15 minutes. A 15 minute video which highlights the four leading causes of fatalities on construction sites and stresses the responsibility for safety as a joint effort of government, management, and employees.

- Instructor Guide [ PDF ]. OSHA.

- Participant Guide [ PDF ]. OSHA.

- Design for Construction Safety PowerPoint [ PPTX ] [ PPT ]. OSHA.

Crane, Derrick and Hoist Safety

- Crane Safety for the Site Superintendent . OSHA Video, (1992), 8 minutes.

- Electrical Discussion . OSHA.

- Electrical [ ZIP ]. OSHA.

- Controlling Electrical Hazards [PDF]. OSHA Publication 3075.

- Electrical . OSHA Safety and Health Topics Page.

- Electrical . Safety and Health Topic. National Institute for Occupational Safety and Health (NIOSH).

- Electric Power Generation, Transmission, and Distribution Industry . OSHA Safety and Health Topics Page.

- Ground-Fault Protection on Construction Sites [ PDF ]. OSHA Publication 3007.

- Ergonomic Programs that Work . OSHA Video, (1998), 21 minutes.

- Fireworks Safety . OSHA Video, 32 minutes.

Flammable Liquids

- Flammable Liquids Introduction [ PDF ]. OSHA.

- Flammable Liquids [ PPTX ] [ PPT ]. OSHA.

- Lesson Plan [ PDF ]. OSHA.

Industrial Hygiene

- Industrial Hygiene Overview . OSHA.

- Examining Fatal Shipyard Accidents . OSHA Video, (2005). A two volume series of 16 short videos intended to raise industry awareness of the hazards specific to shipyard work environments. Each video provides accident examinations and discusses factors contributing to the fatalities.

Most Frequently Cited

FY 2023 Most Frequently Cited Violations in:

- Construction Industry [ PPTX ] [ PDF ]. OSHA.

- General Industry [ PPTX ] [ PDF ]. OSHA.

- Maritime Industry [ PPTX ] [ PDF ]. OSHA.

Nail Salons

- Health Hazards in Nail Salons Presentation [ PPT ]. OSHA Slide Presentation, 12 slides.

Nationally Recognized Testing Laboratories

OSHA developed this slide presentation for its compliance officers (CSHOs). However, the information contained in the slides can help employers and workers better understand certain product-approval requirements in OSHA safety standards. The products affected by these requirements must be approved (i.e., tested and certified) to help ensure they can be used safely. Moreover, they must be tested and certified by an organization recognized as an NRTL by OSHA. There are only infrequent exceptions to these requirements.

In order to ensure that the testing and certification has been done appropriately, OSHA has implemented the NRTL Program. The NRTL Program establishes the criteria that an organization must meet in order to be recognized as an NRTL by OSHA.

- Nationally Recognized Testing Laboratories . OSHA Safety and Health Topics Page.

Nursing Homes

- Benefits of Implementing a Safe Resident Handling Program in Nursing Homes . OSHA Slide Presentation, 18 slides.

- Implementing a Safe Resident Handling Program in Nursing Homes . OSHA Slide Presentation, 18 slides.

- Employers Rights and Responsibilities Following an OSHA Inspection [ PDF ]. OSHA Publication 3000.

- Employee Workplace Rights [ PDF ]. OSHA Publication 3021.

- Nursing Homes and Personal Care Facilities . OSHA Safety and Health Topics Page.

- Successful Approaches to Reducing Occupational Musculoskeletal Disorders (MSDs) Within the Healthcare Industry . OSHA.

OSHA Standards

- Training Requirements in OSHA Standards [ PDF ]. OSHA Publication 2254.

- Most Frequently Cited OSHA Standards . OSHA

Personal Protective Equipment (PPE)

- Assessing the Need for PPE (Discussion) . OSHA.

- Personal Protective Equipment [ ZIP ]. OSHA.

- Chemical Protective Clothing . OSHA Technical Manual.

- Construction, Personal Protective Equipment . OSHA Safety and Health Topics Page.

- Personal Protective Equipment . OSHA Safety and Health Topics Page.

- Personal Protective Equipment [PDF]. OSHA Publication 3151.

- Protective Clothing . National Institute for Occupational Safety and Health (NIOSH).

Powered Industrial Trucks

- OSHA Standard [ 1910.178(l) ]. OSHA.

- General Industry . OSHA.

- Construction Industry . OSHA.

- Maritime Industry . OSHA.

- Maintenance . OSHA.

- Standard Requirements . OSHA.

- Selected Forklift Fatalities Summary [ PDF ]. OSHA.

- Powered Industrial Trucks . OSHA eTool

- Powered Industrial Trucks (Forklifts) . OSHA Safety and Health Topics Page.

- Introduction to Ionizing Radiation . OSHA Slide Presentation, (2001), 54 slides.

- Non-Ionizing Radiation: Standards and Regulations . OSHA Slide Presentation, (2002), 141 slides.

- OSHA Regulation for RF Radiation Exposures . OSHA Slide Presentation, (1995), 16 slides.

- OSHA Requirements for Tower Construction Related to RF Radiation . OSHA Slide Presentation, (1999), 42 slides.

- Suggested Update to RF Standards Related to Wireless Communications . OSHA Slide Presentation, (2001), 90 slides.

- Update of RF Radiation Protection Standards . OSHA Slide Presentation, (1999), 29 slides.

- Introduction to Laser Safety . OSHA Slide Presentation, (2001), 48 slides.

Recordkeeping

- Federal Agency Injury and Illness Recordkeeping and Reporting Requirements . OSHA Slide Presentation, 72 slides.

- Recordkeeping . OSHA Safety and Health Topics Page.

- Recordkeeping Training Presentations . OSHA.

Respiratory Protection

OSHA's Respiratory Protection Standard, 29 CFR 1910.134, applies to general industry, construction, shipyards, marine terminals, and longshoring.

OSHA's Office of Training and Education has prepared the following outreach training materials for OSHA's respirator standard:

- PowerPoint presentation of 29 CFR 1910.134

- Major Requirements of 29 CFR 1910.134

- Frequently Asked Questions

Links to additional resources for respiratory protection are also given below.

- Respirator Standard . OSHA Slide Presentation, 68 slides.

- Major Requirements of OSHA's Respiratory Protection Standard . OSHA.

- Frequently Asked Questions . OSHA.

- Respiratory Protection Videos . OSHA, (2012, January). A series of 17 videos to help workers learn about the proper use of respirators on the job. These short videos, nine in English and eight in Spanish, provide valuable information to workers in general industry and construction. Topics include OSHA's Respiratory Standard, respirator use, training, fit-testing and detecting counterfeit respirators.

- Respirator Change-Out Schedules . OSHA.

- Respiratory Protection . OSHA eTool.

- Respiratory Protection . OSHA Safety and Health Topics Page.

- Small Entity Compliance Guide . OSHA Publication.

Scaffolding

The following materials based on the Notice of Final Rule, Subpart L-Scaffolds which was effective on November 30, 1996.

- Safety Standards for Scaffolds Used in the Construction Industry (Summary) . OSHA.

- Scaffolding: 1926.450 - Subpart L . OSHA Slide Presentation, 50 slides.

- A Guide to Scaffold Use in the Construction Industry . OSHA Publication 3150.

- Scaffolding . OSHA Safety and Health Topics Page.

- Scaffolding . OSHA eTool.

Severe Acute Respiratory Syndrome (SARS)

- SARS: Protecting Workers . OSHA Slide Presentation, (2002), 18 slides.

- Silica, Crystalline . OSHA Safety and Health Topics Page.

- Certified B Readers List . Docket #085, (2006, May 22).

- Preventing Silicosis and Deaths in Rock Drillers . Publication No. 92-107, (1992, August)

- Preventing Silicosis and Deaths From Sandblasting . Publication No. 92-102, (1992, August).

- Publications - Silica (By Industry)

- Silica . Safety and Health Topic.

Tuberculosis

Tuberculosis (TB) is the leading cause of death due to an infectious agent in the world. Since 1985, the incidence of TB in the general U.S. population has increased 14 percent, reversing a 30-year downward trend. Outbreaks have occurred in hospitals, correctional institutions, homeless shelters, nursing homes, and residential care facilities for AIDS patients. Specific control measures recommended by the Centers for Disease Control and Prevention and required by OSHA has contributed to a drop in TB cases in 1994 and 1995.

In February 1996, OSHA issued CPL 2.106, Enforcement Procedures and Scheduling for Occupational Exposure to Tuberculosis to protect workers against the hazards of TB.

- Enforcement Procedures and Scheduling for Occupational Exposure to Tuberculosis . OSHA Instruction CPL 02-02-078.

- Hospital: Tuberculosis Module . OSHA eTool.

- Tuberculosis . OSHA Safety and Health Topics Page.

Workplace Violence

Workplace violence has emerged as an important safety and health issue in today's workplace. The Occupational Safety and Health Administration's (OSHA's) response to the problem of workplace violence in certain industries has been the production of OSHA's guidelines and recommendations to those industries for implementing workplace violence prevention programs.

In 1996, OSHA published Guidelines for Preventing Workplace Violence for Health Care and Social Service Workers. The guidelines are based on OSHA's voluntary generic Safety and Health Program Management Guidelines.

In 1998, OSHA published Recommendations for Workplace Violence Prevention Programs in Late-Night Retail Establishments. The recommendations are based on OSHA's 1989 voluntary generic Safety and Health Program Management Guidelines.

- Guidelines for Preventing Workplace Violence for Health Care & Social Service Workers [ PDF ]. OSHA Publication 3148.

- Recommendations for Workplace Violence Prevention Programs in Late-Night Retail Establishments [ PDF ]. OSHA Publication 3153.

- Workplace Violence . OSHA Safety and Health Topics Page.

Researched by Consultants from Top-Tier Management Companies

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

[Updated 2023] Top 15 PowerPoint Templates to Improve Work Safety

![short safety presentation slides [Updated 2023] Top 15 PowerPoint Templates to Improve Work Safety](https://www.slideteam.net/wp/wp-content/uploads/2021/03/06_1013x441-1011x441.png)

Kritika Saini

1974: The Flixborough disaster, UK’s worst industrial accident. The explosion at the chemical plant killed 28 workers in North Lincolnshire. Almost all the buildings in the neighborhood flattened, further injuring 36 people due to the blast. Multiple investigations exposed that the plant was hastily executed with certain modifications that forged the leak of liquid from one of the plant’s reactors. This led to the creation of flammable hydrocarbons that eventually exploded.

1984 : Bhopal gas tragedy, one of the worst industrial accidents in India. Due to the negligence of 7 employees, more than 5 lakh people were exposed to the lethal methyl isocyanate. About 3,787 people died the same night, and further 8,000 people passed away as a result of the exposure subsequently.

2013: West Fertilizer Company explosion. A routine fire in Texas turned into a local disaster when the fertilizer stored on the site exploded. 12 firefighters and 3 civilians were killed, a majority of them were trying to bring the flare under control. Further, 160 people were injured and around 150 buildings collapsed due to the blast. Later, an investigation revealed that the company had been illegally storing 55 tons of ammonium nitrate on-site, along with a further 55 tons of anhydrous ammonia.

Whether as a result of the disasters mentioned above or on an individual basis, workplace accidents have the potential to alter ordinary people’s lives. An estimate of 2 million men and women die every year due to work-related accidents and diseases. Thus, the spotlight is on the importance of safer design and construction of workplaces; maintenance of site safety; dangers posed to public members, and adherence to legal guidelines for secure storage of dangerous materials.

No business wants their employees to get hurt on the job. Therefore, employers are obliged to provide a safe working environment for their workers. But for those of you who haven’t dealt with safety, let us first understand its meaning.

The gist of work safety

Work safety is the concept that business organizations must implement to recognize hazards in the workplace. It refers to the working environment at a company encompassing the factors that impact all employees’ safety, health, and well-being.

Despite the number of safety guidelines you set in place, it will be of no use if your employees are not aware and invested in following them. Therefore, to help you create a successful safety program, we are sharing five security tips. We have also included the top 15 meticulous work safety templates that can be used for raising awareness on safety protocols among employees.

1. Invest in training

When it comes to workplace safety, there is no better solution than training. It will help you create protocols and ask your workforce to follow them to the letter. Provide your employees with all the necessary information and measures to stay safe. In fact, you can also use the online platform for providing training to avoid any wastage of time. Share the updated training courses with your employees using these well-structured template designs.

Template 1

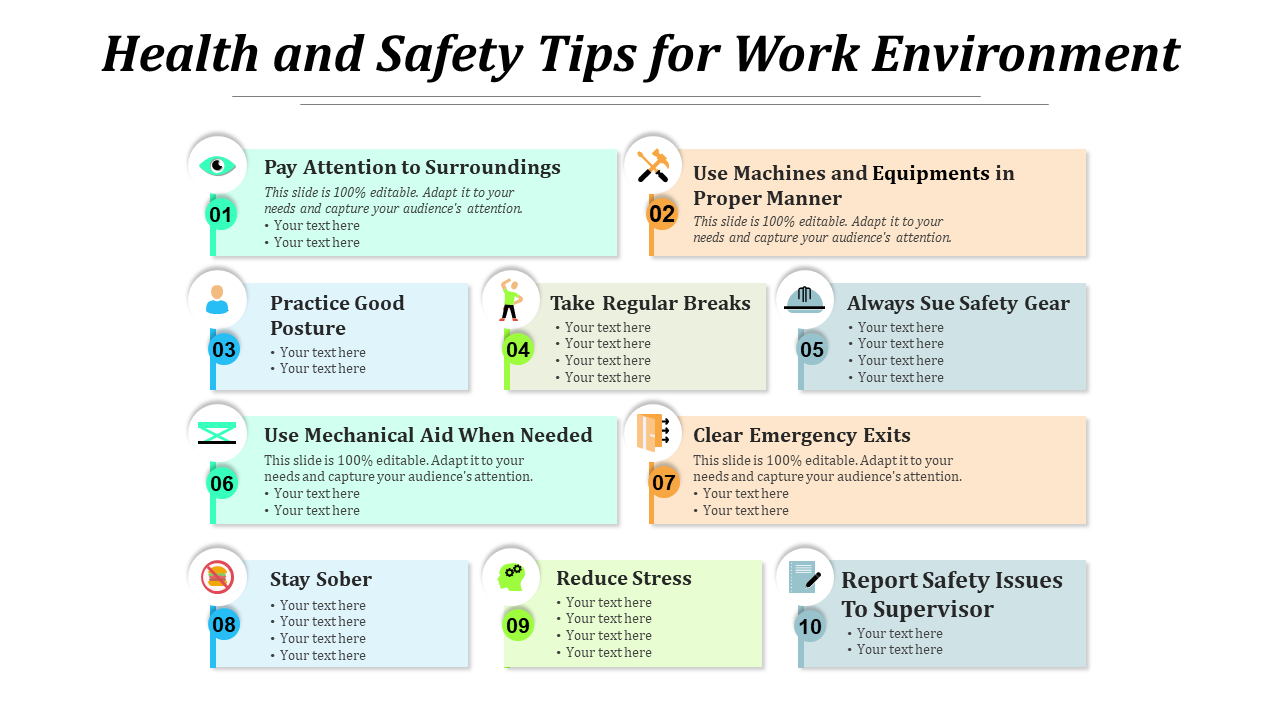

Safety in the workplace is critical for many business KPIs. Therefore, with this template design, you can highlight key areas of improvement such as safety training, tools knowledge, health, protection, and more. So download and edit it as per your working environment.

Download Key Areas To Improve Work Safety

Pick this template to provide a ground for exchanging ideas and data related to the broad field of health and safety in your organization. Help your management understand that an injury and accident-free environment increases the productivity of employees.

Download Safety And Health At Work PPT PowerPoint Presentation

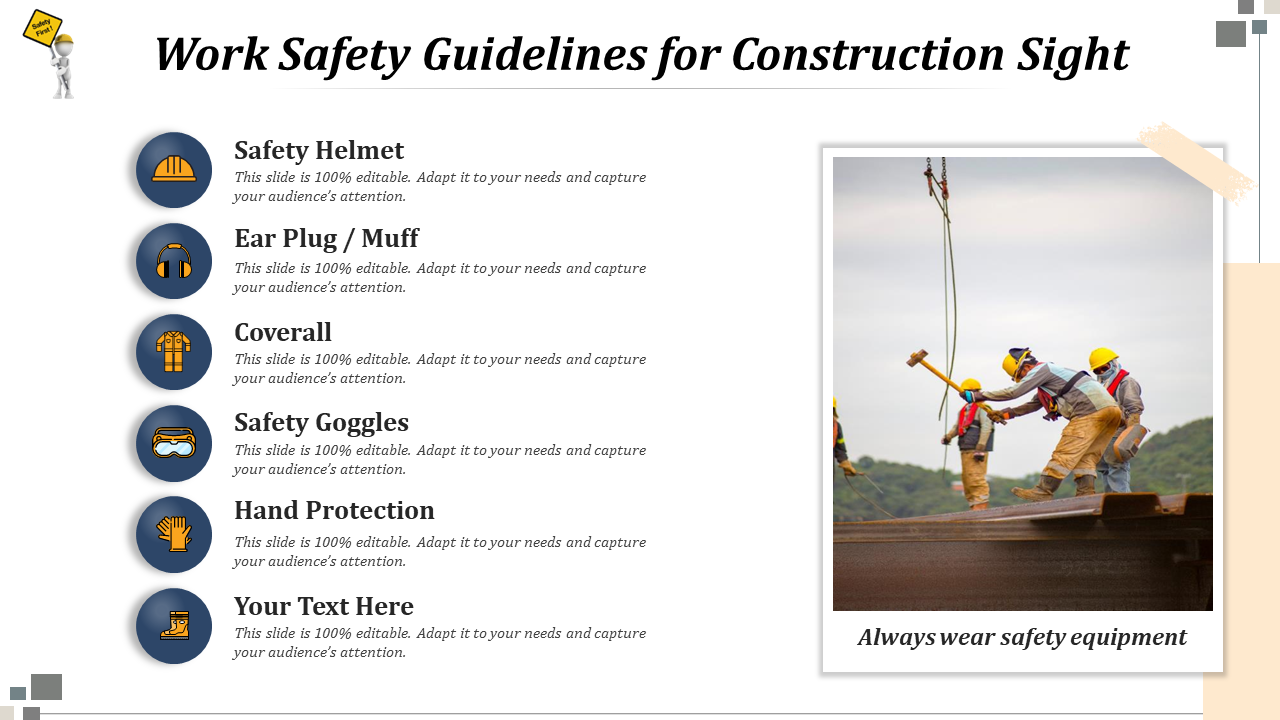

According to an estimate of occupational safety and health administration, nearly a quarter of all work-related fatalities occur on construction sites. Therefore, you can utilize this template to draft safety guidelines for your construction business. Download this design and reduce the risk of deaths and injuries.

Download Work Safety Guidelines For Construction Sight

2. Provide clear instructions

The instructions should be in the form of labels and signs, not wordy and hard to understand. They should be handy and rely on pictures to highlight hazards and procedures. Therefore, it is advised to try and test them before they go “live”. Check out our best work safety templates to assist your endeavors.

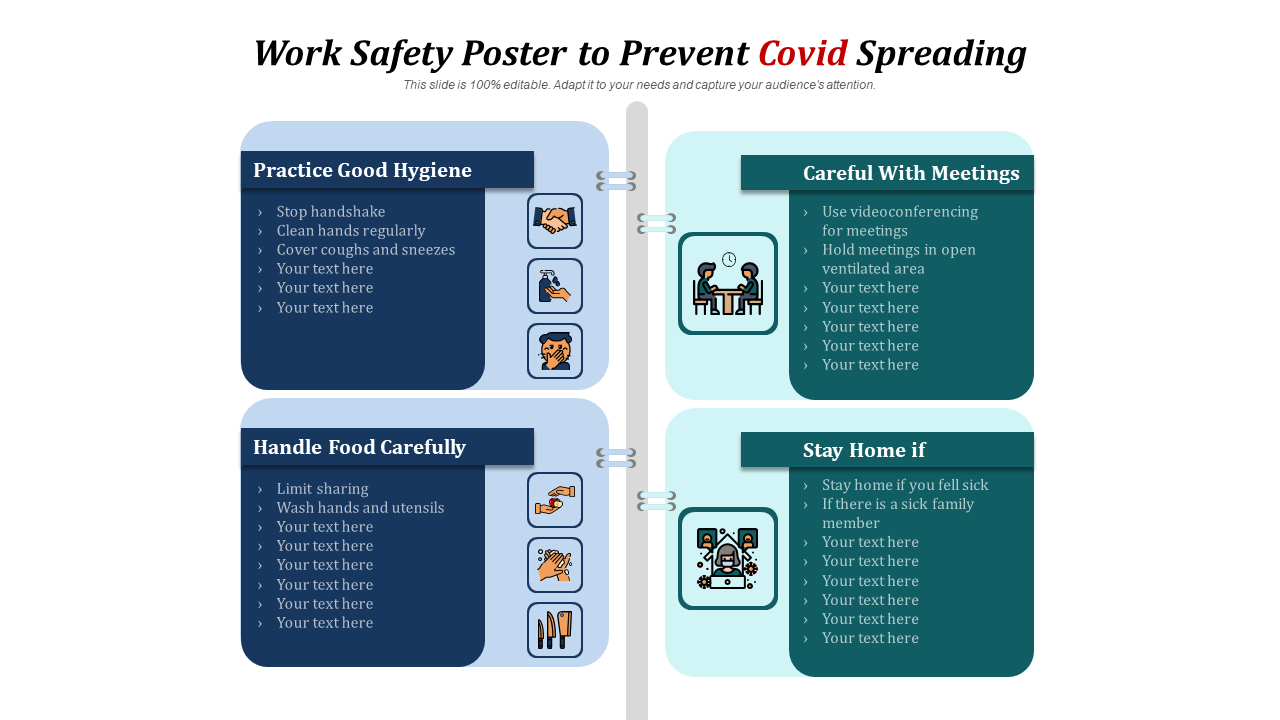

Select this innovative work safety template to support awareness and actions for preventing the spread of COVID-19. To increase productivity and revenue, every business needs specific preventive measures. Therefore, download, edit, and present!

Download Work Safety Poster To Prevent Covid Spreading

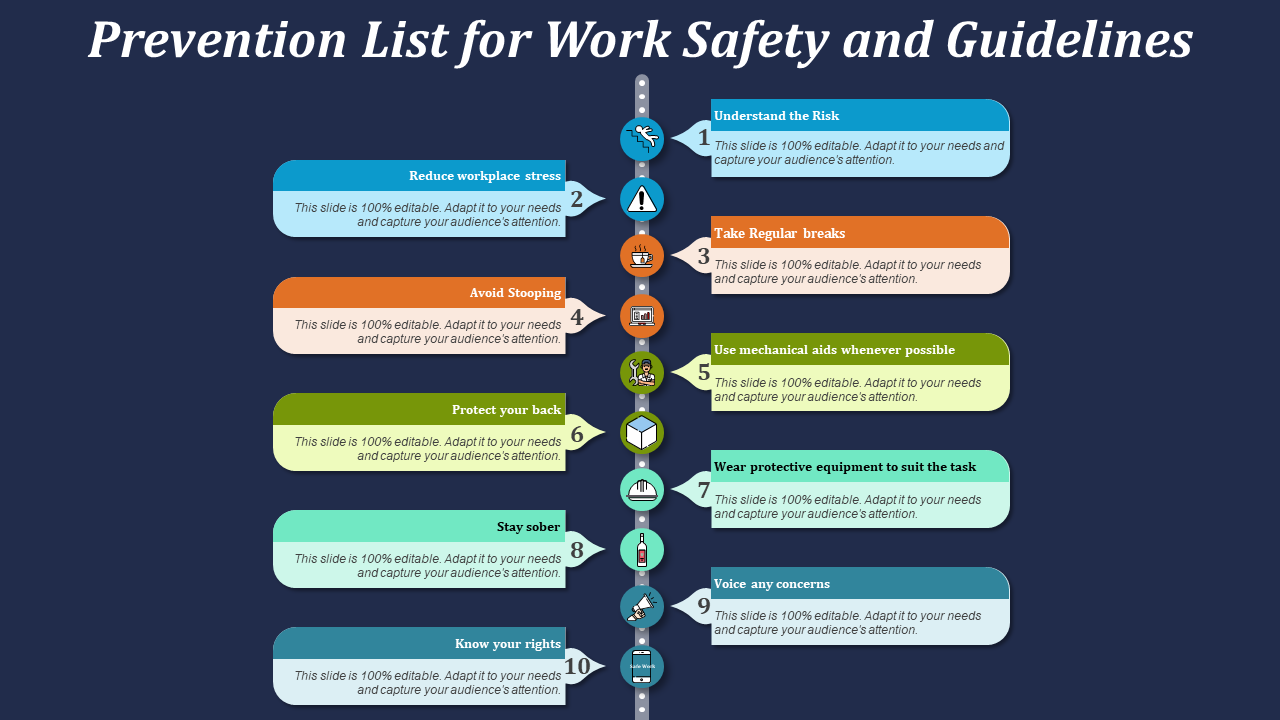

Safety guidelines are critical for all organizations. Pick this template to share a prevention list with your employees. Help them understand that their negligence can put other co-workers at risk. Download and use it multiple times.

Download Prevention List For Work Safety And Guidelines

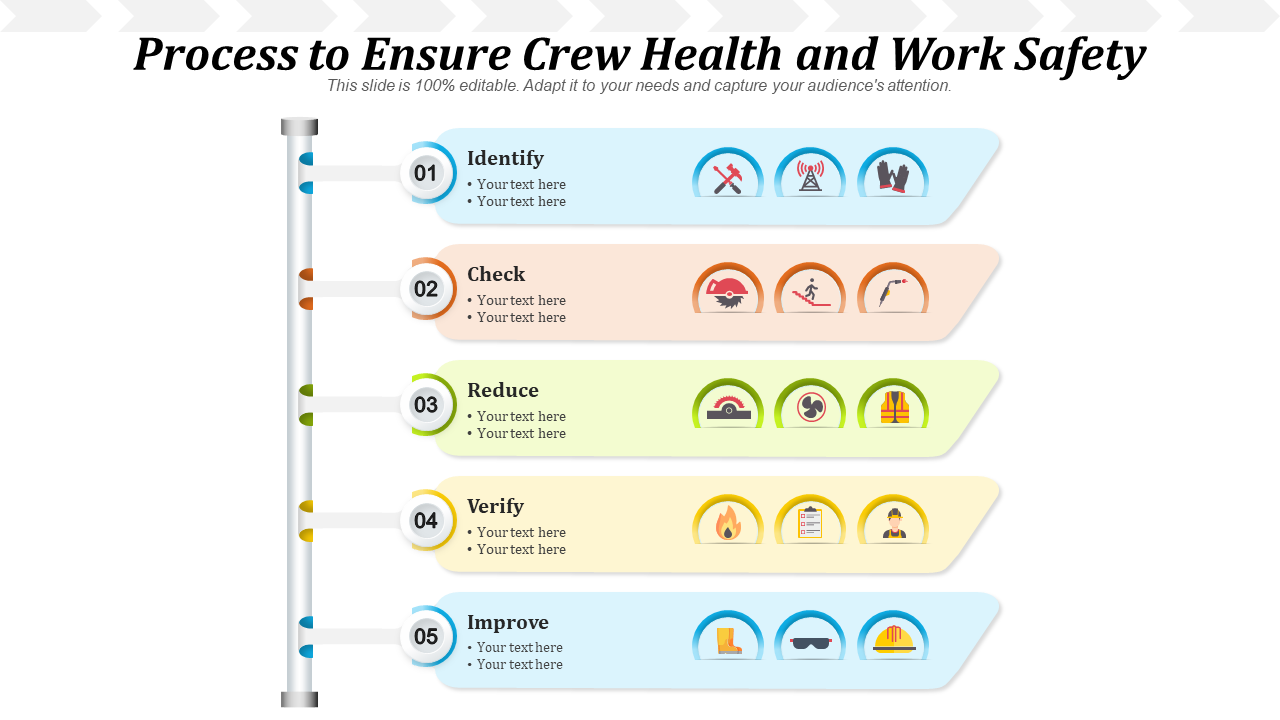

Hazard identification, assessment, and control are paramount for the smooth functioning of all organizations. With this crew safety template, you can develop a robust process to prevent people and materials from getting demolished. Download and edit it conveniently.

Download Process To Ensure Crew Health And Work Safety

3. Understand responsibility

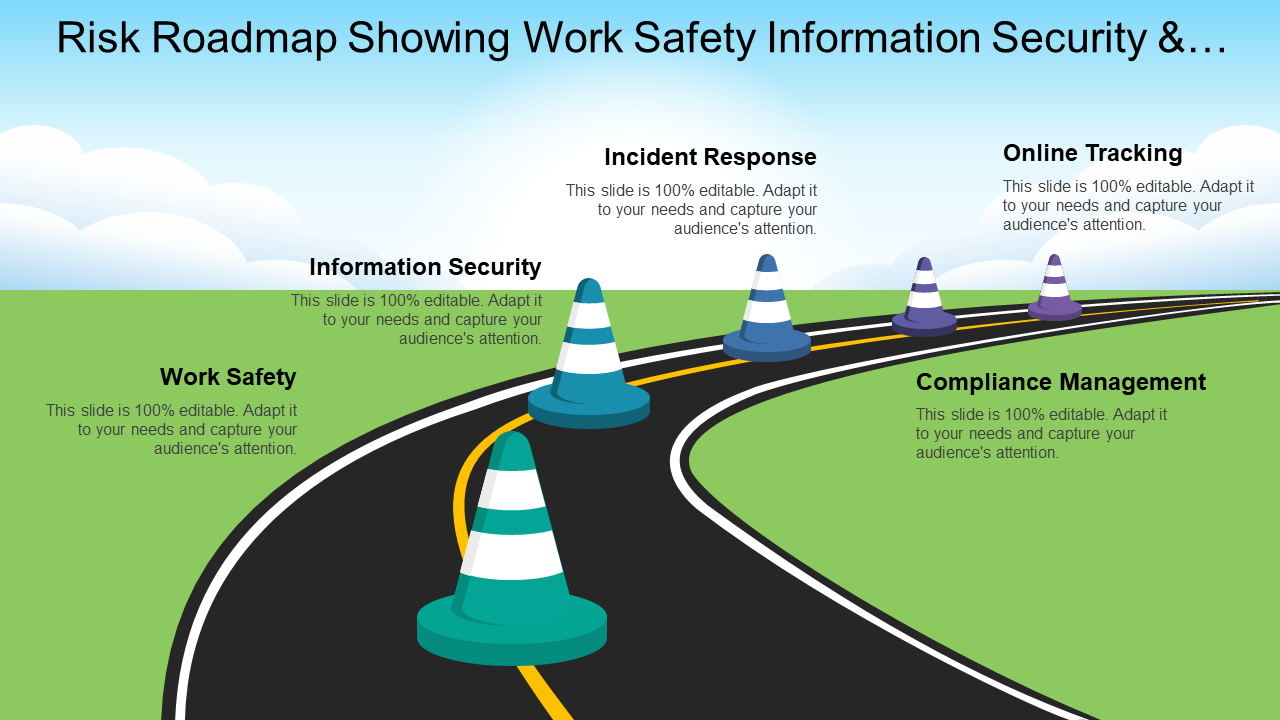

This well-structured template can be used to quickly respond and mitigate the impact of a suspected security breach. So take advantage of this design to create an effective risk roadmap for your business.

Download Risk Roadmap Showing Work Safety Information Security And Incident Response

Your safety is your personal responsibility! Pick this template and share such general precautions with your workforce. The template can be easily edited. So download and utilize it in any safety program presentation.

Download Men At Work Road Safety Regulation Templates

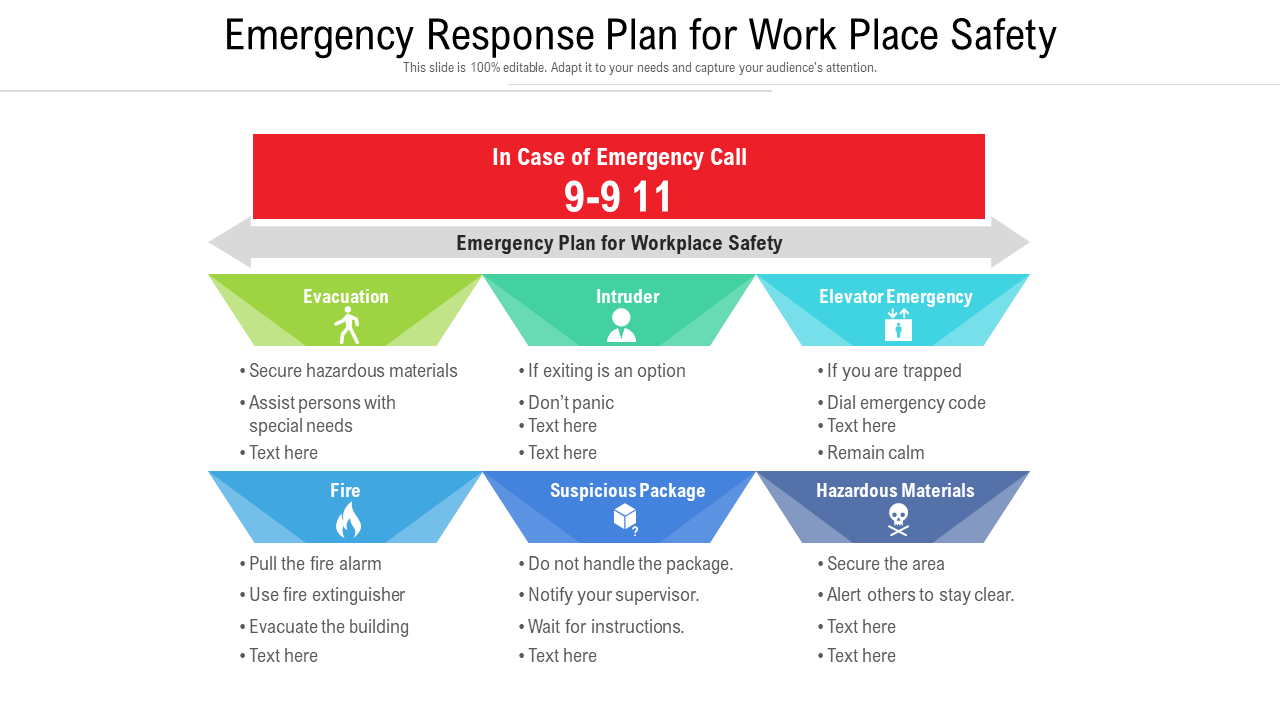

Accelerate the resumption of normal operations by employing this emergency response plan template. Include the procedures necessary during a crisis, set clear roles and responsibilities, and establish instructions for local emergency response. The template is easy to edit. So grab it right away!

Download Emergency Response Plan For Work Place Safety

4. Partner with clinicians

Occupational clinics can provide valuable insights into workplace injury and prevention. Therefore, appoint them to visit your worksites and identify areas of high risk for employees. They can help you screen candidates for physically challenging roles and aid in the work processes. Sketch out a performance evaluation blueprint with these well-crafted templates.

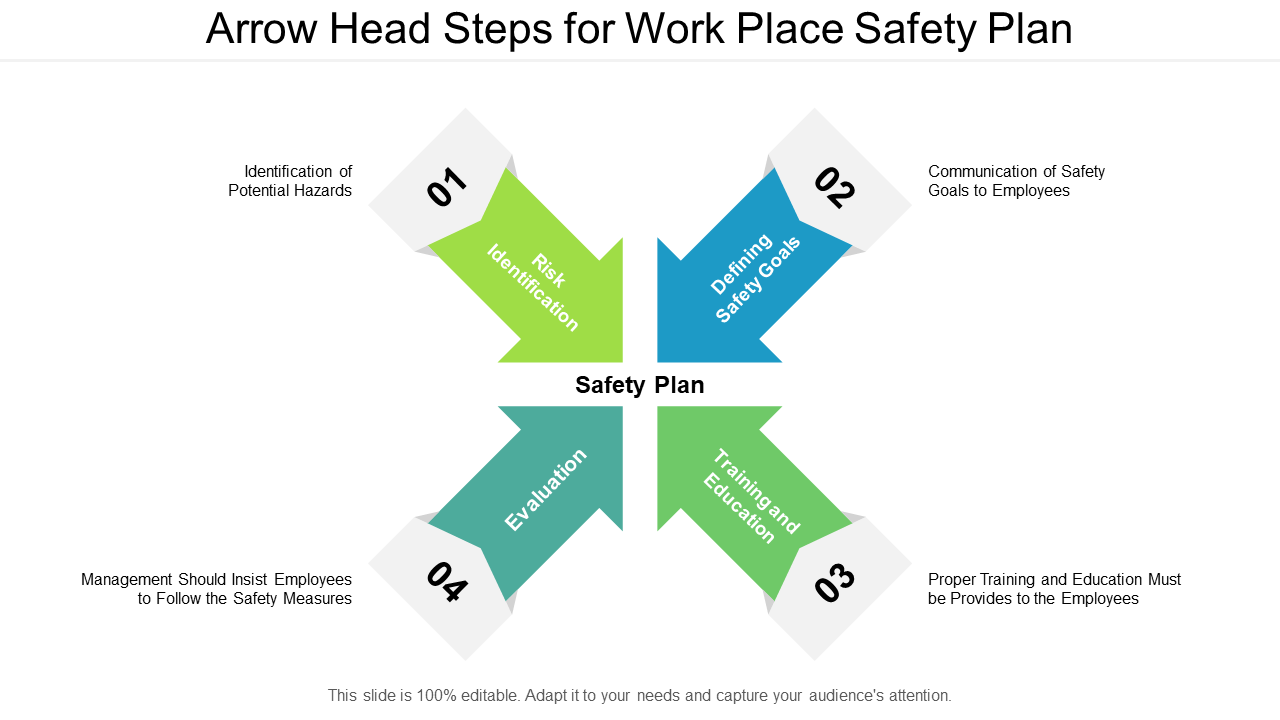

Business operations come with multiple risks. Hence, being safe and healthy at the workplace is imperative. Download this visually appealing template to protect your business and employees from stressful situations.

Download Arrow Head Steps For Work Place Safety Plan

Choose this template to ensure that your workers feel safe while operating in the facilities. Utilize it to create an organized safety management system that also complies with the local health and safety standards. The template already includes certain safety tips. Therefore, download and use it at your convenience.

Download Health And Safety Tips For Work Environment

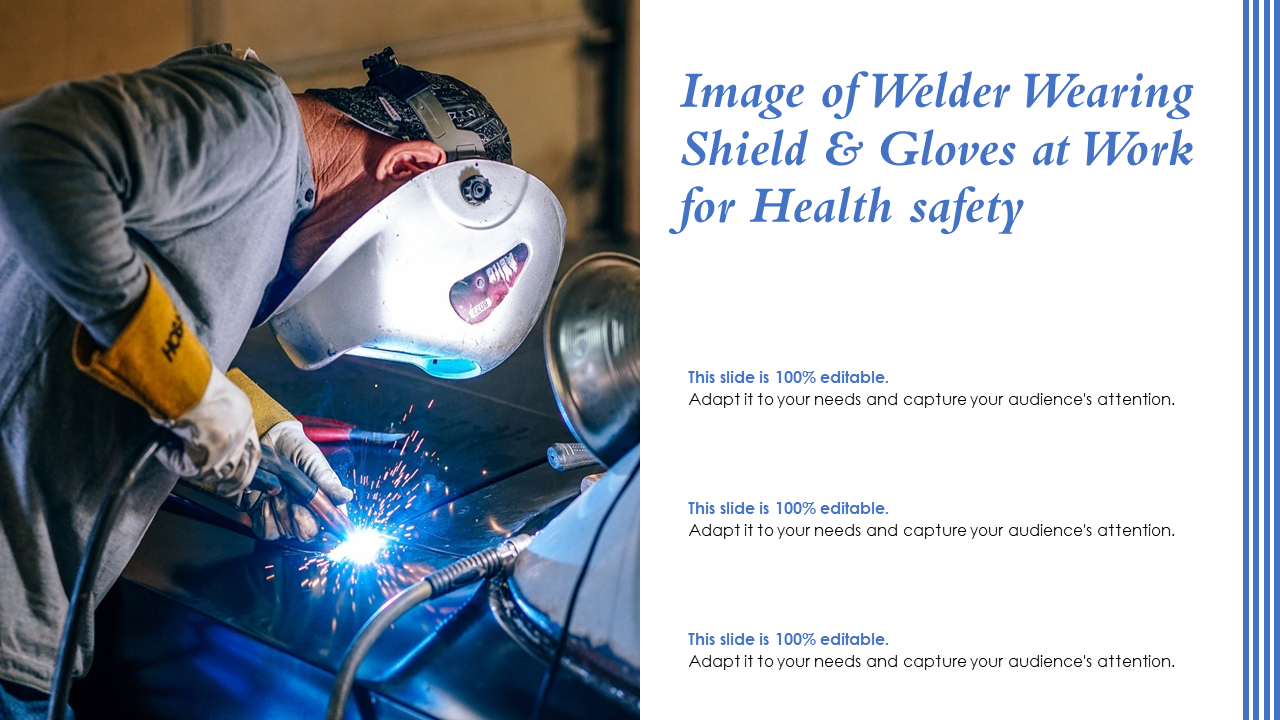

While resistance welding or brazing, the operators must use safety shields and goggles, depending on the job, to protect their eyes and face from any hazard. Pick this well-crafted template and encourage them to take extra protection from any hazardous condition.

Download Templates Of Welder Wearing Shield And Gloves At Work For Health Safety

5. Encourage stretch breaks and regular meetings

Allow your employees to take stretch breaks because even a five-minute break can release muscle tension, loosen joints, and reduce the potential repetitive motion injuries. Besides, you should conduct regular meetings to review safety standards and rules. It doesn’t hurt to be prepared. Select from these invigorating templates and ensure if something wrong happens, everyone knows what to do.

Create a full-fledged manual for implementing safety precautions within your organization using this PowerPoint Template. Determine your primary objectives of safety toward your employees, followed by a framework on how you plan to implement it. Assemble all possibilities of health and safety tips and highlight work areas that in particular require attention. Specify health and safety tips for all departments under your organization and create a safe space for your employees by planning it with this editable PPT Template.

Download Work Safety Planning PowerPoint Template

This is yet another off-the-rack safety and health template slide. You can use it to elucidate the potential hazards of your industry. Share appropriate measures and steps to be taken in such situations. So download and prioritize safety.

Create an invigorating workplace safety plan that provides a two-fold system of ensuring employee safety. Besides, you can also take advantage of the smart art given in the template and design a framework for policies and procedures to make safety a top priority. Therefore, grab it immediately!

Download Employee Health And Safety Planning Process At Work

Safety training begins with leadership. Pick this template and help your management design committed safety policies. Explain your purpose and open up the communication lines between the administrators and workers. So download it and captivate your audience.

Download Developing Safety Training Program Safe Working

Prevention is better than cure! The meaning of safety and employers’ responsibility to prevent injury may vary with different working conditions. But regardless of the work your employees perform, their physical safety should never be out on a limb. Include all the tips mentioned in the blog and hit the health and safety goals of your business.

PS: You can also help your organization avoid potential losses from unpredictable hazards by exploring our top 20 crisis and disaster management templates here.

FAQs on Work Safety

What is workplace safety.

Workplace safety refers to the measures and procedures put in place to ensure the physical and psychological well-being of employees and other individuals in a workplace environment. The primary goal of workplace safety is to prevent accidents, injuries, and illnesses that may occur on the job, and to promote a culture of health and safety within the workplace.

Workplace safety covers a broad range of topics, including but not limited to:

- Hazard identification and risk assessment: identifying potential hazards in the workplace and assessing the risks associated with them.

- Safety policies and procedures: establishing and enforcing policies and procedures to ensure workplace safety, such as emergency evacuation plans, first aid protocols, and safe work practices.

- Training and education: providing employees with the necessary knowledge and skills to work safely, including training on equipment, machinery, and hazardous materials.

- Personal protective equipment (PPE): providing employees with appropriate PPE to protect them from workplace hazards.

- Workplace design: designing workspaces and equipment to minimize the risk of accidents and injuries. Health and wellness: promoting employee health and wellness to reduce the risk of illnesses and injuries.

- Health and wellness: promoting employee health and wellness to reduce the risk of illnesses and injuries.

Overall, workplace safety is an essential aspect of any workplace, and it is the responsibility of employers and employees to ensure that safety protocols are followed and maintained to prevent accidents and injuries.

What are the 7 safety tips?

There are many safety tips that can be applied in different situations and settings, but here are seven general safety tips that can be helpful in various environments:

- Pay attention to warning signs and signals: Be aware of warning signs and signals that indicate potential hazards and follow them.

- Keep emergency exits clear: Make sure emergency exits are clearly marked and free from obstruction.

- Use personal protective equipment (PPE): Wear appropriate PPE such as helmets, goggles, gloves, and safety shoes when working with hazardous materials or equipment.

- Practice good housekeeping: Keep the workplace clean and free of clutter to reduce the risk of slips, trips, and falls.

- Follow safe work practices: Follow established safety procedures and work practices, including using proper lifting techniques and avoiding shortcuts.

- Report hazards and incidents: Report any unsafe conditions, incidents, or injuries to your supervisor or safety team immediately.

- Take care of yourself: Take care of your physical and mental health to ensure that you are alert and able to work safely. Get enough rest, eat well, and take breaks when needed.

Remember that safety is everyone's responsibility, so be aware of your surroundings, follow safety rules and guidelines, and report any hazards or incidents to ensure a safe workplace for all.

What are the three types of safety?

There are three main types of safety:

- Physical Safety: Physical safety refers to protecting people from physical harm, injury, or illness. This includes protection from hazards such as falls, burns, cuts, and other injuries that may result from workplace accidents or exposure to hazardous substances.

- Psychological Safety: Psychological safety refers to creating a work environment that is free from harassment, discrimination, and other forms of negative behavior that can affect employees' mental and emotional well-being. This includes creating a culture of respect, openness, and inclusivity.

- Cybersecurity Safety: Cybersecurity safety refers to protecting digital assets, including information, data, and systems, from unauthorized access, theft, or damage. This includes protecting against cyber threats such as hacking, viruses, and phishing scams.

All three types of safety are essential in ensuring a safe and healthy workplace for employees and protecting a company's assets and reputation.

Related posts:

- [Updated 2023] Top 20 Crisis and Disaster Management PowerPoint Templates for Organizations to Sail Through!

11 Disaster Management PowerPoint Slides To Help You Prepare For Any Fateful Event

- Top 20 Templates to Present Your Company’s Disaster Management Strategy

- Must Have Emergency Operations Plan Templates with Samples and Examples

Liked this blog? Please recommend us

Top 10 Corporate Training Templates to Upraise Productivity and Employee Satisfaction

2 thoughts on “[Updated 2023] Top 15 PowerPoint Templates to Improve Work Safety”

This form is protected by reCAPTCHA - the Google Privacy Policy and Terms of Service apply.

Digital revolution powerpoint presentation slides

Sales funnel results presentation layouts

3d men joinning circular jigsaw puzzles ppt graphics icons

Business Strategic Planning Template For Organizations Powerpoint Presentation Slides

Future plan powerpoint template slide

Project Management Team Powerpoint Presentation Slides

Brand marketing powerpoint presentation slides

Launching a new service powerpoint presentation with slides go to market

Agenda powerpoint slide show

Four key metrics donut chart with percentage

Engineering and technology ppt inspiration example introduction continuous process improvement

Meet our team representing in circular format

Short Safety Talks: Tips and Ideas to Improve Your Presentations

Delivering short safety talks (commonly known as toolbox talks) is crucial for helping teams work safely. But it’s not easy if you struggle with public speaking (as four in 10 Americans do ) or simply find it hard to keep your audience focused.

And if workers become distracted or ignore your advice, they could be unaware of potential risks or solutions to dangerous problems. That’s why it’s vital that you make your short toolbox talks as engaging and informative as you can.

A good safety talk helps prepare teams for the work ahead, raise awareness of potential risks, and increase their knowledge of what to do in an emergency. Ideally, you’ll combine a powerful short safety topic with captivating delivery that holds workers’ attention and makes them remember it long after it’s over.

In this post, we’ll explore five tips to help you improve your presentation skills and 10 ideas to inspire your talks.

Tips for Clear, Effective, and Engaging Short Safety Talks

Great safety talks could help to reduce the likelihood of injuries in your workplace and create a team who is more conscious of safety. But it’s not just the content that matters: the way you present that content and convey your message to listeners is just as important.

Whether you’re new to the prospect of addressing a team regularly (even daily) or want to improve your talks, these tips will help.

Prepare and Rehearse

Trying to plan relevant short safety topics for toolbox meetings multiple times per week might make the process more intimidating. But if you wing it on the day of, you could fail to make a valuable point and, ultimately, waste everyone’s time.

That’s why it’s best to plan ahead. Even if you only write a list of bullet points instead of your entire speech, you’ll have a general idea of what you plan to cover. If you practice them enough ahead of time, then you won’t even have to look down to remember what your bullets are. (Glancing down repeatedly can make you look ill-prepared, so avoid depending on that sheet of paper in your pocket.)

It’s also critical that you rehearse your talk to confirm that it fits within the usual timeframe, covers important points in enough detail to be of use, and is relevant to the audience and their work.

For example, if you’re planning short safety topics for warehouse workers, ensure your talk is relevant to their tools, machinery, and working conditions. Resist the temptation to repeat a conversation you found online if it’s irrelevant to their day-to-day needs.

Make Eye Contact

Eye contact can help you engage your audience and hold their interest. You may feel uneasy about making eye contact even while discussing short safety meeting topics, particularly if you’re new to a workplace or dread public speaking. But try to meet your audience’s gaze while you deliver your talk casually, so they feel as if you’re speaking directly to them. Keep eye contact brief though. Listeners may be unnerved if you stare at them.

If this is easier said than done, consider speaking to people you don’t work with first. There are organizations that are designed to help you improve public speaking. One example is Toastmasters , which has more than 300K clubs in 149 countries. Whether it’s a corporate club or a community club, joining an organization with people at various levels of public speaking who can help dissect your strengths and areas of improvement can make you a better professional speaker in any setting.

They look for things like crutch words (um, uh, like, so) and pay attention to eye contact, but they do it in a constructive way. The entire point of their organization is to make everyone better. And the more practice you can get, the better you’ll be at short safety talks.

Act More Confident than You Might Feel

No matter who you talk to, speaking in public can be nerve-wracking. That doesn’t mean you have to look like it is. No one has to know you’re nervous if you don’t let on, especially if you do the following five things:

- Stand up straight.

- Keep your chin up.

- Speak clearly and loudly.

- Use your hands to make gestures to highlight important points or count off items in a list.

- Keep your hands out of your pockets.

Whether you practice in front of a public speaking group or your hallway mirror, get in the habit of looking at yourself while you talk before anyone else can lay eyes on you. If you can master these five physical tips, you’re already headed in the right direction.

Speak More Slowly than Usual

Do you find yourself rushing through talks to get them over with sooner? You could be making them harder to listen to at the same time.

It’s natural to speak quickly when you feel nervous or excited, but work on slowing your speech so that you take more time to think about what you’re saying. Your audience will also find it easier to keep track of your talk and take in your points.

Tell Stories to Engage Listeners

Add context to safety talks by telling stories from your own professional or personal experiences.

For example, if you want to emphasize how important it is to wear PPE when handling hazardous substances, that story about how a former colleague once burned a hand with acid can help to make the danger more real to your audience.

Keep any stories concise and on topic, though. Avoid telling stories for the sake of shock value.

Short Safety Toolbox Topics to Inspire Your Talks

Finding fresh topics for your toolbox talks can be tough week after week. You may struggle to identify relevant issues that workers need to know about, let alone know how to present them in an engaging way.

Here are 10 free short safety topics for work to help you the next time you need a little inspiration.

1. How to Recognize Risky Workplace Conditions

Help workers become more aware of dangers they face by educating them on unsafe environments.

Common issues to look out for include: Workers wearing inappropriate clothing or incorrectly wearing PPE Lack of concentration for safety regulations Improper handling of dangerous machinery or tools Lack of hygiene and housekeeping standards

They should have the training to recognize when specific oversights like the ones above create a risky situation. As a result, they may be able to warn others of the hazards and make decision-makers aware before an incident occurs.

2. How to Care for an Injured Person

Workers must treat injured persons with care to avoid worsening their condition or causing them further pain. But staff without first-aid training may try to move a coworker after an accident without realizing the danger they create.

Help staff understand how to treat an injured person, who to contact (e.g., a supervisor), and where to find first-aid equipment in an emergency.

3. What Causes Accidents

According to the Occupational Safety and Health Administration (OSHA), 5,333 people died while working in 2019 . Some of the most frequently violated OSHA standards relate to fall protection and machinery.

But the more that workers know about the causes of accidents, the better they can avoid them. Explore some of the common factors that lead to injuries or fatalities in the workplace.

4. How to Use Fire Extinguishers

Knowing how to use a fire extinguisher can empower workers to stop small fires before they get out of control. And they may not have time to check the instructions when every second counts.

Howcast’s quick video guide can make a good springboard for demonstrating how to use a fire extinguisher, discuss common mistakes, and ensure that workers know how to handle one properly in an emergency.

5. Tips for Handling Heavy Equipment Safely

Heavy equipment makes transporting large loads easier and safer, but proper usage is a must to minimize danger to the operator and others. Those who handle heavy equipment regularly should already know how to do so safely, but a dynamic safety talk could refresh them while educating newcomers.

Cover everything from staying alert at the helm to securing loads properly. A practical demonstration, with help from a seasoned operator, would help.

6. Storing Materials Safely

Improper storage of materials, such as flammable goods or toxic chemicals, can cause serious or fatal injuries. Workers who don’t realize the potential danger involved or take a complacent approach could put themselves and others at risk.

Summarize the threats associated with specific materials in your workplace and how to store them safely.

7. Climbing Ladders Properly

Covering ladder usage is particularly helpful if you’re looking for short safety topics for construction sites.

Team members may try to climb up or down ladders while carrying heavy loads, or may let themselves become distracted. They could hurt themselves and people below them if they fall or drop what they’re carrying.

You can cover how to set ladders up, signs of unsafe positioning, and other crucial tips.

8. The Dangers of Horseplay

Teams with a close bond and years of shared experience may occasionally engage in horseplay. This includes pranking or scaring colleagues, wrestling, or tossing items at one another.

It may not seem dangerous, but it can be distracting and lead to accidental injuries. That’s why horseplay belongs on your list of short safety topics for meetings, no matter how responsible the team may seem.

9. Risks of Weather

Teams working outdoors can be at risk during extreme weather: torrential rain, electrical storms, icy conditions. They may be dressed in unsuitable clothing, equipped with inadequate lighting, or at risk of illness from prolonged exposure to high or low temperatures.

But weather can affect indoor workers, too, if they become overly hot or cold. Severe rain may also lead to floods. Wind can blow objects over. The list goes on.

Workers may underestimate the risks that powerful weather can cause, so help them recognize how it might be a hazard.

10. Importance of Listening for Dangers

Some dangers may be heard before they’re seen, such as a power tool overheating or a piece of heavy equipment failing to stop when it should. Alert workers are likely to hear these hazards and take action, but others won’t—and could be in danger.

Perhaps they’re listening to the radio, talking to a colleague, or distracted by their phone. Whatever the cause, a failure to recognize sounds of danger could have severe consequences.

Create a talk that focuses on how workers can stay alert at work, and encourages them to pay attention to how machinery sounds when it functions properly. This may follow the horseplay and heavy equipment talks nicely. These free short safety talks tips and ideas will help you promote responsible behavior in the workplace. Aim to deliver toolbox talks that grab workers’ interest and keep them engaged from start to finish—even if that’s just a few minutes. Remember to rehearse your talks, and act confident even when you’re not.

With a series of engaging short safety talks, you should be able to increase safety, decrease injuries, and encourage staff to take a greater interest in topics that affect their well-being over time.

The Power of Listening in Safety

Free Safety Talks to Print for Your Next Safety Meeting

Looking for safety talk topics to use at work? Scroll down to browse the list of 250+ completely free safety talks below! Print them off to use for your next safety meeting or safety moment with your employees. Use the links below to segment the talks by the most relevant topic category to easily find what you are looking for.

Members have access to over 320+ additional toolbox talks that are not found on this free site. There are also PowerPoint presentations with quizzes, 80 Spanish safety talks, and hand-picked weekly topic ideas. Additional members-only content is added every month!

Click the image of the safety talk to the left to download 1 of the over 550+ ad-free talks that are available for Members!

Save time and money from having to create your own resources. Instead, use that time to continue furthering your safety program.

Separate Talks by Category: BEHAVIORAL | CONSTRUCTION INDUSTRY | GENERAL INDUSTRY | OFFICE | MOTOR VEHICLE | SPANISH

Free Safety Toolbox Talk Topics Complete List

- * Advice for Using These Toolbox Talks *

- Achieving Safety Goals

- Alcohol Use

- Amputations

- Annual Checkup

- Asbestos Dangers

- Attitude and Safety: Fostering Positive Attitude at Work

- Auto Accident Procedures

- Automated External Defibrillators

- Back Injuries and Prevention

- Backing Up Hazards

- Battery Handling

- Battling Complacency

- Bees and Wasps

- Before a Work Task Begins

- Being Client-focused (Construction Industry)

- Being Observant

- Being Respectful to Coworkers

- Benzene Dangers in the Workplace

- Bloodborne Pathogens

- Burn Hazards and Injury Prevention

- Burn Severity

- Carbon Monoxide Safety

- Carcinogens in the Workplace

- Chainsaw General Safety

- Choices at Home and Safety on the Job

- Clothing and Safety

- Cold Stress Hazards

- Common Cold

- Common Issues with Fire Extinguishers

- Communicating Issues

- Communication and Safety

- Communication Tools and Safety

- Concrete Burns

- Concrete Work

- Continually Learning

- Conveyor Belt General Safety

- Costs of Drugs on the Job

- Dangers of Excessive Sitting

- Dealing with Hazards

- Dealing with Stress from Home

- Defensive Driving

- Diesel Exhaust Dangers and Safeguards

- Distracted Driving (Cellphone Use)

- Distracted While Walking

- Distractions Created by Smartphones When Not in Use

- Dog Attacks

- Doing Work Tasks Wrong the First Time

- Driving Safely Where Deer Are Present

- Dropped Objects on the Job

- Drowsy Driving

- Drunk Driving

- Dump Truck Operation

- Dump Truck Overturns

- Dust Hazards in Construction

- Easy Way Instead of the Right Way

- Eating Habits

- Electrical Injuries

- Electrical Safety

- Elimination of Hazards

- Embracing Change in the Workplace

- Emergency Exits

- Energy Drink Dangers

- Everyone is Responsible for the Culture

- Excavation Safety

- Excavator Quick Coupler Device Safety

- Eye Damage Due to Sunlight

- Eye Injuries and Prevention

- Fall Protection

- Falls in the Construction Industry

- Falls on the Same Level

- Fatal Four Hazards (Construction)

- Fatigue on the Job

- Fatigue on the Roadways

- Filter Pot Sock Filter Changeout

- Fire Extinguishers Use and Inspection

- Fire Safety at Home

- Fire Watch General Safety

- Firework Safety and Injury Prevention

- First Aid Preparedness

- First Day Back to Work

- Five Common Contributing Factors

- Fixed Objects (Motor Vehicle Safety)

- Fixed Open Blade Knives

- Food Allergies

- Forklift Fatalities and Injuries

- Four Focus Items for Work Area Inspections

- Front End Loader Safety

- Gasoline Safety

- Glycol Reclamation

- Good Enough Mindset

- Ground Personnel and Mobile Equipment

- Habits and Safety

- Hand Safety and Injury Prevention Safety Talk

- Hand Tool Inspections

- Hazardous Chemicals- Four Routes of Entry

- HDPE Pipe Welding

- Health is Everything

- Heart Attacks

- Heat Stress

- Heat Stroke

- Heavy Equipment (Four Other Hazards)

- Heavy Equipment (Two Significant Hazards)

- Heavy Equipment Operation

- Helping Out

- Hierarchy of Controls

- High Wind Dangers (Construction)

- Horseplay on the Job

- Hose Parting Pneumatic Testing

- Housekeeping in the Construction Industry

- How Observant Are You?

- How to Calculate Your Company’s TRIR (Total Recordable Incident Rate)

- How We React to Our World

- How What We Do at Home Affects Work

- Human Performance

- Hydration: The Importance of Water

- Hydrogen Sulfide

- Importance of Mentoring

- Importance of Organized Laydown Yards

- Incident Report Writing: A Comprehensive Guide

- Insect Sting Allergies

- Instant Gratification and Safety

- Involve the Right Person

- It Was a Matter of Time

- It Won’t Happen to Me

- Know Your Limits at Work

- Knowing What to do in an Emergency

- Lack of Time

- Ladder Safety

- Lawn Mower Safety

- Lead Paint Dangers and Safety

- Learning From Past Incidents

- Learning the Hard Way

- Leave Yourself an Out

- Lifting and Rigging

- Lightning Safety at Work and Home

- Line of Fire Hazards

- Lube Oil Flushing

- Lyme Disease

- Machine Guarding

- Manual Handling Injury Prevention

- Material Recovery Facilities General Safety

- Mechanical Issue-Related Crashes

- Motor Vehicle Safety

- Motor Vehicle Safety (Loose Cargo)

- Muddy Work Areas

- New Employees on the Job

- New Equipment

- Nine Basic Construction Safety Rules

- Noise at Work and Home

- Noise-Induced Hearing Loss

- Not a Big Deal Until it is

- Not My Problem

- Occupational-related Cancer

- Office Safety

- One Billion Dollars Spent on Injuries a Week

- One Decision

- One Safeguard Doesn’t Make it Safe

- Opioid Abuse

- Organization of Work Areas

- Orthostatic Intolerance

- Pinch Points and Hand Injuries

- Playing the Lottery and Workplace Injuries

- Pressure to Get Work Done

- Pressure Washing

- Preventing Equipment Damage Incidents in Construction

- Proactive Versus Reactive Safety Approach

- Questions to Ask Before a Work Task

- Rabies in the US

- Radio Communication on the Job

- Rationalizing Unsafe Choices

- Ready For Work

- Recognized Versus Unrecognized Hazards

- Recordable Injuries – Why Employees Should Care

- Relying on Memory

- Report All Injuries

- Respirator Donning, Doffing, and Seal Checks

- Road Rage (Motor Vehicle Safety)

- S.O.R.T Tool

- Safety Awareness: Being Present in the Moment

- Safety Can Be Redundant

- Safety Glasses

- Safety Related Paperwork

- Seatbelt Use and Safety

- Securing a Construction Site

- Selective Attention at Work

- Seven Basic General Industry Safety Rules

- Severity and Frequency

- Shift Work Dangers

- Shortcuts are a Choice

- Shoveling Snow

- Silica Dust Dangers and Safety Measures

- Skid Steer Safety

- Skin Cancer Due to Sun Exposure

- Sling Inspections

- Slip Hazards and Safety

- Slips, Trips, and Falls

- Smoking and Your Health

- Snakes in the Workplace

- Spill Prevention

- Spotter Safety at Work

- Stopping Work

- Stretching Pros and Cons

- Strokes- Signs and Emergency Response

- Struck-by Incidents (Construction)

- Success Through Reaching Potential

- Surveying (Construction)

- Table Saw General Safety

- Take Safety Home

- Taking Action to Work Safe

- Taking Ownership of Safety

- Taking Safety For Granted

- Taking Shortcuts

- Task Planning

- The “WHY” for “WHAT” Needs Done

- The Little Things

- The Negative Side of Quick Reactions

- The Ripple Effect of Safety

- Theft from a Construction Site

- Think of the Next Person

- Three Self-Centered Reasons to Work Safely

- Three Types of Poor Housekeeping Hazards

- Three Way Communication

- Top Five Reasons to Work Safely Today

- Tornado Safety

- Train Safety

- Trip Injuries and Prevention

- Truck Driving – Hazards On and Off the Road

- Two Types of Workplace Stress

- Types of Fire Extinguishers

- Underground Utility Strikes

- Unloading Trailers (Construction)

- Unsafe Acts

- Unsafe Conditions in the Workplace

- Utility Vehicle Safety at Home and Work

- Vehicle Inspections

- Verbal Communication and Workplace Safety

- Verifying Safeguards

- Weakest Link on Your Team

- Weed Wacker Safety

- West Nile Virus

- What Can Hurt Me Today?

- What is Your “Why”

- What Kind of Influence are You?

- Which Safeguard Makes the Difference?

- Why We All Should Care

- Wildlife in the Workplace

- Wind Chill Index

- Winter Weather

- Winter Weather Driving

- Work Area Best Practices

- Working Alongside Subcontractors

- Working From Home

- Workplace Inspections

- Workplace Shootings

- Workplace Suicides

- Workplace Violence

- Young Drivers and Motor Vehicle Accidents

- Zero Injuries in the Workplace

What Are Workplace Safety Talks?

Safety talks are short safety messages for the members of a work crew prior to work beginning. These talks can be as short as a few minutes or longer than 20 minutes. On average, they are in the range of 5 or 10 minutes long in duration at most companies when conducted often. The talks can cover a range of topics or just a single focal point.

Below are answers to some other common questions individuals may have about conducting these types of talks for their work crews.

$MMT = window.$MMT || {}; $MMT.cmd = $MMT.cmd || [];$MMT.cmd.push(function(){ $MMT.display.slots.push(["57a88d0a-5ddd-4a6a-93de-ba5c49768835"]); })

What are other names for these meetings.

There are many names for safety talks. Some of the more common names are safety toolbox talks, toolbox talks, safety moments, safety briefings, safety pep talks, and tailgate meetings. For the most part, many of these names represent the same thing. However, there can be slight differences between companies or industries.

These meetings, no matter what they are called, are the safety message of the day for a work crew prior to the start of the day.

Providing a Safety Moment of the Day

When done correctly, these talks can have a profound effect on the overall safety program at a workplace. Companies that spend time holding these meetings are less likely to have injuries compared to a company that does not hold them on a regular basis.

Conducting meetings often is an effective way to deliver relevant and timely safety messages to an entire work crew. The time spent conducting these talks also goes a long way toward reinforcing prior training efforts.

Even just holding a 5-minute meeting every day equates to a massive amount of knowledge for your workforce over a year’s time. To be exact- it results in over 20 hours of education per employee a year! (5 minutes X 5 workdays per week X 50 work weeks= 1250 minutes… 1250 minutes/60 minutes per hour= 20.8 hours of education) Imagine the difference that education can make if you make the most out of every talk!

What Topics Should You Cover for These Safety Talks?

The topic or topics you should cover for the next safety toolbox talk will vary greatly from what topic(s) another company should be discussing. Some general questions you can ask yourself to narrow in on some topics:

- What training needs to be reinforced?

- What problems have we been having lately?

- What are common injuries in this line of work?

- What have our near misses been a result of?

- What trends are occurring in the workplace or in our industry?

There are many other questions or guidelines you can use to determine what topics or topics you should cover. Keep topics useful, relevant, and timely.

Where Can I Find Free Safety Topics Online in 2023?

This site has one of the largest libraries of free topics found online today. That being said, there are also a number of great resources online to find topics for your next safety meeting. One of our favorite resources for topics is on OSHA’s website. They have a page called Safety and Health Topics that has a large list of high-quality topics.

Some other high-quality and reputable sources for toolbox talks or materials to support talks:

- Mine Health and Safety Administration

- Center for Disease Control

- National Institute for Occupational Safety and Health

- Bureau of Labor Statistics

Who Should Deliver a Safety Talk?

The person who is directing the work should be the one responsible for conducting or leading the safety talk. The responsibility at many companies, however, falls onto the safety officer or EHS manager instead. The reason for having the individual who is directing the work lead the talk is to show support for the message and efforts to work safely.

If it is constantly the EHS department’s responsibility to present, then employees can be led to believe that the frontline supervisors or managers do not truly support safety. If the workers’ supervisors or managers are not participating in the safety efforts, why should they?

The EHS department should instead serve more of an advisory role to the supervisor conducting the talk. They can provide the supervisor with topics, materials, or information for the talk, as well as chime in as needed to add value.

Do not be afraid to offer employees the chance to present at a meeting. While most employees would never choose to present a topic, you may be surprised to find that many would if given the chance.

How Often Should You Conduct Safety Talks?

There is no short and dry answer to how often your company should be conducting these talks. Some companies do multiple talks daily, and other companies may only do them monthly. A monthly schedule is probably way too sparingly for most companies, and two talks a day may be too often for others.

Companies often settle on conducting daily or weekly talks. At many companies, daily safety meetings prior to work beginning is an appropriate practice. Holding meetings that often may not make sense for all operations, however.

As mentioned earlier, these talks do not have to be extremely long. A lot of value can be added in a short amount of time if the talks are completed often. Employees are more likely to take more away from these talks if they are shorter in duration but are more frequent compared to longer meetings that occur infrequently.

Where Should Safety Talks Be Conducted?

These talks should be held in a place where employees are comfortable and can focus. Meeting rooms or break rooms are common areas where companies choose to hold their safety meetings. Another setting that can be even more effective is the work area(s) themselves.

This should only be done if the work area is comfortable, safe, and convenient for all involved in the talk. Conducting the talk in the work area itself can help employees visualize the information being conveyed, as well as allow the presenter to point out specific examples of what they are discussing.

If holding it in the work area is not an option, pictures or maps of the worksite can be great tools so that employees can visualize what is being said.

What Else Can You Do to Have a Better Safety Meeting or Safety Moment?

There are many things you can do to hold a better meeting. Below are a few quick tips that have not already been mentioned in this post:

- Prepare ahead of time.

- Keep topics relevant and timely to the audience.

- Only take the time necessary to cover the topic; do not drag it out.

- Do not read the talk word for word from the paper.

- Get the audience involved by asking for stories or examples relating to the topic.

- Use visual aids as needed to help get your message across.

- Have fun- don’t take yourself so seriously!

For more tips, check out this post on this site that outlines 10 tips for a better toolbox talk .

Does OSHA Require Safety Toolbox Talks?

While OSHA does not specifically require a company to hold safety talks or toolbox talks in any of their standards, doing so can play a part in helping to ensure compliance with some standards. For example, OSHA requires that employers make employees aware of the hazards of the work that they do and how to eliminate them.

One specific example of this is found in the construction standard under 1926.21(b)(2), where OSHA states: “The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.”

While training will be a large part of ensuring compliance with this specific regulation, safety toolbox talks are also a way to help to ensure compliance. These talks need to have the correct documentation to do so.

How Should You Document Safety Toolbox Talks?

Without documenting these efforts, there is no actual proof they were done. Meaning there is nothing to show OSHA or someone in your company in response to whether or not you were educating your employees on the hazards involved in their work. A lack of documentation can be problematic.

Every time a talk is conducted, a sign-in sheet should be completed by the presenter and signed by everyone present for the meeting. Some guidelines for documentation:

- Include the date and time.

- Include the presenter(s) name(s).

- Have everyone sign the sheet.

- Be detailed about what topics were discussed.

- Attach any materials used for the talk to the sign-in sheet.

- File documentation in chronological order so they can be easily found to be reviewed if needed.

The answers to the who, what, when, why, and how of safety talks can be as long of a list as the possible topics you could cover in your next meeting. The bottom line is your company should be conducting these talks on a regular basis as well as giving thought on how to continually improve on giving them. Use some of the insight here and tailor it to your company’s needs.

Consider checking out the Members Area of the site. There are plenty of other safety topics covered in there (with additional content added each month) if you find yourself not finding what you need in all of the free content offered on this site!

- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

32 Short Safety Talks: Topics & Ideas to Boost Engagement

Leaving conversations about safety to quarterly meetings and occasional safety training means safety skills and awareness atrophy over time. Want a way to refresh critical concepts without losing everyone’s attention? We have you covered with safety-in-the-workplace topics.

- What Are Safety Talks?

- How to Make Safety Talks More Engaging

32 Safety Talk Topics

No matter what kind of work you do, it’s easy to become complacent, especially if you’ve spent most of your days performing familiar tasks on repeat. It can be tempting to cut corners and forego best practices in the interest of time, productivity, and effort. If you find yourself going down this path, be wary because skipping steps and ignoring rules could result in an avoidable emergency.

One way to prevent these lapses and complacency among your team is to use short safety talks to remind everyone of proper procedures and prepare them for new hazards and variables they’ll encounter during the workday.

Safety Meeting Toolkit

What are safety talks in the workplace.