- CBSE Class 10 Study Material

CBSE Class 10 Maths Case Study Questions for Maths Chapter 5 - Arithmetic Progression (Published by CBSE)

Case study questions on cbse class 10 maths chapter 5 - arithmetic progression are provided here. these questions are published by cbse to help students prepare for their maths exam..

CBSE Class 10 Case Study Questions for Maths Chapter 5 - Arithmetic Progression are available here with answers. All the questions have been published by the CBSE board. Students must practice all these questions to prepare themselves for attempting the case study based questions with absolute correctness and obtain a high score in their Maths Exam 2021-22.

Case Study Questions for Class 10 Maths Chapter 5 - Arithmetic Progression

CASE STUDY 1:

India is competitive manufacturing location due to the low cost of manpower and strong technical and engineering capabilities contributing to higher quality production runs. The production of TV sets in a factory increases uniformly by a fixed number every year. It produced 16000 sets in 6th year and 22600 in 9th year.

Based on the above information, answer the following questions:

1. Find the production during first year.

2. Find the production during 8th year.

3. Find the production during first 3 years.

4. In which year, the production is Rs 29,200.

5. Find the difference of the production during 7th year and 4th year.

2. Production during 8th year is (a+7d) = 5000 + 2(2200) = 20400

3. Production during first 3 year = 5000 + 7200 + 9400 = 21600

4. N = 12 5.

Difference = 18200 - 11600 = 6600

CASE STUDY 2:

Your friend Veer wants to participate in a 200m race. He can currently run that distance in 51 seconds and with each day of practice it takes him 2 seconds less. He wants to do in 31 seconds.

1. Which of the following terms are in AP for the given situation

a) 51,53,55….

b) 51, 49, 47….

c) -51, -53, -55….

d) 51, 55, 59…

Answer: b) 51, 49, 47….

2. What is the minimum number of days he needs to practice till his goal is achieved

Answer: c) 11

3. Which of the following term is not in the AP of the above given situation

Answer: b) 30

4. If nth term of an AP is given by an = 2n + 3 then common difference of an AP is

Answer: a) 2

5. The value of x, for which 2x, x+ 10, 3x + 2 are three consecutive terms of an AP

Answer: a) 6

CASE STUDY 3:

Your elder brother wants to buy a car and plans to take loan from a bank for his car. He repays his total loan of Rs 1,18,000 by paying every month starting with the first instalment of Rs 1000. If he increases the instalment by Rs 100 every month , answer the following:

1. The amount paid by him in 30th installment is

Answer: a) 3900

2. The amount paid by him in the 30 installments is

Answer: b) 73500

3. What amount does he still have to pay offer 30th installment?

Answer: c) 44500

4. If total installments are 40 then amount paid in the last installment?

Answer: a) 4900

5. The ratio of the 1st installment to the last installment is

Answer: b) 10:49

Also Check:

CBSE Case Study Questions for Class 10 Maths - All Chapters

Tips to Solve Case Study Based Questions Accurately

Get here latest School , CBSE and Govt Jobs notification and articles in English and Hindi for Sarkari Naukari , Sarkari Result and Exam Preparation . Download the Jagran Josh Sarkari Naukri App .

- IPS Anshika Verma

- RSMSSB Rajasthan CET Answer Key 2024

- ADRE Grade 4 Admit Card 2024

- CTET Form Correction 2024

- RSMSSB CET Admit Card 2024

- RSMSSB CET Exam Analysis 2024

- Rajasthan CET Question Paper 2024

- OSSC CGL Admit Card 2024

- SSC CGL Result 2024

- Star Sighting Time Today

- Education News

- CBSE Study Material

- CBSE Class 10

Latest Education News

ट्रेन छूट जाने पर उसी टिकट पर दूसरी ट्रेन से कैसे करें यात्रा? जानें यहां

Special Trains 2024: दिवाली और छठ पूजा के लिए स्पेशल ट्रेनों का ऐलान, चेक करें रूट और टाइमिंग

344 रनों के साथ इस टीम ने बना डाला T20I का सबसे बड़ा स्कोर, सिकंदर रजा ने तोड़े कई रिकॉर्ड

Cyclone Dana: किस देश ने दिया ‘डाना’ नाम और क्या है इसका हिंदी अर्थ? जानें

GK Quiz on Pole Star: How Well Do You Know the Pole Star? Take This GK Quiz Now

You have a 140+ IQ if you spot the word kite in the picture in 4 seconds!

RSMSSB Exam Calendar OUT at rsmssb.rajasthan.gov.in: Check Revised Dates Here

RSMSSB CET Question Paper 2024: Download Rajasthan 12th Level Shift 1 and 2 Unofficial Answer Key PDF

Brain Teaser IQ Test: Perfect Vision and 120+ IQ Needed! Can You Find the Four-Sided Star in This 5-Second Puzzle

Personality Test: Your Toes Reveal Your Hidden Personality Traits

Aaj Tara Kitne Baje Nikalega? आपके शहर में आज तारा कितने बजे निकलेगा और दिखाई देगा? जानें

Today Current Affairs One Liners 24 October 2024: United Nations Day 2024

[OUT] RSCIT Result 2024: 06 अक्टूबर वीएमओयू आरकेसीएल परीक्षा का रिजल्ट rkcl.vmou.ac.in पर जारी, अभी यहां से डाउनलोड करें सर्टिफिकेट

Current Affairs Quiz 24 October 2024: Anti-Racism Championship Award 2024

राजस्थान CET 12th लेवल आंसर की 2024: 22, 23, 24 अक्टूबर शिफ्ट 1, 2 की अनौपचारिक उत्तर कुंजी PDF डाउनलोड करें

Top 100+ Thought Of The Day For School Assembly In English And Hindi (October 25, 2024)

CBSE Class 12 Physics Sample Paper 2024-25: Download Sample Paper PDF With Marking Scheme For Free!

Today Current Affairs Hindi One Liners: 24 अक्टूबर 2024- लीडरशिप समिट 2024

NCERT Solutions For Class 10 Science Biology Chapter 6 Control And Coordination: Download Free PDF!

Rajasthan CET Answer Key 2024: राजस्थान सीईटी ग्रेजुएट लेवल आंसर की जल्द, यहां देखें कब जारी होगी उत्तर कुंजी पीडीएफ

Case Study: India is competitive manufacturing location due to the low cost of manpower and strong technical and engineering capabilities contributing to higher quality production runs. The production of TV sets in a factory increases uniformly by a fixed number every year. It produced 16000 sets in 6 th year and 22600 in 9 th year. 1) Find the production during 8th year. 2) Find the productiion during first 3 years. 3) Find the difference of the production during 7th and 4th year.

1) production during 8 th year is ( a + 7 d ) = 5000 + 2 ( 2200 ) = 20400 2) production during first 3 year = 5000 + 7200 + 9400 = 21600 3) difference = 18200 − 11600 = 6600.

A manufacturer of TV sets produces 600 units in the third year and 700 units in the 7 t h year. Assuming that the production increases uniformly by a fixed number every year, find :

(i) the production in the first year.

(ii) the production in the 10 t h year.

(iii) the total production in 7 years.

The production of TV in a factory increases uniformly by a fixed number every year, if produced 8000 TV's in 6 t h years and 11300 in 9 t h year find the production in 1 s t year and 8 t h year

A manufacturer of TV sets produced 600 sets in the third year and 700 sets in the seventh year. Assuming that the production increases uniformly by a fixed number every year, find : (i) the production in the 1 s t year (ii) the production in the 10 t h year (iii) the total production in first 7 years

How India's ‘Make in India’ Initiative is Boosting Manufacturing

Updated: Jul 1

In recent years, India's 'Make in India' initiative has emerged as a pivotal driver in boosting the country's manufacturing sector. This ambitious campaign, launched to promote domestic manufacturing and position India as a global manufacturing hub, has been instrumental in attracting investments, fostering innovation, and creating employment opportunities . In this blog post, we delve into the various aspects of the 'Make in India' initiative, exploring its incentives, impact on domestic manufacturing, challenges faced, and successful case studies that exemplify its transformative power . Join us on a journey to understand how this initiative is reshaping India's manufacturing landscape and propelling the nation towards self-reliance and industrial excellence.

Understanding the 'Make in India' Initiative

The 'Make in India' initiative was launched by the Government of India in September 2014 with the aim of transforming the country into a global manufacturing powerhouse. The primary objective of this initiative is to promote domestic manufacturing, attract foreign direct investment (FDI), and boost job creation in various sectors. By encouraging both local and international companies to manufacture their products in India, the government seeks to enhance the country's competitiveness, increase economic growth, and reduce dependency on imports. Under the 'Make in India' program, the government has identified 25 key sectors, including automobiles, textiles, pharmaceuticals, electronics, defense manufacturing, renewable energy, and aerospace, among others. These sectors have been prioritized for focused attention and policy support to drive their growth and development. The initiative is built on four key pillars, known as the '4 Ts':

Tradition: Showcasing India's rich heritage and skilled workforce to establish India as a manufacturing destination.

Talent: Emphasizing skill development and promoting vocational training to enhance the employability of the workforce.

Trade: Simplifying trade regulations and procedures to facilitate ease of doing business and attract investments .

Technology: Encouraging innovation, research and development, and the adoption of advanced technologies to enhance productivity and competitiveness.

By focusing on these pillars, the 'Make in India' initiative aims to address various challenges faced by the manufacturing sector and create an enabling environment for manufacturers to thrive. Furthermore, the initiative also seeks to foster collaboration between the government and industry stakeholders. It emphasizes the importance of public-private partnerships to drive growth, create sustainable manufacturing ecosystems, and promote innovation. Through regular stakeholder consultations, policy reforms, and sector-specific initiatives, the government aims to create a conducive environment for businesses to flourish. In the subsequent sections of this blog post, we will explore the incentives and policies offered under the 'Make in India' initiative, the impact it has had on domestic manufacturing, the challenges faced during its implementation, and successful case studies that exemplify its effectiveness . Let us delve deeper into the world of 'Make in India' and discover how it is reshaping India's manufacturing landscape.

Incentives and Policies Under the 'Make in India' Initiative

The 'Make in India' initiative offers a range of incentives and policies to attract investments, promote manufacturing, and facilitate ease of doing business . These measures aim to create a favorable environment for both domestic and international companies to set up manufacturing operations in India. In this section, we will explore some of the key incentives and policies implemented under the 'Make in India' initiative.

Benefits for Manufacturers

Ease of Doing Business: The government has implemented several reforms to simplify business procedures, reduce bureaucratic red tape, and streamline regulatory processes. This includes the introduction of a single-window clearance system, online application processes, and digitization of various approvals and licenses.

Customized Investment Facilitation: The 'Make in India' initiative provides customized investment facilitation services to help businesses navigate through regulatory requirements, obtain necessary clearances, and identify suitable locations for setting up manufacturing units.

Intellectual Property Rights Protection: The government is committed to protecting intellectual property rights (IPR) and has taken measures to strengthen the legal framework for IPR enforcement. This ensures that manufacturers have the necessary protection for their innovations and technologies.

Access to Finance: The initiative promotes access to finance for manufacturers by encouraging banks and financial institutions to provide loans and credit at competitive rates. It also aims to facilitate collaborations between financial institutions and manufacturing companies to meet their capital requirements.

Special Economic Zones and Tax Incentives

Special Economic Zones (SEZs): The government has established SEZs across the country, which offer various benefits to manufacturers, including tax incentives, duty exemptions, and streamlined regulatory processes. These zones provide a conducive environment for businesses to operate and facilitate exports.

Tax Incentives: The government has implemented tax incentives to encourage manufacturing activities in India. These incentives include reduced corporate tax rates, tax holidays for specific sectors, and exemptions on customs duties for imports of raw materials and capital goods used in manufacturing.

Goods and Services Tax (GST): The implementation of the Goods and Services Tax has simplified the tax structure and eliminated multiple indirect taxes, making it easier for manufacturers to comply with tax regulations and reduce the overall tax burden.

Ease of Doing Business Policies

Single Window Clearance: The government has introduced a single-window clearance mechanism, where businesses can obtain all necessary approvals and clearances from a single platform. This reduces bureaucratic delays and simplifies the process of starting and operating a manufacturing unit.

Labor Law Reforms: The government has initiated labor law reforms to simplify compliance requirements, improve worker-employer relations, and enhance flexibility in labor regulations. These reforms aim to promote industrial growth and create a conducive environment for businesses.

Infrastructure Development: The government is investing heavily in infrastructure development, including transportation networks, industrial parks, and connectivity. This ensures better logistics and access to markets, reducing costs and improving the overall business environment.

Through these incentives and policies, the 'Make in India' initiative aims to attract investments, promote manufacturing activities, and create a business-friendly environment. In the next section, we will explore the impact that the 'Make in India' initiative has had on domestic manufacturing in India.

Impact of 'Make in India' on Domestic Manufacturing

The 'Make in India' initiative has had a significant impact on domestic manufacturing in India. It has not only increased the overall production capacity but has also contributed to job creation, skill development, and the growth of innovation and technology in the manufacturing sector. In this section, we will delve into the various positive impacts that the 'Make in India' initiative has had on domestic manufacturing.

Increase in Domestic Production

One of the primary objectives of the 'Make in India' initiative is to boost domestic production across various sectors. By encouraging both domestic and international companies to manufacture their products in India, the initiative has resulted in a surge in the production of goods within the country. This increase in domestic production has not only reduced the dependence on imports but has also stimulated economic growth and contributed to national self-reliance.

Creation of Jobs and Skill Development

The 'Make in India' initiative has played a crucial role in generating employment opportunities across different sectors. As companies set up manufacturing units in India, they require a skilled workforce to operate and manage these facilities. This has led to a significant increase in job opportunities, especially for the youth. Additionally, the initiative emphasizes skill development and vocational training programs to enhance the employability of the workforce . This focus on skill development ensures that individuals have the necessary skills and expertise to contribute effectively to the manufacturing sector.

Boost in Innovation and Technology

The 'Make in India' initiative has also stimulated innovation and the adoption of advanced technologies in the manufacturing sector . To compete on a global scale, companies are encouraged to innovate and develop new products and processes. The initiative promotes research and development activities, collaboration between industry and academia, and the adoption of cutting-edge technologies to enhance productivity and competitiveness. This focus on innovation and technology has not only improved the quality of products but has also positioned India as a hub for technological advancements in manufacturing. The impact of the 'Make in India' initiative on domestic manufacturing has been significant, with increased production, job creation, skill development, and technological advancements. In the next section, we will explore the challenges faced during the implementation of the initiative and the solutions that have been devised to overcome them.

Related Article: Sector-Wise Impact: How Different Industries Are Benefiting from Make in India

Challenges and Solutions in the Implementation of 'Make in India'

While the 'Make in India' initiative has brought about several positive changes in the manufacturing sector, it has also encountered various challenges during its implementation. In this section, we will discuss some of the key challenges faced and the solutions devised to overcome them.

Addressing Infrastructure and Logistical Challenges

One of the major challenges faced in the implementation of the 'Make in India' initiative is the need for robust infrastructure and logistical capabilities. Adequate transportation networks, reliable power supply, and well-developed industrial parks are essential for smooth manufacturing operations. To address these challenges, the government has undertaken significant infrastructure development projects, including the construction of new roads, ports, airports, and the establishment of industrial corridors. Additionally, initiatives like the National Investment and Infrastructure Fund (NIIF) have been introduced to attract investments and mobilize resources for infrastructure development.

Overcoming Regulatory Hurdles

Another challenge in the implementation of the 'Make in India' initiative is the presence of complex regulatory procedures and bureaucratic bottlenecks. This can deter businesses from setting up manufacturing units in India. To tackle this issue, the government has implemented several reforms to simplify regulatory processes, reduce paperwork, and digitize approvals. The introduction of a single-window clearance system has streamlined the process of obtaining necessary licenses and permits. Moreover, efforts have been made to enhance transparency and accountability in regulatory bodies to ensure a smoother business environment.

Dealing with Skilled Labour Shortage

The availability of a skilled workforce is crucial for the success of the 'Make in India' initiative. However, there is a shortage of adequately skilled workers in certain sectors. To address this challenge, the government has initiated skill development programs to enhance the employability of the workforce. These programs focus on providing vocational training, apprenticeships, and industry-specific skill development to bridge the skill gap. Collaboration between industry and educational institutions has also been encouraged to align the curriculum with industry requirements and ensure that graduates are job ready.

Promoting Research and Development

Another challenge lies in promoting research and development (R&D) activities in the manufacturing sector. Innovation and technological advancements are vital for the growth and competitiveness of Indian industries. To address this, the government has introduced various policies and incentives to encourage R&D, such as tax benefits for R&D investments, setting up technology incubation centers, and promoting collaborations between industry and research institutions. These measures aim to foster a culture of innovation, drive technological advancements, and position India as a global leader in innovation-driven manufacturing. By addressing these challenges and implementing effective solutions, the 'Make in India' initiative aims to create a conducive environment for manufacturing growth and attract investments. In the next section, we will explore case studies of successful 'Make in India' projects that demonstrate the impact and potential of the initiative.

Related Article: Overcoming Challenges: How 'Make in India' is Addressing Industry Hurdles

Driving India's Manufacturing Renaissance

The 'Make in India' initiative has been instrumental in boosting domestic manufacturing, attracting investments, and creating employment opportunities. By offering a range of incentives and policy frameworks, the initiative has not only encouraged local businesses to expand their operations but has also drawn significant international interest. This collaborative approach between the government and industry stakeholders has led to increased innovation and enhanced productivity across various sectors.

Through strategic partnerships and a focus on cutting-edge technologies, 'Make in India' has successfully positioned the country as a competitive manufacturing destination. The initiative's emphasis on quality standards and ease of doing business has resulted in a more conducive environment for both existing manufacturers and new entrants. Furthermore, the development of industrial corridors and smart cities under the initiative has provided the necessary infrastructure to support large-scale manufacturing operations.

As India continues on its path of industrial excellence, the 'Make in India' initiative will play a pivotal role in shaping the future of manufacturing in the country. By fostering a culture of innovation and efficiency, the initiative is set to transform India into a global manufacturing hub. With ongoing reforms and a steadfast commitment to growth, 'Make in India' will continue to drive economic progress and create sustainable employment opportunities, ensuring long-term prosperity for the nation.

Related Article: Vision 2030: Long-Term Goals and Prospects of Make in India

Related Posts

Wholesale Tool Distributors: A Quick Guide

Choosing the Right Wholesale Tool Distributor for Your Business: Key Factors to Consider

How Wholesale Tool Distributors Manage Risk in a Volatile Market

- 中文 (Chinese)

Trending Topics

- Look Forward: Multidimensional Transition

- Look Forward: Supply Chain 2024

- AI in Banking: AI Will Be An Incremental Game Changer

- The Return of Energy Security

- The AI Governance Challenge

- India's Future: The Quest for High and Stable Growth

Offerings by Division

- S&P Global Market Intelligence

- S&P Global Ratings

- S&P Global Commodity Insights

- S&P Dow Jones Indices

- S&P Global Mobility

- S&P Global Sustainable1

S&P Global Offerings

Featured Topics

Featured Products

- Market Intelligence

- Commodity Insights

- Sustainable1

S&P Capital IQ Pro

Platts Connect

S&P Global ESG Scores

AutoCreditInsight

SPICE: The Index Source for ESG Data

- S&P Global Home

- Explore S&P Global

- Data & Analytics

- Research & Insights

Ratings & Benchmarks

- Technology Solutions

- See all S&P Global Products & Solutions

Find a Rating

Market Insights

- Special Reports

Sustainability

Capital Markets

Global Trade

Energy & Commodities

Technology & Innovation

Geopolitical Risk

Artificial Intelligence

Featured S&P Global Events

Webinar Replays

About S&P Global

- Corporate Responsibility

Diversity, Equity, & Inclusion

- Investor Relations

- Find Products

- Research and insights

- / Research & Insights /

- / Look Forward / 'Make In India' Needs Logistics

- Look Forward

'Make In India' Manufacturing Push Hinges on Logistics Investments

A strong logistics framework will be key to transforming India from a services-dominated economy into a manufacturing-dominant one.

Published: August 3, 2023

By Rahul Kapoor and Chris Rogers

India has an immense opportunity to increase its share of global manufacturing exports, and the government is seeking to raise manufacturing to 25% of GDP from 17.7% by 2025.

Developing a strong logistics framework will be key to transforming India from a services-dominated economy to a manufacturing-dominant one, particularly enhancements in intermodal connectivity and heavy investments in ports and shipping capacity.

Accelerated investments should aid India's ambition; a boom in Indian mobile phone production provides a template for future policies in other sectors.

India stands on the cusp of a massive opportunity to increase its share of global manufacturing exports. Corporate manufacturing giants are looking for alternative production and sourcing destinations to accelerate supply chain diversification. India should benefit from these positive tailwinds, aided by significant milestones already achieved in its domestic and export logistics framework as well as by projects now underway. The telecom sector provides a case study for the delivery of the Modi administration’s “Make in India, Make for the World” policies. Global smartphone manufacturers are setting up shop in India after years of patient government intervention via targeted trade policies focused on phones and components.

Successive Indian governments have emphasized policies promoting domestic manufacturing to reduce India’s import dependence and to increase its share of global exports. The current administration’s focus on “Make in India, Make for the World” encourages investments in manufacturing, especially through Production-Linked Incentive (PLI) schemes. First introduced in 2020 for electronics makers, PLIs provide incentives to domestic and foreign companies that invest in Indian manufacturing and meet predetermined output targets.

India’s policy landscape is often disparate , spanning multiple states with independent reform agendas. Approaching reform at a national level through platforms like PLIs can allow the central government to circumvent state-level differences. Effective uptake of these schemes will be crucial as India seeks to increase manufacturing to 25% of GDP by the year ending March 2025 . It was 17.7% last fiscal year, according to S&P Global Market Intelligence.

Policies in complementary sectors — especially logistics — will be key to meeting the government’s goal of transforming India from a services-dominated economy into a manufacturing-dominant one. Sophisticated logistics could give India a competitive advantage over other countries vying for inbound investment.

Accelerated Investments Should Aid India’s Global Manufacturing Ambitions

India’s ability to compete internationally against other manufacturing exporters will be enhanced by its two-pronged approach to logistics. This is focused on improving intermodal connectivity and on heavy investment in ports and shipping capacity.

Capital-intensive infrastructure projects would also be supported by the government’s strong digitalization efforts. Existing frameworks such as the National Logistics Policy (NLP) could help to build a technology-enabled, integrated, cost-effective and dependable logistics ecosystem.

Digital and infrastructure initiatives have already helped India to rise six spots since 2018 in the World Bank’s Logistics Performance Index (LPI), to rank 38th out of 139 countries in 2023. The country has significantly improved its score in four of the six LPI indicators (infrastructure, international shipments, logistics quality and competence, and timeliness), which bodes well for the future.

A key variable affecting India’s manufacturing potential is cost competitiveness in logistics. Costs are about 14% to 18% of GDP, according to the country’s full-year 2022–23 Economic Survey. The government aims to lower these costs to below 10% to be more in line with major Asian exporters.

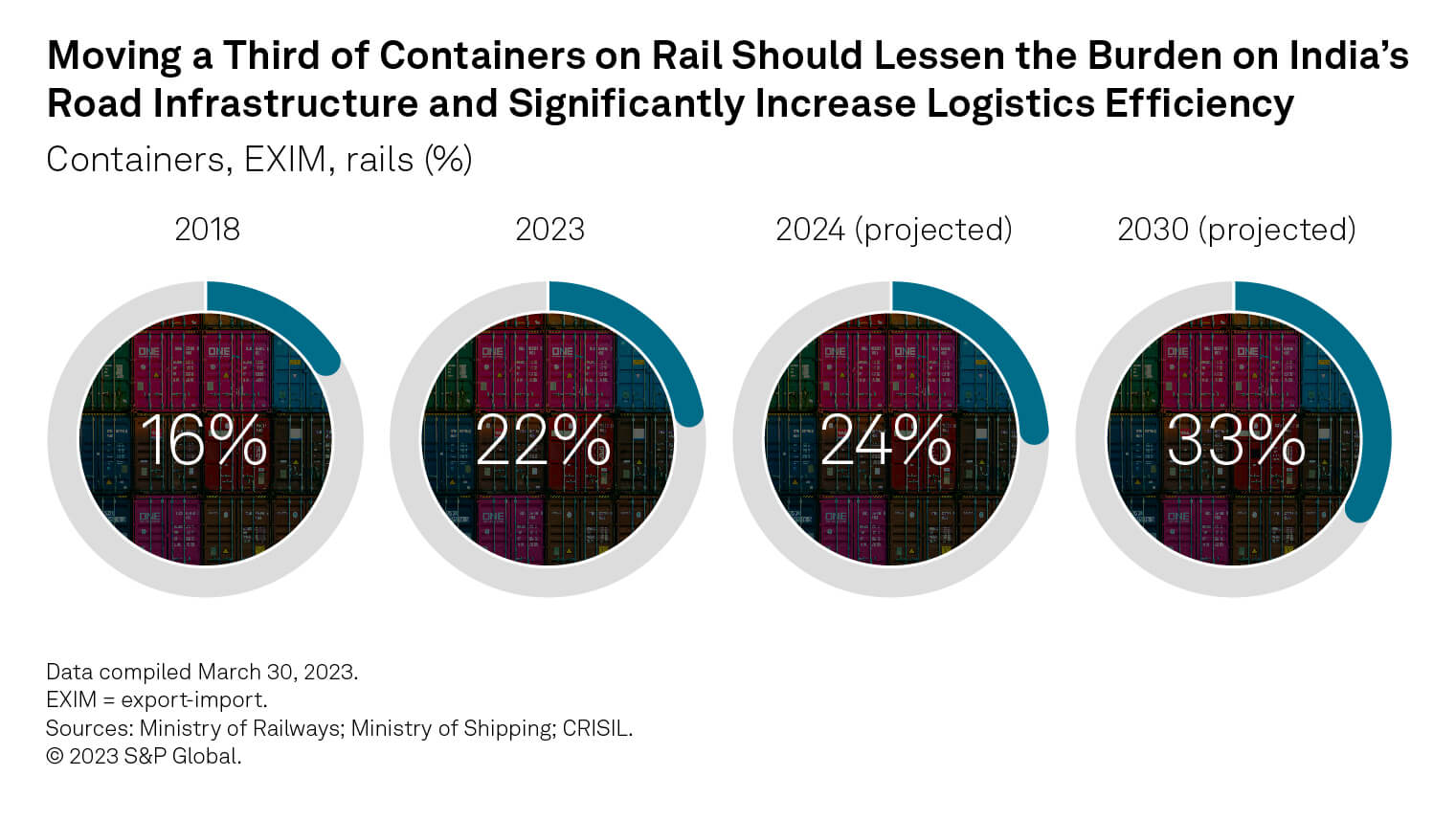

Improving road and rail connectivity will help to cut logistics costs. There is already a noticeable acceleration in national highway building, with the government expecting construction to reach 33 km/day in fiscal year 2024, almost double the 17 km/day achieved in fiscal year 2016. The share of containers being shipped by rail is also rising: It is forecast to hit 23.5% in fiscal year 2024 and 33% in fiscal year 2030, according to the government.

Ports Need Investment to Boost India’s Cargo Capacity and Throughput

Increasing India’s manufacturing exports in a cost-competitive and efficient manner will require improvements in logistics. The country has geographical advantages including a long coastline of more than 7,500 km and proximity to shipping traffic transiting the Indian Ocean.

Looking Forward

India lags Japan, South Korea and mainland China in export infrastructure and efficiency, particularly in terms of port capacity. To narrow this infrastructure gap and to become the global manufacturing destination of choice, India will need massive upgrades covering areas such as rail, ports and freight corridors.

India needs to reduce its reliance on transshipments via hubs such as Singapore and Hong Kong to help manufacturers avoid potentially lengthy transit times. This means adding efficient high-capacity ports that can handle the largest container ships or incentivizing operators to introduce direct services to major markets. It will also entail strengthening links with global container carriers and freight forwarders.

India has an opportunity to increase its share of global container shipments and bulk commodities, even if North Asia will likely continue to be the driver of global container volumes, according to S&P Global’s Global Trade Analytics suite. Accelerating port infrastructure development will be key to achieving this goal.

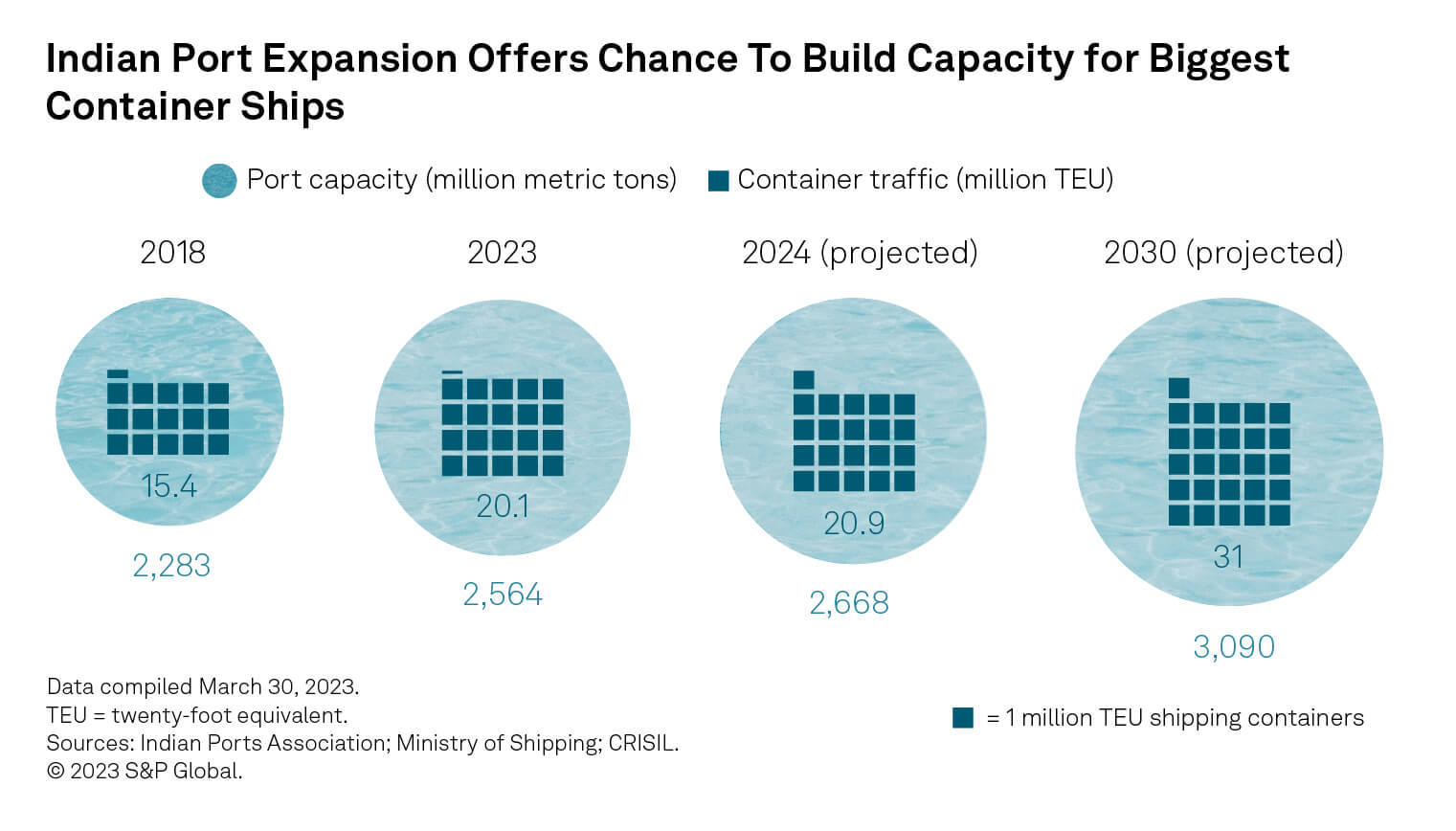

Port capacity and container throughput have experienced robust growth in India over the last five years. Looking forward, capacity will have a compound annual growth rate of 2.7% in 2023–30, with container traffic achieving 6.5%, based on estimates from CRISIL, an S&P Global company. This is growth from a low base, and a key question is how India facilitates significantly more port investments and higher growth rates in support of its bid to become an export powerhouse.

Successfully emerging as a global manufacturing hub is central to achieving India’s domestic growth target and geopolitical ambitions. The path to achieving this goes via the government’s ability to design and build a world-class logistics system, encompassing domestic road and rail networks, as well as international shipping services.

Smartphones Show Potential for Electronics Manufacturing

Getting the logistics framework right should facilitate growth in sectors earmarked for exports, especially high-strategic areas like electronics that require tightly integrated supply chains. Electronics makers also generally rely on airfreight, which means the sector is less affected by India’s existing seaport constraints.

India’s policy interventions in the smartphone sector illustrate its ambitions for manufacturing as a conduit to service the domestic market as well as its geopolitical aims. Smartphones are among the most sophisticated manufactured products, and their ubiquity makes them a logical target for any country looking to extend its economic development. The arrival of Apple contractors as major players in Indian mobile phone production shines a light on the nation’s success so far and on its opportunities for future growth.

Evolution in India’s Domestic Market

Reshoring of telecom manufacturing is a competitive field, with India facing significant competition as multinationals look to expand their operations. However, India’s large domestic market gives it an advantage, especially over Southeast Asian countries.

A revolution in India’s telecom services has helped to make the country one of the world’s most digitalized economies. India’s next target is to ensure the availability of low-cost mobile phones.

Sales of telecom products in India are projected to reach $18.3 billion — or 1.3% of the global total — in 2027, according to forecasts by S&P Global Market Intelligence. The market is expected to grow 7.3% annually through 2027, outpacing the global average of 6.2%. India’s large mobile phone sales make it worthwhile setting up local supply chains serving both domestic and export markets. Major manufacturers that already operate in India include Samsung Electronics and Xiaomi, as well as contract producers for Apple including Wistron and Pegatron.

The “Make in India” strategy includes a variety of import restrictions on phones and parts, which offers support to local manufacturers. Domestically produced, low-cost phones may also help bring informal, unregistered businesses into the mainstream economy.

India’s Viability as Export Hub

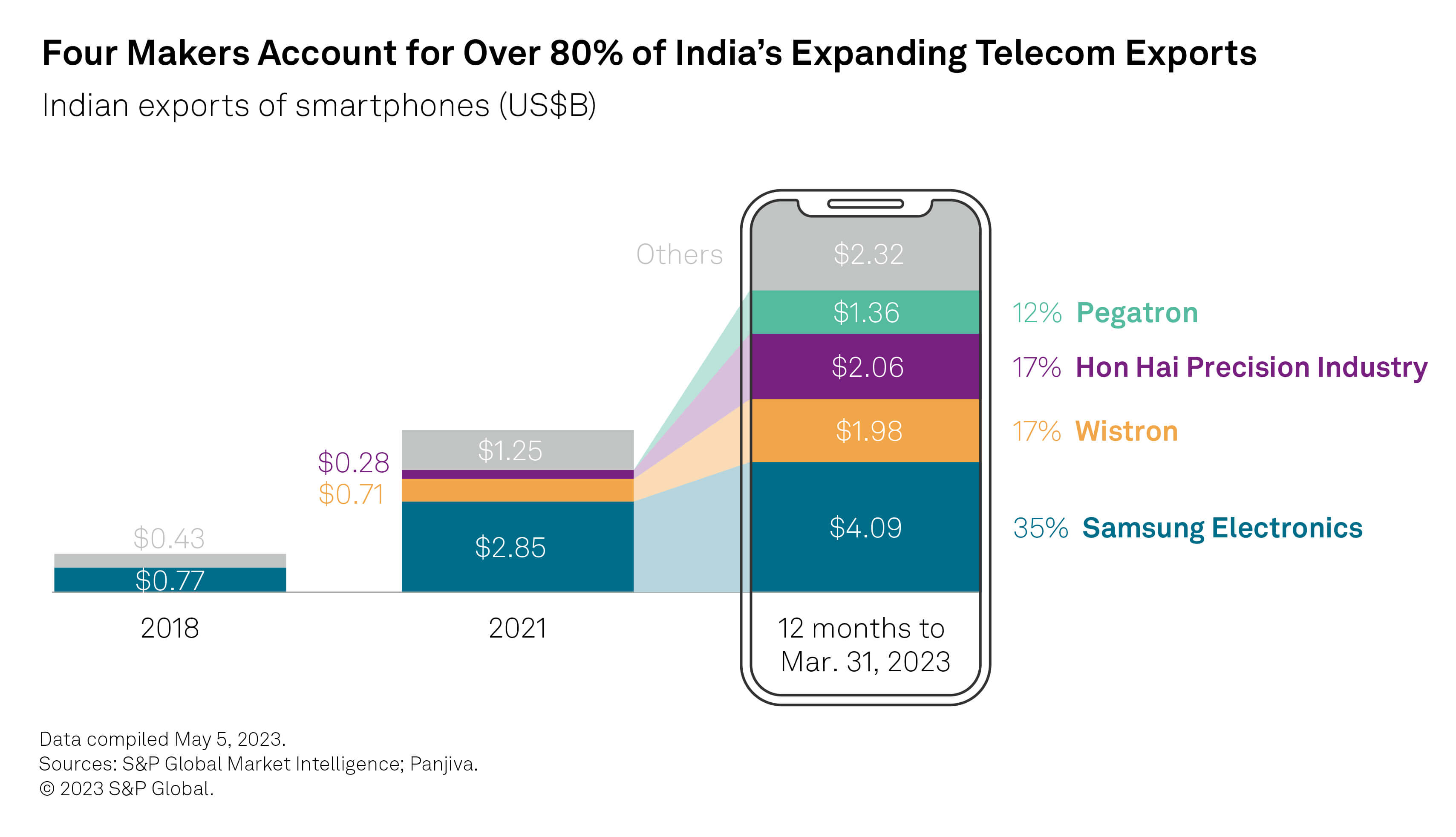

India’s export industry for telecom equipment, including smartphones, is rapidly expanding. Exports reached $11.8 billion in the 12 months to March 31, 2023, data from S&P Global Market Intelligence and Panjiva shows. Samsung Electronics led with 35% of exports, followed by contract manufacturers Wistron and Foxconn (Hon Hai Precision Industry) with 17% each.

To ensure sustainable growth in telecom, public and private sector coordination will be needed to transition beyond only assembling smartphones. This work can always be relocated to lower-cost locations, whereas fully integrated operations are stickier. Such operations would also make India pivotal to the global telecom equipment supply chain.

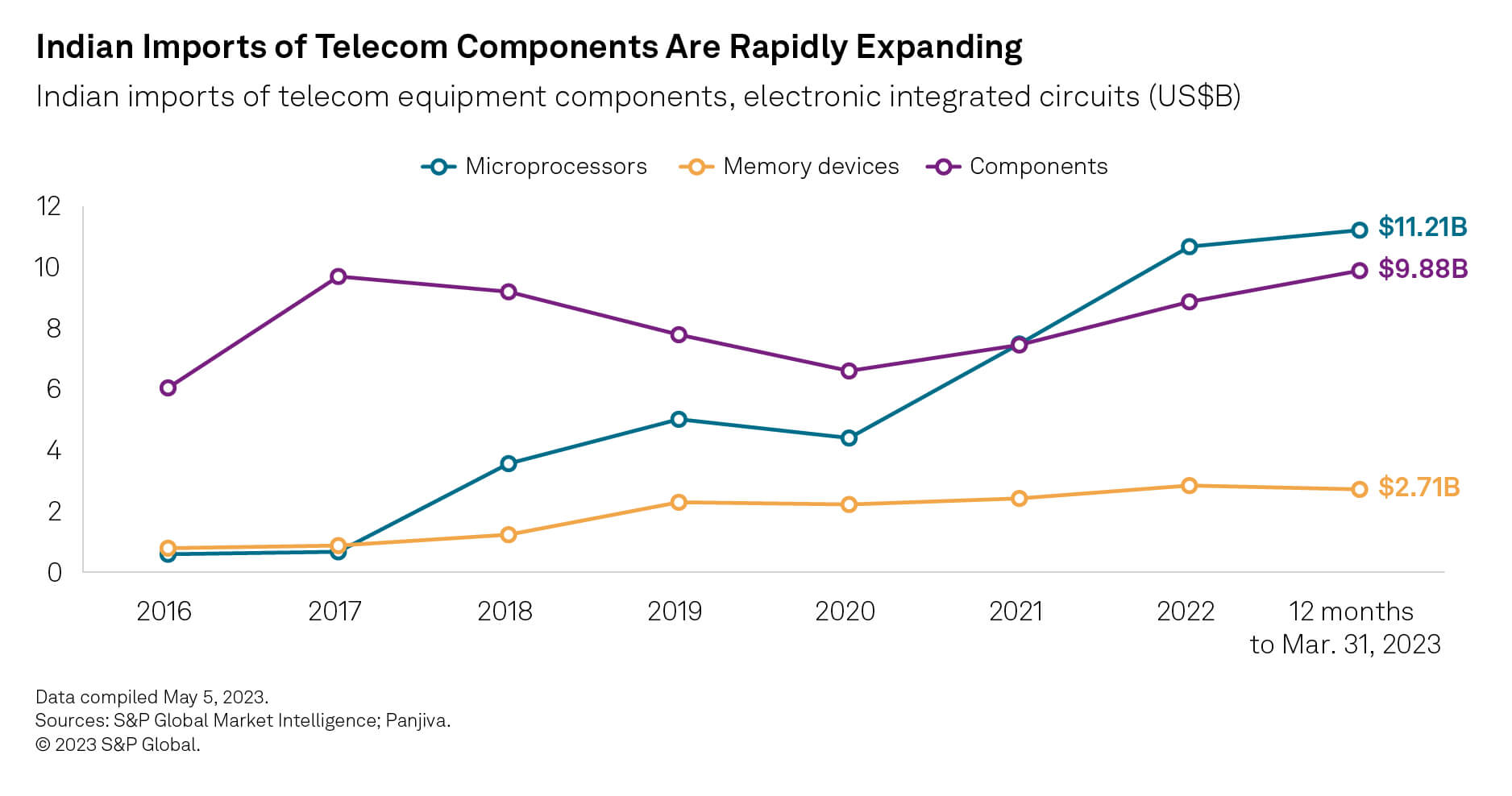

Replicating the full supply chain back to semiconductors is not necessary. For instance, mainland China and Vietnam both import processors and other chips. India’s imports of semiconductors and other parts for telecom and computing devices have tracked steadily upward. Panjiva data shows imports of telecom equipment and computer chips reached $27.4 billion in the 12 months to March 31, 2023, after 12% of compound annual growth since 2017.

India has significant opportunities for manufacturing expansion across a range of sectors. Success so far in smartphone supply chains provides a template for future development potential — in terms of both scale and the complex hurdles to be overcome.

Right place, right time: Supply chain outlook for third quarter 2023 Before the battery and magnet: IRA and mineral supply chains

Next Article: Future Farming: Agriculture’s Role in a More Sustainable India

This article was authored by a cross-section of representatives from S&P Global and in certain circumstances external guest authors. The views expressed are those of the authors and do not necessarily reflect the views or positions of any entities they represent and are not necessarily reflected in the products and services those entities offer. This research is a publication of S&P Global and does not comment on current or future credit ratings or credit rating methodologies.

- X LinkedIn Facebook Email WhatsApp

Content Type

- Our Purpose

- Our History

- News Releases

- Quarterly Earnings

- SEC Filings & Reports

- Customer Care & Sales

- Support by Division

- Report an Ethics Concern

- Office Locations

- Our Organization

- IOSCO ESG Rating & Data Product Statements

- Terms of Use

- Cookie Notice

- Privacy Policy

- Client Privacy Portal

- Do Not Sell or Share My Personal Information

© 2024 S&P Global

Case Study Questions Class 10 Geography – Manufacturing Industries

- Post author: studyrate

- Post published:

- Post category: class 10th

- Post comments: 0 Comments

Case study Questions on Class 10 Social Science Geography Chapter 6 are very important to solve for your exam. Class 10 Social Science Chapter 6 Case Study Questions Class 10 Geography have been prepared for the latest exam pattern. You can check your knowledge by solving case study-based questions for Class 10 Social Science Chapter 6 Manufacturing Industries

Join our Telegram Channel, there you will get various e-books for CBSE 2024 Boards exams for Class 9th, 10th, 11th, and 12th.

In CBSE Class 10 Social Science Paper, Students will have to answer some questions based on Assertion and Reason . There will be a few questions based on case studies and passage-based as well. In that, a paragraph will be given, and then the MCQ questions based on it will be asked.

Manufacturing Industries Case Study Questions With Answers

Here, we have provided case-based/passage-based questions for Class 10 Social Science Chapter 6 Manufacturing Industries

Case Study/Passage-Based Questions Case Study 1: India stands second as a world producer of sugar but occupies first place in the production of gur and Khansari. The raw material used in this industry is bulky, and in haulage its sucrose content reduces. The mills are located in Uttar Pradesh, Bihar, Maharashtra, Karnataka, Tamil Nadu, Andhra Pradesh, Gujarat, Punjab, Haryana, and Madhya Pradesh. Sixty percent of mills are in Uttar Pradesh and Bihar. This industry is seasonal in nature so, it is ideally suited to the cooperative sector. Can you explain why this is so? In recent years, there is a tendency for the mills to shift and concentrate in the southern and western states, especially in Maharashtra; this is because the cane produced here has higher sucrose content. The cooler climate also ensures a longer crushing season. Moreover, the cooperatives are more successful in these states. Major challenges include the seasonal nature of the industry, old and inefficient methods of production, transport delay in reaching cane to factories, and the need to maximize the use of bagasse.

(i) Fill in the blank from the given options: India stands second as a world producer of sugar but occupies first place in the production of gur and khandsari. The sugar industry comes under …………… group of industries. (a) Public sector (b) Cooperative sector (c) Private sector (d) Joint sector

Answer: (b) Cooperative sector

(ii) Read the following statements about cooperative sector and find the incorrect from the given options. I. Cooperative Sector is owned and operated by the producers or suppliers of raw materials, workers, or both. II. This sector pools in the resources and share the profits or losses proportionately. III. This sector is jointly run by the state and individuals or a group of individuals. Codes (a) Only I (b) Both I and II (c) Only III (d) Both I

Answer: (c) Only III

(iii) Why sugar mills are perfectly convenient for the sector in which industries are owned by suppliers or producers of raw materials, workers, or both? With reference to the above context, infer the appropriate option. (a) Because this industry is seasonal in nature. (b) Dueto its efficient methods of production. (c) Due to better transport system. (d) Because raw material are bulky

Answer: (a) Because this industry is seasonal in nature.

(iv) Why there is a high concentration of sugar mills in Uttar Pradesh? Select the best suitable option from the following in reference to the context. (a) Because Uttar Pradesh is the largest producer of sugarcane. (b) Because labour is easily available in Uttar Pradesh. (c) Due to high consumption in Uttar Pradesh. (d) All of the above

Answer: (a) Because Uttar Pradesh is the largest producer of sugarcane.

(v) Why Sugar industries are shifting to the South and the West? Identify the best suitable reason from the given options. (a) Due to cooler climate in these areas. (b) Due to success of cooperative movement in these areas. (c) Due to higher sucrose content in the sugarcanes cultivated in these areas. (d) All of the above

Answer: (d) All of the above

(vi) Which of the following is not a major challenge for sugar industry? Select the best suitable option from the following. (a) Traditional methods of production (b) Need to maximise the use of bagasse (c) Availability of water (d) Seasonal nature of this industry

Answer: (c) Availability of water

Case Study 2: The chapter “Minerals and Energy Resources” in Class 10 Geography explores the various types of minerals and energy resources found on Earth and their significance in human activities. It discusses the classification of minerals based on their chemical composition and uses, as well as the distribution of major mineral resources in India and the world. The chapter also covers the extraction and utilization of minerals, the environmental impacts of mining, and the conservation of mineral resources. Additionally, it examines different types of energy resources, including conventional and non-conventional sources, and their importance in meeting the energy demands of societies.

Which chapter in Class 10 Geography focuses on manufacturing industries?

a) Chapter 2: Forests and Wildlife Resources

b) Chapter 4: Agriculture

c) Chapter 6: Manufacturing Industries

d) Chapter 7: Minerals and Energy Resources

Answer: c) Chapter 6: Manufacturing Industries

What are some of the factors influencing the location of industries?

a) Political stability and cultural heritage

b) Availability of raw materials, labor, capital, and market demand

c) Proximity to tourist attractions

d) Geographic location and climate

Answer: b) Availability of raw materials, labor, capital, and market demand

Which industries are discussed in the chapter as examples of manufacturing industries?

a) Only textile industry

b) Only iron and steel industry

c) Only IT industry

d) Textile, iron and steel, and IT industries

Answer: d) Textile, iron and steel, and IT industries

What are some of the challenges faced by manufacturing industries?

a) Lack of technological advancements

b) Environmental conservation

c) Decreased market demand

d) Competition, environmental degradation, and social impacts

Answer: d) Competition, environmental degradation, and social impacts

Hope the information shed above regarding Case Study and Passage Based Questions for Class 10 Social Science Geography Chapter 6 Manufacturing Industries Resources with Answers Pdf free download has been useful to an extent. If you have any other queries about the CBSE Class 10 Social Science Manufacturing Industries Case Study and Passage-Based Questions with Answers, feel free to comment below so that we can revert back to us at the earliest possible By Team Study Rate

You Might Also Like

Mcq class 10 english mijbil the otter questions with answers english chapter 8, mcq class 10 english the hack driver questions with answers english chapter 8.

NTSE Syllabus 2024 | DPP Class 10 NTSE Exam 2024

Leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

Sustainability in Indian Manufacturing: Challenges and Opportunities

The industrial landscape of India pulsates with the rhythm of progress. Manufacturing stands as a cornerstone of the nation’s economic might, generating jobs and propelling growth. However, this very engine of prosperity now finds itself at a crossroads. As India aspires to become a global manufacturing leader, the environmental consequences of unfettered industrial activity cast a long shadow. Resource depletion and pollution threaten not just the ecological balance but also the long-term sustainability of this crucial sector. This necessitates a paradigm shift – a decisive move towards sustainable manufacturing practices.

We will explore the challenges that impede progress, unveiling the hurdles that stand between aspiration and reality. However, despair will not be our sole companion. We will also illuminate the immense opportunities that await those who embrace a greener future. By understanding the complexities of this transition, Indian manufacturers can unlock a path towards sustainable success, ensuring economic prosperity in harmony with environmental well-being.

The Imperative for Sustainable Manufacturing in India: A Multifaceted Crisis Demanding Action

India’s manufacturing sector is a double-edged sword. On one hand, it acts as a powerful engine propelling economic growth and creating vital job opportunities for millions. It’s a cornerstone of national prosperity, contributing a significant chunk – over 14% – to the Gross Value Added (GVA). However, on the other hand, this very growth has come at a steep environmental cost. The relentless pursuit of industrial expansion has left a trail of resource depletion and environmental degradation that can no longer be ignored.

The looming crisis necessitates a paradigm shift – a decisive move towards sustainable manufacturing practices. Here’s why this is no longer a choice, but an absolute imperative:

Resource Depletion: A Looming Threat to Future Growth: India faces an alarming scarcity of natural resources, particularly water and raw materials. Unsustainable practices exacerbate this problem, jeopardizing not only the environment but also the future viability of the manufacturing sector itself. Without readily available resources, the engine of growth risks sputtering to a halt.

Environmental Degradation: A Public Health Crisis in the Making: Industrial pollution from manufacturing processes isn’t just an environmental concern; it’s a public health crisis in the making. Air and water pollution, byproducts of unsustainable practices, have severe consequences for human health, impacting respiratory systems, waterborne diseases, and overall well-being. The economic benefits of manufacturing pale in comparison to the cost of a sick and ailing population.

Climate Change: A Global Challenge with Local Roots: Energy-intensive manufacturing processes are major contributors to greenhouse gas emissions, accelerating the pace of climate change. This global phenomenon has local repercussions – erratic weather patterns, rising sea levels, and extreme weather events. Sustainable practices aren’t just a fad; they are a crucial step towards mitigating the climate crisis and ensuring a habitable future for generations to come.

Global Market Pressures: Competing on a Green Stage: International trade is no longer blind to environmental considerations. Sustainability standards are increasingly emphasized, acting as a gatekeeper to global markets. Businesses that fail to adopt eco-friendly practices risk being locked out, missing out on valuable opportunities and hindering their own growth potential.

These factors paint a clear picture: sustainable manufacturing is not just a feel-good initiative, it’s a matter of economic survival and environmental responsibility. Inaction is no longer an option. The time for decisive action towards a greener future for Indian manufacturing is now.

Challenges on the Road to Sustainability: A Multifaceted Landscape

The path towards sustainable manufacturing in India is paved with good intentions, but it’s a journey fraught with hurdles. Here, we delve into the key challenges that impede progress, acting as roadblocks on the path to a greener future:

Knowledge Gap: Ignorance Isn’t Bliss : Many small and medium-sized enterprises (SMEs) – the backbone of Indian manufacturing – operate in a bubble of limited awareness. Sustainable practices and their benefits often remain shrouded in mystery. This lack of knowledge hinders their ability to embrace greener practices and capitalize on the opportunities they present. Capacity building initiatives and knowledge dissemination programs are crucial to bridge this gap and empower SMEs to become active participants in the sustainability movement.

The Cost Conundrum: Bridging the Investment Gap : Implementing sustainable solutions often comes with a hefty price tag. Renewable energy systems, waste-reduction processes, and eco-friendly technologies all require significant upfront investments. For many SMEs, these initial costs can be a major deterrent, acting as a barrier to entry on the path to sustainability. Innovative financing mechanisms and government incentives are essential to bridge this financial gap and make sustainable practices more accessible.

Fragmented Ecosystem: A Supply Chain Challenge : The Indian manufacturing landscape is a complex tapestry woven with numerous small players. This fragmented ecosystem presents a unique challenge in the pursuit of sustainability. Integrating sustainable practices across the entire supply chain, from raw material sourcing to product distribution, necessitates a coordinated effort. Collaboration and information sharing between stakeholders are crucial to ensure that sustainability becomes a collective endeavor, not an isolated pursuit.

Infrastructure Deficit: Building a Foundation for Green Growth : The current infrastructure in India poses a significant barrier to sustainable manufacturing. Limited access to renewable energy sources like solar and wind power restricts the adoption of clean energy alternatives. Inefficient waste management systems and inadequate water treatment facilities further complicate the path to environmental responsibility. Investing in infrastructure development is paramount to create a foundation that supports and incentivizes sustainable practices.

Skills Gap: Equipping the Workforce for the Green Revolution : The existing manufacturing workforce may not possess the skillset necessary to operate and maintain eco-friendly technologies. A significant skills gap exists, hindering the adoption and effective implementation of sustainable solutions. Investing in upskilling and reskilling programs is crucial to equip the workforce with the knowledge and expertise required to navigate the complexities of sustainable manufacturing.

Regulatory Labyrinth: The Need for Clear and Enforceable Regulations : The effectiveness of environmental regulations in India is often under scrutiny. Regulations may not be stringent enough to create a compelling incentive for sustainable practices. Additionally, weak enforcement mechanisms can allow companies to flout environmental norms with impunity. Establishing clear, robust regulations with strong enforcement mechanisms is essential to create a level playing field and incentivize businesses to embrace sustainability.

These challenges paint a complex picture, highlighting the multifaceted nature of the obstacles on the path to sustainable manufacturing. However, by acknowledging these hurdles and taking proactive measures to address them, India can pave the way for a greener future, one where economic prosperity and environmental responsibility co-exist in harmony.

Opportunities Abound: Embracing Sustainability for Competitive Advantage

The narrative around sustainability in Indian manufacturing often focuses on the challenges, painting a picture of an insurmountable uphill battle. However, a closer look reveals a landscape brimming with exciting opportunities for those who dare to embrace a greener future. Let’s explore the multitude of benefits that await manufacturers who take the leap towards sustainability:

Cost Reduction: Turning Green into Greenbacks : Sustainable practices aren’t just good for the environment; they’re good for the bottom line. Resource optimization, a cornerstone of sustainability, leads to a reduction in water and raw material consumption, translating into significant cost savings in the long run. Additionally, energy efficiency measures can lower energy bills, further bolstering profitability. Sustainability becomes a strategic investment, not just an environmental obligation.

Brand Image Makeover: The Power of Being Green : Consumers today are increasingly environmentally conscious. They actively seek out brands that align with their values and prioritize sustainability. By adopting sustainable practices, manufacturers can elevate their brand image, attracting a loyal customer base that values eco-friendly products and responsible manufacturing processes. This translates into a competitive advantage in the marketplace.

Market Access: A Green Passport to Global Opportunities : Sustainability standards are becoming increasingly stringent in global markets. Manufacturers who fail to demonstrate a commitment to environmental responsibility risk being locked out. Embracing sustainability becomes a passport to global opportunities, granting access to new markets and fostering international trade expansion.

Resource Security: A Sustainable Future Starts with Secure Resources : Resource depletion is a looming threat in India. Sustainable practices, like efficient resource utilization and exploring renewable materials, can ensure a secure supply of resources for future production needs. This reduces dependence on dwindling resources and mitigates risks associated with price fluctuations, fostering long-term business stability.

Innovation Unleashed: A Catalyst for Green Tech and Jobs : The transition to sustainability acts as a catalyst for innovation. Manufacturers are driven to develop clean technologies, optimize processes, and explore eco-friendly materials. This fosters a vibrant ecosystem of innovation, leading to the creation of new green technologies and job opportunities in the clean energy and resource management sectors. Sustainability becomes an engine for economic growth and technological advancement.

Government Backing: Riding the Green Wave with Policy Support : The Indian government is actively promoting sustainability through various initiatives. Programs like the ‘Sustainable Strategic Action Plan for GRIHA’ provide a framework for responsible construction practices. Additionally, tax breaks for green technologies incentivize their adoption and make sustainable solutions more accessible. Government support creates a favorable environment for manufacturers to embrace sustainability.

These opportunities highlight the multifaceted benefits of sustainable manufacturing in India. It’s not just about environmental responsibility; it’s about cost savings, brand enhancement, market access, resource security, innovation, and government support. By seizing these opportunities, Indian manufacturers can position themselves for long-term success in a world increasingly focused on environmental sustainability.

Case Studies: Illuminating the Path with Beacons of Sustainable Manufacturing in India

The narrative of sustainability in Indian manufacturing isn’t just about challenges and opportunities; it’s about inspiration. Across the vast landscape, several companies are blazing a trail, demonstrating that environmental responsibility and economic success can co-exist in perfect harmony. Let’s delve into a few of these inspiring case studies:

ITC: A Commitment to Water Conservation and Renewable Energy : This Indian conglomerate, a household name, has taken a leadership role in sustainable practices. ITC has implemented comprehensive water conservation initiatives across its manufacturing plants, significantly reducing water usage. Additionally, they are actively transitioning towards renewable energy sources like solar and wind power, minimizing their dependence on fossil fuels and reducing their carbon footprint. ITC’s commitment to sustainability doesn’t just benefit the environment; it also translates into cost savings and a positive brand image.

Godrej Green Building: Building a Greener Future, Brick by Brick : The construction industry has a significant environmental impact. Godrej Green Building, a leading player in this sector, recognizes this and is at the forefront of sustainable construction practices. The company focuses on developing and utilizing eco-friendly building materials like recycled content and low-carbon alternatives. They also champion energy-efficient construction methods, leading to buildings that consume less energy throughout their lifespan. Godrej Green Building is demonstrating that sustainable construction is not just feasible but can be a competitive advantage.

Marico: Optimizing Water Usage and Embracing Recycled Materials : This FMCG giant, known for its popular consumer goods, understands the importance of responsible resource management. Marico has adopted water-efficient processes in its manufacturing facilities, minimizing water consumption without compromising on production quality. Additionally, they are actively incorporating recycled materials into their packaging, reducing their reliance on virgin resources and minimizing waste generation. Marico’s commitment to sustainability resonates with environmentally conscious consumers, fostering brand loyalty and contributing to long-term success.

Tata Motors: Gearing Up for a Sustainable Future with Electric Vehicles : The transportation sector is a major contributor to greenhouse gas emissions. Tata Motors, a leading Indian automotive manufacturer, is taking a proactive approach to address this challenge. They are investing heavily in electric vehicle technology, developing innovative electric cars and striving to reduce emissions across their entire manufacturing process. Tata Motors understands that the future of transportation lies in sustainability, and they are positioning themselves as a leader in this transformative shift.

These are just a few examples of the many Indian companies leading the charge towards sustainable manufacturing. Their success stories demonstrate the diverse approaches to achieving environmental responsibility. From water conservation and renewable energy to sustainable construction materials and electric vehicle technology, Indian manufacturers are proving that a greener future is not only possible but also commercially viable. These case studies serve as an inspiration for others, encouraging them to embrace sustainability and pave the way for a more responsible and environmentally conscious future for Indian manufacturing.

The Road Ahead: Building a Collaborative Future for Sustainable Manufacturing

The journey towards sustainable manufacturing in India is not a solitary expedition; it’s a collective endeavor that necessitates a collaborative effort from various stakeholders. Each player has a crucial role to play in building a future where environmental responsibility and economic prosperity go hand-in-hand. Let’s explore the multifaceted contributions required from each key participant:

Government: Setting the Stage for Green Growth : As the architect of national policy, the government has a critical role to play in fostering sustainable manufacturing. Enacting stricter environmental regulations with clear enforcement mechanisms incentivizes businesses to adopt greener practices. Furthermore, providing financial incentives, such as tax breaks for green technologies and subsidies for sustainable practices, can bridge the cost gap and make sustainability more accessible. Investing in infrastructure development, particularly focusing on renewable energy sources and efficient waste management systems, creates a foundation for sustainable operations. A proactive government sets the stage for, and actively participates in, the green transformation of Indian manufacturing.

Industry Leaders: Pioneering the Path and Lighting the Way : Large corporations, with their vast resources and influence, can act as pioneers in sustainable manufacturing. These industry leaders can set ambitious sustainability benchmarks, demonstrating the viability and benefits of eco-friendly practices. Additionally, they can support smaller players in the ecosystem by providing knowledge resources, technical assistance, and mentorship programs. Investing in research and development of clean technologies and innovative manufacturing processes further propels the industry towards a sustainable future. Industry leaders have the power to not only transform their own operations but also to inspire and guide the entire manufacturing sector.

SMEs: Embracing Sustainability Within Their Capacities : Small and medium-sized enterprises (SMEs) form the backbone of Indian manufacturing. While they may face resource constraints, embracing sustainability within their capacities is crucial. SMEs can explore cost-effective sustainable practices, such as resource optimization, waste reduction, and energy efficiency measures. Seeking knowledge resources and participating in government-sponsored programs can equip them with the necessary expertise. Additionally, advocating for government support and collaborating with larger players in the ecosystem can pave the way for collective action and shared learning. Every step taken by an SME towards sustainability contributes to the overall progress of the sector.

Financial Institutions: Greening the Financial Landscape : Financial institutions have a significant role to play in facilitating the transition towards sustainable manufacturing. Developing green financing products, such as loans with preferential interest rates for sustainable technologies, can make eco-friendly solutions more accessible for businesses. Supporting responsible investment practices by offering investment opportunities in companies with strong sustainability credentials further incentivizes greener practices. By integrating sustainability considerations into their financial services, financial institutions act as catalysts for a greener future in manufacturing.

Research Institutions and Academia: Knowledge Catalysts for Sustainable Solutions : Research institutions and academia play a critical role in developing innovative, cost-effective sustainable technologies. Conducting research on resource optimization, waste management strategies, and clean energy solutions empowers manufacturers with practical tools to implement sustainable practices. Additionally, training the workforce with the necessary skills and knowledge to operate and maintain eco-friendly technologies ensures a skilled workforce equipped for the future of manufacturing. By fostering innovation and knowledge dissemination, research institutions and academia become catalysts for a sustainable manufacturing revolution.

Consumers: The Power of Choice for a Greener Future : Consumers hold immense power in shaping the manufacturing landscape. Making informed choices by purchasing products from environmentally conscious manufacturers sends a powerful message. Advocating for sustainable practices and holding companies accountable for their environmental impact creates a strong consumer demand for green products and services. This, in turn, incentivizes businesses to prioritize sustainability and drives the manufacturing sector towards a more responsible future.

By collaborating effectively, each stakeholder plays a vital role in building a robust ecosystem for sustainable manufacturing in India. A proactive government sets the policy framework, industry leaders pave the way, SMEs embrace sustainability within their capacities, financial institutions support green initiatives, research institutions provide innovative solutions, and consumers drive demand for eco-friendly products. When all these forces converge, a powerful synergy emerges, propelling India’s manufacturing sector towards a future that is not just economically prosperous but also environmentally responsible.

A Sustainable Future for Indian Manufacturing: A Marathon Worth Running

The path towards sustainable manufacturing in India is long and winding, a marathon demanding endurance and unwavering commitment. However, the finish line beckons, not just with a metaphorical trophy, but with a bounty of rewards: a cleaner environment, a more secure resource base, and a competitive edge in the global marketplace.

The road ahead necessitates acknowledging the challenges that lie ahead – the knowledge gap amongst SMEs, the high initial costs of sustainable solutions, the fragmented supply chain, the inadequate infrastructure, the skills gap in the workforce, and weak regulatory frameworks. Ignoring these hurdles will only prolong the journey. However, by taking a proactive approach, these challenges can be transformed into opportunities.

Capitalizing on the immense opportunities that abound is key. Sustainable practices can lead to significant cost reductions through resource optimization and energy efficiency. Eco-friendly manufacturing can elevate brand image and open doors to global markets with stringent environmental standards. A secure supply of resources can be ensured through sustainable practices, mitigating risks associated with resource depletion. By complying with regulations, manufacturers can avoid penalties and ensure smooth business operations. The transition to sustainability fosters innovation, leading to the development of clean technologies and eco-friendly processes, creating new business opportunities. Furthermore, government support, in the form of initiatives and incentives, can smoothen the path for businesses.

This transformative journey cannot be undertaken by a lone runner. Collaboration across stakeholders is the key to achieving sustainable manufacturing at scale. The government must set the pace through stricter, well-enforced environmental regulations, provide financial incentives, and invest in critical infrastructure. Industry leaders can illuminate the path by setting sustainability benchmarks, supporting smaller players, and investing in R&D. SMEs must embrace sustainability within their capacities, seek knowledge resources, and advocate for government support. Financial institutions can act as catalysts by developing green financing products and supporting responsible investment practices. Research institutions and academia have a vital role to play in developing cost-effective sustainable technologies and training the workforce. Finally, consumers hold immense power – by demanding sustainable products and services, they can shape the future of manufacturing.

When all these stakeholders – government, industry leaders, SMEs, financial institutions, academia, and consumers – come together in a spirit of collaboration, a powerful synergy emerges. This collective effort will propel India’s manufacturing sector towards a future that is not just economically prosperous but also environmentally responsible. The marathon towards sustainable manufacturing is indeed a long journey, but with every step taken, India builds a brighter future for generations to come, one where progress and environmental responsibility go hand-in-hand. It’s a marathon worth running, one that will ensure a thriving manufacturing sector and a healthy planet for all.

- Aerospace and Defence Tech, Talent, and Innovation

- Awards & Recognitions

- Branding for SMEs

- Business Leaders Awards

- Business Powerhouse

- Digital Magazine

- DigitalSMEs

- Exhibition, Expo, Trade Show, Trade Fair

- Financial Inclusion

- Franchise Development

- Global Alliance for Clean Energy and Transportation (GACET)

- Global Alliance for Climate Change and Environment (GACCE)

- Global Alliance for Digital Innovation, Economy & Governance (GADIEG)

- Global Alliance for Digital MSMEs (GADM)

- Global Alliance for Ecotourism and Sustainable Tourism (GAEST)

- Global Alliance for Good Health & Well Being (GAGHW)

- Global Alliance for Industry, Innovation and Infrastructure (GAIII)

- Global Alliance for MSME Advancement and Sustainable Prosperity (GAMASP)

- Global Alliance for Packaging and Processing (GAPP)

- Global Alliance for Retailers and Traders (GART)

- Global Alliance for Sustainable Fashion (GASF)

- Global Alliance for Sustainable Media and Publishing (GASMP)

- Global Alliance for the Future of Food and Agriculture (GAFFA)

- Global Alliance for Water, Sanitation and Hygiene (GAWASH)

- Global Alliances

- Global Council for Trade Facilitation and Electronic Business (GCTFEB)

- Global Council of Digital Equity, Literacy, Safety and Inclusion (GCDELSI)

- Global Cybersecurity & Privacy Alliance (GCPA)

- Global Founders Magazine

- Global Sales, Marketing & Branding Council (GSMBC)

- Global Trade

- Global Trade and Investment Policy Alliance (GTIPA)

- Global Womenomics Impact Alliance (GWIA)

- Global Workforce Development Council (GWDC)

- International Trade

- NFT & Gaming

- Semiconductor

- Space Economy

- Sustainable Cities and Communities

- Sustainable Development

- Sustainomics

- Technology and IP Licensing and Acquisitions

- Technology Business Briefing

- Technology Development and Promotion

- The Great Leaders Council (TGLC)

- The Nation of Series

- Uncategorized

This site uses cookies. Find out more about cookies and how you can refuse them.

New membership are not allowed.

- Screen Reader

- Skip to main content

- Text Size A

- Language: English

- Case Studies

- EXIM Procedure

Media & Events

- Image Gallery

- Media Coverage

Other Links

- Discover India

- GI of India

- Experience India

- Indian Trend Fair 2022

- India Organic Biofach 2022

- Gulfood Dubai 2023

Transforming India's Logistics Sector: Challenges and Opportunities

Recent case studies.

The logistics industry plays a vital role in the dynamic economic landscape of India by enabling the efficient movement of goods and services throughout the country's large territory. As India strives to realise its ambitious economic goals, including achieving a GDP of US$ 5.5 trillion by 2027, the transformation of its logistics sector emerges as a pressing imperative. Given its pivotal role in supporting various industries, from manufacturing to agriculture and e-commerce, the logistics sector faces a myriad of challenges, and offers a number of opportunities. In this case study, we delve into India's logistics ecosystem, exploring the hurdles impeding its efficiency and growth, while also highlighting the pathways towards innovation and sustainable development. Through a comprehensive analysis of the sector's dynamics, we aim to uncover actionable insights that can inform strategic interventions and nurture the emergence of a more agile, resilient, and competitive logistics infrastructure in India.

Growing significance of the Indian logistics sector

The Indian economy, which ranks fifth in the world with a GDP of approximately US$ 3.7 trillion in 2023, grew rapidly between 2015 and 2019, averaging more than 7% annually. However, because of stringent COVID-induced lockdown, GDP shrank 7.3% in 2020. The service sector's comeback, manufacturing sector's revival and agricultural growth propelled strong recovery in 2021 and 2022, resulting in a remarkable 15.3% growth over 2020-22. The manufacturing sector, which accounted for 15.3% of GDP in FY22, stands to gain further given the government’s focus on promoting ‘Make in India’ and transforming India into a ‘global manufacturing hub.’ India is poised to benefit from the shift in manufacturing bases, reaping significant benefits as new global trends offer the country a unique chance to build top-notch infrastructure, attracting companies to set up operations and become a leading global manufacturing centre.

Growth in manufacturing would need efficient and technology-enabled supply chain solutions to support global companies. India has the capabilities to become a trusted supply chain partner to domestic and global trade by offering efficient and complex supply chain solutions. With technological advancements, the country is also revamping its logistics sector by integrating technological solutions to automate and optimise the process. Over the last five years, India has consistently improved its ranking on various global manufacturing performance indicators, logistics and ease of business, while rising six places to 38th among 139 countries on the Logistics Performance Index.

Overview of India's logistics landscape

The Indian logistics sector is one of the largest in the world and presents a huge addressable opportunity. The sector is critical for the country's economic growth as it connects various elements of the economy and consists of transportation, warehousing and other supply chain solutions ranging from suppliers to end customers.

The Department of Commerce set up a logistics division in July 2017 to oversee the integrated development of the sector. Led by the Special Secretary to the Government of India, the division aims to enhance the sector by devising action plans for policy reforms and process enhancements, addressing challenges, and embracing technology.

The industry is characterised by dynamism, undergoing rapid evolution to meet escalating demands. Technological advancements, infrastructure enhancements and governmental initiatives, including GST implementation and the National Logistics Policy (NLP), are precipitating substantial transformations within the sector. Digitalisation, augmented connectivity, and the adoption of cutting-edge innovations such as Radio Frequency Identification (RFID) and Global Positioning System (GPS) are bolstering operational efficiency while mitigating costs. Furthermore, the surge in e-commerce activities and international trade is propelling demand for streamlined logistics solutions. Despite persistent challenges such as infrastructural deficits and regulatory intricacies, the industry stands poised for significant expansion, presenting domestic and international entities with opportunities to flourish within India's burgeoning market.

Key advantages of efficient logistics infrastructure

Supply chain efficiency: Logistics ensures a smooth and efficient supply chain, minimising delays and reducing lead times. This efficiency is vital for businesses to meet consumer demand promptly and optimise production processes.

Connectivity and accessibility: Logistics networks enhance connectivity and accessibility, linking various regions and markets. This connectivity contributes to economic integration by enabling businesses to reach a wider customer base and fostering trade between states and regions.

Cost reduction and competitiveness: Efficient logistics operations contribute to cost reduction in transportation, storage, and distribution. This, in turn, enhances the competitiveness of businesses as they can offer products at competitive prices in the market.

Job creation: The logistics sector is a significant source of employment, providing jobs in transportation, warehousing, distribution, and related services. Job creation contributes to income generation and economic empowerment. Logistics and warehousing exhibition platform LogiMAT stated that the logistics industry in India, which is one of the largest employment sectors, currently provides livelihoods to over 22 million people. The sector is projected to add 1 crore jobs by 2027.

Technology adoption: The industry's embrace of technology (such as GPS tracking, RFID, and advanced analytics) improves operational efficiency, reduces costs, and enhances overall productivity. This technological advancement positively influences the broader economic landscape.

Economic integration: A well-developed logistics sector facilitates economic integration by connecting various economic zones and promoting a seamless flow of goods and services. This integration is essential for fostering a more robust and interconnected national economy.

Contribution of Logistics Industry to Economic Advancement

With the pivotal role in driving economic progress by facilitating the efficient movement of goods and services across the supply chain, the logistics sector contributes around 13-14% to GDP and provides livelihood for more than 22 million people. It enables timely delivery, decreases costs, and enhances competitiveness, crucial for thriving businesses. Logistics boosts productivity and trade by improving connectivity infrastructure and adopting innovative technologies, thereby stimulating economic growth. Moreover, it fosters investment and supports various sectors, contributing significantly to GDP expansion. As a key enabler of trade and commerce, the logistics sector underpins economic development, enabling nations like India to harness their full potential and achieve sustainable progress.

According to an EY report titled ‘India@100’, India's GDP is estimated to be around US$ 26 trillion in market exchange rate terms by 2047-48. The transportation and logistics sector are expected to play a crucial role in supporting the country's ambitious growth targets. As India aims to reach this milestone over the next 25 years, the transportation and logistics industry would be essential for enabling this growth as logistics cost as a % of GDP accounts for currently. The considerable expenses in the logistics industry can be ascribed to the fact that most freight movement in India depends on road transportation, which constitutes 66% of cargo in ton-kilometres. Rail transportation comes next with a share of 31%, whereas shipping and air transportation comprise only 3% and 1%, respectively. However, the distribution of freight transportation varies across sectors.

Government measures targeting India's logistics and supply chain industry

India's logistics and supply chain industry is experiencing a major transformation, led by several government initiatives aimed at boosting the sector. Notably, implementing GST and recognising logistics as infrastructure status are two critical moves that have been instrumental in driving this change. Initiatives that have been implemented to streamline goods movement and reduce turnaround times are listed below.